ORIGINAL PAPER

Hakan Köçkar1 &Nadir Kaplan1&Ali Karpuz2&Hilal Kuru1&Birol Kaya1

Received: 7 November 2018 / Accepted: 5 December 2018 / Published online: 9 January 2019 # Springer Science+Business Media, LLC, part of Springer Nature 2019

Abstract

A series of 50-nm binary FeCr martensitic thin films were sputtered from a single source made of commercial AISI 430 ferritic stainless steel under the deposition rates gradually increased from 0.03 to 0.11 nm/s with 0.02 nm/s steps at stationary condition. And, under 0.09 nm/s deposition rate, a second series of the films were also deposited under the rotation speed of their substrates which was chosen at 0, 25, and 45 rpm. As far as we are concerned, this study is the first investigation of properties of the thin films produced from AISI 430. The atomic Fe content in the films increased from 79.3 to 98.6% while atomic Cr content decreased from 20.5 to 1.2% with the increase of deposition rate from 0.03 to 0.11 nm/s. According to compositional analysis, the Fe content increased while Cr content decreased with increasing deposition rate. The reason for this may be attributed to the relatively different bond energy/melting point of metals which have different contents sputtered from source material since this physical parameter is very significant for the sputtering process. And, the Fe content in the films decreased from 84.9 to 79.2 at. % while the Cr content increased from 14.9 to 20.6 at. % when the increase of rotation speed of substrate. The crystal structure of all films was observed to have a body-centered tetragonal phase and the intensity of (110) peak varied with the atomic Fe content. The surface observations of films performed by a scanning electron microscope exposed that the number of surface grains increased with the increase of deposition rate and decreased with the increase of rotation speed. According to surface roughness analysis done by an atomic force microscope, the roughness of the film surfaces increased as the deposition rate increased. And, the roughness of the film surfaces decreased as the rotation speed increased. This has been consistent with the grain size and roughness parameters. Thus, increasing deposition rate and decreasing rotation speed of the substrate caused an increase in grain size and roughness parameters. The magnetic measurements of the films achieved, by a vibrating sample magnetometer at room temperature, displayed that the saturation magnetization, Ms, values increased from 820.1 to 1700.4 emu/cm3, the remanence magnetization, Mr, values increased from 293 to 817 emu/cm3, and the coercivity, Hc, value also increased from 38 to 107 Oe with the increasing of deposition rate. It is also seen that the magnetic easy axis are in the film plane due to the shape anisotropy. With the increase rotation speed, the values of Msand Mrincreased and the Hc decreased. It was seen that variation of Fe content in the films influences the Msvalues and the Hcvalues are consistent with the surface properties. It was concluded that the deposition rate and the rotation speed of the substrate play a considerable role on the structural and related magnetic properties of the sputtered FeCr thin films, and the properties of the films can be easily controlled by changing production parameters.

Keywords FeCr thin films . AISI 430 . Deposition rate . Rotation speed . Magnetic properties . Structural properties . dc sputtering technique

1 Introduction

In recent years, the magnetic thin film technology is one of the most developing areas in science and technology [1–5]. The scientists have been investigated different materials due to the quite interesting properties caused in the nanostructure [6]. They use also different material and their combination for * Hakan Köçkar

hkockar@balikesir.edu.tr 1

Physics Department, Science and Literature Faculty, Balikesir University, 10145 Balikesir, Turkey

