INTRODUCTION

Metal-ceramic restorations are among the most commonly used treatment options in fixed partial dentures but have several disadvantages, such as discoloration due to the metal frame showing at the gingival margin, an opaque shade unlike natural teeth and possible metal allergy, which deems them unacceptable for both clinicians and patients1). Particularly, the high demand for esthetics in recent years has led to the development of all-ceramic restorations2). Dental ceramics with a high crystalline content, such as zirconia ceramics, are a popular core material for fixed restorations, due to their high fracture toughness3,4) and chemical inertia5,6) compared to other silica-based ceramics.

Zirconia has superior physical properties and high biocompatibility, which has attracted clinical research investigations and led to its applications as a framework for crowns and fixed partial dentures7-10). Zirconia has three different crystallographic phases: at room temperature, pure zirconia exists as a monoclinic crystal structure while it transforms to a tetragonal structure at 1,170°C and cubic structure at 2,370°C6,11,12). When zirconia is cooled down, a tetragonal-monoclinic transformation occurs6), and the zirconia expands 3 to 5% in volume11-13), creating stresses in the material that may cause cracks14,15). In dental applications, zirconia is usually stabilized by the addition of 3 mol% yttrium oxide, which ensures its tetragonal crystalline phase at room temperature15,16). However, under high localized

stress, such as grinding, sandblasting, and impact, phase transformation exhibits a volume expansion that induces compressive stresses, thereby closing the crack tip and preventing crack propagation. This mechanism is commonly referred to as transformation-toughening13,17,18). Nonetheless, an excessive amount of transformed monoclinic phase may cause strength reduction19). Consequently, microcrack formation at the intergrain level, which would be detrimental to the longevity of the restorations, may occur as a result of surface treatments20).

Yttria-stabilized tetragonal zirconia polycrystalline (Y-TZP) has broad applications in dentistry, such as frame material for crowns and metal-free fixed partial dental prostheses21), implants and abutments22), and orthodontic brackets23). Computer-aided design/ manufacturing technology has simplified the laboratory procedures required when using Y-TZP for dental prostheses5), as manufacturing techniques can be used to mill dental restorations from pre-sintered or fully sintered Y-TZP blocks24,25).

Various types of cement have been proposed for luting Y-TZP ceramic26), yet resin cements are preferred due to their superior retention27), marginal fit28), and increased durability of restorations29). Y-TZP is chemically and biologically inert, so it is difficult to obtain an acceptable bonding to the tooth structure30). Several surface treatment methods, such as hydrofluoric acid etching, grinding, airborne particle abrasion with aluminum oxide (Al2O3), tribochemical silica-coating, and laser irradiation have been suggested to achieve a bond to Y-TZP ceramic13,31-34). Hydrofluoric acid etching, a popular surface treatment method, followed

Effect of airborne particle abrasion and sintering order on the surface roughness

and shear bond strength between Y-TZP ceramic and resin cement

Yener OKUTAN1, Munir Tolga YUCEL2, Tugce GEZER2 and Mustafa Borga DONMEZ2

1 Department of Prosthodontics, Faculty of Dentistry, Adnan Menderes University, Aydın, Turkey 2 Department of Prosthodontics, Faculty of Dentistry, Selcuk University, Konya, Turkey Corresponding author, Yener OKUTAN; E-mail: yenerokutan@hotmail.com

This study examined the surface roughness (Ra) and shear bond strength (SBS) of Yttria-stabilized tetragonal zirconia polycrystalline (Y-TZP) ceramic after airborne particle abrasion at different pressures and particle sizes, pre- and post-sintering. Ninety specimens, prepared from Y-TZP ceramic blocks (Vita In-Ceram YZ, Vita Zahnfabrik), were divided into nine subgroups: control, and 50 and 110 µm Al2O3 airborne particle abrasion at 3 and 4 bar pressure, before and after sintering, respectively. According to the sintering order,

before and after surface treatments, Ra values were measured using a profilometer. SBS to Y-TZP was assessed after thermocycling, using self-adhesive resin cement (Rely X U200, 3M ESPE). Scanning electron microscopy (SEM) and X-ray diffractometry (XRD) were performed on one specimen per group. All surface-treated samples were rougher than the controls. ABS50-4 (50 µm Al2O3 airborne

particle abrasion at 4 bar pressure before sintering), ABS110-3, and ABS110-4 showed the highest Ra values, among all cohorts. The controls displayed lower SBS values than the treated groups (p<0.05), which had statistically similar results to each other. Airborne particle abrasion of pre-sintered Y-TZP, followed by sintering, increased the tetragonal structure contents.

Keywords: Shear bond strength, Surface treatment, Y-TZP ceramic

Color figures can be viewed in the online issue, which is avail-able at J-STAGE.

