Int J Appl Ceram Technol. 2019;16:1425–1440. wileyonlinelibrary.com/journal/ijac © 2019 The American Ceramic Society

|

14251

|

INTRODUCTION

In the recent years, zirconia‐based high strength ceramic materials have been developed for use in dental practice. Zirconia‐based ceramics provide long‐term viability and im-proved fracture resistance when compared to porcelain and other silica‐based materials.1,2 The strength of this material allows its use as frameworks for posterior dental prosthe-ses and permits a considerable reduction in core thickness of zirconia crowns.3 Nowadays, it is possible to fabricate

full‐contour zirconia restorations without veneering ceramic

using monolithic zirconia.4,5 In dentistry, milling of

zirco-nia into reconstructions with complex shapes is possible with computer‐aided design/computer‐aided manufacturing technology.5 Two types of zirconia milling procedures are

currently available: soft‐milling of pre‐sintered blanks and hard‐milling of fully sintered dense blanks. Milling of pre‐ sintered zirconia blanks is today a well‐established process, and soft‐milled restorations must additionally be sintered to full density.3‒5

Pure zirconia exists in three temperature‐dependent forms: monoclinic (m), tetragonal (t), and cubic (c). The monoclinic

O R I G I N A L A R T I C L E

Effect of surface treatments and aging on phase transformation

and flexural strength of different Y‐TZP ceramics

Yener Okutan

1|

Munir T. Yucel

21Department of Prosthodontics, Faculty

of Dentistry, Aydın Adnan Menderes University, Aydın, Turkey

2Department of Prosthodontics, Faculty of

Dentistry, Selcuk University, Konya, Turkey

Correspondence

Yener Okutan, Department of

Prosthodontics, Faculty of Dentistry, Aydın Adnan Menderes University, Aydın, Turkey. Email: yenerokutan@hotmail.com

Funding information

Scientific Research Project Council of Selcuk University, Turkey, Grant/Award Number: 12202017

Abstract

This study aimed to evaluate the influence of surface treatments and artificial aging on surface roughness (Ra), phase transformation, and flexural strength of yttria‐sta-bilized tetragonal zirconia polycrystalline (Y‐TZP) ceramics. Two‐hundred and eighty specimens from four types of Y‐TZP were divided into seven groups, accord-ing to the surface treatments and agaccord-ing used: control, air‐abrasion, air‐abra-sion + aging, grinding, grinding + aging, erbium: yttrium‐aluminum‐garnet (Er:YAG) laser, Er:YAG laser + aging. The Ra values were measured using a pro-filometer. X‐ray diffraction (XRD) analysis was performed to determine phase trans-formation. Specimens were subjected to a three‐point bending test and loaded until fracture. Scanning electron microscope (SEM) and atomic force microscope (AFM) analyses were performed on one specimen per group. Grinding and air‐abrasion groups exhibited higher Ra values than the others (P < 0.05). The differences in the roughness and flexural strength values between the laser and control groups were not significant. For all materials, the highest amount of monoclinic phase was found after air‐abrasion. Grinding groups showed lower flexural strength values compared with the control groups (P < 0.05), while there was no significant difference between the control and air‐abrasion groups. Aging did not affect the roughness and flexural strength (P > 0.05). The grinding process is not recommended in clinical usage for Y‐TZP because of the remarkable decrease in flexural strength and reliability.

K E Y W O R D S

phase is stable between room temperature and 1170°C; trans-forms to the tetragonal form above this temperature and the cubic form is observed above 2370°C.3,5‒8 Various oxides, like CaO,

MgO, CeO2, and Y2O3, have been added to the structure for

sta-bilizing zirconia in the tetragonal phase at room temperature.3,6,9

Yttria‐stabilized tetragonal zirconia polycrystal (Y‐TZP), which is the most commonly used among the zirconia materials,7 is

obtained by adding 3‐6 wt% Y2O3.10 External stresses, such as

airborne particle abrasion, grinding and also thermal aging, can trigger the t → m phase transformation.9,11 This stress‐related

microstructural change in Y‐TZP explains the transformation‐ toughening mechanism. Tetragonal to monoclinic phase trans-formation results in a 3%‐4% volume expansion,6 which creates

compressive stresses on the tip of cracks, and initial crack prop-agation is blocked by this mechanism.7,9

Various techniques have been reported to enhance the bond strength between resin cement and ceramic. Hydrofluoric acid etching, followed by application of a silane coupling agent, is a well‐known and recommended method.12 However, the composition and physical

proper-ties of Y‐TZP differ from silica‐based ceramics because of the high crystalline content and absence of a glass phase.1,13

For this reason, zirconia is resistant to acid etching and re-quires more aggressive treatment methods to increase sur-face roughness.14‒16 These surface treatments can directly

affect the mechanical behavior and reliability of zirconia. The surface flaws occurring by surface treatments act as stress concentration zones, and these areas lead to crack ini-tiation and propagation.14 The effects of airborne particle

abrasion, which is a common application for zirconia to ob-tain rough surfaces, has been investigated.15,17‒19 However,

there is still no consensus about phase transformation and surface damage. Commonly, final adjustments by grinding may be necessary to fabricate a zirconia restoration.20‒23

Chairside adjustments of zirconia restorations using grind-ing may be required to achieve optimal occlusal contacts, and this procedure results in loss of surface smoothness.24

In addition to the currently used surface conditioning meth-ods, the effects of various types of laser treatments on zir-conia ceramics have also been evaluated.13,25‒28 Although

different surface pre‐treatments applied to zirconia have been recently studied, the most appropriate method is still unclear.13

In dentistry, fracture resistance and deformation under cyclic conditions are the main criteria for choosing the ce-ramic materials.15 Zirconia ceramics tend to age in a wet

environment. Aging starts first in isolated surface grains, by a slow phase transformation in the presence of water or water vapor.29 Water is incorporated into the zirconia

lattice by dissolving Zr‐O‐Zr bonds and filling oxygen va-cancies. This action reduces the energy barrier for t → m transformation, thereby increasing the rate of transforma-tion.7 After the surface is saturated with monoclinic phase,

degradation proceeds into the bulk material.9 This

neg-ative situation is also commonly referred to as low‐tem-perature degradation. This mechanism progresses slowly at oral temperature7; nonetheless, it can cause a remarkable

reduction in strength, density, and toughness.6,7 Repeated

thermal stress can also generate tension within the ceramic, thereby reducing the strength. This reduction may be in-creased by cyclic loadings, like chewing forces.7 Damage

accumulation is a major concern for the lifetime of appli-cations. Such stresses can cause microcracks within the damaged area, and these microcracks can turn into radial macrocracks in excess of the mentioned zone.30 Decreasing

of the strength, which is related to the transformation ex-tent, may also occur due to the missing transformation ca-pacity during critical loading.31 Moreover, the effect of the

surface treatments might be modified by aging. Therefore, it is essential to evaluate cyclic conditions for applying suc-cessful restorations using zirconia.7

This study aimed to investigate the influence of various surface treatments and artificial aging on the surface rough-ness, phase transformation and flexural strength of Y‐TZP ceramics. The null hypothesis of this study was that the face treatments and artificial aging would not impact on sur-face roughness, phase transformation, and flexural strength of different Y‐TZP ceramics.