2 Physics Department, Kamil Ozdag Science Faculty, Karamanoglu Mehmetbey University, 70100 Karaman, Turkey

Characterizations of Binary FeCr (AISI 430) Thin Films Deposited

from a Single Magnetron Sputtering Under Easy Controllable Deposition

Parameters

enhancing the properties of the small-sized magnetic struc-tures, such as magnetic recording heads and sensors [7,8]. The FeCr (AISI 430) material as a bulk, which is also known as ferritic-stainless steel, has been used for many years due to their wide usage areas in industry. And, the scientists investi-gate the production of thin films which also preferred the binary alloy in recent years [9–12] since it was expressed that the stainless steel thin films produced at the nanoscale can appear extraordinary magnetic properties in earlier studies [13,14]. The deposition parameters, deposition rate [15], change the structural and magnetic properties of the films produced by a sputtering technique and therefore, different deposition rates can cause important effects [16–18]. And, the rotation speed of substrate is also seen as quite important parameter under investigation. Understudy, a single-source dc sputtering is used for the production of the binary FeCr thin films and is quite a different process from the classical bulk production process of stainless steel since the bulk and nano-film properties are expected to be quite different from each other. For a long time, dual alloy thin films were produced and characterized using two pure sources [19,20]. In this study, the thin films are sputtered by a single commercial AISI 430 ferritic stainless steel source under high-vacuum condition. To our knowledge, the effect of deposition rate and rotating sub-strate speed on the properties of binary FeCr films produced from AISI 430 ferritic stainless steel source by using single-source dc sputtering technique has not been investigated ear-lier. Therefore, in this study, it was aimed to investigate the effect of different deposition rates (0.03, 0.05, 0.07, 0.09, and 0.11 nm/s) and different rotating speed of substrates (0, 25, and 45 rpm) on the structural and magnetic properties of FeCr thin films sputtered from AISI 430. According to the results of the analysis, the deposition rate and the rotation speed of the substrate play a considerable role on the structural and corre-sponding magnetic properties of the sputtered binary FeCr martensitic thin films. It was seen that the films have rougher surfaces and harder magnetic properties at having increased deposition rates, however, when the rotation of the substrate increased, the surface of the film is smoother and hence, lower coercivity concludes the magnetically softer properties. And, in the XRD results, the atomic contents change explains the variations of the (110) peak intensities of the present films. It is seen that the binary FeCr martensitic thin films were for the first time produced by a single source by sputtering technique and the performed analysis displayed that the structural and magnetic properties were affected the deposition process parameters.

2 Experimental

The magnetic FeCr thin films were deposited on commer-cial flexible acetate substrates by using single-source dc

sputtering system (Mantis, Q-Prep 500, UK). The atomic compositional analysis of the source was determined by using inductively coupled plasma-atomic emission spec-troscopy (ICP-AES, Perkin-Elmer, Optima 7300 DV, USA). The source has the atomic contents of 87.2% Fe and 12.6% Cr and 0.2% other elements such as Mn, Ni, and V, see Table 1. The source made from a commercial AISI 430 ferritic stainless steel was 0.8 mm thick and 50.8 mm in diameter. For the production of the films, the acetate substrate was cleaned with distilled water with an ultrasonic bath before deposition. After the bath, it was dried at room temperature. The distance between substrate and source was ~ 125 mm in the vacuum chamber. Firstly, the pressure of the vacuum chamber was 3 × 10−6mBar before argon gas was dispatched to the vacuum chamber. A pressure value of ~ 4.20 × 10−3mBar was obtained after argon gas was dispatched and all films were produced under this pressure value. The films were sputtered at room tem-perature and the temtem-perature of the substrates varied around 3 °C due to irrepressible experimental factor. The thick-nesses of the films were measured by using a quartz crystal microbalance thickness monitor (Sycon Instruments, STM 100/MF, USA) which can provide thickness information with a statistical accuracy of ± 0.01 nm during the sputtering process. The thickness of all films was 50 nm. In order to investigate the effect of the different deposition rates and rotation speed of the substrate on the structural and relating magnetic properties of the FeCr Alloy thin films, the depo-sition rates of the films were systematically changed in the range of 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s with the step size of 0.02 nm/s, and the rotation speed of substrate was selected as 0, 25, and 45 rpm under deposition rate of 0.09 nm/s since the rotation speed of substrate is limited to 50 rpm.

The compositional analysis of the films was done by an energy-dispersive X-ray spectroscopy (EDX; Bruker, Quantax EDS XFlash® 6|30, USA). The films contain a total of 0.2 at. % of other elements of Ni, Mn, and V. The crystal structure of films was examined by using the X-ray diffraction technique (XRD; Bruker, Advance with Davinci Design for XRD2, UK). The analysis was performed with Cu-Kα radiation and by scanning the 2θ angle between 30 and 80° with the step size of 0.005°. The surfaces of the films were investigated by using a scanning electron micro-scope (SEM; Zeiss, Evo Ls 10, Germany) and an atomic force microscopy (AFM; NanoMagnetics Instruments, hpAFM, UK). The magnetic hysteresis curves were obtain-ed by using a vibrating sample magnetometer (VSM; Ade Technologies DMS-EV9, USA) at room conditions be-tween ± 20 kOe with 1-Oe intervals. For avoiding magnetic shape anisotropy, the films were cut in circular shape in order to avoid shape anisotropy, and their diameter was 6 mm. The hysteresis loops were also obtained to

determinate the magnetically easy axis by applying the magnetic field perpendicular to the film plane. The plots of the magnetic measurements were presented at ± 2 kOe.