Received Feb 14, 2018: Accepted Jun 5, 2018

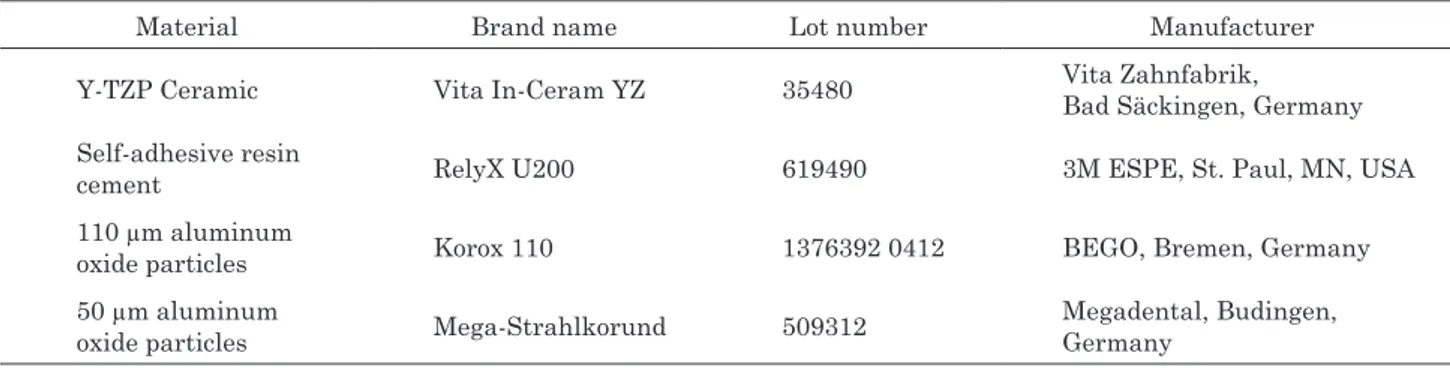

Table 1 Brand names, lot numbers, and manufacturers of the Y-TZP ceramic, resin cement, and aluminum oxide particles

Material Brand name Lot number Manufacturer

Y-TZP Ceramic Vita In-Ceram YZ 35480 Vita Zahnfabrik, Bad Säckingen, Germany Self-adhesive resin

cement RelyX U200 619490 3M ESPE, St. Paul, MN, USA

110 µm aluminum

oxide particles Korox 110 1376392 0412 BEGO, Bremen, Germany 50 µm aluminum

oxide particles Mega-Strahlkorund 509312 Megadental, Budingen, Germany

by silanization, is not efficient to produce significant surface changes in ceramics with a high crystal content35). Therefore, airborne particle abrasion has been recommended to roughen the Y-TZP surface36). Besides increasing the surface roughness, airborne particle abrasion can improve the adhesion by cleaning the Y-TZP surface, providing undercuts and enhancing high surface energy and wettability37). On the contrary, airborne abrasion may cause surface damage38) and, due to the phase transformation, abrasion may affect the mechanical properties and reliability of Y-TZP ceramic. A decrease in the strength, which is related to the transformation extent, may also occur, due to missing transformation capacity during critical loading15).

Surface treatment of Y-TZP for cementation is typically carried out after the sintering process, but this may increase the monoclinic phase of Y-TZP, demanding an additional heat treatment. For this reason, it is thought that the airborne abrasion of pre-sintered Y-TZP, followed by the sintering procedure, may produce monoclinic structures in a reduced amount than post-sintering abrasion, which may improve the mechanical properties of Y-TZP ceramic15). It has also been reported that applying surface treatments at the pre- versus post-sintered stage, leads to higher surface roughness values39). In comparison to the existing data on the bond strength between Y-TZP and resin cement after different airborne particle abrasion and sintering protocols, information about the effect of surface treatments on Y-TZP ceramic treated before sintering is limited15,40,41).

The purpose of this in vitro study was to examine the surface roughness and shear bond strength (SBS) of self-adhesive resin cement to Y-TZP ceramic after airborne particle abrasion, using various particle sizes and at different pressures, pre- and post-sintering. The two null hypotheses were that 1) the surface roughness of Y-TZP and 2) the SBS of resin cement are not affected by airborne particle abrasion performed pre- and post-sintering, with various particle sizes at different pressures.

MATERIALS AND METHODS

Preparations of the specimens

Ninety specimens were cut from a pre-sintered Y-TZP block (Vita In-Ceram YZ, Vita Zahnfabrik, Bad Säckingen, Germany), using a sectioning saw (Isomet 1000, Buehler, Lake Bluff, IL, USA) under running water. Table 1 presents the brand names, manufacturers and lot numbers of the materials used in this study. The surface of each sample was ground using silicon carbide abrasive papers (400, 600, 1000, and 1200 grit) for 15 s under water irrigation, to obtain standardized smooth surfaces. The specimens were ultrasonically cleaned in distilled water for 10 min and air-dried before surface treatments. The prepared specimens were randomly divided into nine groups, as follows: control group (non-treated); 50 µm Al2O3 airborne particle abrasion at 3 bar pressure before sintering (ABS50-3); 110 µm Al2O3 airborne particle abrasion at 3 bar pressure before sintering (ABS110-3), 50 µm Al2O3 airborne particle abrasion at 4 bar pressure before sintering (ABS50-4), 110 µm Al2O3 airborne particle abrasion at 4 bar pressure before sintering (ABS110-4), 50 µm Al2O3 airborne particle abrasion at 3 bar pressure after sintering (AAS50-3), 110 µm Al2O3 airborne particle abrasion at 3 bar pressure after sintering (AAS110-3), 50 µm Al2O3 airborne particle abrasion at 4 bar pressure after sintering (AAS50-4), and 110 µm Al2O3 airborne particle abrasion at 4 bar pressure after sintering (AAS110-4). Airborne particle abrasion procedures were performed at a distance of 20 mm for 15 s.

Prepared specimens were sintered in a furnace (Protherm MOS 160, Ankara, Turkey), according to the manufacturer’s instructions, and were then embedded in auto-polymerizing acrylic resin.