2

|

EXPERIMENTAL PROCEDURE

2.1

|

Specimen preparation

Two‐hundred and eighty bar‐shaped specimens (70 per material) were prepared from four different Y‐TZP ceram-ics: Prettau (Zirkonzahn GmbH, Bruneck, Italy), IPS e.max ZirCAD (Ivoclar Vivadent, Schaan, Liechtenstein), Vita In‐Ceram YZ (Vita Zahnfabrik, Bad Sackingen, Germany), Lava Frame Zirconia (3M ESPE, Seefeld, Germany). The specimens were cut at the pre‐sintered stage, using a water‐ cooled low‐speed diamond saw (Isomet, Buehler Ltd., Lake Bluff, IL, USA) and polished with 600,1000 and 1200 grit silicon carbide papers (English Abrasives & Chemicals Ltd., London, United Kingdom), to obtain standardized smooth surfaces. The specimens were then sintered to full density, ac-cording to the manufacturer's instructions. ZirCAD and Lava specimens were sintered at 1500°C while Vita and Prettau specimens were sintered at 1530°C and 1600°C, respectively. The final specimen dimensions of the control, airborne parti-cle abrasion and laser groups were 20 mm × 4 mm × 1.2 mm. The thickness of specimens was calculated as 1.3 mm for the grinding groups, considering the material removed during the process. Ten specimens of each zirconia ceramic, without any surface treatment and aging procedure, were assigned as the control group. Table 1 lists the groups of the study and associated abbreviations.

2.2

|

Surface treatments

2.2.1

|

Airborne particle abrasion

A unique device was designed to adjust the distance be-tween the sample and abrasion machine tip (Bego, Bremen, Germany), for standardization of treatment. Specimens were placed at 20 mm distance from the tip, and air particle abrasion was applied using 110 µm aluminum oxide particles (Korox, Bego, Bremen, Germany) at 4 bar pressure for 15 seconds.

2.2.2

|

Grinding

Medium grit (107 µm) diamond burs (Komet, Komet Dental, Germany) were used for grinding. The bars were ground until 0.1 mm of material was removed from the surface with a grinding device (K‐Powergrip Handstück 4941, KaVo Dental GmbH, Biberach, Germany) at 20,000 rpm, without water‐spray cooling. Dimensions of the specimens were con-trolled using a high precision digital caliper (TorQ, 150 mm, PRC) during the grinding process.

2.2.3

|

Laser treatment

The specimen surfaces were irradiated with the Erbium Yttrium Aluminum Garnet laser (At Fidelis Er:YAG; Fotona, Ljubljana, Slovenia) at a wavelength of 2,940 nm, using a special handpiece (R02) under water irrigation and air cool-ing for 15 seconds. The distance between the laser handpiece and specimen surface was adjusted to 1 mm. The laser param-eters were: energy: 400 mJ, power: 4 W, frequency (pulse/s): 10 Hz and MSP mode (100 µs) (pulse width).

2.3

|

Artificial aging

Thermal and mechanical cycling was performed on half of the surface‐treated samples. Thermal cycling (10,000 cycles) was applied to specimens between 5 and 55°C with 30 sec-onds dwell time and 10 secsec-onds transfer time, using a thermal cycling machine (Nova, Konya, Turkey). Mechanical loading (100,000 cycles) was performed, using a custom‐made sam-ple holder and an upper rod with a 1.6 mm diameter tip. The loading machine (Vega chewing simulator, Nova, Konya,

Turkey) frequency and applied force were set at 0.5 Hz and 50 N, respectively. The load was exerted in the middle of the samples. After the surface treatments and artificial aging, all specimens were ultrasonically cleaned (Biosonic JR, Whaledent, Int., NY, USA) in distilled water for 10 minutes to remove debris.

2.4

|

Surface roughness

The surface roughness of specimens was measured using a profilometer (Sj‐201, Mitutoyo, Minato‐ku, Tokyo, Japan). Roughness values were measured at five different locations, to determine the mean surface roughness. The surface pro-filometer device was calibrated for every 10 samples.

2.5

|

X‐ray diffraction (XRD) analysis

The crystal structure was determined using an X‐ray dif-fractometer (Bruker D8 Advance, Bruker AXS, Karlsruhe, Germany), with monochromatic CuK α radiation. Current and voltage were set at 40 mA and 40 kV, respectively. The surfaces were scanned between 20 and 40 2Ɵ degrees with a step size of 0.018. The relative amount of monoclinic phase (Xm) was calculated with Equation (1), based on the method of Garvie and Nicholson,32 volumetric fraction (Fm)

and transformation zone depth (TZD) were calculated using Equation (2)33 and Equation (3),34 respectively, as shown

below:

In Equation (1), Im (−111), It (101) and Im (111) are the intensities of the peaks around 28, 30 and 31°, respectively. In Equation (3), Ɵ is the reflection angle (15°), and µ is the absorption coefficient (0.0642).

2.6

|

Flexural strength test

The flexural strength of the specimens was measured using a three‐point bending test, performed in a universal

(1)

Xm= [Im( − 111) + Im(111)]∕[Im( − 111) + Im(111) + It(101)]

(2) Fm= (1.311Xm)∕(1 + 0.311Xm) (3) TZD= (Sin𝜃∕2𝜇) ln [1∕(1 − Fm)] Condition Abbreviation

Prettau ZirCAD Vita Lava

Control PC ZC VC LC

Laser, laser + aging PL, PLA ZL, ZLA VL, VLA LL, LLA Grinding, grinding + aging PG, PGA ZG, ZGA VG, VGA LG, LGA Air‐particle abrasion,

air‐parti-cle abrasion + aging PA, PAA ZA, ZAA ZA, ZAA LA, LAA

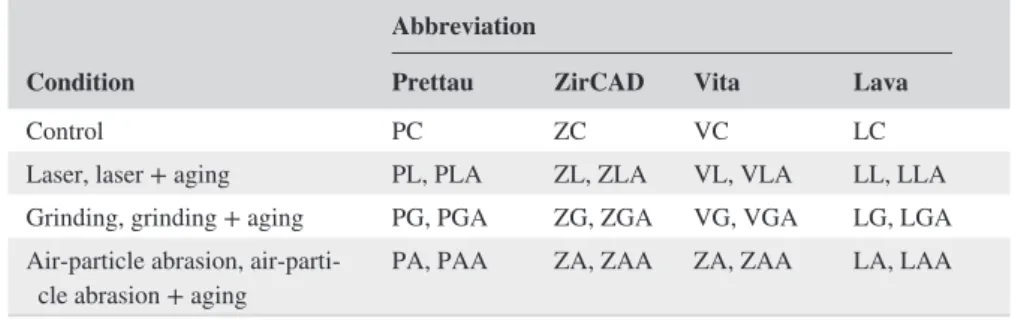

TABLE 1 Surface treatments and group abbreviations

testing machine (Elista, TSTM02500, Elista Corp., İstanbul, Turkey). Specimens were placed inside the sample holder, and the load was applied at the center at a constant cross‐head speed of 1 mm/min until failure, to determine the critical load for fracture. The supports and loading piston were knife edges rounded to radii of 0.8 mm. Specimens were tested at room temperature. Mean values of flexural strength were cal-culated as MPa, using the following equation:

where P is the breaking load in Newtons; l is the test span (center‐to‐center distance between supports) in mm; w is the width of the specimen in mm; b is the thickness of the speci-men in mm.

