https://www.journals.elsevier.com/journal-of-materials-research-and-technology Availableonlineatwww.sciencedirect.com

Original

Article

Mechanical

and

durability

properties

of

ground

calcium

carbonate-added

roller-compacted

concrete

for

pavement

Sadik

Alper

Yildizel

a,

Gokhan

Calis

a,∗,

Bassam

A.

Tayeh

baKaramanogluMehmetbeyUniversity,FacultyofEngineering,CivilEngineeringDepartment,Turkey bCivilEngineeringDepartment,FacultyofEngineering,IslamicUniversityofGaza,Palestine

a

r

t

i

c

l

e

i

n

f

o

Articlehistory: Received25June2020 Accepted14September2020 Availableonline30September2020

Keywords:

Roller-compactedconcrete Groundcalciumcarbonate Freeze–thawcycles

Magnesiumsulphateresistance Durabilityproperties

a

b

s

t

r

a

c

t

This research aimed toinvestigate the mechanical and durability properties of roller-compacted concrete (RCC) containing ground calcium carbonate (GCC). Five different mixturecombinationswerepreparedbyreplacingcementwithGCCatthelevelsof5%, 10%,15%,20%and25%byweight.Thewatercontentsofthemixturewereoptimisedwith themaximumdensitymethod.ThecompressiveandflexuralstrengthsoftheRCCmixtures wereevaluatedupto90days.Durabilitycharacteristics,suchaswaterabsorptionrates, sul-phateandfreeze–thawresistances,werealsoevaluatedinthisstudy.TheGCCinclusionof upto15%increasedthemechanicalstrengthvaluesandenhancedthedurability charac-teristicsoftheRCCmixtures.Scanningelectronmicroscopyimagesoftheadditional15% GCCwerealsoutilised.ResultsrevealedthatGCCinclusionexhibitedanimprovementin thedurabilitypropertiesofthespecimens.

©2020TheAuthor(s).PublishedbyElsevierB.V.Thisisanopenaccessarticleunderthe CCBY-NC-NDlicense(http://creativecommons.org/licenses/by-nc-nd/4.0/).

1.

Introduction

Roller-compactedconcrete(RCC)hasbeenwidelystudieddue toitsbenefits,suchaslowapplicationcost,high-density con-structiontechnologyandreducedcementcontents,compared with other types of concrete pavement [1]. RCC is gener-allydesignedwithzero-slumpvaluesandcompactedsimilar to soil [2,3]. Moreover, considerable amounts of construc-tioncompactionenergyandincreasedaggregatecontentsare requiredforthetraditionalRCCdesigns[4].

RCC structures are continuously and directly exposed toenvironmentaldeteriorativefactors,suchasfreeze–thaw cyclesand chemicals.Therefore, inadditiontoits strength

∗ Correspondingauthor.

E-mail:gokhancalis@kmu.edu.tr(G.Calis).

characteristics,thedurabilitypropertiesofRCCpavementsare alsovital[5].Especiallyincoldregions,deteriorationsonRCC structuresareacceleratedwithcontinuousfreeze–thawcycles andtheuseofde-icingsalts[6].Concretedamages,suchas cracksandsurfacescaling,canemergeasaresultof harm-fulmechanisms.Numerousstudieshavebeenconductedto predict andeliminatetheeffectsoffreeze–thawcycles and chemicalattacks[7,8].Theoptimisationofwater-to-cement ratio and the usage ofsupplementary cementitious mate-rials andair-entrainingchemicalswerewidelyevaluatedin manydurabilityreports[9–11].Inaddition,air-entrainedRCC productionispopularamongstscientistsinthelastdecade; however, itsapplicationwaslimitedduetoutilisation diffi-cultiesofair-entrainingchemicalsduringtheRCCdesign[8].

The interest in utilising supplementary cement materi-als to formulate nature-friendly and economical concrete has increased in recent years due to environmental rea-https://doi.org/10.1016/j.jmrt.2020.09.070

2238-7854/©2020The Author(s).Published byElsevier B.V.Thisis anopen accessarticleunderthe CC BY-NC-NDlicense (http:// creativecommons.org/licenses/by-nc-nd/4.0/).

sons.Therefore,manystudieshavebeenfocusedoncement replacementand alternative binding materialsin the con-crete productionindustry [12–14]. Utilising ground calcium carbonate (GCC)as acementreplacementmaterialin con-crete mixturesmay improve its strength and cohesiveness behaviour.GCCisgenerallyusedtoeliminatestructuralpores inthemicrostructureofconcretes.Inaddition,GCCusagein theRCCdesigncanlimitthenegativeeffectofbleedingand shrinkagemechanisms[15].

Themechanical and durabilitypropertiesofGCC-added RCCwereinvestigatedinthisstudy.Themechanical exper-imental study focused on the compressive and flexural strength test results at 7, 28 and 90 days. Durability tests include determination of sulphate and freeze–thaw resis-tancesandwaterabsorptiontests.Inaddition,theabrasion resistanceofthepreparedmixeswasmeasured with sand-blasting.

