INT. J. COMPUTER INTEGRATED MANUFACTURING, 1995, VOL. 8, NO. 2, 133-144

Experimental investigation of an FMS due-date

scheduling problem: an evaluation of due-date

assignment rules

IHSAN SABUNCUOGLU and DON L. HOMMERTZHEIM

Abstract. This paper investigates the performance of due-date assignment rules in a flexible manufacturing system (FMS). Although emphasis is placed on a comparison of due-date assignment rules, machine and automated guided vehicle (AGV) scheduling rules are also evaluated under various exper-imental conditions using an FMS simulation model. The mean job tardiness is the measure of performance by which the rules are compared. The sensitivity to AGV workload, buffer capa-city, and processing time distribution is also investigated to assess the robustness of the due-date assignment rules.

1. Introduction

Flexible manufacturing systems (FMSs) can be described as batch manufacturing systems which consist of a group of computer-controlled (CNC) machines con-nected by an automated materials handling system. These systems are used to process a wide variety of different parts with low to medium demand volume.

Even though the FMS concept was originated in the 1960s with an emphasis on the integration of standard machine tools, materials handling equipment, and com-puter systems (Ranky 1986), the number of FMS appli-cations did not start to increase significantly until the early 1980s. By 1987, approximately 300 FMSs had been implemented around the world (Singha! et al. 1987). Today, FMSs seem to be a very promising technology for batch manufacturing companies. They possess the effi-ciency of dedicated transfer lines in mass production systems while retaining the flexibility of a job shop in batch manufacturing systems.

In many respects, an FMS can be viewed as an auto-mated job shop. The major difference between an FMS and a conventional job shop is that the human functions

Authors: Ihsan Sabuncuoglu, Department of Industrial Engineering, Bilkent University, Ankara, Turkey 06533 and Don L. Hommertz-heim, Department oflndustrial Engineering, Wichita State University, Wichita, KS 67208, USA.

are automated in the FMS. Moreover, an FMS is a highly integrated system with an automated materials handling system (usually an AGV system) which ties together the machining centres and has a significant impact on the system performance. Thus, scheduling problems of FMSs are more difficult than traditional job shop problems due to considerations of the additional resource constraints (materials handling, limited in-process buffer spaces, etc.).

The FMS scheduling literature also includes a number of studies and proposed solution approaches ranging from analytical techniques to simulation and artificial intelligence/ expert systems (Sabuncuoglu and Hom-mertzheim 1989b, Ranky 1988, Kusiak and Chen 1988, Kusiak 1986, and Raman, Talbot and Rachamadugu 1986). This paper is primarily concerned with scheduling problems of an FMS with the objective of investigating the performances of due-date assignment rules against the mean tardiness criterion.

2. Relevant literature

An FMS survey made by Smith et al. (1986) showed that the most important criterion used in FMS sched-uling is meeting due-dates. This is followed by the maxi-mization of system utilization and the minimaxi-mization of in-process inventory. While this limited survey (22 FMS

installations), gives some insight as to which criteria are currently the most important, in general, the FMS scheduling problem is multi-objective, and the selection of a particular criterion depends upon various factors such as the state of the shop, characteristics of jobs, due-date tightness, the overall objectives of the company, etc.

The objective of due-date management is to achieve on-time delivery of the products to customers, but this is rarely accomplished in practice. Because of the complex and dynamic interactions in manufacturing environ-0951-192X/95 $10·00 © 1995 Taylor & Francis Ltd.

134

ments and unexpected interruptions, some orders are completed early while other orders are late. Each late delivery can cause a penalty cost or at least a loss of good-will. Similarly, each early completion of jobs can increase the inventory cost because the customer may not be willing to accept early shipment due to its production and inventory policies.

Although meeting due-dates is very important, it is also a very difficult problem, since it is hard to find a compromise of due-date performances of the system from the wide variety of measures used in the industry. Some of these are as follows: mean tardiness, conditional tardi-ness, proportion of late orders, mean latetardi-ness, maximum lateness, etc.