3 Results and Discussion

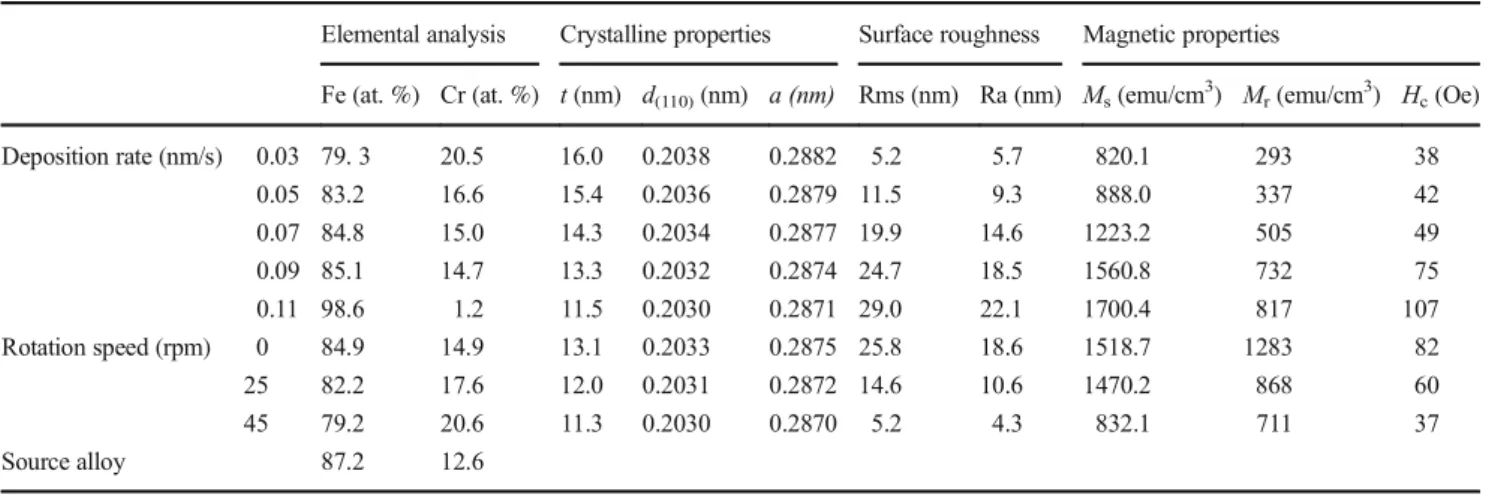

The atomic contents of the films by the EDX and source by ICP-AES are presented in Table1. The EDX analysis revealed that the atomic Fe contents were 79.3%, 83.2%, 84.8%, 85.1%, and 98.6% and the atomic Cr contents were 20.5%, 16.6%, 15.0%, 14.7%, and 1.2% for FeCr thin films produced

at the deposition rates of 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s, respectively. The Fe content was found to increase depending on increasing deposition rates whereas the Cr content de-creased with increasing deposition rates. It should also be pointed out that the bond energy/melting point of the metals might be influenced by the variations of the deposition rates since their compositions are changed in a different range. The most likely reason for this is that ferromagnetic content can reach more effectively from the source to the surface of the substrate with the increase deposition rate during sputtering process. For the films sputtered under at 0, 25, and 45 rpm rotation speed of the substrate, the atomic Fe contents were Table 1 Elemental analysis, crystal structure values, surface roughness values, and magnetic properties of FeCr thin films produced at different deposition rates and rotation substrate speeds