Supplementary cementitious materials, suchas flyash, silica fume and furnace slags, can be used as partial replacements of cement in concrete mixture designs to reducecement production-originatedcarbon dioxide emis-sions[16,17]. The addition ofthese kinds ofmaterials not onlylimitsthenegativeimpactsontheenvironmentbutalso resultsinenhancedlong-termmechanicalbehavioursof con-cretes.Supplementarycementitiousmaterialshavealsobeen widelyusedinvarioustypesofconcretes,includingRCC pave-ments[18,19].Severaltypesofresearchhavebeenfocusedon thereplacementofcementbynaturalandindustrialmaterials [18,20].Literaturereportsindicatedthatcementreplacement materialscanbeusedtoenhancethemechanicaland dura-bilitypropertiesoftheRCCpavements.

RCCisespeciallypreferredforroadanddamconstruction projectsduetoits rapidsettingcharacteristics.Inaddition, RCC ismoresuitable forthe construction ofroad surfaces comparedwiththeasphalticcoversbecauseitdevelopshigh compressivestrengths[21,22].TheuseofRCCindamprojects requireshighwater-to-cementratiosandlowcement quanti-ties.Lowwater-to-cementcontentusageinRCCroadsleads to decrease in bleeding [23]. The bleeding and shrinkage behavioursoftheconcretecanalsobelimitedbyGCC inclu-sion. GCCadditions increased the compressive strength of

theconcretewiththecuringageaccordingtotherelated lit-erature studies[24–26]. Theprincipal advantageofutilising GCCinconcretemixesnotonlyleadstoimprovedmechanical anddurabilitypropertiesbutalsoprovideslessCO2emissions

caused bythecement industry.However,high dosageGCC additionascementreplacementmaterialsinconcretemixes canresultindecreasedstrengthvalues[27].Thereactivityof GCCisrelatedtoitsspecificsurfacearea,andsmallparticles haveanadditionalsurfaceareaforC3Areactions[25].

Grind-ingoftheGCCrequireslesserenergyconsumptioncompared withthatofothercementreplacementmaterialsbecauseGCC haslowhardness[28].

TheGCCinclusiontoconventionalconcretehasprovided improved structural, mechanical and durability properties accordingtoliteraturereportsinthelastdecades.However, resultsontheGCCadditiontoRCCmixturesarelimited.This study aimsto enrich the available experimentaldata con-cerning GCC utilisationinRCC pavementstoreach aclear understandingofitsbehaviour.

2.

Materials

and

methods

2.1. Materialsandmixturepreparations

River sand was utilised asfine aggregates, and crush rock materialcontaininglimestonewasusedascoarseaggregates inthisexperimentalwork.Themaximumaggregatesizewas chosenas20mmtopreventsegregation.Allaggregateswere cleanedfromanyorganicmaterialsfollowingtheair-drying process. Theaggregates were utilisedaccording tothe ACI requirements [29]. A commercial product, Betocarb®, was usedastheGCCfillermaterial.Thecombinedgradationcurves and material propertiesofthe aggregates are presentedin Fig.1andTable1,respectively.Scanningelectronmicroscopy (SEM)imagesoftheGCCparticlesareprovidedinFig.2.

CemItypecementconformingtotheEN197[32]standard wasutilisedasthethebindermaterial.Table2presentsthe chemicalandphysicalpropertiesofthecementandGCC.

Table3showsthemixtureproportionsofthestudiedRCC. SixdifferentRCCmixtureswerepreparedinthis

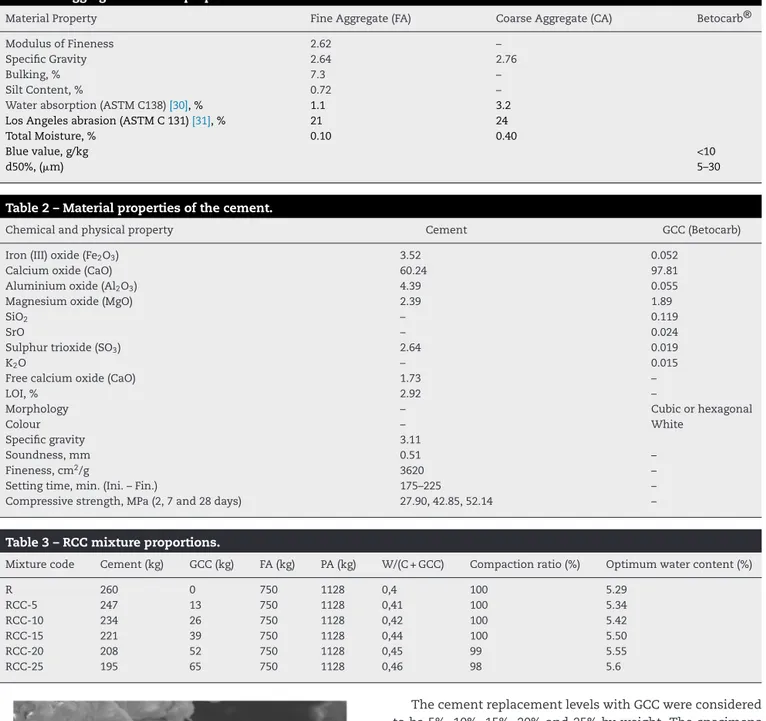

Table1–Aggregatematerialproperties.