In practice, due-dates are sometimes dictated by the customer and are called 'exogenous' due-date assign-ments. At other times, they are totally under the control of the company, which sets due-dates based on the expected completion time of orders. This type of due-date setting procedure is called an 'endogenous' due-due-date assignment. Actual systems usually operate somewhere between these two extremes. There may be situations where negotiation with customers is possible. Sometimes the management may even impose due-date restrictions based on targeted service levels or assembly, and master schedules may dictate the due-dates. This paper focuses on endogenous due-date assignment.

Due-date assignment is a critical task since it rep-resents a delivery commitment of the system. Further-more, the performance of the scheduling system, including the scheduling algorithms and rules, are highly dependent on the due-date information. Since it also serves as the basis for many production and inventory decisions in a company, the due-date assignment problem has been studied extensively in the literature.

Smith and Seidmann ( 1981) reviewed previous work related to the job-shop. In their study, they identified three basic categories for due-date assignment pro-cedures: direct, heuristic, and analytical. According to their terminology, the direct procedure refers to simple procedures which utilize the current information about jobs or the state of the system. Heuristic procedures involve more complex methodologies to set the due-dates by using simulation runs, whereas analytical procedures are based on the results obtained from ana-lytical investigations ( see Baker and Scudder ( 1990) for summary of analytical work for static scheduling problems).

Since the due-date assignment problem cannot be iso-lated from the overall scheduling problem, the scheduling problem is very difficult to handle by analytical means. Because of this, the majority of previous work has focused on the investigation of direct and heuristic pro-cedures. Furthermore, since heuristic procedures

exten-sively utilize results obtained from direct procedures, the analyses of direct procedures have received extensive attention by many researchers (Baker 1984, Baker and Bertrand 1981, Miyazaki 1981). According to the above classification, this paper is concerned with the direct procedures.

A direct procedure is a simple rule which assigns a flow-time allowance to an arriving job by using the job characteristics and/ or the current state of the system. In this context, the flow-allowance refers to the total time allocated to a job in the system for several activities such as processing, transportation, and waiting. The job characteristics refer to the processing times, the number of operations, etc. On the other hand, the state of the system can be defined by the number of jobs in the system, utilization rates, etc.

As reported by other researchers such as Kanet (1982), the flow-allowance ( or lead time) has a quite different meaning to the flow-time. While the flow-allowance is a reasonable amount of time budgeted to perform all activities related to a job, the flow-time is the the actual time realized in the system (the time between job release and its completion). Since management has limited control over the flow-times, it directly results from the system performance and is a random variable. On the other hand, flow-allowances ( or lead times) can be totally controlled and set by the management and are constants rather than a random variable. The relationship between the flow-allowance and flow-time is such that attainable

Symbol

CON

SLKTWK

NOP

PPW

CON

SLKTWK

NOP

PPW:

Table 1. Due-date assignment rules. Description

Constant flow allowance

Flow-allowance is equal to the total processing time of the job plus a constant slack

Flow-allowance proportional to the total work ( or processing time)

Flow-allowance proportional to the total number of operations

Flow-allowance equal to the processing time plus an estimate of waiting time

Table 2. Flow-allowance equations.

A;=k•ETWK

A;=P1 +(k- l)•ETWK A; = k • P1

A;= k • N; • ETWK/ENOP

FMS due-date scheduling 135 due-dates can be determined if the flow-time is fairly

pre-dictable. In this context, the expected flow-time is very useful in setting the allowances.

In this paper, five due-date assignment rules ( or direct procedures) are considered (Table 1 ). Mathematical definitions of these due-date assignment are presented in Table 2.

