ORIGINAL PAPER

Easy Controlled Properties of Quaternary FeNiCrCd Thin Films

Deposited from a Single dc Magnetron Sputtering

Under the Influence of Deposition Rate

Hakan Köçkar1 &ÖzgürŞenturk1&Ali Karpuz2&Oznur Karaagac1&Nadir Kaplan1&Hilal Kuru1

# Springer Science+Business Media, LLC, part of Springer Nature 2019 Abstract

The quaternary FeNiCrCd thin films were produced from a single FeNiCrCr source on a commercial flexible polymer substrate using one dc magnetron sputtering technique. For that, a series of the films with a thickness of 50 nm were produced at different deposition rates of 0.02, 0.04, 0.06, and 0.08 nm/s, separately. In this study, as far as concerned, this was the first time that structural and magnetic properties of FeNiCrCd thin films were investigated. According to compositional analysis, the Fe and Cr contents slightly decreased with increasing deposition rate while Ni was almost constant, whereas those of the amount of Cd atoms increased. However, the atomic amounts of Fe and Cd in the films are quite different from those of the source material. The change of the atomic contents in the films from the source may be attributed to the relatively different bond energy/melting point of metals which have different contents sputtered from source material since this physical parameter is very significant for the sputtering process. For crystal structural analysis, a combination of hexagonal close-packed (hcp) and body-centered cubic (bcc) were observed. The peak intensity of the bcc-dominated planes decreased while the hcp-dominant plane increased since the change in peak intensities is compatible with the compositional analysis with increasing deposition rate. And, the grain sizes decreased gradually from 40.1 to 23.4 nm, with increasing deposition rate from 0.02, to 0.08 nm/s. Also, the film surfaces transformed from a rough to smooth surfaces with decreasing grain sizes as deposition rate increased. For magnetic analysis, the saturation magnetization Msvalues decreased as 1030, 773, 730, and 217 emu/cm3with increasing deposition rate as 0.02, 0.04,

0.06, and 0.08 nm/s, respectively. In the same manner, the coercivity Hcvalues were found as 11, 7, 6, and 2 Oe with the

deposition rate of 0.02, 0.04, 0.06, and 0.08 nm/s, respectively. The decrease of the Hcmay have primarily come from the

transformation of rough to smooth surface of the films. It may also be said that the films showed soft magnetic properties due to their low Hcvalues with increasing deposition rate. Thus, the magnetic properties of the quaternary FeNiCrCd alloy films were

seen to be easily improved with the deposition rate parameter for potential use in different industrial applications.

Keywords Quaternary FeNiCrCd thin films . dc sputtering technique . Thin films . Magnetic properties, structural properties

1 Introduction

The magnetic materials have attracted an attention in the sci-entific community due to their wide range of applications. The creation of thin alloys with various combinations of metals

makes possible development of new and controllable proper-ties for technological devices [1]. The diversity in use of mag-netic materials is quite important in technological applications such as magnetic sensors and magnetic recording media, high-tech products, and many more [2,3].

In recent years, the important physical techniques have also been developed for thin film production. These techniques have different advantages depending on the production pa-rameters and application areas. Sputtering system is one of the most important techniques to produce such films. There are a lot of advantages to produce a film by using a sputtering technique. To obtain high-quality surfaces is possible when the films are produced by a sputtering method. Another * Hakan Köçkar

hkockar@balikesir.edu.tr 1

Physics Department, Balikesir University, Balikesir, Turkey 2 Physics Department, Karamanoglu Mehmetbey University,

Karaman, Turkey

advantage of this method is that the production parameters are easily controllable. The deposition rate is one of the most important production parameters changes the properties of films in the sputtering process [4].

The remarkable magnetic properties of the FeNi alloy and their different triple alloys have made them an intense study topic [5]. The FeNi-based ternary alloy films, e.g., FeNiMo [5] and FeNiCo [6], are very important soft magnetic materials since Mo and Co have contributed on their structural and magnetic properties. They are used applied industry and com-monly in magnetic sensing devices [5–8]. Various properties of FeNiCr ternary alloys have been earlier investigated in the literature for many years [9,10]. Yu Cao [3] investigated sur-face roughness and magnetic properties as a function of FeNiCr thin film thickness. In addition, FeNiCr-based alloys, e.g., FeNiCrCo [11], have also been reported with their inves-tigated properties. And, the Cd alloys are generally preferred for battery technology (NiCd) [12] and it has been the focus of intense investigations in recent years due to the need for ma-terial in the aerospace industry (MgCd) [13,14]. On the other hand, to our knowledge, there is no any investigation on the properties of quaternary FeNiCrCd thin films deposited on flexible substrate for potential electric and electronic applica-tions such as MEMs. Therefore, in this study, the influence of deposition rate on the structural and magnetic properties of sputtered quaternary FeNiCrCd thin films has been investigat-ed. For that, a series of quaternary FeNiCrCd alloys sputtered by considering different deposition rates using single dc mag-netron sputtering system. It is seen that the variation of depo-sition rates has easy-controlled influence on the compodepo-sition, structural and thus magnetic properties the thin films.