MaterialProperty FineAggregate(FA) CoarseAggregate(CA) Betocarb®

ModulusofFineness 2.62 –

SpecificGravity 2.64 2.76

Bulking,% 7.3 –

SiltContent,% 0.72 –

Waterabsorption(ASTMC138)[30],% 1.1 3.2

LosAngelesabrasion(ASTMC131)[31],% 21 24

TotalMoisture,% 0.10 0.40

Bluevalue,g/kg <10

d50%,(m) 5–30

Table2–Materialpropertiesofthecement.

Chemicalandphysicalproperty Cement GCC(Betocarb)

Iron(III)oxide(Fe2O3) 3.52 0.052

Calciumoxide(CaO) 60.24 97.81

Aluminiumoxide(Al2O3) 4.39 0.055

Magnesiumoxide(MgO) 2.39 1.89

SiO2 – 0.119

SrO – 0.024

Sulphurtrioxide(SO3) 2.64 0.019

K2O – 0.015

Freecalciumoxide(CaO) 1.73 –

LOI,% 2.92 –

Morphology – Cubicorhexagonal

Colour – White

Specificgravity 3.11

Soundness,mm 0.51 –

Fineness,cm2/g 3620 –

Settingtime,min.(Ini.–Fin.) 175–225 –

Compressivestrength,MPa(2,7and28days) 27.90,42.85,52.14 –

Table3–RCCmixtureproportions.

Mixturecode Cement(kg) GCC(kg) FA(kg) PA(kg) W/(C+GCC) Compactionratio(%) Optimumwatercontent(%)

R 260 0 750 1128 0,4 100 5.29 RCC-5 247 13 750 1128 0,41 100 5.34 RCC-10 234 26 750 1128 0,42 100 5.42 RCC-15 221 39 750 1128 0,44 100 5.50 RCC-20 208 52 750 1128 0,45 99 5.55 RCC-25 195 65 750 1128 0,46 98 5.6

Fig.2–SEMimagesofGCCparticles.

tal study,and thesemixtures were coded in linewith the GCCinclusions.‘R’definesthereferencemixturewithnoGCC content.Othermixtureswereclassifiedas‘RCC-x’,where‘x’ representsthecementreplacementratioofGCCbyweight.

ThecementreplacementlevelswithGCCwereconsidered tobe5%,10%,15%,20%and25%byweight.Thespecimens werecompactedinthreelayerswithacompactorattheblow countof1000and1870r/min(10kgsurcharge)inaccordance withthe ASTM C1435procedure [33].Theoptimumwater content oftheconcretes isprovidedinTable 3. Cylindrical specimens(150mm×300mm)withwater-to-cementratiosof 0.35,0.4,0.45and0.50werepreparedtodeterminethe opti-mummoisturecontentoftheRCCmixtures. Theoptimum watercontentoftheRCCmixesgenerallyvariesbetween4.6% and5.6%[34].AllthepreparedRCCspecimenwatercontents werewithinthelimitsoftheserates.

Themixtureswere preparedwitha60Lpan mixer.The aggregates,namely,Betocarb® andcement,wereinitiallydry mixed,andthentherequiredwaterwasadded.Themixerrate waskeptconstantat250r/minfor5mintoobtaina homoge-nousmixture. Thespecimenswere cured atthe laboratory temperaturefor24h.Then,allspecimenswereremovedfrom themouldsandkeptunderlime-saturatedwater(23◦C)until

themechanical tests.Theconsistencyofthemixtureswas measuredwithaVe–Betestat10,20and30minaftercasting. Thefreshdensityofthemixtureswasalsorecorded.

2.2. Mechanicalanddurabilitytests

The 100mm×100mm cubic specimens were prepared for thecompressivestrengthtests.Thesetestswereconducted usingacompressivestrengthtestingmachinewithaloading rateof0.3MPa/s.Flexuralstrengthtestswereconductedon 100mm×100mm×500mmrectangularsamples.Auniversal testmachine withaloadingrate of1.00MPa/minwas also used.Thestaticmodulusofelasticityvalueswasmeasured onthedifferentmixtures(150mm×300mmcylindrical sam-ples)at90daysaccordingtotherequirementsofASTMC469 [35].Youngmodulusofelasticityvalueswasdeterminedwith thefollowingformulapresentedinEq.(1),where‘E’represents Youngmodulusofelasticity;‘1’and‘2’definecompressive

strengthwith50microstrainandstressunder40%ultimate load,respectively;and‘2’representsthelongitudinalstrain

under2stress.