The following notation is used in defining flow allowances:

i = job index

j = operation index

t = time at which the scheduling decision is being made

D; = due-date of job i

R; = ready time or arrival time of job i A;= original flow allowance for job i

C; = completion time of job i

k = allowance factor or measure of due-date tightness

T; = tardiness of job i F; = flow-time of job i

N; = total number of operations of job i

PJ = total remaining operation time of job at its jth operation

ETWK = estimated average total work content for all jobs

ENOP = estimated average number of operations D; =R; +A;

T; = max(O, C; - D;)

In the above definition, ETWK is determined from distribution functions which generate processing times and the number of operations.

The due-date which is set by using the procedures listed in Table 1 represents the job due-date. Operation due-dates can also be determined. For example, operation-based due-date assignment using TWK is

d;,J = d;,J-1 + k xp;,J

where d;,J = due-date of job i for operation j and p;,J = operation time for jth operation of job i.

Thus, not only the job due-dates but also the operation due-dates can be used to schedule the jobs. While the job due-date represents the expected date that the job must be released from the system, the operation due-date rep-resents the expected date that a job must complete a par-ticular operation.

From earlier job-shop studies, there is some evidence that the relative performance of the due-date assignment rules change with scheduling rules. Therefore, sched-uling rules are also considered in this paper. Since machine and materials handling aspects of FMSs are pri-marily under study, scheduling rules are further classified

into ( 1) machine scheduling rules and (2) AGV sched-uling rules. The machine schedsched-uling rules are those which are used to select the next job from the input queue upon the availability of machine. On the other hand, AGV rules are used to select the best workcentre (machine) and job to be served upon the availability of an AGV. Machine scheduling rules for this study were selected from the recent FMS and job-shop literature and are listed in Table 3. For the AGV scheduling rules, the FCFS (first come first served) and LQS (largest queue size) rules were tested. FCFS has the ability to comple-ment the machine scheduling rules by serving a work-centre with the earliest job completion. On the other hand, LQS uses information on queue level. This rule was found to be the best rule against the mean flow-time criterion in earlier studies (Sabuncuoglu and Hommertz-heim 1989a, 1992). In addition, some of the machine due-date scheduling rules were also used as a part of AGV scheduling.

Due-date assignment rules here already been tested in job-shop environments (Baker 1984, Baker and Kanet 1984, Baker and Bertrand 1981, Kan et and Christy 1989). In these studies, TWK was found to be the best rule. In the FMS scheduling literature, there are relatively few simulation studies which address due-date scheduling.

Montazeri and W asssenhowe ( 1989) investigated the performance of several slack-based due-date rules in a prospective FMS. Their conclusion was that S/OPN (smallest remaining slack per operation) performs better than other due-date scheduling rules. Choi and Malstrom ( 1988) have also tested FMS scheduling rules in a limited study based on a comparison of job-shop scheduling rules using a physical simulator. Their results indicated that SLK was the preferred due-date sched-uling rule based on the varous measures. In the above studies, neither the due-date assignment was analysed nor was the AGV subsystem explicitly modelled. Ro and Kim ( 1990) developed a routeing algorithm for an FMS and compared it with the linear programming model using various scheduling criteria. In their study, they used TWK as the due-date assignment rule, but did not compare various methods of setting due-dates. Thus,

Table 3. List of machine due-date scheduling rules. Symbol EDD SLK SCR S/OPN

MOD

Description Earliest due-date Smallest remaining slack Smallest critical ratioSmallest remaining slack per operation Smallest modified operation due-date

136

there is a real need to test due-date assignment rules in an FMS environment.

3. System considerations, simulation model and assumptions

Figure 1 shows the layout of the hypothetical FMS studied in this research. This same system was used in Sabuncuoglu and Hommertzheim (1992, 1993). In this system, there are eight workstations, six of which are machining centres that perform a wide variety of oper-ations, such as turning, milling and drilling. The two remaining stations are used for washing and inspection. Each workcen~re has a limited input/ output buffer at which parts can wait before and after an operation. In

addition, there is an input/output carousel where parts are loaded and unloaded. There are also two central buffer areas at which parts are temporarily stored to prevent system blocking. Materials and parts are transferred in the system by an AGV. Each AGV moves a part between the workcentres along a predetermined path which is assumed to be unidirectional. Upon com-pletion of a part transfer, an idle AGV either stays at the destination station or returns to the staging area for the next journey, depending upon the current operating policy. However, based on pilot simulation runs, the former method was used in the simulation experiments. Also, a 'direct access part retrieval design' is considered to be operational so that any part from the queue can be retrieved regardless of its position in the queue.