2 Experimental

The films were produced on a commercial polymer acetate substrate under the deposition rates of values of 0.02, 0.04, 0.06, and 0.08 nm/s by the one dc sputtering source (Mantis, Q-Prep, 500, UK). All thin films were grown by using a source material source (Fe51.07Ni13.42Cr12.67Cd22.74at.%)

which has a diameter of 50.8 mm and a thickness of 0.6 mm. Firstly, the surface of the substrate was cleaned by an ultrasonic bath before each deposition. Then, the substrate was fixed by using a sample holder in the vacuum chamber. The distance between the substrate and the source material was kept constant for each deposition. The vacuum chamber was in a pressure value of ~ 10−6mbar before deposition. Both the rotary pump and the turbo molecular pump were together used to achieve this pressure value. After obtaining a high vacuum atmosphere, argon gas was sent into the vacuum chamber. Thus, the pressure value of the vacuum chamber increased to ~ 3 × 10−3mbar and the sputtering was carried out under this pressure. During the production of each sample,

the temperature of the substrate was at room temperature. The change in the substrate temperature due to experimental fac-tors was in the range of ± 2 °C. All film thicknesses were adjusted as 50 nm by using quartz crystal microbalance thick-ness monitor located very close to deposition area. The film thicknesses were measured during the production process.

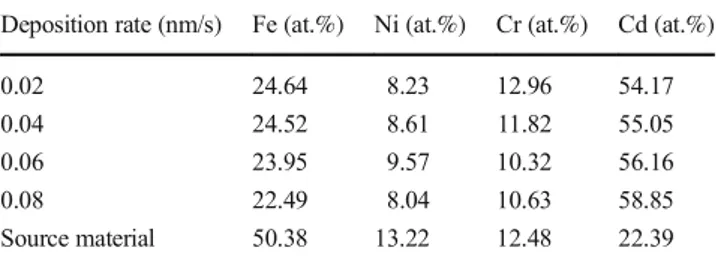

The atomic content of source material was detected by using inductively coupled plasma-atomic emission spectros-copy (ICP-AES, Perkin-Elmer, Optima 7300 DV, USA). The source measured by ICP-AES has the atomic contents of 50.38% Fe, 13.22% Ni, 12.48% Cr, and 22.39% Cd, and 2.0% other elements such as Mn (see Table1). The composi-tional analysis of films (see Table1) was detected by using the energy dispersive X-ray spectroscopy (EDX, Bruker, Advance with Davinci Design for XRD2, UK). The films measured by EDX contain less than totally 0.2 at.% other elements such as Mn (see Table1). The crystalline structure analysis was done with Cu-Kαradiation (λ = 1.54056 Å) by

using an X-ray diffraction (XRD, Bruker D8 Advance) tech-nique. The 2θ angle was scanned between 30 and 70° with the step size of 0.005° for the XRD measurements. The surfaces of the films were observed with a scanning electron micro-scope (SEM, Zeiss Evo LS 10) and the magnetic properties were measured by using a vibrating sample magnetometer (VSM, Ade Technologies DMS-EV9, USA). The measure-ments were done in the range of ± 20 kOe with 1 Oe intervals at room temperature. The films used for the magnetic analysis were circular-shaped and have 6 mm in diameter. The mea-surements were performed with perpendicular and parallel magnetic field to the film surface to determine the magneti-cally easy axis for each film.