E= (1−2)/(2−0.000050). (1)

Modulusofelasticitytestswereperformedonthree sam-ples from each mix. Modulus of elasticity was evaluated utilisingthe chord method. All mechanicaltests were per-formed with the guide ofEN 12390-2, EN 12390-3 and EN 13390-5standardrequirements[36–38].

ThewaterabsorptionratesoftheRCCsampleswere mea-suredaccording totheASTM C642 [39]requirements.The specimenswerefirstlydriedinanovenat105◦Cforoneday and cooled under laboratorytemperature (23◦C), and their weightswererecordedas‘W1’.Thesamesampleswereboiled

for5hinacontainerandcooledandthenboiledagain.The cooledweightswererecordedas‘W2’.Thewaterabsorption

(Wa,%)oftheRCCmixeswasdeterminedbyEq.(2).

Wa=[(W2−W1)/W1]×100. (2)

The freeze and thaw resistance of the specimens was determinedaccordingtotheASTMC666standard[40].The compressive strength losses wererecorded at90 days.The magnesium sulphateeffectontheRCCsampleswas inves-tigatedwiththecompressivestrengthchange.Onegroupwas keptincuringwater,andthesecondgroupwasexposedtothe magnesiumsulphateconcentrationsof10inaseparate con-tainer.Themagnesiumsulphateconcentrationwasrenewed every15daysuntiltheendoftestingtime(90days).The abra-sionresistanceoftheRCCmixtureswasdeterminedaccording totheASTMC418:AbrasionResistanceofConcreteby Sand-blastingstandard.

3.

Results

and

discussions

3.1. FreshandmechanicalpropertiesofRCCmixtures

As shown in Table 3, high optimum water contents were gainedwiththeincreaseinthesupplementarycementitious materialamount.Thisphenomenoncanbeattributedtothe higherspecificsurfaceareaandthesmallerspecificgravityof GCCcomparedwiththoseofcement[41].

TheconsistencyoftheRCCmixtureswasinvestigatedwith modifiedVe–Betestsat10,20and30minfollowingthe cast-ingprocessaccordingtotheASTMC1170standard[42].The Ve–BetestresultsaregiveninFig.3.TheresultsshowthatGCC addedconcretemixturesshowlessVe–Betimethanthe refer-encemixture.Withtheadditionof%5GCCtothesample,vebe timeof30mintestincreasedtwiceastheothertestresults.Itis determinedthatadditionofGCChasgreaterimpacton10min Ve-betestresultsthan20minVebetestresults.The consis-tencyofthemixturesconsiderablyimprovedascementwas replacedwithGCC.Thisimprovementcouldbeattributedto thehighfinenessvalueandpartlyroundedsurfacesoftheGCC particles(Fig.2).Thetestresultsshowedparallelresultswith thesupplementarycementmaterial-addedRCCpavement lit-erature[8,18].

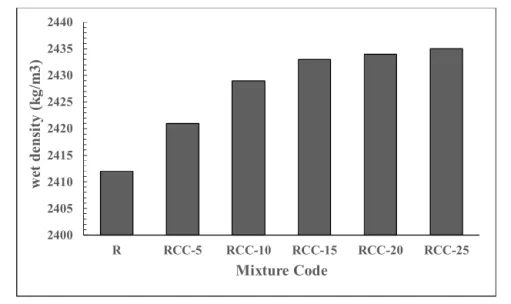

The test results of wet density are presented in Fig. 4. Asshowninthefigure,GCCadditionconsiderablyincreased the wetdensity ofthe mixturescomparedwiththatofthe

Fig.4–WetdensityoftheRCCmixtures.

referencemix.Thiscondition canbeclarified bythe filling of voids by the GCC particles. As a result, the same vol-ume is filled with higher amount of mass. Figs. 3 and 4 also show that low Ve–Be times correspond with high wet density. Wet density test results also reflected the utilisation boundaries for different types of implementa-tions.

The compressive strength test results are presented in Fig.5,whereGCCinclusionupto15%increasedthetestresults comparedwiththoseofthereferencemixture.GCCinclusion alsocontributedtotheearlystrengthdevelopmentoftheRCC mixtures.However,the samplescontain10%and 15%GCC havealittleincreasein7dayscompressivestrength(0.6%and 0.9%).Thisfindingindicatesthattheuseofvariouscement replacementmaterialsor fibres haspositive effectson the compressivestrengthofRCC[43–45].ItwasobservedthatGCC mainlyactedascementreplacementmaterialandincreased thestrength.Theremainingmaterialfromthehydration pro-cessactedasfillermaterialduetoparticlesize.Ontheother hand,thecompressivestrengthvaluesofthemixtures con-tainingmorethan15%GCCcontentreducedatallages.This resultcan beattributedto the high GCCcontents and the dilutioneffect.Thosesampleshavemorethan15%ofGCC, havemorevoidsandhigherwater/cementratiowhichresults adecreaseincompressivestrength.RCC-15showedthebest performanceat42.71MPacomparedwiththatoftheotherRCC mixturesat90days.Allcompressivestrengthtestresultsat28 dayswereobtainedwithintherangeofACI325-10R require-ments[46].