Elemental analysis Crystalline properties Surface roughness Magnetic properties

Fe (at. %) Cr (at. %) t (nm) d(110)(nm) a (nm) Rms (nm) Ra (nm) Ms(emu/cm3) Mr(emu/cm3) Hc(Oe) Deposition rate (nm/s) 0.03 79. 3 20.5 16.0 0.2038 0.2882 5.2 5.7 820.1 293 38 0.05 83.2 16.6 15.4 0.2036 0.2879 11.5 9.3 888.0 337 42 0.07 84.8 15.0 14.3 0.2034 0.2877 19.9 14.6 1223.2 505 49 0.09 85.1 14.7 13.3 0.2032 0.2874 24.7 18.5 1560.8 732 75 0.11 98.6 1.2 11.5 0.2030 0.2871 29.0 22.1 1700.4 817 107 Rotation speed (rpm) 0 84.9 14.9 13.1 0.2033 0.2875 25.8 18.6 1518.7 1283 82 25 82.2 17.6 12.0 0.2031 0.2872 14.6 10.6 1470.2 868 60 45 79.2 20.6 11.3 0.2030 0.2870 5.2 4.3 832.1 711 37 Source alloy 87.2 12.6

Fig. 1 XRD patterns of the FeCr thin films sputtered at 0.03, 0.05, 0.07, 0.09 and 0.11 nm/s deposition rates, and the substrate

Fig. 2 XRD patterns of FeCr thin films sputtered at 0-, 25- and 45- rpm rotation speed, and the substrate

found as 84.9%, 82.2%, and 79.2%, the atomic Cr contents were found as 14.9%, 17.6%, and 20.6%, respectively. It was seen that Fe content decreased and Cr content increased when the substrate was rotated. The most likely reason for this is that, according to the Cr content, Fe content less effectively forms a hold on to surface of the substrate due to the different cohesive forces at the high rotating speeds during a sputtering process.

Figures1and2show the XRD patterns of the thin films produced at different deposition rates and different rotating speeds of the substrate, respectively together with the sub-strate patterns. In the figures, the crystalline structure is body-centered tetragonal (bct). This result is consistent with the study [13] which investigated the FeCr superlattice film produced on the GaAs substrate by molecular beam epitaxy. The martensitic bcc (110) planes appeared at the angle of ~ 44.1° was marked with“▼” for all films. Also, the substrates do not have any peak in XRD pattern due to

polymer structure. In Fig.1, the peak intensity of the (110) planes increased when the deposition rate increased from 0.03 to 0.11 nm/s. The increase in the intensity may be attributed to the increase in Fe contents in the films caused by the increase in the deposition rate. In the case of Fig.2, the crystalline structure remained as the martensitic bct phase with main peak of (110) marked with“▼” and appeared at the angle of ~ 44.1°. It is clearly seen that these films in Figs.1and2 have single phase due to the small amount of materials and the peaks of the position of the film slightly shifted in compatible with [21]. In addition, a small peak of bcc structure, (211) marked with“♦” for FeCr alloy appeared at the angle of ~ 77.9° as the Fe content decreased for the film produced at 45 rpm. The peak positions of all films were in compatible with the study [22] which investigated the FeCr alloy films produced on the copper substrate by electrodepo-sition. The grain sizes, t of (110) plane were presented in Table1which were calculated with the Scherrer formula by

(a) 0.03 nm/s (b) 0.05 nm/s

(e) 0.11 nm/s

(c) 0.07 nm/s (d) 0.09 nm/s

(f) substrate

Fig. 3 SEM images of FeCr thin films deposited at a 0.03, b 0.05, c 0.07, d 0.09, and e 0.11 nm/s deposition rates, and f the substrate

using the full width at half maximum (FWHM) values [23]. In the table, the t values decreased from 16.0 to 11.5 nm with increasing deposition rate from 0.03 to 0.11 nm/s, respective-ly. Also, the t values decreased from 13.1 to 11.8 nm while the rotation speed of the films increased from 0 to 45 rpm. It was found that the t values increased with the increase of deposi-tion rate but decreased with the increase of rotating speed. Further, structural parameters for the thin films were also cal-culated from (110) plane of the XRD data. The interplanar spacing for the (110) planes, d(110), and the lattice constant, a are also presented in Table1. Thus, the d(110)values were calculated by using the Bragg formula and they decreased from 0.2038 to 0.2030 nm as deposition rate increased from 0.03 to 0.11 nm/s. And, d values decreased from 0.2033 to 0.2030 with increasing rotation speed from 0 to 45 rpm. In the case of lattice parameters, a values were calculated from the peak position of (110) plane. They were found as 0.2882, 0.2879, 0.2877, 0.2874, and 0.2871 nm for films deposited at 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s, respectively. And, the a values were 0.2875, 0.2872, and 0.2870 nm for the films deposited with the rotation speed of 0, 25, and 45 rpm, respec-tively. The calculated a values are compatible with those of the bulk Fe (a = 0.2866 nm) and Cr (a = 0.2885 nm) [23]. As seen in the table, increase of the Fe content of the films makes the a values close to the bulk Fe one and the same was for the Cr content of the films. From the results, it was shown that different deposition rates and different rotating speeds have a considerable effect on the crystalline structures and thus their parameters of binary FeCr thin films.