Cell #3 Cell #2

q

J

q

" Cent al b re r#2J

(

Cell #4 Cell #5J

q

q

Each workcentre can handle at most one operation at a time and each machine and AGV is continuously oper-ational without any breakdown. Pre-emption is not allowed and the setup time is included in the operation time. Whenever a machine and an AGV becomes idle, the next job in the queue is processed immediately (non-delay scheduling). An AGV transfers only one part at a time (the unit load is one). At intersections in the AGV path network (Figure 1 ), an AGV moving a part has priority over other AGVs travelling empty. In the case of a tie, the right of passing at the intersection is determined on a FCFS basis. Upon job completion at any work-centre, if there is more than one AGV available to transfer the part to the next station, the one closest to the workcentre which is demanding service is selected.

A discrete simulation model was developed to rep-resent the hypothetical FMS described above. As a simu-lation modelling tool, SIMAN (Pegden 1986) was used. The purpose of this study is to analyse the FMS sched-uling problem by taking into account the limited capac-ities of not only the machines but also the materials handling system and the in-process inventory. Therefore, the simulation model was developed in such a way that these three resources and their interactions were repre-sented in detail.

Data for the simulation runs was generated as follows: the job interarrival time was exponentially distributed. Each job was processed by a series of workcentres. The number of operations was determined by a discrete uniform distribution between 1 and 6. Parts entered the system based on availability of machines and AGVs and

[ Input/output carousel Cell #1 Inspection

(~

0

8 t Central buffer#1_J

a g I n g Cell #8 Washingq

qJ

FMS due-date scheduling 137 their earliest due-date priority. The machine assignment

was random and no job was allowed to visit the same machine more than once. Besides the workcentres, all jobs visited the washing station. However, only 50% of the jobs were processed by the inspection station. The scheduling rules were tested under the following exper-imental conditions:

• varying levels of due-date allowances (tightnesses); • different buffer ( or queue) capacities;

• varying AGV speeds;

• different types of processing time distributions and their parameters ( exponential and normal distri-butions).

The normal distribution is used because it is one of the distributions for which the variance is independent of mean. This allows the analyst to control the variance in the system.

Since the study objective is to measure the relative per-formance of alternative rules or operating policies, it is logical to compare them under identical conditions. Thus, a common random number (CRN) variance reduction technique (VR T) was utilized to provide the same experimental conditions (i.e. each job arrived at the same time and was assigned the same routeing and oper-ation times for each case considered). Furthermore, in order to obtain consistent samples from the simulation model across the alternatives tested, a scheme suggested by Conway (1963) was utilized. This involved num-bering the jobs in the order of their arrival. Based on some pilot runs, the statistics for the f1rst 300 jobs were discarded and samples were collected for only the jobs numbered between 301 and 3300.

4. Analysis of simulation results

The mean tardiness performance of different due-date assignment rules was measured using both normally and exponentially distributed processing times. In the exper-iments, only the positive values are considered for the normally distributed operation times. First, the rules were compared under a set of standard experimental con-ditions and then the sensitivity of the results were measured by varying the conditions. Under the standard conditions, the queue ( or the buffer) capacity at each workcentre was five and FCFS was used as the AGV rule for scheduling two AGV s. In addition, the average utiliz-ation rates of the machines and the AGV system was approximately 85 and 87 · 5 % , respectively.