The flexural strength test results at 7, 28 and 90 days are presentedinFig.6. All measuredflexural strengthtest resultsvaried between3.11 and 5.11MPa. Itis determined thatthetrendofcompressiveand flexuralstrength testsis alike.GCCadditionupto15%improvedtheflexuralstrength developmentatallages.Thisimprovementcanbeexplained asthe filler and accelerationeffects ofGCC on the hydra-tion process ofcementas stated insomeprevious studies [47–49].Thisoutcome alsosupportsthe deductionthatthe utilisationofcementreplacementfillingmaterialhasan

incre-mental impact on RCC compressive and flexuralstrengths [50].

Themodulusofelasticityresultswerechangedfrom32.17 and37.56GPa.Thereplacementofcementwith20%GCC rep-resentsasimilarmodulusofelasticityof35.04GPacompared withthatofthereferencemixture(35.20GPa).GCCinclusion up to 15% increasedthe modulusofelasticity test results. The maximum test result was obtained as 37.56GPa with the ‘RCC-15’mixture.GCCaddition intothemixturesmore than15%hadnegativeimpactontheresults.Previousreports mentionedthatGCCcouldenhancemechanicalpropertiesby providingadditionalintegratedmicrostructures[48].

3.2. DurabilitypropertiesofRCCmixtures

Waterabsorptiontestresultsat7,28and90daysarepresented inFig.7.Thewaterabsorptionratesofthespecimensvary between2.41%and3.01%at28days,andRCC-15hadthe min-imumtestresults.Unlikefibre-addedRCC[44],GCCaddition decreasedthewaterabsorptionrates.Thisdecreasecanbe attributedtothefillingoutofporesbytheGCCminerals.

The compressive strength reduction percentage of RCC mixturesareplottedinFig.8,following300freeze–thawcycles. Comparedwiththereferencemixture,compressivestrength lossesdecreasedastheGCCreplacementincreasedupto15%, andsimilarlossvalueswereobtainedfortheotherRCC mix-tures.InadditiontothepositiveeffectsofGCCadditionsonthe microstructure,theseresultscanbeattributedtotwofactors. Thedecreaseinthecompressivestrengthafterfreeze–thaw cycles issimilar tothatofanotherstudy [44],inwhichthe macro syntheticfibre-added RCCisinvestigated. The com-pressivestrengthlossescoulddecreasewiththecompactivity leveloftheRCCmixtures.AsshowninTable3,RCC-5, RCC-10andRCC-15hadbettercompaction ratioscomparedwith thoseofRCC-20andRCC-25mixtures.Itcanbeconcludedthat RCCsampleshavereachedtheoptimummixturedesignwith 15%GCCaddition.BeyondthispointGCCadditionwillrequire additionalwatertobondwiththeconcrete.Thecompressive strengthlossescanalsobeattributedtotheW/C+GCCratio.

Fig.5–Compressivestrengthtestresults.

Fig.6–Flexuralstrengthtestresults.

Theincreaseinthisratioalsoraisedthevolumeandnumber ofcapillarypores withfreezablewaterpotentialincement paste.Thesamplethathavehigherthan15%GCCaddition showhighercompressivestrengthloseafterfreezeandthaw cycles.Thistypeofeffectisexpectedasthosesampleshave morewater content and voids than the other samples. In addition,themaincauseofinternalexpansionduring freez-ing can be due to this increase as stated in the literature [41].

Theabrasion resistancetest results ofspecimens at90 daysarepresentedinFig.9.SandsconformingwiththeASTM C778[51]standardwereblastedwithaninjectortypegunat arateof690kPathroughthecentreofthespecimens.Fig.9

shows that GCC addition up to15% decreased the weight losses ofspecimens exposed duringsandblasting. Thetest results were in parallel with the mechanical compressive strength testresults.Thestrengthofmixturesisan impor-tant factorintheabrasionresistancetestresults,asstated inthe literature[43]. AllGCC hassomesilica content,and this materialpresents concerns on theabrasion resistance dependingonitsparticlesizeandconcentration[52].Notably, the utilisedBetocarb® had aconsiderableamount ofsilica content based on the improvement in abrasion resistance characteristics ofspecimenscomparedwiththatofthe ref-erencemixture.

Fig.7–Waterabsorptiontestresults.

Fig.8–Compressivestrengthlossesafterfreeze–thawcycles.

MagnesiumsulphateresistanceofRCCmixturesis plot-tedinFig.10.RCC-5,RCC-10andRCC-15specimensshowed the lowest compressive strength losses compared with the other mixtures. The overall test results indicated that cement replacement with certain amounts of GCC (up to 15%)had asignificant effect onRCC interms ofdurability properties. Utilisingcertain amounts ofGCC enhancedthe sulphateresistancebehavioursoftheRCC mixturesby fill-ingvoidsinitsstructures.Theeffectsofmagnesiumsulphate attacksalsoincreasedwiththe exposuretimeasshown in Fig.10.