Measuring the surface roughness

Before the surface roughness test, all specimens were ultrasonically cleaned in distilled water for 10 min to remove any surface residues. The surface was measured using a profilometer (Surftest SJ-210, Mitutoyo, Tokyo, Japan), to obtain the surface roughness values (Ra,

µm). Surface roughness tests were conducted on 1) airborne particle abraded non-sintered specimens, 2) remeasurements of the same airborne particle abraded

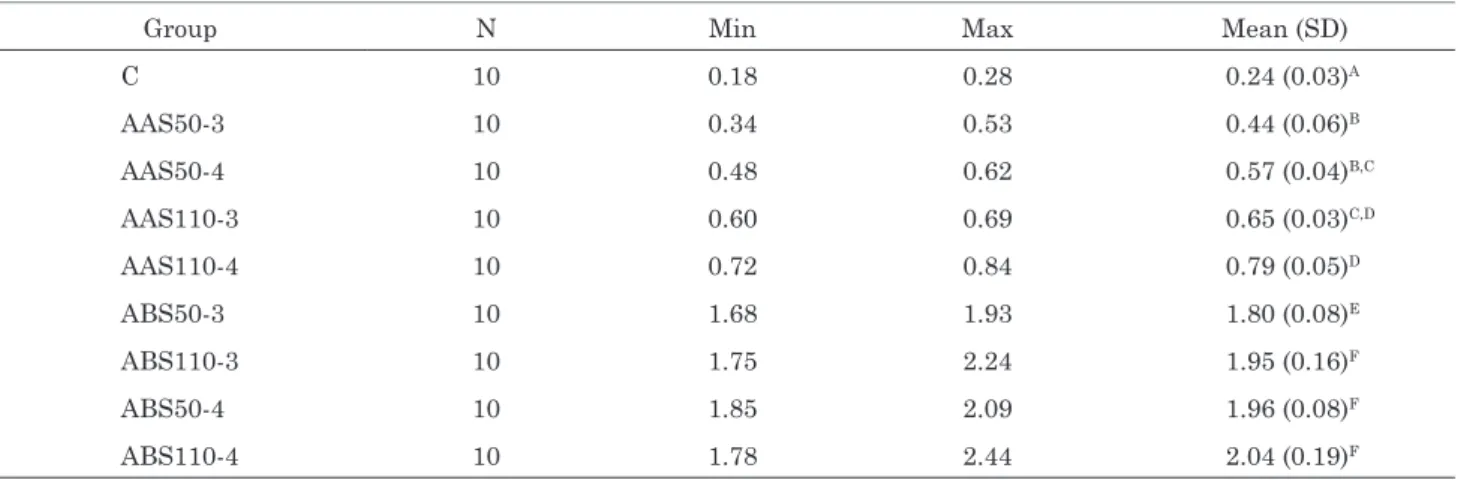

Table 2 The mean and standard deviations (SD) of surface roughness values (µm) for the experimental groups

Group N Min Max Mean (SD)

C 10 0.18 0.28 0.24 (0.03)A AAS50-3 10 0.34 0.53 0.44 (0.06)B AAS50-4 10 0.48 0.62 0.57 (0.04)B,C AAS110-3 10 0.60 0.69 0.65 (0.03)C,D AAS110-4 10 0.72 0.84 0.79 (0.05)D ABS50-3 10 1.68 1.93 1.80 (0.08)E ABS110-3 10 1.75 2.24 1.95 (0.16)F ABS50-4 10 1.85 2.09 1.96 (0.08)F ABS110-4 10 1.78 2.44 2.04 (0.19)F

*The same superscript letters indicate no significant differences (Tukey’s HSD test: α=0.05)

specimens in step 1 after sintering, and 3) sintered and then airborne particle abraded specimens. For each sample, nine traces were recorded at three locations, in parallel, perpendicular, and oblique directions.

Scanning electron microscopy (SEM)

A scanning electron microscope (EVO LS-10, Zeiss, Cambridge, UK) was used to visualize one specimen from each group, at 1,000 and 5,000× magnifications, separately.

X-ray diffractometry (XRD)

Before and after airborne particle abrasion, one specimen from each group was examined by XRD (Bruker D8 Advance, Bruker AXS, Karlsruhe, Germany) using monochromatic Cu-Kα radiation. Scans of the surfaces were performed at 40 mA, 40 kV, between 20 and 40 2Ɵ (degree), with a step size of 0.018. XRD graphs obtained by the scanning were evaluated by using the computer software (Eva, Bruker AXS). The relative amount of transformed monoclinic phase (Xm) on the Y-TZP

surfaces was calculated using the following equation, based on the method of Garvie and Nicholson42):

Xm=[Im(−111)+Im(111)]/[Im(−111)+Im(111)+It(101)]

where Im(−111), It(101) and Im(111) are the intensities of

the peaks around 28, 30, and 31°, respectively.

Bonding, thermocycling and testing procedures

All specimens were cleaned ultrasonically in 96% isopropanol for 180 s and air-dried. Self-adhesive resin cement (Rely X U200, 3M ESPE, St. Paul, MN, USA) was applied on the sintered specimens, according to the manufacturer’s instructions, using a polytetrafluoroethylene mold (diameter: 4 mm; height: 3 mm) and then light-polymerized for 40 s by an LED unit (Bluephase, Ivoclar Vivadent, Schaan, Liechtenstein). The molds were gently removed from the bonded specimens. Before testing, the bonded specimens were stored in distilled water at 37°C for 24

h and then thermocycled 5,000 times between 5–55°C, with a dwell time of 30 s. The specimens were tested for SBS, using a universal testing machine (Lloyd LRX, Lloyd Instruments, Fareham, UK) at a crosshead speed of 1 mm/min, and the shear load at failure moment was recorded. The SBS values were expressed as MPa, by using the following equation:

Stress=failure load (N)/surface area (mm2)

Statistical analysis

Statistical analysis was performed using SPSS software (version 24, SPSS, Chicago, IL, USA) at a significance level of α=0.05. One-way ANOVA and Tukey’s HSD tests

were used to determine statistical differences in the

Ra and SBS values between subgroups. Paired sample

t-tests were used to determine significant differences in

Ra values measured pre- and post-sintering. Pearson’s correlation analysis (r) was performed to define the association between SBS and Ra values.