4.1. Analysis of the due-date assignment rules under the standard experimental conditions

This section presents the simulation results of five due-date assignment rules (given in Table 1 ). From earlier job-shop results, there was some evidence that the

rela-tive performance of the due-date assignment rules change with due-date scheduling rules at varying due-date allowances. Thus, simulation experiments were repeated with different date scheduling rules at varying due-date tightnesses. The flow-allowances were controlled by a flow-allowance (or due-date tightness) parameter, k, so that each due-date assignment rule produced the same average flow allowances.

As can be seen in Table 4, the performance of due-date assignment rules were slightly different for the lower values of the tightness parameter, but they became similar when the due-date tightness was reduced. The mean tardiness performance of the scheduling rules became better as the tightness decreased. Among the due-date assignment rules tested, none of the rules domi-nated. The relative performance of due-date assignment rules changed with the different scheduling rules at the varying levels of due-date tightness. PPW was the

pre-ferred rule when the due-date was tight (k = 3). In the

Table 4. Mean tardiness performance (in minutes) of the due-date assignment rules under the standard experimental

conditions.

Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWY NOP PPW

EDD 131 · 6 122 · 1 126·4 114 · 7 132·8 SLK 124 · 1 114 · 8 137·8 111 · 4 131 · 5 3 SCR 157·3 164·9 150·5 115·0 132·4 MOD 102 ·5 130·7 99·0 96·2 80·5 S/OPN 155·4 126·9 142·7 116·4 150·3 EDD 68·8 60·6 59·7 57·8 80·7 SLK 61 · 3 54·5 37·4 71 · 5 44·0 4 SCR 64·9 91·1 85·4 75·9 83·9 MOD 70·7 64·8 51 ·O 50·4 50·6 S/OPN 60·7 57 ·6 46·9 58·2 78·2 EDD 30·0 24· 7 18·2 22·4 28·3 SLK 25·8 23 · 1 26·8 30·8 23 · 1 5 SCR 59 · 1 40·4 31 · 3 22·5 26·3 MOD 39·9 62·6 29·2 36·9 36·9 S/OPN 28·9 34·2 31 ·9 26·3 22·4 EDD 11 · 2 8·4 10·7 9·8 10·3 SLK 10 · 5 9·9 21 · 0 13·3 10·7 6 SCR 11 · 9 31 · 5 22·7 9·6 20 · 1 MOD 19·9 28·9 17·3 21 ·8 14·4 S/OPN 13·6 16·0 13·6 16·0 8·7

138

other conditions, the results were so mixed that it was not possible to identify the best due-date assignment rule.

The same type of crossover effect was also observed in the performance of scheduling rules. Again, none of the rules outperformed the others. The relative performance of due-date scheduling rules changed with the different due-date assignment rules at varying values of the tightness parameter. Except for the SLK due-date assign-ment rule,

MOD

performed slightly better than the other scheduling rules when the tightness parameter was small (k = 3).In

conclusion, neither the due-date assignment rules nor the scheduling rules provided substantially different mean tardiness performances.From job-shop studies (Baker 1984, Kanet and Christy 1989), it is known that TWK and MOD are preferred due-date assignment and scheduling rules, respectively. However, from the results of the FMS simulated, there was no evidence indicating their superior performance. None of the rules clearly dominated in terms of due-date performance. This problem in discriminating the relative effectiveness of the rules can be due to one or more of the following reasons:

(1) A job which had the highest priority at a current station would not have the same degree of urgency at the other stations, because in the FMS model the job pool at any station was limited by the queue capacity.

(2) A job finishing the current operation could not be delivered to the next station immediately by the AGV system due to the FCFS AGV rule which was insensitive to due-date information.

(3) Variances of the processing times were low. There-fore, the due-date assignment rules which are based on the processing times with small variance would not yield significantly different due-date per-formances.

There might be some other reasons for this type of similar due-date performances of the rules. These possi-bilities will be explored as follows:

Case 1. Using different AGV scheduling rules

Under the standard experimental conditions, FCFS was used as the AGV rule. However, it is known that the FCFS rule does not use the due-date information in prioritizing the AGVs. The aim was to use the due-date rules to assign both machines and AGVs so that differ-ences in the performances of rules could be identified. The experiments were repeated and the simulation results are displayed in Table 5.