Figs.11and 12representtheSEMimagesoftheRCC-15 specimenswithmagnificationsof1000×and5000×, respec-tively. Thefigures show thatthe pores are filled withGCC particles. This phenomenon can be attributed to reduced waterabsorptionrateandimprovedtransportationproperties ofthespecimen.

Fig.12showsthatporesarequitereplacedwiththeGCC particles.BycomparingFigs.11and12,thecompletefillingof poresinthescannedareaswasalsoobserved.

4.

Conclusion

The influences of utilising GCC as cement supplementary materials on the RCC mixtures were examined in this research.Themainconclusionofthisstudycanbedrawnas follows.

• CementreplacementwithGCCupto15%increasedthe opti-mumwatercontentofthemixturescomparedwiththatof thereference.

• UtilisingGCCupto15%alsoresultedinlowwater absorp-tion rates and less compressive strength losses against

Fig.9–Weightlossesofspecimensexposedtosandblasting.

Fig.10–Compressivestrengthlossesaftermagnesiumsulphateattack.

freeze–thawcycles.Thiscanbeattributedtofillerand poz-zolaniceffectofGCC.WiththeadditionofGCCresultsin decreaseinvoidsofthespecimens.

• The early strength characteristics of specimens were enhancedwithacertainamountofGCCinclusionthatis resultofthepositiveeffectofGCCadditioninthehydration processofcement[25].

• Magnesium sulphate attacked the resistance ofthe RCC improvedwiththepreparedmixtures.RCC-15showedthe bestperformanceagainstsulphateattacks.Duetoreduce intheporewiththeadditionofGCC,theeffectofsulphate attacksdecreases.

• Atotalof15% cementreplacementwithGCCwasfound tobeeffectivethroughstrengthanddurabilityproperties. Thisapproachcanbeutilisedforcostoptimisationstudies ofRCCmixtures.

• Similartoutilisationofflyash[50],GCCincorporationalso has a positive impact in reducing the pores in RCC as observedintheSEManalysisfigures.

• Besidesimprovingmechanicalanddurabilitypropertiesof concrete,GCCadditionmightbebeneficialtoproduce sus-tainableconcrete.WiththeuseofGCCascementreplacing material,lessenergyconsumedduringcementproduction. InthisrespectlessCO2willbereleasedfromthefactories.

Fig.11– SEMimagesoftheRCC-15specimenat1000×magnification.

Fig.12– SEMimagesoftheRCC-15specimenat5000×magnification.

Conflicts

of

interest

Theauthorsdeclarenoconflictsofinterest.

Acknowledges

Theauthorswouldliketoacknowledgetothestaffof KMU-BILTEMfortheirhelpandsupports.

r

e

f

e

r

e

n

c

e

s

[1]LaHucikJ,DahalS,RoeslerJ,AmirkhanianAN.Mechanical propertiesofroller-compactedconcretewithmacro-fibers. ConstrBuildMater2017;135:440–6,

http://dx.doi.org/10.1016/j.conbuildmat.2016.12.212. [2]LinY,KaradelisJN,XuY.Anewmixdesignmethodforsteel

fibre-reinforced,rollercompactedandpolymermodified bondedconcreteoverlays.ConstrBuildMater2013;48:333–41, http://dx.doi.org/10.1016/j.conbuildmat.2013.06.020. [3]DelatteN.Roller-compactedconcretepavements.In:

Concretepavementdesign,construction,andperformance. seconded;2014,http://dx.doi.org/10.1201/b17043-16. [4]NeocleousK,AngelakopoulosH,PilakoutasK,GuadagniniM.

Fibre-reinforcedroller-compactedconcretetransport

pavements.ProcInstCivEng-Transp2011, http://dx.doi.org/10.1680/tran.9.00043.

[5]PigeonM.Durabilityofconcreteincoldclimates;2018, http://dx.doi.org/10.1201/9781482271447.

[6]AlirezaS,RadM,ModarresA.Coldregionsscienceand technologydurabilitypropertiesofnon-airentrainedroller compactedconcretepavementcontainingcoalwasteashin presenceofde-icingsalts.ColdRegSciTechnol

2017;137:48–59,

http://dx.doi.org/10.1016/j.coldregions.2017.02.006. [7]RamezanianpourAA,JafariNadooshanM,PeydayeshM,

RamezanianpourAM.Effectofentrainedairvoidsonsalt scalingresistanceofconcretecontaininganewcomposite cement.KSCEJCivEng2014,

http://dx.doi.org/10.1007/s12205-014-0365-x. [8]NiliM,ZaheriM.Deicersalt-scalingresistanceof

non-air-entrainedroller-compactedconcretepavements. ConstrBuildMater2011,

http://dx.doi.org/10.1016/j.conbuildmat.2010.10.004.