2.7

|

Microscopy analysis

Randomly selected specimens from each group were analyzed using an atomic force microscope (AFM, NTEGRA Solaris, NT‐MDT, Russia). A scanning area of 25 µm × 25 µm was considered, and images were taken in air. Additionally, one zirconia specimen from each experi-mental subgroup was evaluated under a scanning electron microscope (SEM, Zeiss Evo LS‐10; Carl Zeiss) at 1000× and 5000× magnifications, to determine changes in surface topography.

2.8

|

Statistical analyses

The Kolmogorov‐Smirnov and Levene's statistical tests were performed on calculated data, for evaluation of nor-mal distribution and homogeneity of variances, respectively. One‐way ANOVA, followed by Tukey's HSD test, and the Kruskal‐Wallis test, followed by Dunn's test, were used to determine differences among subgroups. The relationships among measured parameters were analyzed using Pearson's correlation analysis. The two‐parameter Weibull distribution function was used to determine the variability of the flexural

strength. Weibull modulus (m) and characteristic strength (σ0) values of each group were calculated. The following

for-mula35 was used to calculate Weibull modulus:

where Pf(σ) is the probability of failure, σ is the fracture

strength, σ0 is the characteristic parameter at the fracture

probability of 63.2%, and m is the Weibull modulus. All of the statistical tests were performed at a significance level of

α = 0.05.

3

|

RESULTS

3.1

|

Surface roughness

Table 2 lists the mean Ra values and standard deviations of the subgroups and the statistical differences found. Figure 1 presents the box plot of the surface roughness for the sub-groups. Prettau‐treated with grinding showed the highest Ra (1.34 ± 0.14) while ZirCAD control group showed the low-est Ra (0.24 ± 0.02). Grinding groups showed higher Ra val-ues compared to the other groups, for all zirconia materials (P < 0.05). Airborne particle‐abraded groups showed higher Ra values compared to laser and control groups (P < 0.05), whereas the differences in the Ra values between the laser and control groups were insignificant (P > 0.05). Artificial aging did not significantly affect the Ra values.

3.2

|

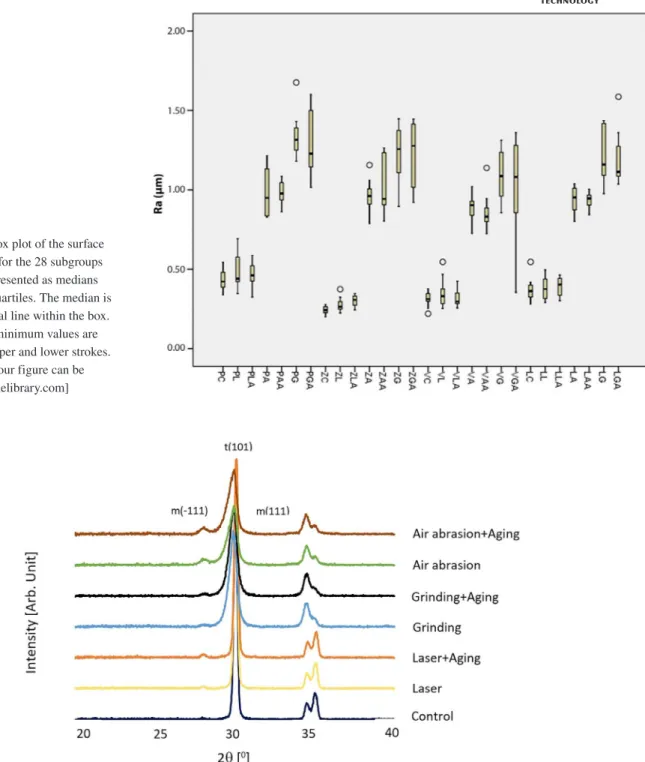

Phase transformation

Figure 2 is the representative XRD patterns of zirconia. Table 3 gives the mean (±SD) relative monoclinic phase (Xm) of the subgroups and Table 4 provides the volumetric fraction (Fm) and TZD of the subgroups. Figure 3 demonstrates the box plot of the Xm values for the experimental groups. According to XRD analysis, airborne particle abrasion and grinding proto-cols showed a significant impact on the phase transformation. For all materials, the highest amount of monoclinic phase was (4)

𝜎= (3Pl)∕(2wb2

)

(5)

Pf(𝜎)= 1 − exp [ − (𝜎∕𝜎0)m]

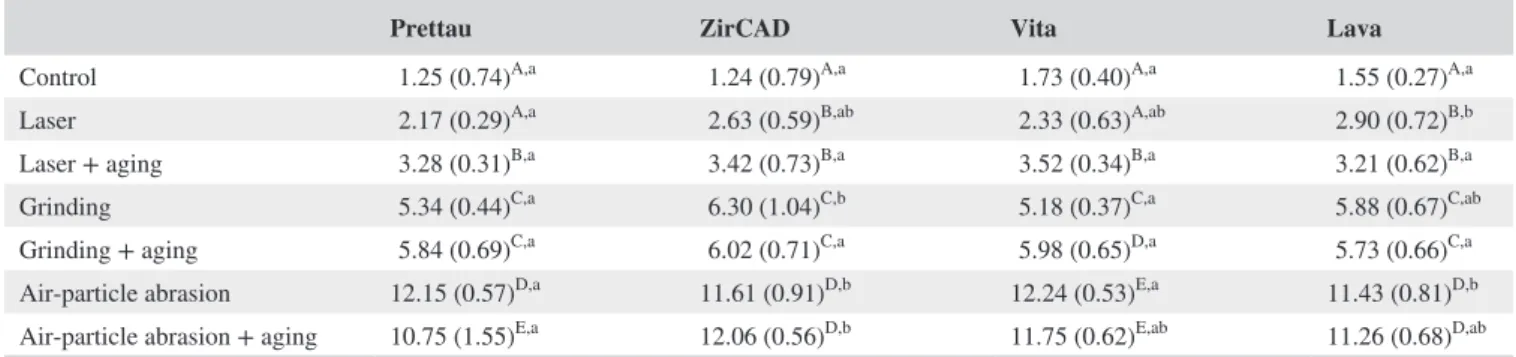

TABLE 2 Mean (±SD) surface roughness (Ra, µm) values of subgroups

Prettau ZirCAD Vita Lava

Control 0.43 (0.07)A,a 0.24 (0.02)A,b 0.31 (0.05)A,c 0.37 (0.08)A,ac

Laser 0.49 (0.11)A,a 0.28 (0.05)A,b 0.35 (0.09)A,bc 0.38 (0.08)A,c

Laser + aging 0.46 (0.09)A,a 0.30 (0.04)A,b 0.32 (0.06)A,bc 0.39 (0.06)A,ac

Air‐particle abrasion 0.98 (0.15)B,a 0.96 (0.11)B,a 0.90 (0.09)BC,a 0.95 (0.08)B,a