RESULTS

Surface roughness analysis

The highest Ra values were observed in the treated and

tested before sintering (TBS) groups while the control groups showed the lowest values. Nine subgroups, except TBS groups, were statistically analyzed using one-way ANOVA. Surface roughness Ra values showed

statistically significant (p<0.001) differences between the various groups. Table 2 lists the mean values, standard deviations, and group comparisons. ABS50-4, ABS110-3, and ABS110-4 showed significantly higher

Ra values compared to the other groups (p<0.05), and the control group exhibited lower Ra values than the

treated groups (p<0.05). Additionally, paired sample

t-tests, which were undertaken to compare the repeated measurements of the before and after sintering groups (Table 3), indicated there were significant differences in the Ra values between the pre- and post-sintering

Table 3 Mean and standard deviations (SD) of the surface roughness values (µm) of subgroups and results of paired sample

t-tests

Tested before sintering Tested after sintering Differences between before and after sintering*

C 0.37 (0.07) 0.24 (0.03) p=0.002

ABS 50-3 2.10 (0.13) 1.80 (0.08) p<0.001

ABS 110-3 2.23 (0.13) 1.95 (0.16) p<0.001

ABS 50-4 2.23 (0.13) 1.96 (0.08) p<0.001

ABS 110-4 2.32 (0.11) 2.04 (0.19) p<0.001

*p<0.05 indicates significant differences between groups.

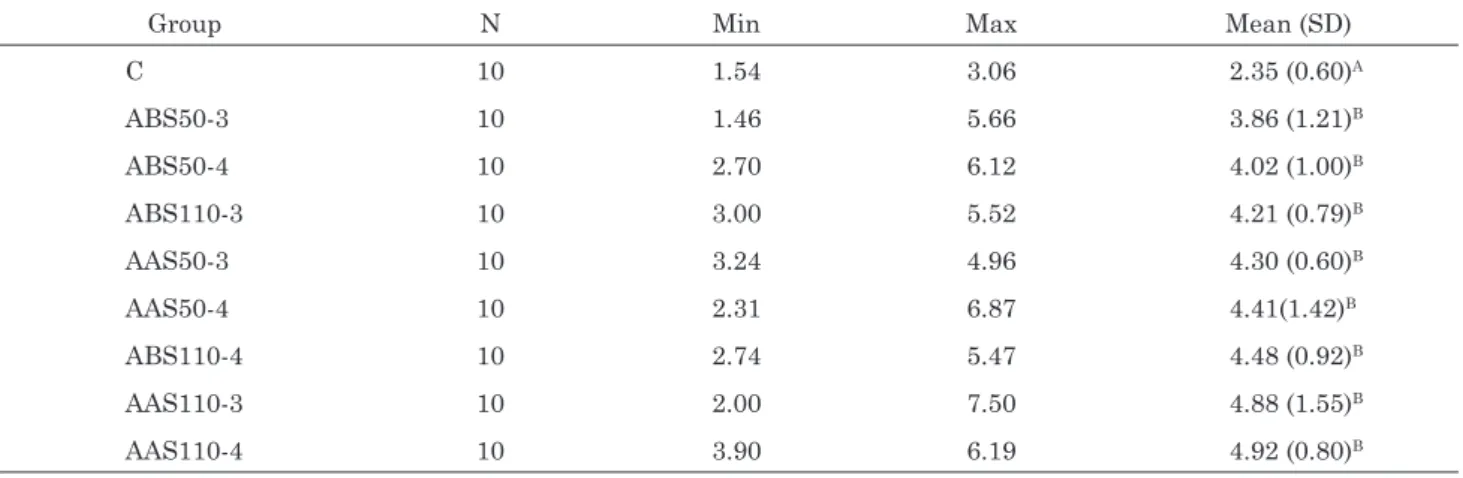

Table 4 The mean and standard deviations (SD) of shear bond strength values (MPa) for the experimental groups

Group N Min Max Mean (SD)

C 10 1.54 3.06 2.35 (0.60)A ABS50-3 10 1.46 5.66 3.86 (1.21)B ABS50-4 10 2.70 6.12 4.02 (1.00)B ABS110-3 10 3.00 5.52 4.21 (0.79)B AAS50-3 10 3.24 4.96 4.30 (0.60)B AAS50-4 10 2.31 6.87 4.41(1.42)B ABS110-4 10 2.74 5.47 4.48 (0.92)B AAS110-3 10 2.00 7.50 4.88 (1.55)B AAS110-4 10 3.90 6.19 4.92 (0.80)B

*The same superscript letters indicate no significant differences (Tukey’s HSD test: α=0.05)

values were remarkably decreased after sintering.

SBS analysis

One-way ANOVA revealed significant differences in SBS between subgroups (p<0.001). According to Tukey’s HSD test results, all the treated groups showed higher SBS values than the control group (p<0.05, Table 4). Among the groups, AAS110-3 and AAS110-4 presented higher SBS values, but there were no statistically significant differences between the ABS and AAS groups (p>0.05). Pressure and particle size of abrasion had a slight but non-significant effect (p>0.05) on the SBS values. Pearson’s correlation test, which allowed to identify any associations between the measured parameters, revealed no significant correlation existed between the SBS and Ra values (p=0.35, r=0.10).

XRD analysis

Figure 1 summarizes the calculated Xm (%) values. The

highest Xm values were observed in the ABS (TBS) groups

(15–22%). The ABS and control groups tested after sintering consisted of almost full tetragonal phases (0.7– 1.1%). XRD patterns (Fig. 2) revealed that monoclinic peaks decreased to nearly zero. On the contrary, after the airborne particle abrasion procedure in sintered

specimens, prominent monoclinic peaks appeared. The monoclinic phases were present at between 7.2– 10.4%. Sintering and airborne particle abrasion order dramatically affected the Xm values.