3 Results and Discussion

The results of the compositional analysis of FeNiCrCd source and films obtained by the ICP-AES and EDX are presented in Table1, respectively. As shown in Table1, the atomic content of Fe decreased from 24.63 to 22.49% with the increase of deposition rate from 0.02 to 0.08 nm/s, respectively. And, the atomic percentage of Cd in the films was found to increase

Table 1 The atomic contents of the thin films produced at different deposition rates

Deposition rate (nm/s) Fe (at.%) Ni (at.%) Cr (at.%) Cd (at.%)

0.02 24.64 8.23 12.96 54.17

0.04 24.52 8.61 11.82 55.05

0.06 23.95 9.57 10.32 56.16

0.08 22.49 8.04 10.63 58.85

from 54.17 to 58.85% with the increase of deposition rate. On the other hand, the atomic percentages of Cd and Fe in the source material are 22.74% and 51.17%, respectively. This shows that the atomic amounts of Cd and Fe in the films are quite different from those of the source material. The reason for this may be attributed to the relatively higher bond energy/ melting point of Fe metals than that of the Cd metals [15] since this physical parameter is very significant for a sputtering process. As also seen in Table1, the atomic percentage of Cr atoms in the films slightly decreased with increasing deposi-tion rate from the lowest to the highest value. However, the atomic Ni percentage varied in between 8.04 and 9.57 while the deposition rate was systematically changed. In general, it should also be pointed out that the bond energy/melting point of the metals might be influenced by the variations of the deposition rates since their compositions are changed in a different range.

The XRD patterns of the films deposited at 0.02, 0.04, 0.06, and 0.08 nm/s are demonstrated in Fig.1. The XRD measurement of the substrate was also achieved and is plotted in Fig.1to distinguish the results from the substrate and the films. No peak was observed in the XRD pattern of the sub-strate. In the XRD patterns of the films, hexagonal close-packed (hcp) plane were observed at 2θ ≈ 38° for (101) plane, and two peaks belong to body-centered cubic (bcc) planes were observed at 2θ ≈ 44° for (110) plane and 64° for (200) plane. It was understood that all FeNiCrCd films have a mixed crystal structure consisting of hcp and bcc phases. The peaks observed at 2θ ≈ 38°, 44°, and 64° were ascribed from Cd, FeNiCr, and FeCr planes based on the JCPDS Card Nos. 85-1328, 35-1375, and 34-0396, respectively. The peak intensity of bcc planes decreased while the hcp plane increased since the change in peak intensities is compatible with the compo-sitional analysis with increasing deposition rate. And, the dominations of bcc structure at two low deposition rates con-verted to the hcp-dominated planes at last two rates. The grain

sizes were calculated with Scherrer’s formula from the full width of half maximum values [16], using the highest peak for each film. The grain sizes of the films in Table1decreased gradually as 40.1, 37.3, 34.4, and 23.4 nm, depending on the increasing deposition rate as 0.02, 0.04, 0.06, and 0.08 nm/s, respectively. The plane spacing d for the highest peak intensi-ties was obtained to be 0.1448 nm, 0.2054 nm, 0.2055 nm, and 0.2367 nm as the increase of deposition rates in the range of 0.02, 0.04, 0.06, and 0.08 nm/s, respectively. The calculated values of the lattice parameters a and c for hcp structure were around 0.3096 and 0.5066 nm which are compatible with the bulk Cd (aCd= 0.2979 nm) and (cCd= 0.5617 nm) [15]. The a

parameter for bcc structure was calculated as around 0.2903 nm that are closely among the those of the bulk Fe (aFe= 0.2866 nm), Ni (aNi= 0.3524 nm), and Cr (aCr=

0.2885 nm) [15]. It was shown that crystalline structure of the FeNiCrCd films was affected with different film contents caused by different deposition rates.

Figure2a–d show the SEM images of the films deposited at the (a) 0.02, (b) 0.04, (c) 0.06, and (d) 0.08 nm/s deposition rates, respectively. From the figure, the rough surfaces were converted to a clear and smooth surface of the films produced from low to high deposition rates. It was also seen that rela-tively smaller grain size structure also confirms homogeny and smooth surface structure for investigated quaternary FeNiCrCd alloys with increasing higher deposition rates. It was understood that different deposition rates have a signifi-cant effect on the surface morphology as earlier reported in [4].