Figures3and4demonstrate the SEM images of the films grown at different deposition rates and rotation speeds, respec-tively. In the figures, the SEM image of substrate is also shown. In Fig.3a, for the SEM image of the film deposited at 0.03 nm/s, it was clearly seen that the grain sizes have not exceeded ~ 50 nm although few number of them are on the film surface. As seen in Fig.3b, it was seen that the grain sizes have increased up to ~ 100 nm while a few more grains on the surface for the SEM image of the film deposited at 0.05 nm/s. As shown in Fig.3c, for the SEM image of the film deposited at 0.07 nm/s, the grain sizes have increased up to ~ 300 nm. As displayed in Fig.3d, for the SEM image of the film deposited at 0.09 nm/s, the grain sizes decreased but the film surface consisted of smaller grains and needle-like structure. In the last image (Fig.3e), for the SEM image of the film deposited at 0.11 nm/s, it is seen that the number of smaller grains in-creased and the film became slightly delicate from the cracks. In the case of the films sputtered at various rotation speeds, in Fig.4a, at 0 rpm, the grain sizes have not exceeded ~ 50 nm. As seen in Fig.4b for the SEM image of the film deposited at 25 rpm, it was seen that the number of grains considerably decreased and smoother surface occurred. Figure 4c, at 45 rpm, it is clearly seen that the smoothest surface is obtain-ed. In both cases, the grains have the similar composition with the other parts of the film according to local EDX measure-ments on the surface. As to the films sputtered at different rotation speed of the substrate, relatively more homogeneous and smoother surface were found compared to the films de-posited at various deposition rates.

(d) substrate (b) 25 rpm

(c) 45 rpm (a) 0 rpm

Fig. 4 SEM images of FeCr thin films deposited at a 0-, b 25-, and c 45-rpm rotation speed, and d the substrate

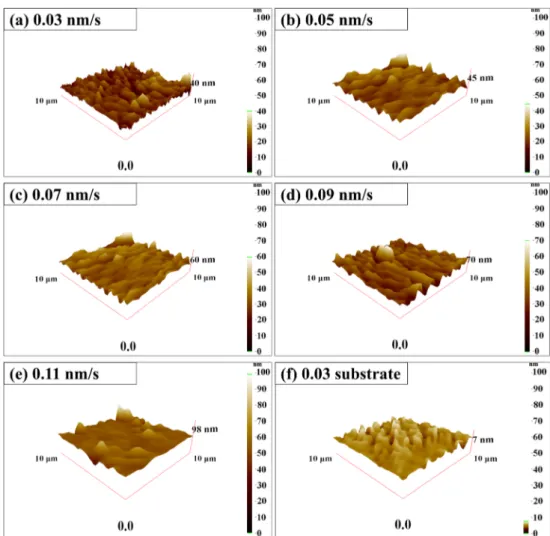

Figure5a–e shows the AFM images of the films deposited

at 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s, respectively. And, Fig.6a–c displays the AFM images of the films deposited at 0, 25, and 45 rpm, respectively. The AFM image of the

substrate was also added as Fig. 5f and Fig.6d. The AFM images in Figs.5and6are compatible with the SEM images in Figs. 3and 4, respectively since the light colors indicate high regions in AFM images which correspond to the surface Fig. 5 AFM images of FeCr thin

films deposited at a 0.03, b 0.05, c 0.07, d 0.09, and e 0.11 nm/s deposition rates, and f the substrate