Air‐particle abrasion + aging 0.98 (0.08)B,ab 1.01 (0.17)B,a 0.87 (0.11)B,b 0.94 (0.05)B,ab

Grinding 1.34 (0.14)C,a 1.23 (0.19)C,ab 1.09 (0.16)C,b 1.21 (0.18)C,ab

Grinding + aging 1.29 (0.20)C,a 1.23 (0.20)C,a 1.03 (0.32)BC,a 1.19 (0.17)C,a Same superscript uppercase letters in the same column and same superscript lowercase letters in the same row denote subgroups that were not significantly different (Tukey's HSD and Dunn's tests, P > 0.05). SD, standard deviation.

found after airborne particle abrasion. Grinding groups showed higher values of monoclinic phase compared to laser and con-trol groups (P < 0.05). Laser irradiation affected the Xm values in ZirCAD and Lava materials when compared with control groups (P < 0.05); however, there were no significant differ-ences between the same surface treatment groups in Prettau and Vita (P > 0.05). Aging increased the Xm values of Prettau laser, Prettau air‐abrasion, Vita laser, and Vita grinding groups (P < 0.05). There were no statistical differences between aged and non‐aged subgroups of Lava and ZirCAD groups (P > 0.05).

3.3

|

Flexural strength

Table 5 shows the statistical differences in the flexural strength values between subgroups and Figure 4 presents the box plot of flexural strength values for 28 groups. Table 6 lists the char-acteristic strength and Weibull modulus values of each group. Surface treatment groups of ZirCAD ceramic showed the high-est flexural strength and characteristic strength values among all cohorts. The lower flexural strength values were recorded in grinding groups. There were no significant differences in

FIGURE 1 Box plot of the surface roughness (Ra, µm) for the 28 subgroups (n = 10). Data are presented as medians and first and third quartiles. The median is shown by a horizontal line within the box. The maximum and minimum values are illustrated via the upper and lower strokes.

0marks outliers [Colour figure can be

viewed at wileyonlinelibrary.com]

FIGURE 2 XRD patterns of zirconia after different surface treatments (example: e.max ZirCAD groups) [Colour figure can be viewed at wileyonlinelibrary.com]

the flexural strength values between the control and air‐parti-cle abrasion groups (P > 0.05). Laser treatment did not impact flexural strength (P > 0.05). Aging groups showed statistically similar flexural strength values to non‐aged groups (P > 0.05).

According to the Weibull analysis, the grinding procedure decreased the m values in each material. The Weibull modulus value was highest for the Vita control group (m = 22.24), and lowest for the ZirCAD grinding + aging group (m = 4.00).

TABLE 3 Mean (±SD) relative monoclinic phase (Xm) of subgroups (%)

Prettau ZirCAD Vita Lava

Control 1.25 (0.74)A,a 1.24 (0.79)A,a 1.73 (0.40)A,a 1.55 (0.27)A,a

Laser 2.17 (0.29)A,a 2.63 (0.59)B,ab 2.33 (0.63)A,ab 2.90 (0.72)B,b

Laser + aging 3.28 (0.31)B,a 3.42 (0.73)B,a 3.52 (0.34)B,a 3.21 (0.62)B,a

Grinding 5.34 (0.44)C,a 6.30 (1.04)C,b 5.18 (0.37)C,a 5.88 (0.67)C,ab

Grinding + aging 5.84 (0.69)C,a 6.02 (0.71)C,a 5.98 (0.65)D,a 5.73 (0.66)C,a

Air‐particle abrasion 12.15 (0.57)D,a 11.61 (0.91)D,b 12.24 (0.53)E,a 11.43 (0.81)D,b

Air‐particle abrasion + aging 10.75 (1.55)E,a 12.06 (0.56)D,b 11.75 (0.62)E,ab 11.26 (0.68)D,ab Same superscript uppercase letters in the same column and same superscript lowercase letters in the same row denote subgroups that were not significantly different (Tukey's HSD and Dunn's tests, P > 0.05).

TABLE 4 Volumetric fraction (Fm, %) and transformation zone depth (TZD, µm) of subgroups

Prettau ZirCAD Vita Lava

Fm TZD Fm TZD Fm TZD Fm TZD Control 1.62 0.08 1.62 0.08 2.26 0.12 2.02 0.10 Laser 2.83 0.15 3.42 0.18 3.03 0.16 3.77 0.19 Laser + aging 4.26 0.22 4.43 0.23 4.56 0.24 4.17 0.22 Grinding 6.88 0.36 8.10 0.43 6.68 0.35 7.56 0.40 Grinding + aging 7.52 0.40 7.74 0.41 7.69 0.41 7.38 0.39 Air‐particle abrasion 15.35 0.84 14.69 0.81 15.46 0.85 14.47 0.79 Air‐particle abrasion + aging 13.63 0.74 15.24 0.84 14.85 0.82 14.26 0.78

FIGURE 3 Box plot of the relative monoclinic phase (Xm, %) for the 28 subgroups (n = 10). Data are presented as medians and first and third quartiles. The median is shown by a horizontal line within the box. The maximum and minimum values are illustrated via the upper and lower strokes. 0marks outliers *marks extreme

values [Colour figure can be viewed at wileyonlinelibrary.com]

Pearson's correlation analysis showed a statistically sig-nificant positive correlation between surface roughness and phase transformation in each zirconia ceramic (P < 0.001);

however, there was no meaningful correlation between flex-ural strength and phase transformation (P > 0.05). For all ceramics, a negative correlation existed between surface

TABLE 5 Mean (±SD) flexural strength values (MPa) of subgroups

Prettau ZirCAD Vita Lava

Grinding 779.11 (126.22)A,a 965.25 (153.33)A,b 900.20 (110.51)A,ab 829.12 (171.98)A,ab

Grinding + aging 743.17 (120.03)A,a 1034.79 (176.32)AB,b 888.33 (176.30)A,ab 888.99 (149.09)AB,ab

Control 992.64 (81.06)B,a 1180.04 (118.31)BC,b 1123.50 (46.19)B,b 1070.81 (120.49)BC,ab

Laser 1041.14 (124.43)B,a 1193.64 (146.95)BC,b 1142.47 (84.90)B,ab 1007.28 (135.11)ABC,a

Laser + aging 991.27 (140.93)B,bc 1199.03 (174.69)BC,a 1154.98 (94.10)B,ab 959.56 (141.79)ABC,c

Air‐particle abrasion 1102.63 (108.40)B,a 1261.83 (99.03)C,b 1210.19 (86.81)B,ab 1149.19 (76.19)C,a

Air‐particle

abrasion + aging 1052.43 (151.61)

B,a 1203.28 (103.68)BC,a 1153.85 (65.20)B,a 1063.76 (160.22)BC,a

Same superscript uppercase letters in the same column and same superscript lowercase letters in the same row denote subgroups that were not significantly different (Tukey's HSD and Dunn's tests, P > 0.05).