[9]OmranA,HarbecD,Tagnit-HamouA,GagneR.Productionof roller-compactedconcreteusingglasspowder:fieldstudy. ConstrBuildMater2017;133:450–8,

http://dx.doi.org/10.1016/j.conbuildmat.2016.12.099. [10]KhayatKH,LibreNA.Rollercompactedconcrete-field

evaluationandmixtureoptimization.ANatlUnivTransp CentMissouriUnivSciTechnol2014.

[11]JayasreeS,GanesanN,AbrahamR.Effectofferrocement jacketingontheflexuralbehaviourofbeamswithcorroded

reinforcements.ConstrBuildMater2016,

http://dx.doi.org/10.1016/j.conbuildmat.2016.05.131. [12]JuengerMCG,WinnefeldF,ProvisJL,IdekerJH.Advancesin

alternativecementitiousbinders.CemConcrRes2011, http://dx.doi.org/10.1016/j.cemconres.2010.11.012. [13]ShowK-Y,TayJ-H,LeeD-J.Cementreplacementmaterials.

SustainSludgeManag2018,

http://dx.doi.org/10.1142/97898132382680005.

[14]MayooranS,RagavanS,SathiparanN.Comparativestudyon openairburntlow-andhigh-carbonricehuskashaspartial cementreplacementincementblockproduction.JBuildEng 2017,http://dx.doi.org/10.1016/j.jobe.2017.07.011.

[15]Antoni,ChandraL,HardjitoD.Theimpactofusingflyash, silicafumeandcalciumcarbonateontheworkabilityand compressivestrengthofmortar.ProcediaEng2015, http://dx.doi.org/10.1016/j.proeng.2015.11.132.

[16]RosellóJ,SorianoL,SantamarinaMP,AkasakiJL,MonzóJ, PayáJ.RicestrawashApotentialpozzolanicsupplementary materialforcementingsystems.IndCropsProd2017, http://dx.doi.org/10.1016/j.indcrop.2017.03.030.

[17]KeenEC,BliskovskyVV,MalagonF,BakerJD,PrinceJS,Klaus JS,etal.Supplementarymaterialssupplementarymaterials andmethods.MBio2017,https://doi.org/000112383[pii]. [18]GhahariSA,MohammadiA,RamezanianpourAA.

Performanceassessmentofnaturalpozzolanroller compactedconcretepavements.CaseStudConstrMater 2017;7:82–90,http://dx.doi.org/10.1016/j.cscm.2017.03.004. [19]AghaeipourA,MadhkhanM.Effectofgroundgranulated

blastfurnaceslag(GGBFS)onRCCPdurability.ConstrBuild Mater2017,

http://dx.doi.org/10.1016/j.conbuildmat.2017.03.019. [20]GanjianE,JalullG,Sadeghi-PouyaH.Usingwastematerials

andby-productstoproduceconcretepavingblocks.Constr BuildMater2015,

http://dx.doi.org/10.1016/j.conbuildmat.2014.12.048. [21]SilvaRV,DeBritoJ,DhirRK.Propertiesandcompositionof

recycledaggregatesfromconstructionanddemolitionwaste suitableforconcreteproduction.ConstrBuildMater2014, http://dx.doi.org/10.1016/j.conbuildmat.2014.04.117. [22]CopeJL,SchraderEK,Abdun-NurEA,CannonRW,McEwen

WD,AndersonFA,etal.Rollercompactedmassconcrete. ACIMaterJ1988.

[23]HansenWG,ReindhardtKD.In:Roller-CompactedConcrete Dams.Tokyo:McGraw-Hill;1991.

[24]DeSilvaP,BuceaL,MooreheadDR,SirivivatnanonV. Carbonatebinders:reactionkinetics,strengthand microstructure.CemConcrCompos2006,

http://dx.doi.org/10.1016/j.cemconcomp.2006.03.004. [25]MatscheiT,LothenbachB,GlasserFP.Theroleofcalcium

carbonateincementhydration.CemConcrRes2007, http://dx.doi.org/10.1016/j.cemconres.2006.10.013. [26]YipCK,ProvisJL,LukeyGC,vanDeventerJSJ.Carbonate

mineraladditiontometakaolin-basedgeopolymers.Cem ConcrCompos2008,

http://dx.doi.org/10.1016/j.cemconcomp.2008.07.004. [27]QianX,WangJ,WangL,FangY.Enhancingtheperformance

ofmetakaolinblendedcementmortarthroughin-situ productionofnanotosub-microcalciumcarbonate particles.ConstrBuildMater2019,

http://dx.doi.org/10.1016/j.conbuildmat.2018.11.134. [28]ChenY,YuH,YiL,LiuY,CaoL,CaoK,etal.Preparationof

groundcalciumcarbonate-basedTiO2pigmentbyatwo-step coatingmethod.PowderTechnol2018,

http://dx.doi.org/10.1016/j.powtec.2017.11.040. [29]ACI318-95.Buildingcoderequirementsforstructural

concrete(ACI318-95)andcommentary(ACI318R-95). https://www.doi.org/30CFR250.901(d)(1),2011.