Fig. 6 AFM images of FeCr thin films deposited at a 0-, b 25-, and c 45-rpm rotation speed, and d the substrate

inhomogeneities seen in the SEM images for different depo-sition rates and different rotation substrate. As an example, the light colors mostly disappeared from the surface when the film was rotated at 45 rpm in Fig.6c. The roughness values of the root mean square (Rms) and the average roughness (Ra) values are presented in Table1. The Rms parameters of films were measured to be 5.2, 11.5, 19.9, 24.7, and 29.0 nm for the films deposited at 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s, re-spectively and 25.8, 14.6, and 5.2 nm for the films deposited at 0, 25, and 45 rpm, respectively. And, the Ra parameters of films were measured to be 5.7, 9.3, 14.6, 18.5, and 22.1 nm for the films deposited at 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s, respectively and 18.6, 10.6, and 3.4 nm for the films deposited at 0, 25, and 45 rpm, respectively. It is seen that the Rms values increased with increasing deposition rate and the Ra values decreased with increasing rotation speed of the sub-strate depending on the surface roughness of the AFM images of the films.

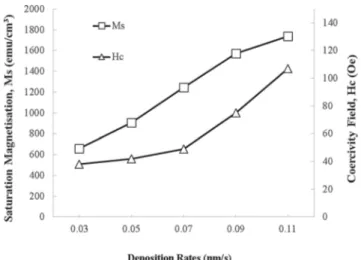

The hysteresis loops of the films sputtered at different de-position rates by magnetic measurement were plotted at ± 2 kOe and given in Fig.7. The saturation magnetization, Ms, and coercivity, Hc, values of the films obtained from the hys-teresis loops were presented in terms of deposition rate at ± 15 kOe in Fig.8. It is seen that saturation magnetization, Ms, remanence, Mr, and coercivity, Hc, values obtained from the hysteresis loops are displayed in Table1. The Msvalues were calculated from the loops considering all films volume were 820.1, 888.0, 1223.2, 1560.8, and 1700.4 emu/cm3for the deposition rate of 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s, re-spectively. The Msvalues increased with the increase of atom-ic Fe content caused by the increase in deposition rates. These Msvalues are in compatible with the values found in the Fe/Cr study [24], which investigated the effect of Fe/Cr content ratio on magnetic properties of FeCr alloys. And, the Mrvalues also increased with the increase of deposition rate. The Mrvalues were detected as 293, 337, 505, 732, and 817 emu/cm3 for deposition rates of 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s,

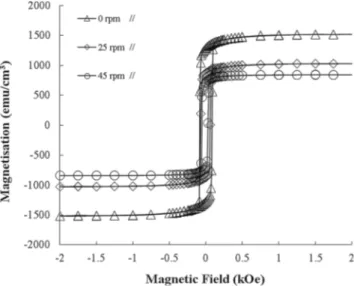

respectively. The Hcvalues showed the same trend of increase as 38, 42, 49, 75, and 107 Oe for the films sputtered as in the range of 0.03, 0.05, 0.07, 0.09, and 0.11 nm/s, respectively. The increase in deposition rate resulted in an increase in Hc values of the FeCr films. The reason for change in Hcvalues can be attributed to the changes in the film surface. In other words, a inhomogeneities and cracks on the surface led to an increase in Hcvalues of the films deposited at different depo-sition rates. The Ms and Hcvalues against deposition rates were also plotted in Fig.8. Furthermore, as an example, par-allel and perpendicular loops of the films sputtered at 0.07 nm/ s is presented in Fig.9to observe the magnetic easy axis in the films. From the figure, it is observed that the easy axis is in the film plane due to the magnetic shape anisotropy of the films. The hysteresis loops obtained at ± 20 kOe from magnetic measurement for the films sputtered at different rotation speeds were presented at ± 20 kOe and given in Fig.10. The Msvalues were calculated from the loops considering the film volumes are in the range of 1518.7, 1616.1, and 1694.9 emu/ cm3 with increasing rotation speed as 0, 25, and 45 rpm, Fig. 8 Saturation magnetization, Ms, and coercivity field, Hc, values of FeCr thin films sputtered at different deposition rates

Fig. 7 Parallel (//) hysteresis loops of FeCr thin films sputtered at different deposition rates