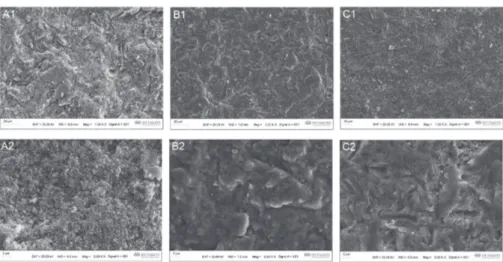

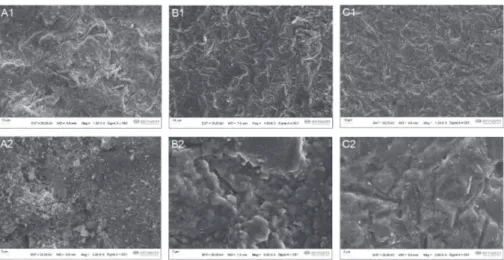

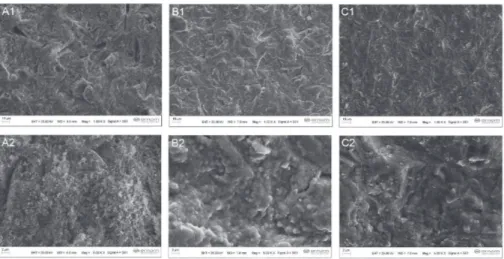

SEM analysis

The SEM images of the non-treated surfaces appeared relatively smooth when compared with the air-abraded specimens (Fig. 3). The surface topography of the airborne particle abrasion pre-sintering groups was considerably different from the airborne particle abrasion post-sintering groups, as evident in the SEM images. Visible roughness of the air-abraded Y-TZP surface topography was evident (Figs. 4–7). In the airborne particle abrasion pre-sintering groups, the Y-TZP surface exhibited a grainy structure with round edges, whereas the Y-TZP surface showed a sharp-edged structure in the airborne particle abrasion post-sintering groups. Moreover, the SEM images in Figs. 5 and 7 revealed that 110 µm particle size of air abrasion at both 3 and 4 bar pressure, increased the surface irregularities and changed the surface morphology of sintered specimens compared to 50 µm airborne particle abrasion, corroborating the

Ra results (Figs. 4 and 6). Airborne particle abrasion with 110 µm at 4 bar pressure created deep grooves

Fig. 1 The relative amount of transformed monoclinic phase (Xm) (%).

Fig. 2 X-ray diffractometry patterns of Y-TZP ceramic. A: control groups; B: example: 110-3 groups.

Fig. 3 Scanning electron micrographs of the control group (1,000 and 5,000× magnifications).

A1, A2: non-treated surface before sintering; B1, B2: non-treated surface after sintering.

Fig. 4 Scanning electron micrographs of Y-TZP surfaces treated by air abrasion with 50 µm Al2O3 at 3 bar (1,000 and 5,000× magnifications).

A1, A2: treated pre-sintered Y-TZP; B1, B2: sintered Y-TZP surface, treated before sintering; C1, C2: sintered Y-TZP surface, treated after sintering.

on the surfaces, especially on the treated pre-sintering specimens (Fig. 7A).

Fig. 5 Scanning electron micrographs of Y-TZP surfaces treated by air abrasion with 110 µm Al2O3 at 3 bar (1,000 and 5,000× magnifications).

A1, A2: treated pre-sintered Y-TZP; B1, B2: sintered Y-TZP surface, treated before sintering; C1, C2: sintered Y-TZP surface, treated after sintering.

Fig. 6 Scanning electron micrographs of Y-TZP surfaces treated by air abrasion with 50 µm Al2O3 at 4 bar (1,000 and 5,000× magnifications).

A1, A2: treated pre-sintered Y-TZP; B1, B2: sintered Y-TZP surface, treated before sintering; C1, C2: sintered Y-TZP surface, treated after sintering.

DISCUSSION

Surface treatment plays an important role in the SBS and increases the surface wettability43). It also increases the surface area and surface energy for the adhesion of resin cements and promotes micromechanical retention44). However, bonding to Y-TZP has always been a challenging issue, as the material is acid-resistant due to its polycrystalline structure29,35,45). To achieve adequate bond strength between Y-TZP and resin cement, airborne particle abrasion is recommended36,46). The present study was designed to evaluate the effects of airborne particle abrasion, using various particle sizes and at different pressures, on the Ra and SBS of

Y-TZP, with varying orders of sintering. It was found

that all treated surfaces were roughened significantly compared to the untreated ones. The increase in Ra also

strengthened the connection between resin cement and Y-TZP ceramic.

Particle size, duration, pressure, and the distance between the applying probe and the ceramic surface are the key factors when using airborne particle abrasion35). Independent studies have evaluated the effects of different particle sizes and pressures15,30). In a study by Su et al.37), sandblasting at a pressure ≥2 bar, longer blasting times, and larger powder sizes increased short-term bond strengths. These authors also reported that the risk of failure increased with increased pressure. In the present study, the Al2O3 particle sizes were 50 and 110 µm while the pressures were 3 and 4 bar, respectively.

Fig. 7 Scanning electron micrographs of Y-TZP surfaces treated by air abrasion with 110 µm Al2O3 at 4 bar (1,000 and 5,000× magnifications).

A1, A2: treated pre-sintered Y-TZP; B1, B2: sintered Y-TZP surface, treated before sintering; C1, C2: sintered Y-TZP surface, treated after sintering.