FIGURE 4 Box plot of the flexural strength (MPa) for the 28 subgroups (n = 10). Data are presented as medians and first and third quartiles. The median is shown by a horizontal line within the box. The maximum and minimum values are illustrated via the upper and lower strokes. 0marks outliers *marks extreme

values [Colour figure can be viewed at wileyonlinelibrary.com]

TABLE 6 Characteristic strength (MPa) and Weibull modulus of subgroups

Prettau ZirCAD Vita Lava

σo m σo m σo m σo m Control 1025 8.72 1232 9.13 1144 22.24 1123 8.64 Laser 1094 7.30 1247 4.35 1181 13.81 1064 6.46 Laser + aging 1047 4.80 1270 5.25 1196 12.16 1017 5.32 Grinding 832 6.52 1027 5.00 944 5.43 898 4.57 Grinding + aging 794 6.93 1104 4.00 960 5.13 950 5.25 Air‐particle abrasion 1148 8.01 1304 10.28 1249 13.72 1186 17.84 Air‐particle abrasion + aging 1115 5.96 1247 9.43 1182 15.68 1128 5.11

roughness and flexural strength, but this was not statistically significant for Lava ceramic (P > 0.05).

3.4

|

AFM and SEM analyses

SEM and AFM images (Figures 5‒8) identified surface ir-regularities of zirconia surfaces treated by airborne particle abrasion and grinding. Deep surface grooves were seen at the surfaces after the grinding procedure. Conversely, Er:YAG laser irradiation did not cause a remarkable change to the sur-face topographies of ceramics. Additionally, the microscope images of aged and non‐aged specimens were similar to each other.

4

|

DISCUSSION

In this study, the effects of airborne particle abrasion, grind-ing, and laser treatment on surface roughness, flexural strength, and phase transformation of Y‐TZP zirconia ceram-ics were evaluated. The null hypothesis of the study was re-jected because there were significant differences among the experimental surface treatment groups.

Although zirconia materials have similar compositions, they differ from each other because of different grain sizes and sintering temperatures. Particularly, the sintering tem-perature affects microstructure, lifetime, hydrolytic perfor-mance, and fatigue of materials.24 Increasing the sintering

temperature may increase the grain sizes and consequently affect the mechanical properties of zirconia, which are closely related to its grain size. An increase in the grain size may enhance crack formation. Besides, raising the sintering temperature has been found to migrate yttrium to the grain boundaries. An investigation into the influence of sintering temperature on the grain size and flexural strength of zirconia ceramics, established that sintering above 1600°C increased the grain size and decreased flexural strength while flexural strength was enhanced when sintering between 1400 and 1550°C.5 Internal stresses may be associated with the high

sintering temperatures.4 Moreover, the properties of zirconia

may be linked to the purity of the zirconium oxide powder, fabrication technique, and the accurate concentration and uniform distribution of yttrium oxide.36 In the current study,

four different Y‐TZP ceramic were used. The zirconia mate-rials exhibited remarkable variations in their flexural strength and Weibull modulus values. Prettau, which is a monolithic zirconia, is sintered at a higher temperature (1600°C) than the other zirconia ceramics evaluated. The comparatively lower flexural strength of this ceramic may be due to its high sin-tering temperature.

In some earlier reports, dry grinding resulted in damaged and partial plastically deformed surfaces.37,38 If the

transfor-mation heat is exceeded, a reverse transfortransfor-mation (m → t)

occurs.37 The strength is generally determined by surface

flaws due to the grinding process because the depth of flaws are longer than the surface compressive layer.37‒39 In prior

literature, grinding with coarse burs decreased the flexural strength and reliability of zirconia.37,40 Grigore et al41

per-formed 150 µm grinding to zirconia and observed intensive defect areas. Similarly, Scherrer et al42 documented that

grind-ing of zirconia surfaces with 120 µm diamond burs created 10‐20 µm radial cracks. In the present study, grinding using a medium grit diamond bur decreased the flexural strength of each material and microscopic evaluation revealed the sharp grooves, which may act as stress concentration areas. Furthermore, the roughness values of the grinding groups were higher than the other groups, indicating that their lower flexural strength and reliability could be attributed to the sur-face defects resulting from the grinding process.

In contrast to grinding altough the lower stress levels, a high t → m transformation occurs by airborne particle abrasion. During the airborne particle abrasion, the heat generation is less than grinding.37 Some studies reported

the increase in strength after airborne particle abrasion.18,43

According to Kosmač et al,37 surface flaws cannot exceed the

stress‐induced transformation depth. In this way, the damage caused by airborne particle abrasion is surface‐localized, and it cannot affect the whole of the material. Conversely, some authors underlined that airborne particle abrasion has no increasing impact on mechanical properties of zirconia.15

An increase or decrease in the strength is dependent on sur-face damage44 or preventive residual compressive stresses37

after airborne particle abrasion. Zhang et al44 noted that the

volume expansion due to phase transformation might be responsible for plastic deformation of zirconia. Similarly, Grigore et al41 demonstrated that airborne particle abrasion

with 105 μm causes high defect concentration and surface damage. According to our findings, airborne particle abra-sion slightly increased the flexural strength compared to untreated specimens; however, this difference was not statis-tically significant. The increase in strength by the formation of a compressive layer, which is a result of the phase trans-formation, may be eliminated by the surface defects that occur with airborne particle abrasion.

In prior investigations, usually 50 or 110 µm Al2O3

par-ticle air abrasion was used. Wang et al45 documented an

increase in the strength of Y‐TZP after the treatment using 50 µm Al2O3 particle compared to 120 µm. However, some

researchers emphasized the abrasion using small air‐parti-cle sizes is not effective in creating irregularities on densely sintered ceramic surfaces, necessary to obtain sufficient bond strength with resin cement.46 Demir et al26 observed

microretentive groove formation in microscope analysis after 110 µm air abrasion treatment. Therefore, in the pres-ent study, 110 µm Al2O3 air abrasion protocol was selected.

groups, as evident in the SEM and AFM images. Future stud-ies should investigate the effects of different air abrasion pro-tocols on Y‐TZP ceramic.