Fig. 9 Parallel (//) hysteresis loop and perpendicular (┴) loop of FeCr thin film sputtered at 0.07 nm/s”

respectively. The Mr values also increased with the increase of rotating speed and were detected as 1280, 1362, and 1427 emu/cm3 for the rotation speed of 0, 25, and 45 rpm, respectively. As in the deposition rates, the Msand Mrvalues also increased with the increase of atomic Fe content caused by the increase in rotation speeds. On the other hand, as op-posite to deposition rate, the Hcvalues decreased as 145, 104, and 64 Oe with increasing rotation speed as 0, 25, and 45 rpm, respectively. The reason for the change in Hcvalues can be attributed to the changes in the film surface. In other words, decrease of the inhomogeneities on the surface lead to de-crease in Hcvalues of the films. In other words, the most probable reason for this situation, it can become that the sur-faces of the films have smoother and grainless with the in-crease in rotation speed which resulted in a dein-crease in Hc values of the FeCr films. Also, in Fig.11, the change of the saturation magnetization, Ms, and coercivity, Hc, values of the films obtained from the hysteresis loops were presented de-pending on rotating speed.

4 Conclusions

In this study, the effect of different deposition rates and sub-strate rotation on the properties of binary FeCr martensitic thin films was investigated, separately. As far as we are concerned, it is the first time, this was the first investigation of properties of the thin films produced from AISI 430 ferritic stainless steel source. Increase deposition rate and decrease of rotation speeds resulted in an increase in Fe content of the films. The structural properties were also affected by the deposition pa-rameters. The intensity of the peak belongs to martensitic bct (110) planes increased with the increase of Fe content. Consequently, increasing deposition rate and decreasing rota-tion speed of the substrate caused an increase in grain size and roughness parameters. As having the high deposition rates, surfaces showed inhomogeneities and some cracks; whereas, a smoother surface was obtained when the substrate was ro-tated and the rotation speed is getting higher. Consequent of the elemental and structural properties, the magnetic proper-ties of FeCr films were also affected by deposition parameters. The saturation magnetization and remanence increased with increasing Fe content in the films caused by the increase of the deposition parameters. And, the coercivity increased with in-creasing surface roughness of the films by inin-creasing deposi-tion rate and decreasing rotadeposi-tion speed. The structural and roughness parameters are compatible each other and also con-firms magnetic findings. It was concluded that different depo-sition rates and rotation speed of the substrate play a consid-erable role on the structural and thus magnetic properties of the sputtered binary FeCr martensitic thin films. And, the properties of the thin films are showed to be controlled by changing the production parameters for potential applications. Acknowledgements The authors are very grateful to the Selçuk University, Advanced Technology Research & Application Center for the SEM and EDX analysis, and the Karamanoglu Mehmetbey University, Scientific and Technological Researches Application and Research Center for the XRD measurements and the AFM imaging. Funding information This study was financially supported by the Balikesir University, BAP under grant no 2016/149 and also by the State Planning Organization/Turkey under grant no 2005K120170 for Sputtering and VSM systems

Publisher’s Note Springer Nature remains neutral with regard to jurisdic-tional claims in published maps and institujurisdic-tional affiliations.

References

1. Wasa, K., Kitabatake, M., Adachi, H.: Thin film materials technol-ogy: sputtering of control compound materials. Springer Science & Business Media., p. 1–20 (2004)

2. Ajayan, P.M., Schadler, L.S., Braun, P.V.: Nanocomposite science and technology. John Wiley & Sons (2006)

Fig. 11 Saturation magnetization, Ms, and coercivity field, Hc, values of the FeCr alloy thin films sputtered at different rotation speeds

Fig. 10 Parallel (//) hysteresis loops of the FeCr film sputtered at the different rotation speeds of the substrate

3. Shannon, M.A., Bohn, P.W., Elimelech, M., Georgiadis, J.G., Marinas, B.J., Mayes, A.M.: Science and technology for water purification in the coming decades. In: Nanoscience and tech-nology: a collection of reviews from nature Journals (pp. 337– 346) (2010)

4. Frey, H.,“Handbook of thin film technology”, Berlin: Springer, p.: 1–3. (2015)

5. Han, X., Dai, W., Li, D., Xie, X., Xin, Z., Wei, D.,… & Xie, C. “Design and fabrication of electronically controlled liquid crystal microlens arrays with non-uniform coil electrode arrays.”. International Society for Optics and Photonics., 10607, 1060709, (2018)

6. Jiles, D.,“Magnetism and magnetic materials.”, CRC press, (2016) 7. Heinrich, B., Bland, J.A.C.: Ultrathin magnetic structures I & II.