The different deposition rates also influenced the corre-sponding magnetic properties of the films. The parallel hysteresis loops of the films sputtered at different deposi-tion rates are illustrated in Fig.3. And, the saturation mag-netization MSand coercivity HCversus deposition rates are

also displayed in Fig.4. As seen in the figures, the Msand

Hc values were affected by the deposition rates. The Ms

values were decreased from 1030 to 217 emu/cm3 with the decrease from 0.02, 0.04, to 0.08 nm/s, respectively. Also, the values of Hcwere found as 11 Oe, 7 Oe, 6 Oe,

and 2 Oe for the films deposited at 0.02, 0.04, 0.06, and 0.08 nm/s, respectively. The Hcvalues are compatible with

the grain sizes and also surface smoothness in the SEM images caused by the increase of the deposition rate. The dependency of the HCto the grain size was found to have

the same trend in the other studies [16,17]. Furthermore, according to the HC values, all films have soft magnetic

properties since the HC of the films lower than 12.5 Oe

[17].

In Fig.5, as an example, the hysteresis loops obtained from parallel and perpendicular (to the film plane) measurements for the film sputtered at deposition rate of 0.06 nm/s were drawn at ± 10 kOe. Due to magnetic shape anisotropy [18], it has been understood that the direction of the magnetically Fig. 1 XRD patterns of the substrate and alloys films sputtered at 0.02,

easy axis is parallel to the film plane. The rest of the films also displayed the same findings. Further study will concentrate on metalo-organic structures deposited on flexiable substrate similar [19–23].

4 Conclusions

Under the study, as far as concerned, the first investigation on controllable properties of sputtered quaternary FeNiCrCd thin Fig. 2 SEM images of the thin films deposited at a 0.02, b 0.04, c 0.06, and d 0.08 nm/s deposition rates

Fig. 3 Parallel hysteresis loops of the films deposited at 0.02, 0.04, 0.06, and 0.08 nm/s deposition rates were drawn at ± 150 Oe

films was presented. The changes of structural and corre-sponding magnetic properties of a series of 50-nm quaternary FeCrNiCd thin films grown at 0.02, 0.04, 0.06, and 0.08 nm/s by a single magnetron sputtering were investigated. With in-creasing deposition potential, compositional analysis of the films revealed that the Cd content increased from 54.17 to 58.85 at.%, and however, Fe and Cr contents decreased from 24.64 to 22.49 at.% and from 12.96 to 10.32 at.%, respective-ly, while the Ni content of the films varied between 8.04 and 9.57 at.%. The films have a mixed crystal structure consisting of hcp and bcc. While the bcc planes dominate the film struc-ture at low deposition rates, hcp increased and dominate the structure at last two rates. In the films, the highest peak inten-sity gradually transformed from (200) plane of body-centered cubic to (101) plane of hexagonal close-packed with the in-crease of the deposition rate. It is also pointed out that the changes in the peak intensity of the films are compatible with the composition analysis. For the surface analysis with SEM,

it was found that the clearness and smoothness of the film surfaces increased with increasing deposition rate. The satu-ration magnetization values of the films decreased from 1030 to 217 emu/cm3with decrease of ferromagnetic Fe contents in the films under increasing deposition rate from 0.02 to 0.08 nm/s. And, the coercivity values of the films were found to decrease from 11 to 2 Oe as the deposition rate increased from 0.02 to 0.08 nm/s. The gradual decrease in the coercivity values can be attributed to the decrease of grain size and num-bers on the surface, and clear surface structure of FeNiCrCd films. Also, it was found that the alloy films produced were magnetically soft. The parallel hysteresis loop was found to have a higher remanence and lower coercivity values than those of the perpendicular hysteresis loop, and thus the easy-axis direction of magnetization was found in the film planes due to the magnetic shape anisotropy. The structural and cor-responding magnetic properties of the FeNiCrCd films are significantly affected by the parameter of the deposition rate. Fig. 4 Saturation magnetization

Msand coercivity Hcvalues versus applied deposition rates

Fig. 5 Parallel and perpendicular hysteresis loops for the FeNiCrCd film produced at deposition rate of 0.06 nm/s were drawn at ± 10 kOe

For this reason, the feasibility of magnetic properties may provide use of ease for potential flexiable electric and elec-tronic technology in different applications.

Acknowledgements The authors are very grateful to the Selçuk University, Advanced Technology Research & Application Center for the SEM and EDX analysis, and the Karamanoglu Mehmetbey University, Scientific and Technological Researches Application and Research Center for XRD measurements.

Funding information This work was financially supported by Balikesir University Research Grant No. BAP 2018/107. Also, it was financially supported by the State Planning Organization/Turkey under grant no. 2005K120170 for Sputtering and VSM systems.