The dental literature contains several studies that investi-gated the effect of Er:YAG laser on Y‐TZP.13,25‒27 Er:YAG

laser is known to have a thermomechanical impact on the structure, but there is still no consensus about the potential impacts of this laser type. During the process, local thermal changes may cause internal stresses, which can cause dam-age to the material.47 Additionally, mechanical properties of

Y‐TZP may be affected by the thermal changes, which are related to phase transformation.25 Demir et al26 found 400 mJ

laser energy is effective for surface modification, whereas 200 and 300 mJ, respectively, were insufficient. In the study by Subaşı and İnan,13 Er:YAG laser treatment increased the

roughness of zirconia and, similarly to our research, they found higher roughness values after airborne particle abra-sion compared to laser treatment. In the current study, laser irradiation increased surface roughness slightly, but there was no statistically significant influence on surface rough-ness and flexural strength. This outcome may be explained by the white/opaque and water‐free features of zirconia, which could block the laser absorption.13

Low‐temperature aging of zirconia is a growing and fu-sion process, which starts from isolated surface grains and then spreads internally.48,49 First, the t → m transformation

is initiated at the surface, which is insignificant for physi-cal properties. However, when the saturation in monoclinic phase is reached at the surface, transformation proceeds into the bulk. Under these conditions, internal flaws causing fail-ure of the material can be critical.49 This degradation

mecha-nism is based on the destabilization of the tetragonal phase in water vapor at temperatures ranging from room temperature up to 400°C.41,48 By this mechanism, zirconia loses its

tough-ening effect, as a result of the high transformation rate.24 A

spontaneous, slow t → m transformation may also cause sur-face roughness and grain pull‐out.29 Oblak et al22 highlighted

that monolithic zirconia restorations are directly exposed to the moist environment of the oral cavity, which explains why aging is an important factor for this material. Perdigao et al50 noticed an increase in the percentage of monoclinic

phase and grain pull‐out from the surface after thermocy-cling. Conversely, Shimizu et al51 found little changes (<5%)

in the crystal structure of zirconia and no serious decrease in bending strength over 3 years. Similarly, Ardlin52 and

Papanagiotou et al43 demonstrated that low‐temperature

deg-radation procedures did not reduce the flexural strength of zirconia.

Cyclic stresses, such as chewing, are a major concern in dentistry9 because the reliability of zirconia under cyclic

loading conditions is still unclear. Numerous studies have investigated the effect of mechanical cycling on zirconia. For instance, Yang et al53 applied 105 dynamic cycling

(100 N) to zirconia, and the aging procedure had a signif-icant influence on the failure load. The difference in the applied loads may explain the discrepancies between this result and the present study. Cycling loading parameters of the current study were similar to those implemented by Souza et al,8 who applied 105 mechanical cycles (50 N)

and observed no difference in flexural strength between aged and non‐aged control groups. Egilmez et al9 found no

significant difference between the control and 20,000 me-chanical cycles (200 N) group. Borchers et al7 examined

the Y‐TZP under various thermal and loading conditions. Although the amount of monoclinic phase differed among the groups, biaxial flexural strength values were similar. The explanation for this lack of correlation may be that the transformation zone was not deep enough to influence the entire material. In this study, thermal and mechani-cal artificial aging did not impact the flexural strength of materials. This finding concurs with Borchers et al7 and

may be justified by the shortness of the aging simulation and superficiality of the transformation zone. The authors7

also evaluated the effect of 10,000 thermal cycling on zirconia. The number of thermal cycles (10,000) used in this study corresponds to approximately 1 year of clinical use.50,54 One of the limitations of the present study was

the usage of the short‐term thermal aging. In an earlier investigation,15 the researchers observed significant

re-ductions in the strength of air‐abraded zirconia ceramics after dynamic and cyclic tests. Zhang and Lawn30 studied

the effect of sharp indentation damage on the long‐term performance of zirconia and determined that sandblast-ing and sharp indentations are detrimental to long‐term performance, even at low loads in the cyclic conditions. Likewise, Kosmač et al38 illustrated that impact flaws

might grow to become stress intensifiers, by thermal and mechanical aging in an aqueous environment over long periods. Even if high strength might appear as an advan-tage, long‐term performance and reliability should also be considered.3,38

In the dental literature, phase transformation values are seen to vary widely. Souza et al8 found that the Fm ranged from

16.51% to 27.21% in the experimental groups while Guazzato et al55 reported a comparatively lower value (9.5%). Other

researchers31,41 reported that the relative amount of

trans-formed monoclinic phase (Xm) was approximately 11% in the air‐abraded groups. Karakoca and Yılmaz20 documented

higher Xm values (9.44%‐14.5%) after air‐particle abrasion compared to grinding (4.98%‐7.02%). Compatible with the findings of that research, in the present study, airborne par-ticle abrasion increased the proportion of monoclinic phase compared to grinding and laser irradiation. In addition, the higher transformation values suggest that the airborne parti-cle abrasion, as well as grinding, have a higher stress‐forming effect on the zirconia surface compared to laser treatment.

The grinding groups showed relatively lower transformation levels compared to airborne particle abrasion, which could be associated with reverse transformation (monoclinic to tetragonal) resulting from the higher locally‐developed tem-peratures. On the contrary, the higher monoclinic levels ob-served in air‐abraded surfaces compared to grinding may be due to the generation of lower heat during this process. As a result, the reverse phase transformation may not have oc-curred. Thus, although airborne particle abrasion is consid-ered to be a more gentle process compared to grinding due to the removal of less material from the surface, this treat-ment may increase the thickness of the transformed layer.37

In earlier work, after air abrasion protocols the TZD ranged between 0.91 and 1.60 µm,8 whereas, in another study,9 these

values were between 0.138 and 0.294 µm. The variation in transformation values between literature studies could be due to chemical and structural differences between the zirconia ceramics, such as concentration, distribution, type of the sta-bilizer oxides, and grain sizes.6,8 Future studies are needed to

investigate various Y‐TZP ceramics under different experi-mental conditions.

Strength data of the ceramic materials usually show an asymmetrical distribution and Weibull statistics can be used to analyze the strength variability.20 Özcan et al56

empha-sized that the strength data should be coupled with Weibull analysis. Two important parameters of Weibull distribu-tion funcdistribu-tion are the Weibull modulus and characteristic strength.57 A high Weibull modulus indicates a small error

range, a high level of structural integrity and potentially improved structural reliability of the material.9 The

char-acteristic strength or scale parameter represents the 63.21 percentile of strength distribution.20 In the present study,

the untreated Vita group showed a higher Weibull mod-ulus compared to the other groups, indicating the greater clinical reliability of the material. Grinding groups

gener-ally showed low Weibull modulus. Karakoca and Yılmaz20

illustrated that airborne particle abrasion groups (n = 10) have high flexural strength but low Weibull modulus val-ues. Therefore, unexpected failures of material after treat-ment may occur.

5

|

CONCLUSIONS

From this study, the following statements were concluded:

1. Airborne particle abrasion and grinding created more

roughness and surface irregularities compared to laser and control groups.

2. Airborne particle‐abraded groups showed higher

mono-clinic levels compared to other groups.