Among the sintered groups, ABS110-4 specimens, which were abraded pre-sintering with 110 µm Al2O3 particles at 4 bar pressure, displayed the highest Ra values.

Furthermore, there were significant differences in the

Ra values between air abraded sintered groups with 50 and 110 µm Al2O3 particles, revealing higher Ra values

after air abrasion with 110 µm particles and this finding was confirmed in the SEM images of Y-TZP surfaces. The results also demonstrated higher Ra values when the

specimens were treated pre-sintering relative to those treated post-sintering. This behavior was similar to that observed by Ebeid et al.47), who stated that despite using a reduced pressure to treat zirconia surface, enhanced

Ra values could be achieved, which might be related to the differences in densities between pre-sintered and sintered Y-TZP. Papia et al.48) suggested that airborne particle abrasion may cause surface damage, as well as a significant loss of substances from the surface, potentially reducing the flexural strength of Y-TZP. Similarly, another previous study documented that airborne particle abrasion may cause damage to the ceramic, thereby decreasing the strength under cyclic conditions49). In contrast, Kern50) stated that airborne particle abrasion produces significant clinical outcomes with no ceramic fractures during a 15-year follow-up. Chintapalli et al.51) reported that airborne particle abrasion with particles sizes equal or smaller than 110 µm and pressures less than 4 bar increase the biaxial strength and the reliability, by inducing compressive residual stresses that counteract the abrasion-induced damage. An increased or decreased strength of the Y-TZP ceramic has been closely related to the transformation zone depth and length of cracks that occur on the surface after airborne particle abrasion13).

Tsuo et al.52) recommended Al

2O3 particles of 50 µm for airborne particle abrasion of sintered Y-TZP, whereas, Phark et al.53) concluded that airborne particle abrasion

with either 50 or 110 µm Al2O3 particles increases the SBS of Y-TZP ceramic. Aboushelib et al.54) demonstrated that airborne particle abrasion of Y-TZP surface with 50 µm Al2O3 increased the bond strength between the Y-TZP core and the veneer ceramic. Conversely, some researchers indicated that sandblasting of the Y-TZP surface does not necessarily enhance the bond strength of Y-TZP surface55,56). Moon et al.15) noted that sandblasted groups showed higher SBS values compared to the control group, but the differences between different sintering and air abrasion protocols were not significant. Similarly, among the specimens examined in the current study, the control group presented statistically lower SBS values while there were no statistical differences between the remaining cohorts. There was a slight increase in the 110 µm compared to 50 µm specimens with the same sintering order, but it was not statistically significant. The two null hypotheses that Ra of zirconia

and SBS of resin cement are not affected by airborne particle abrasion performed pre- and post-sintering with various particle sizes at different pressures were rejected.

Abi-Rached et al.40) investigated the effect of different airborne particle abrasion and sintering protocols on the bond strength of Y-TZP ceramic to resin cement. The authors reported that changes in surfaces with air abrasion pre-sintering probably impaired the wettability of Y-TZP. The authors found higher bond strength values with the air abrasion pre- and post-sintering, when used in combination. Su et al.37) examined the SBS of Y-TZP ceramic to a composite resin using various sandblasting conditions and observed mean SBS values between 9.10–13.11 MPa. In comparison, the mean SBS values in the present study were considerably lower (2.35–4.92 MPa) probably because the mentioned study used 10-methacryloxydecyldihydrogen phosphate-containing bonds.

Thermal cycling, which is considered to be a clinically relevant aging procedure, is most often used to test the durability of resin bonds, because the chemical, thermal, and mechanical factors in the mouth affect the bond strength between the resin cement and the restorative material4,33,38). Similarly to Al-Shehri et al.30), a short-term thermal cycling (5,000 cycles) was performed in our study. Also, the application of thermocycling process in our study may have reduced the mean SBS values.

Airborne particle abrasion generates stress on Y-TZP surfaces, which accelerates tetragonal-monoclinic transformation13,15). In the present study, while the monoclinic phase of AAS groups was between 7.2–10.4%, the values in the ABS group ranged from 0.7–0.9%. In AAS groups, the specimens with abraded 110 µm Al2O3 particles at 4 bar pressure showed the highest monoclinic phase. This finding may be attributed to high stress levels on surfaces due to airborne particle abrasion. The sintering process performed after the airborne particle abrasion protocol increased the content of tetragonal structure. Also, the monoclinic phase was importantly decreased post-sintering. These findings agree with those documented by Moon et al.15), who reported that this situation might improve the mechanical properties of Y-TZP ceramic. The reduced proportion of monoclinic phase seen for sintering after airborne particle abrasion can be an advantage15). Ebeid et al.47) also observed only peaks characteristic of the tetragonal phase in the XRD patterns of air-abraded and then sintered Y-TZP specimens; however, subgroups air-abraded in the pre-sintered stage and un-sintered condition showed a combination of monoclinic and tetragonal peaks. Also, in the current study, the airborne particle abrasion process affected the Y-TZP surface structure of both groups. While the airborne particle abrasion before sintering created round edges on the Y-TZP surface, airborne particle abrasion after sintering formed a sharp-edged Y-TZP surface, which might decrease the fracture strength.

The limitations of the current study were the use of only one type of resin cement and also insufficient aging time. Therefore, future investigations should focus on using different resin cements or Y-TZP primers and examine the effect of long-term aging on the material structure and bond strength. Moreover, further studies of airborne particle abrasion with varying distances and pressures are needed to understand the effects on surface roughness and phase transformation of Y-TZP, and also bond strength between Y-TZP ceramic and resin cement.

CONCLUSIONS

Within the limitations of this study, the following conclusions were drawn:

1. Airborne particle abrasion treatment to the Y-TZP surface is an important step to improve surface roughness and the bond strength.