References

1. Ferrando, R., Jellinek, J., Johnston, R.L.: Nanoalloys: from theory to applications of alloy clusters and nanoparticles. Chem. Rev. 108(3), 845–910 (2008)

2. Karpuz, A., Kockar, H., Alper, M.: Properties of electrodeposited Co-Mn films: influence of deposition parameters. Appl. Surf. Sci. 358, 605–611 (2015)

3. Cao, Y., Zhou, C.G.: Thickness dependence of surface roughness and magnetic properties of FeNiCr thin films. J. Magn. Magn. Mater. 333, 1–7 (2013)

4. Karpuz, A., Colmekci, S., Kockar, H., Kuru, H., Uckun, M.: Impact of deposition rate on the structural and magnetic properties of sputtered Ni/Cu multilayer thin films. Zeitschrift für Naturforschung A. 73(1), 85–90 (2017)

5. Fuzer, J., Kollar, P., Oleksakova, D., Roth, S.: AC magnetic prop-erties of the bulk Fe–Ni and Fe–Ni–Mo soft magnetic alloys pre-pared by warm compaction. J. Alloys Compd. 483(1–2), 557–559 (2009)

6. Kuru, H., Kockar, H., Demirbas, O., Alper, M.: Characterizations of electrodeposited NiCoFe ternary alloys: influence of deposition po-tential. J. Mater. Sci. Mater. Electron. 26(6), 4046–4050 (2015) 7. Oleksakova, D., Kollar, P., Fuzer, J.: Structure and magnetic

prop-erties of powdered and compacted FeNi alloys. J. Electr. Eng. 68(2), 163–166 (2017).https://doi.org/10.1515/jee-2017-0024

8. Svalov, A.V., Asensio, B.G., Chlenova, A.A., Savin, P.A., Larranaga, A., Gonzalez, J.M., Kurlyandskaya, G.V.: Study of the effect of the deposition rate and seed layers on structure and

magnetic properties of magnetron sputtered FeNi films. Vacuum. 119, 245–249 (2015)

9. Chater, R., Bououdina, M., Chaanbi, D., Abbas, H.: Synthesis and magnetization studies of nanopowder Fe70Ni20Cr10alloys prepared by high energy milling. J. Solid State Chem. 201, 317–323 (2013) 10. Sinha, G., Chatterjee, R., Uehara, M., Majumdar, A.K.: Relaxation of thermo-remanent magnetization in different magnetic phases of Fe-richγ-FeNiCr alloys. J. Magn. Magn. Mater. 164(3), 345–356 (1996)

11. Jacob, K.T., Rao, D.B., Nelson, H.G.: Phase relations in the Fe-Ni-Cr-S system and the sulfidation of an austenitic stainless steel. Oxid. Met. 13(1), 25–55 (1979)

12. Wu, Z., Gao, Y.F., Bei, H.: Single crystal plastic behavior of a single-phase, face-center-cubic-structured, equiatomic FeNiCrCo alloy. Scr. Mater. 109, 108–112 (2015)

13. Espinosa, DCR., Tenorio,JAS.“Use of nitrogen in the recycling of nickel cadmium batteries.”, J. Power Sources, 136 (1), 186–190, (2004)

14. Gao, S., Xia, L., and Wu, ZS. “Effect of Cd Additions on Microstructure and Properties of Mg-Cd Binary Magnesium Alloy.”, International Conference on Mechanical Engineering and Technology (ICMET-London 2011), ASME Press. 675–677, (2011)

15. Liao Y.,“Practical Electron Microscopy and Database” - An Online Book:http://www.globalsino.com/EM/., Second Edition, (2007) 16. Jiles, D.: Introduction to Magnetism and Magnetic Materials,

Chapter 4. Chapman and Hall, London (1991)

17. Karaagac, O., Kockar, H., Alper, M.: Composition dependence of structural and magnetic properties of electrodeposited Co-Cu films. IEEE Trans. Magn. 46(12), 3973–3977 (2010)

18. Vopsaroiu, M., Georgieva, M., Grundy, P.J., Vallejo Fernandez, G., Manzoor, S., Thwaites, M.J., O’Grady, K.: Preparation of high mo-ment CoFe films with controlled grain size and coercivity. J. Appl. Phys. 97(10), 10N303 (2005)

19. Nano Letters 18, 7839–7844, 2018 20. Nanoscale 9, 12855–12861, 2017

21. Journal of Materials Chemistry C 3, 7075–7080, 2015 22. Nanoscale 7, 2877–2882, 2015

23. Nanoscale 7, 2877–2882, 2015

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.