3. Grinding of zirconia surfaces remarkably decreased the

flexural strength and Weibull modulus values.

4. Flexural strength values of Y‐TZP ceramics were not

af-fected by artificial aging used in this study.

ACKNOWLEDGMENT

This work was supported by the Scientific Research Project Council of Selcuk University, Turkey (grant no. 12202017).

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest.

ORCID

Yener Okutan https://orcid.org/0000-0002-7188-4929

REFERENCES

1. Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cemen-tation to zirconia and other non‐silicate ceramics: where are we now? Dent Mater. 2011;27:71–82.

2. Elsaka SE. Influence of surface treatments on the surface proper-ties of different zirconia cores and adhesion of zirconia‐veneering ceramic systems. Dent Mater. 2013;29:239–51.

3. Denry I, Kelly JR. State of the art of zirconia for dental applica-tions. Dent Mater. 2008;24:299–307.

4. Stawarczyk B, Emslander A, Roos M, Sener B, Noack F, Keul C. Zirconia ceramics, their contrast ratio and grain size depending on sintering parameters. Dent Mater J. 2014;33:591–8.

5. Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hammerlet CH. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013;17:269–74. 6. Piconi C, Maccauro G. Zirconia as a ceramic biomaterial.

Biomaterials. 1999;20:1–25.

7. Borchers L, Stiesch M, Bach F‐W, Buhl J‐C, Hübsch C, Kellner T, et al. Influence of hydrothermal and mechanical conditions on the strength of zirconia. Acta Biomater. 2010;6:4547–52.

8. Souza RO, Valandro LF, Melo RM, Machado JP, Bottino MA, Ozcan M. Air‐particle abrasion on zirconia ceramic using differ-ent protocols: effects on biaxial flexural strength after cyclic load-ing, phase transformation and surface topography. J Mech Behav Biomed Mater. 2013;26:155–63.

9. Egilmez F, Ergun G, Cekic‐Nagas I, Vallittu PK, Lassila LV. Factors affecting the mechanical behavior of Y‐TZP. J Mech Behav Biomed Mater. 2014;37:78–87.

10. Kern M, Wegner SM. Bonding to zirconia ceramic: adhesion meth-ods and their durability. Dent Mater. 1998;14:64–71.

11. Pittayachawan P, McDonald A, Petrie A, Knowles JC. The biaxial flexural strength and fatigue property of Lava Y‐TZP dental ce-ramic. Dent Mater. 2007;23:1018–29.

12. Özcan M, Vallittu PK. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater. 2003;19:725–31.

13. Subaşı MG, İnan Ö. Evaluation of the topographical surface changes and roughness of zirconia after different surface treat-ments. Lasers Med Sci. 2012;27:735–42.

14. Luthardt RG, Holzhüter M, Sandkuhl O, Herold V, Schnapp JD, Kuhlisch E, et al. Reliability and properties of ground Y‐TZP‐zir-conia ceramics. J Dent Res. 2002;81:487–91.

15. Zhang Y, Lawn BR, Rekow ED, Thompson VP. Effect of sandblast-ing on the long‐term performance of dental ceramics. J Biomed Mater Res B Appl Biomater. 2004;71:381–6.

16. Zhang Y, Lawn B. Long‐term strength of ceramics for bio-medical applications. J Biomed Mater Res B Appl Biomater. 2004;69:166–72.

17. Kosmač T, Oblak Č, Marion L. The effects of dental grinding and sandblasting on ageing and fatigue behavior of dental zirconia (Y‐ TZP) ceramics. J Eur Ceram Soc. 2008;28:1085–90.

18. Sato H, Yamada K, Pezzotti G, Nawa M, Ban S. Mechanical prop-erties of dental zirconia ceramics changed with sandblasting and heat treatment. Dent Mater J. 2008;27:408–14.

19. Chintapalli RK, Marro FG, Jimenez‐Pique E, Anglada M. Phase transformation and subsurface damage in 3Y‐TZP after sandblast-ing. Dent Mater. 2013;29:566–72.

20. Karakoca S, Yılmaz H. Influence of surface treatments on surface roughness, phase transformation, and biaxial flexural strength of Y‐TZP ceramics. J Biomed Mater Res B Appl Biomater. 2009;91:930–7.

21. İşeri U, Özkurt Z, Yalnız A, Kazazoğlu E. Comparison of different grinding procedures on the flexural strength of zirconia. J Prosthet Dent. 2012;107:309–15.

22. Oblak C, Verdenik I, Swain MV, Kosmac T. Survival‐rate analysis of surface treated dental zirconia (Y‐TZP) ceramics. J Mater Sci Mater Med. 2014;25:2255–64.

23. Zucuni CP, Guilardi LF, Rippe MP, Pereira G, Valandro LF. Fatigue strength of yttria‐stabilized zirconia polycrystals: Effects of grinding, polishing, glazing, and heat treatment. J Mech Behav Biomed Mater. 2017;75:512–20.

24. Preis V, Schmalzbauer M, Bougeard D, Schneider‐Feyrer S, Rosentritt M. Surface properties of monolithic zirconia after den-tal adjustment treatments and in vitro wear simulation. J Dent. 2015;43:133–9.

25. Cavalcanti AN, Foxton RM, Watson TF, Oliveira MT, Giannini M, Marchi GM. Bond strength of resin cements to a zirco-nia ceramic with different surface treatments. Oper Dent. 2009;34:280–7.

26. Demir N, Subaşı MG, Ozturk AN. Surface roughness and morpho-logic changes of zirconia following different surface treatments. Photomed Laser Surg. 2012;30:339–45.

27. Kara O, Kara HB, Tobi ES, Ozturk AN, Kilic HS. Effect of various lasers on the bond strength of two zirconia ceramics. Photomed Laser Surg. 2015;33:69–76.

28. Kurtulmus‐Yilmaz S, Aktore H. Effect of the application of sur-face treatments before and after sintering on the flexural strength, phase transformation and surface topography of zirconia. J Dent. 2018;72:29–38.

29. Chevalier J. What future for zirconia as a biomaterial? Biomaterials. 2006;27:535–43.

30. Zhang Y, Lawn BR. Fatigue sensitivity of Y‐TZP to microscale sharp‐contact flaws. J Biomed Mater Res B Appl Biomater. 2005;72:388–92.

31. Moon JE, Kim SH, Lee JB, Ha SR, Choi YS. The effect of prepa-ration order on the crystal structure of yttria‐stabilized tetragonal zirconia polycrystal and the shear bond strength of dental resin ce-ments. Dent Mater. 2011;27:651–63.

32. Garvie RC, Nicholson PS. Phase analysis in zirconia systems. J Am Ceram Soc. 1972;55:303–5.

33. Toraya H, Yoshimura M, Somiya S. Calibration curve for quantita-tive analysis of the monoclinic‐tetragonal ZrO2 System by X‐Ray

Diffraction. J Am Ceram Soc. 1984;67:119–21.