Springer-Verlag (1994)

8. Karpuz, A., Colmekci, S., Kockar, H., Kuru, H., Uckun, M.: Impact of deposition rate on the structural and magnetic properties of sputtered Ni/Cu multilayer thin films. Zeitschrift für Naturforschung A. 73(1), 85–90 (2017).https://doi.org/10.1515/ zna-2017-0207

9. Shi, D., Aktas, B., Pust, L., & Mikailov, F.,“Nanostructured mag-netic materials and their applications.”. Springer, 593, (2008) 10. Kockar, H., Alper, M., Sahin, T., Karaagac, O.: Role of electrolyte

pH on structural and magnetic properties of Co–Fe films. J. Magn. Magn. Mater. 322(9–12), 1095–1097 (2010)

11. Karaagac, O., Alper, M., Kockar, H.: Characterisations of CoCu films electrodeposited at different cathode potentials. J. Magn. Magn. Mater. 322(9–12), 1098–1101 (2010)

12. Kuru, H., Kockar, H., Alper, M., Karaagac, O.: Growth of binary Ni–Fe films: characterisations at low and high potential levels. J. Magn. Magn. Mater. 377, 59–64 (2015)

13. Rar, A., Frafjord, J.J., Fowlkes, J.D., Specht, E.D., Rack, P.D., Santella, M.L., Pharr, G.M.: PVD synthesis and high-throughput property characterization of Ni–Fe–Cr alloy libraries. Meas. Sci. Technol. 16(1), 46 (2004)

14. Kockar, H., & Meydan, T.,“The rotation and clamping effect on the magnetic properties of iron films deposited onto a rotating sub-strate.”, Phys. B Condens. Matter, 321, 1-, 124–128, (2002) 15. Yi, J.B., Zhou, Y.Z., Ding, J., Chow, G.M., Dong, Z.L., White, T.,

Yu, X.J.: An investigation of structure, magnetic properties and magnetoresistance of Ni films prepared by sputtering. J. Magn. Magn. Mater. 284, 303–311 (2004)

16. Zeng, X.T., Wong, H.K.: Effects of discharge pressure on the prop-erties of Ag/Ni superlattices prepared by facing-target sputtering. J. Appl. Phys. 79(8), 6279–6281 (1996)

17. Kawabata, K., Tanaka, T., Kitabatake, A., Yamada, K., Mikami, Y., Kajioka, H., Toiyama, K.: High rate sputtering for Ni films by an rf-dc coupled magnetron sputtering system with multipolar magnetic plasma confinement. J. Vac. Sci. Technol. A. 19(4), 1438–1441 (2001)

18. Baibich, M.N., Broto, J.M., Fert, A., Van Dau, F.N., Petroff, F., Etienne, P., Chazelas, J.: Giant magnetoresistance of (001) Fe/ (001) Cr magnetic superlattices. Phys. Rev. Lett. 61(21), 2472– 2475 (1988)

19. Fujimoto, S., Newman, R.C., Smith, G.S., Kaye, S.P., Kheyrandish, H., Colligon, J.S.: Passivation thresholds in iron-chromium alloys prepared by ion-beam sputtering. Corros. Sci. 35(1–4), 51–55 (1993)

20. Zhou, X., Thompson, G.B.: Phase and microstructures in sputter deposited nanocrystalline Fe–Cr thin films. Materialia. (2018).

https://doi.org/10.1016/j.mtla.2018.07.007

21. R.W. Cahn, P. Hassen, Physical Metallurgy, fourth ed., 1, North Holland, Amsterdam, (1996)

22. Wang, F., Watanabe, T.: Preparation and characterization of the electrodeposited Fe–Cr alloy film. Mater. Sci. Eng. A. 349(1–2), 183–190 (2003)

23. Cullity, B. D.,“Answers to problems: elements of X-ray diffrac-tion.”, Addison-Wesley Publishing Company, (1978)

24. Murugesan, M., Kuwano, H.: Magnetic properties of nano-crystalline Fe-Cr alloys prepared by mechanical alloying. IEEE Trans. Magn. 35(5), 3499–3501 (1999)