2. Surface roughness was remarkably decreased after sintering of the Y-TZP specimens.

3. SBS values were not significantly influenced by the air pressure and particle size of airborne abrasion.

4. Airborne particle abrasion before sintering may be recommended as a surface treatment of Y-TZP ceramic to receive a tetragonal surface structure.

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest. There is no external funding source for this study.

REFERENCES

1) Kim JE, Kim JH, Shim JS, Roh BD, Shin Y. Effect of surface treatment on shear bond strength between resin cement and Ce-TZP/Al2O3. Biomed Res Int 2016; 2016: 7576942. 2) Peumans M, Van Meerbeek B, Lambrechts P, Vanherle G.

Porcelain veneers: a review of the literature. J Dent 2000; 28: 163-177.

3) Fischer H, Weber M, Marx R. Lifetime prediction of all-ceramic bridges by computational methods. J Dent Res 2003; 82: 238-242.

4) Lüthy H, Loeffel O, Hammerle CH. Effect of thermocycling on bond strength of luting cements to zirconia ceramic. Dent Mater 2006; 22: 195-200.

5) Sari F, Secilmis A, Simsek I, Ozsevik S. Shear bond strength of indirect composite material to monolithic zirconia. J Adv Prosthodont 2016; 8: 267-274.

6) Hatanaka GR, Polli GS, Fais LM, Reis JM, Pinelli LA. Zirconia changes after grinding and regeneration firing. J Prosthet Dent 2017; 118: 61-68.

7) Ito Y, Okawa T, Fukumoto T, Tsurumi A, Tatsuta M, Fujii T, Tanaka J, Tanaka M. Influence of atmospheric pressure low-temperature plasma treatment on the shear bond strength between zirconia and resin cement. J Prosthodont Res 2016; 60: 289-293.

8) Tanaka S, Takaba M, Manabe M, Gotou D, Baba K. Two cases report of implant supported full-arch prostheses by CAD/CAM crown and zirconia frame. Dent Med Res 2010; 30: 50-56.

9) Omori S, Komada W, Yoshida K, Miura H. Effect of thickness of zirconia-ceramic crown frameworks on strength and fracture pattern. Dent Mater J 2013; 32: 189-194.

10) Tinschert J, Natt G, Mautsch W, Spiekerman H, Anusavice KJ. Marginal fit of alumina and zirconia based fixed partial dentures produced by a CAD/CAM system. Oper Dent 2001; 26: 367-374.

11) Garvie RC, Hannink RH, Pascoe RT. Ceramic steel? Nature 1975; 258: 703-704.

12) Glauser R, Sailer I, Wohlwend A, Studer S, Schibli M, Scharer P. Experimental zirconia abutments for implant-supported single-tooth restorations in esthetically demanding regions: 4-year results of a prospective clinical study. Int J Prosthodont 2004; 17: 285-290.

13) Kosmač T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater 1999; 15: 426-433.

14) Tholey MJ, Swain MV, Thiel N. SEM observations of porcelain Y-TZP interface. Dent Mater 2009; 25: 857-862.

15) Moon JE, Kim SH, Lee JB, Ha SR, Choi YS. The effect of preparation order on the crystal structure of yttria-stabilized tetragonal zirconia polycrystal and the shear bond strength of dental resin cements. Dent Mater 2011; 27: 651-663. 16) Kelly JR, Denry I. Stabilized zirconia as a structural ceramic:

17) Egilmez F, Ergun G, Cekic-Nagas I, Vallittu PK, Lassila LV. Factors affecting the mechanical behavior of Y-TZP. J Mech Behav Biomed Mater 2014; 37: 78-87.

18) Borchers L, Stiesch M, Bach FW, Buhl JC, Hubsch C, Kellner T, Kohorst P, Jendras M. Influence of hydrothermal and mechanical conditions on the strength of zirconia. Acta Biomater 2010; 6: 4547-4552.

19) Song JY, Park SW, Lee K, Yun KD, Lim HP. Fracture strength and microstructure of Y-TZP zirconia after different surface treatments. J Prosthet Dent 2013; 110: 274-280.

20) Casucci A, Mazzitelli C, Monticelli F, Toledano M, Osorio R, Osorio E, Papacchini F, Ferrari M. Morphological analysis of three zirconium oxide ceramics: Effect of surface treatments. Dent Mater 2010; 26: 751-760.

21) Molin MK, Karlsson SL. Five-year clinical prospective evaluation of zirconia based Denzir 3-unit FPDs. Int J Prosthodont 2008; 21: 223-227.

22) Basílio MA, Cardoso KV, Antonio SG, Rizkalla AS, Santos Junior GC, Arioli Filho JN. Effects of artificial aging conditions on yttria-stabilized zirconia implant abutments. J Prosthet Dent 2016; 116: 277-285.

23) Springate SD, Winchester LJ. An evaluation of zirconium oxide brackets: a preliminary laboratory and clinical report. Br J Orthod 1991; 18: 203-209.

24) Filser F, Kocher P, Weibel F, Lüthy H, Schärer P, Gauckler LJ. Reliability and strength of all-ceramic dental restorations fabricated by direct ceramic machining (DCM). Int J Comput Dent 2001; 4: 89-106.

25) Sundh A, Molin M, Sjögren G. Fracture resistance of yttrium oxide partially-stabilized zirconia all-ceramic bridges after veneering and mechanical fatigue testing. Dent Mater 2005; 21: 476-482.

26) Subaşı MG, Inan Ö. Influence of surface treatments and resin cement selection on bonding to zirconia. Lasers Med Sci 2014; 29: 19-27.