34. Kosmać T, Wagner R, Claussen N. X‐Ray determination of trans-formation depths in ceramics containing tetragonal ZrO2. J Am

Ceram Soc. 1981;64:72–3.

35. Bona AD, Anusavice KJ, DeHoff PH. Weibull analysis and flex-ural strength of hot‐pressed core and veneered ceramic structures. Dent Mater. 2003;19:662–9.

36. Casucci A, Mazzitelli C, Monticelli F, Toledano M, Osorio R, Osorio E, et al. Morphological analysis of three zirconium oxide ce-ramics: Effect of surface treatments. Dent Mater. 2010;26:751–60. 37. Kosmač T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of

surface grinding and sandblasting on flexural strength and reliabil-ity of Y‐TZP zirconia ceramic. Dent Mater. 1999;15(6):426–33. 38. Kosmač T, Oblak C, Jevnikar P, Funduk N, Marion L. Strength

and reliability of surface treated Y‐TZP dental ceramics. J Biomed Mater Res. 2000;53:304–13.

39. Xu H, Jahanmir S, Ives LK. Effect of grinding on strength of tetrag-onal zirconia and zirconia‐toughened alumina. Mach Sci Technol. 1997;1:49–66.

40. Curtis AR, Wright AJ, Fleming GJ. The influence of surface modi-fication techniques on the performance of a Y‐TZP dental ceramic. J Dent. 2006;34:195–206.

41. Grigore A, Spallek S, Petschelt A, Butz B, Spiecker E, Lohbauer U. Microstructure of veneered zirconia after surface treatments: a TEM study. Dent Mater. 2013;29:1098–107.

42. Scherrer SS, Cattani‐Lorente M, Yoon S, Karvonen L, Pokrant S, Rothbrust F, et al. Post‐hot isostatic pressing: a healing treatment for process related defects and laboratory grinding damage of den-tal zirconia? Dent Mater. 2013;29:180–90.

43. Papanagiotou HP, Morgano SM, Giordano RA, Pober R. In vitro evaluation of low‐temperature aging effects and finishing proce-dures on the flexural strength and structural stability of Y‐TZP dental ceramics. J Prosthet Dent. 2006;96:154–64.

44. Zhang Y, Lawn BR, Malament KA, Van Thompson P, Rekow ED. Damage accumulation and fatigue life of particle‐abraded ceram-ics. Int J Prosthodont. 2006;19:442–8.

45. Wang H, Aboushelib MN, Feilzer AJ. Strength influencing variables on CAD/CAM zirconia frameworks. Dent Mater. 2008;24:633–8.

46. Borges GA, Sophr AM, de Goes MF, Sobrinho LC, Chan DC. Effect of etching and airborne particle abrasion on the microstruc-ture of different dental ceramics. J Prosthet Dent. 2003;89:479–88. 47. Gökçe B, Ozpinar B, Dündar M, Cömlekoglu E, Sen BH, Güngör

MA. Bond strengths of all‐ceramics: acid vs laser etching. Oper Dent. 2007;32:173–8.

48. Chevalier J, Gremillard L, Virkar AV, Clarke DR. The tetragonal‐ monoclinic transformation in zirconia: Lessons learned and future trends. J Am Ceram Soc. 2009;92:1901–20.

49. Kim HT, Han JS, Yang JH, Lee JB, Kim SH. The effect of low temperature aging on the mechanical property & phase stability of Y‐TZP ceramics. J Adv Prosthodont. 2009;1:113–7.

50. Perdigao J, Pinto AM, Monteiro RC, Braz Fernandes FM. Laranjeira P, Veiga JP. Degradation of dental ZrO2‐based mate-rials after hydrothermal fatigue. Part I: XRD, XRF, and FESEM analyses. Dent Mater. J. 2012;31:256–65.

51. Shimizu K, Oka M, Kumar P, Kotoura Y, Yamamuro T, Makinouchi K, et al. Time‐dependent changes in the mechanical properties of zirconia ceramic. J Biomed Mater Res. 1993;27:729–34.

52. Ardlin BI. Transformation‐toughened zirconia for dental inlays, crowns and bridges: chemical stability and effect of low‐tempera-ture aging on flexural strength and surface struclow‐tempera-ture. Dent Mater. 2002;18:590–5.

53. Yang R, Arola D, Han Z, Zhang X. A comparison of the fracture resistance of three machinable ceramics after thermal and mechan-ical fatigue. J Prosthet Dent. 2014;112:878–85.

54. Gale MS, Darvell BW. Thermal cycling procedures for laboratory testing of dental restorations. J Dent. 1999;27:89–99.

55. Guazzato M, Quach L, Albakry M, Swain MV. Influence of sur-face and heat treatments on the flexural strength of Y‐TZP dental ceramic. J Dent. 2005;33:9–18.

56. Özcan M, Melo RM, Souza RO, Machado JP, Felipe Valandro L, Botttino MA. Effect of air‐particle abrasion protocols on the

biaxial flexural strength, surface characteristics and phase trans-formation of zirconia after cyclic loading. J Mech Behav Biomed Mater. 2013;20:19–28.

57. Siarampi E, Kontonasaki E, Andrikopoulos KS, Kantiranis N, Voyiatzis GA, Zorba T, et al. Effect of in vitro aging on the flexural strength and probability to fracture of Y‐TZP zirconia ceramics for all‐ceramic restorations. Dent Mater. 2014;30:306–16.

How to cite this article: Okutan Y, Yucel MT. Effect

of surface treatments and aging on phase transformation and flexural strength of different Y‐TZP ceramics. Int J

Appl Ceram Technol. 2019;16:1425–1440. https://doi. org/10.1111/ijac.13238

![FIGURE 5 SEM and AFM images of Prettau zirconia [Colour figure can be viewed at wileyonlinelibrary.com]](https://thumb-eu.123doks.com/thumbv2/9libnet/5390105.101580/8.892.146.749.70.1081/figure-images-prettau-zirconia-colour-figure-viewed-wileyonlinelibrary.webp)

![FIGURE 6 SEM and AFM images of e.max ZirCAD [Colour figure can be viewed at wileyonlinelibrary.com]](https://thumb-eu.123doks.com/thumbv2/9libnet/5390105.101580/9.892.145.746.70.1062/figure-sem-images-zircad-colour-figure-viewed-wileyonlinelibrary.webp)

![FIGURE 7 SEM and AFM images of Vita In‐Ceram YZ [Colour figure can be viewed at wileyonlinelibrary.com]](https://thumb-eu.123doks.com/thumbv2/9libnet/5390105.101580/10.892.152.745.77.1061/figure-images-vita-ceram-colour-figure-viewed-wileyonlinelibrary.webp)

![FIGURE 8 SEM and AFM images of Lava zirconia [Colour figure can be viewed at wileyonlinelibrary.com]](https://thumb-eu.123doks.com/thumbv2/9libnet/5390105.101580/12.892.152.749.66.1069/figure-images-lava-zirconia-colour-figure-viewed-wileyonlinelibrary.webp)