[30]ASTM:C138.ASTMC138:standardtestmethodfordensity (unitweight),yield,andaircontent(Gravimetric).ASTMInt 2013,http://dx.doi.org/10.1520/C0138.

[31]ASTMC131-12.Standardtestmethodforresistanceto degradationoflarge-sizecoarseaggregatebyabrasionand impactintheLosAngelesMachine.ASTMInt2012, http://dx.doi.org/10.1520/C0131.

[32]EN197-1:2004.EN197-1:composition,specifications,and conformitycriteriaforcommoncements.EurStand2004, http://dx.doi.org/10.3403/30205527U.

[33]TestCC.Standardpracticeformoldingroller-compacted concreteincylindermoldsusingavibratinghammer1. AnnuBookASTMStandSect11WaterEnvironTechnol2010, http://dx.doi.org/10.1520/C1435.

[34]USArmyCorpsofEngineers.Standardpracticeforconcrete forcivilworksstructures.EngStruct2000,

http://dx.doi.org/10.1016/0141-0296(95)90030-6. [35]ASTMC469.StandardtestmethodforstaticModulusof

elasticityandPoisson’sratioofconcrete;2015, http://dx.doi.org/10.1520/C0469.

[36]BSEN12390-3.BSEN12390-3.Test.HardenedConcr.-Part3 compressivestrengthtestspecimens;2009.

[37]BSEN12390-5.Testinghardenedconcrete-Part5:flexural strengthoftestspecimens.BrStand2009.

[38]EN12390-2.EN12390-2.Test.HardenedConcr.-Part2Mak. Curingspecimensstrengthtests;2009.

[39]ASTMInternational.ASTMC642-06standardtestmethod fordensity,absorption,andvoidsinhardenedconcrete. UnitedStatesAmSocTestMater2008,

http://dx.doi.org/10.1520/C0642-13.5.

[40]AstmC666/C666M-03.Standardtestmethodforresistance ofconcretetorapidfreezingandthawing.ASTMInt2008, http://dx.doi.org/10.1520/C0666.

[41]Mardani-AghabaglouA,Andic¸-C¸akirÖ,RamyarK. Freeze-thawresistanceandtransportpropertiesof high-volumeflyashrollercompactedconcretedesignedby maximumdensitymethod.CemConcrCompos

2013;37:259–66,

http://dx.doi.org/10.1016/j.cemconcomp.2013.01.009. [42]ACTMC1170/C1170M.Determiningconsistencyanddensity

ofroller-compactedconcreteusingavibratingtable.Annu BookASTMStandSect11WaterEnvironTechnol2014, http://dx.doi.org/10.1520/C1170.

[43]RaoSK,SravanaP,RaoTC.Abrasionresistanceand mechanicalpropertiesofRollerCompactedConcretewith GGBS.ConstrBuildMater2016;114:925–33,

http://dx.doi.org/10.1016/j.conbuildmat.2016.04.004. [44]AlginZ,GerginciS.Freeze-thawresistanceandwater

permeabilitypropertiesofrollercompactedconcrete producedwithmacrosyntheticfibre.ConstrBuildMater 2020;234:117382,

http://dx.doi.org/10.1016/j.conbuildmat.2019.117382. [45]LuhrD.(DepartmentofTAUSACofE.Engineeringanddesign

ROLLER-COMPACTEDCONCRETE);2006.

[46]HesamiS,ModarresA,SoltaninejadM,MadaniH. Mechanicalpropertiesofrollercompactedconcrete pavementcontainingcoalwasteandlimestonepowderas partialreplacementsofcement.ConstrBuildMater2016, http://dx.doi.org/10.1016/j.conbuildmat.2016.02.116. [47]BeddeyA,MarzoukiA,LecomteA,BenOuezdouM,Diliberto

C.Theeffectsofgrindingonthepropertiesof Portland-limestonecement.ConstrBuildMater2013, http://dx.doi.org/10.1016/j.conbuildmat.2013.07.053. [48]DeWeerdtK,KjellsenKO,SellevoldE,JustnesH.Synergy

betweenflyashandlimestonepowderinternarycements. CemConcrCompos2011,

[49]NejadFM,ToloueiM,NazariH,NaderanA.Effectsofcalcium carbonatenanoparticlesandflyashonmechanicaland permeabilitypropertiesofconcrete.AdvCivEngMater 2018;7:651–68,http://dx.doi.org/10.1520/ACEM20180066. [50]CaoC,SunW,QinH.Analysisonstrengthandflyasheffect

ofroller-compactedconcretewithhighvolumeflyash.Cem ConcrRes2000;30:71–5,

http://dx.doi.org/10.1016/S0008-8846(99)00203-3.

[51]C778A.Standardspecificationforstandardsand.AmSoc TestMater2017,http://dx.doi.org/10.1520/D7544-09.2. [52]AbrasionCharacteristicsofGroundCalciumCarbonate

Products.Focuspowdercoatings;2018, http://dx.doi.org/10.1016/j.fopow.2018.09.032.