27) Burke FJ, Fleming GJ, Nathanson D, Marquis PM. Are adhesive technologies needed to support ceramics? An assessment of the current evidence. J Adhes Dent 2002; 4: 7-22.

28) Derand T, Molin M, Kvam K. Bond strength of composite luting cement to zirconia ceramic surfaces. Dent Mater 2005; 21: 1158-1162.

29) Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent 2003; 89: 268-274. 30) Al-Shehri EZ, Al-Zain AO, Sabrah AH, Al-Angari SS, Al

Dehailan L, Eckert GJ, Ozcan M, Platt JA, Bottino MC. Effects of air-abrasion pressure on the resin bond strength to zirconia: a combined cyclic loading and thermocycling aging study. Restor Dent Endod 2017; 42: 206-215.

31) Chaiyabutr Y, McGowan S, Phillips KM, Kois JC, Giordano RA. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J Prosthet Dent 2008; 100: 194-202.

32) Sato H, Yamada K, Pezzotti G, Nawa M, Ban S. Mechanical properties of dental zirconia ceramics changed with sandblasting and heat treatment. Dent Mater J 2008; 27: 408-414.

33) Kern M, Wegner SM. Bonding to zirconia ceramic: adhesion methods and their durability. Dent Mater 1998; 14: 64-71. 34) Stübinger S, Homann F, Etter C, Miskiewicz M, Wieland M,

Sader R. Effect of Er:YAG, CO2 and diode laser irradiation on surface properties of zirconia endosseous dental implants. Lasers Surg Med 2008; 40: 223-228.

35) Della Bona A, Donassollo TA, Demarco FF, Barrett AA, Mecholsky Jr JJ. Characterization and surface treatment effects on topography of a glass infiltrated alumina/zirconia reinforced ceramic. Dent Mater 2007; 23: 769-775.

36) Qeblawi DM, Munoz CA, Brewer JD, Monaco Jr EA. The effect of zirconia surface treatment on flexural strength and shear bond strength to a resin cement. J Prosthet Dent 2010;

103: 210-220.

37) Su N, Yue L, Liao Y, Liu W, Zhang H, Li X, Wang H, Shen J. The effect of various sandblasting conditions on surface changes of dental zirconia and shear bond strength between zirconia core and indirect composite resin. J Adv Prosthodont 2015; 7: 214-223.

38) Wolfart M, Lehmann F, Wolfart S, Kern M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent Mater 2007; 23: 45-50. 39) Monaco C, Tucci A, Esposito L, Scotti R. Microstructural

changes produced by abrading Y-TZP in presintered and sintered conditions. J Dent 2013; 41: 121-126.

40) Abi-Rached FDO, Martins SB, Almeida-Júnior AAD, Adabo GL, Góes MS, Fonseca RG. Air abrasion before and/or after zirconia sintering: surface characterization, flexural strength, and resin cement bond strength. Oper Dent 2015; 40: 66-75. 41) Kurtulmus-Yilmaz S, Aktore H. Effect of the application of

surface treatments before and after sintering on the flexural strength, phase transformation and surface topography of zirconia. J Dent 2018; 72: 29-38.

42) Garvie RC, Nicholson PS. Phase analysis in zirconia systems. J Am Ceram Soc 1972; 55: 303-305.

43) Hao L, Lawrence J. Effects of Nd:YAG laser treatment on the wettability characteristics of a zirconia-based bioceramic. Opt Laser Eng 2006; 44: 803-814.

44) Menani LR, Farhat IA, Tiossi R, Ribeiro RF, Guastaldi AC. Effect of surface treatment on the bond strength between yttria partially stabilized zirconia ceramics and resin cement. J Prosthet Dent 2014; 112: 357-364.

45) Ahrari F, Boruziniat A, Alirezaei M. Surface treatment with a fractional CO2 laser enhances shear bond strength of resin cement to zirconia. Laser Ther 2016; 25: 19-26.

46) Özcan M, Vallittu PK. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater 2003; 19: 725-731.

47) Ebeid K, Wille S, Salah T, Wahsh M, Zohdy M, Kern M. Evaluation of surface treatments of monolithic zirconia in different sintering stages. J Prosthodont Res 2018; 62: 210-217.

48) Papia E, Larsson C, du Toit M, Vult von Steyern P. Bonding between oxide ceramics and adhesive cement systems: a systematic review. J Biomed Mater Res B Appl Biomater 2014; 102: 395-413.

49) Zhang Y, Lawn BR, Rekow ED, Thompson VP. Effect of sandblasting on the long-term performance of dental ceramics. J Biomed Mater Res B Appl Biomater 2004; 71: 381-386. 50) Kern M. Bonding to oxide ceramics-laboratory testing versus

clinical outcome. Dent Mater 2015; 31: 8-14.

51) Chintapalli RK, Mestra Rodriguez A, Garcia Marro F, Anglada M. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. J Mech Behav Biomed Mater 2014; 29: 126-137.

52) Tsuo Y, Yoshida K, Atsuta M. Effect of alumina-blasting and adhesive primers on bonding between resin luting agent and zirconia ceramics. Dent Mater J 2006; 25: 669-674.

53) Phark JH, Duarte Jr S, Blatz M, Sadan A. An in vitro evaluation of the long-term resin bond to a new densely sintered high-purity zirconium-oxide ceramic surface. J Prosthet Dent 2009; 101: 29-38.

54) Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Effect of zirconia type on its bond strength with different veneer ceramics. J Prosthodont 2008; 17: 401-408.

55) Fischer J, Stawarczyk B, Sailer I, Hammerle CH. Shear bond strength between veneering ceramics and ceria-stabilized zirconia/alumina. J Prosthet Dent 2010; 103: 267-274. 56) Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ.

Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater 2005; 21: 984-991.