Again, the results indicated that none of the due-date assignment rules dominated. The relative performances of scheduling rules were also quite mixed. Only MOD

Table 5. Mean tardiness performance (in minutes) of the due-date assignment rules using the due-due-date rules as machine and

AGV scheduling rules.

Machine Due-date assignment rules Flow-allowance /AGV

parameter k rules CON SLK TWK NOP PPW

EDD 124·9 111 ·6 95·6 93·7 96·5 SLK 132·9 118· 0 103·9 113 · 3 122 · 1 3 SCR 143·4 126·8 108·8 137·0 104·6 MOD 104·5 104·8 90·5 95·4 81 · 4 S/OPN 134·9 138·2 94·6 107·6 133·7 EDD 63·3 51 ·9 48·4 41·5 44·6 SLK 69·6 56· 1 39·6 48 · 1 46·5 4 SCR 58·5 67·3 61 ·9 57·6 53·9 MOD 59·9 66·3 39·9 48·4 37·9 S/OPN 67·4 48·3 54·2 42·2 54·5 EDD 26·6 20·4 22·4 20·6 29·0 SLK 31 · 6 23·4 38·2 15 · 1 21 ·O 5 SCR 20·9 27·4 24·9 19·5 25·1 MOD 21 ·9 24·8 25 · 1 21 ·9 19·9 S/OPN 31 ·8 28·3 21 · 9 21 · 8 24· 1 EDD 9·7 6·9 6·2 7·4 6·9 SLK 13·3 8·4 9·5 5·2 6 · 1 6 SCR 14·5 18·0 15·2 7·5 7·4 MOD 9·8 21·4 9·5 6·2 13·6 S/OPN 19·5 23·2 19 · 1 15·2 18·9

was slightly better when the due-date was tight (k

=

3) due to its SPT (shortest processing time) characteristic. But at other values of k, neither the due-date assignment rules nor scheduling rules resulted in relatively better mean tardiness performances.In

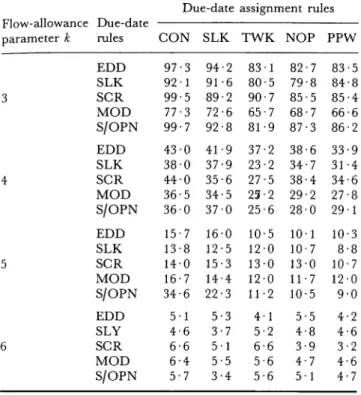

the investigation of performance of AGV scheduling rules, LQS was found to be the best AGV rule against the mean flow-time measure (Sabuncuoglu and Hom-mertzheim 1992, 1989a). Thus, the performance of the date assignment and scheduling rules were also com-pared using LQS as the AGV rule.As shown in Table 6, the resulting mean tardiness values were relatively small compared to the results obtained with the FCFS AGV rule (Table 4). This indicated that the better flow-time performance can lead to lower mean tardiness. But still their relative perform-ance changed with the different combination of due-date scheduling rules. A similar crossover effect · was also observed in the due-date scheduling rules.

From the simulation results discussed in the previous sections, there was not sufficient evidence of superior per-formance for any rule from either the due-date assign-ment or scheduling rule sets. Therefore, the performance of the due-date assignment rules were further analysed under new experimental conditions such as increasing the queue capacity, increasing the processing time vari-ances, reducing the AGV load level, and applying all the

PMS due-date scheduling 139

Table 6. Mean tardiness performance (in minutes) of the due-date assignment rules using LQS and the AGV rule.

Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWK NOP PPW EDD 97·3 94·2 83·1 82·7 83·5 SLK 92 · 1 91·6 80·5 79·8 84·8 3 SCR 99·5 89·2 90·7 85·5 85·4 MOD 77·3 72·6 65·7 68·7 66·6 S/OPN 99·7 92·8 81·9 87·3 86·2 EDD 43·0 41·9 37·2 38·6 33·9 SLK 38·0 37 ·9 23·2 34·7 31 ·4 4 SCR 44·0 35·6 27·5 38·4 34·6 MOD 36·5 34·5 2j·2 29·2 27·8 S/OPN 36·0 37·0 25·6 28·0 29 · 1 EDD 15·7 16·0 10·5 10 · 1 10·3 SLK 13·8 12·5 12·0 10·7 8·8 5 SCR 14·0 15·3 13·0 13·0 10·7 MOD 16·7 14·4 12·0 11 · 7 12·0 S/OPN 34·6 22·3 11·2 10·5 9·0 EDD 5 · 1 5·3 4 · 1 5·5 4·2 SLY 4·6 3·7 5·2 4·8 4·6 6 SCR 6·6 5 · 1 6·6 3·9 3·2 MOD 6·4 5·5 5·6 4·7 4·6 S/OPN 5·7 3·4 5·6 5 · 1 4·7

first three changes simultaneously. Five due-date assign-ment rules were considered in the experiassign-ments. While FCFS was used as the AGV rule, EDD and MOD were taken as the machine scheduling rules. These two rules were selected due to the fact that EDD is a commonly used scheduling rule in practice and MOD was found to be the best rule in earlier job-shop studies. Each of the ten rule combinations (five due-date assignment and two due-date scheduling rules) were tested at varying levels of due-date tightness. Again, the flow-allowances were con-trolled by the due-date tightness parameter. As men-tioned above, the due-date performances of rules were measured under four new experimental conditions. These are as follows:

Case 2. Increasing the queue capacity

The queue ( or buffer) capacity was increased to ten from the original capacity of five. Here, the aim was to give the rules more decision opportunities by providing a larger number of jobs in the queue. Recall that when the queue capacity is increased, the job finishing the current operation can be delivered to the next station immediately as long as an AGV is available. Also, the possible interference or delay caused by limited queue capacities can be reduced. Therefore, it was expected that some of the due-date assignment . rules would perform better under this type of less restrictive situation.

Table 7. Mean tardiness performance (in minutes) of the due-date assignment rules when queue capacity is ten.

Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWK NOP PPW

3 EDD MOD 92·0 91 · 5 74·5 82·2 79·9 71·3 62·5 61 · 0 60·5 60·0 4 EDD 38·0 38 · 1 24· 7 29·9 29·4 MOD 32'6 .- 27·7 20·4 22·9 22·0 5 EDD 11 · 7 11 ·9 6 · 1 7·4 5·6 MOD 11 ·8 11 · 0 6 · 1 6·9 6·7 6 EDD 2·3 2·5 1 ·O 1 · 3 1 · 3 MOD 2·6 4·2 1 · 4 1 · 3 1 · 2

As shown in Table 7, simulation results confirmed the initial expectations. The performance of the rules began to differ. Among the due-date assignment rules tested TWK, NOP, and PPW produced better mean tardiness than the CON and SLK rules. Similarly, the MOD

scheduling rule was better than the EDD rule especially when k is small (k = 3 and 4). The differences in the per-formance of due-date assignment rules were greater with the EDD scheduling rule (Table 7). Also, the differences between the rules (both the due-date and scheduling rules) increased as the due-date tightness increased.

Case 3. Increasing the variance of processing times

It is known from job-shop studies that the variance of the processing time affects the relative performance of the scheduling rules. Most of the scheduling rules utilize operation time related information to prioritize the jobs. Moreover, some of the rules, such as MOD, are very sensitive to the variance of the processing time distri-bution. In the scheduling literature, the due-date assign-ment rules were not tested at varying levels of operation time variances; there was some expectation in this study that an increase in the variance of operation time distri-butions would affect the relative performances of due-date assignment rules.

To test the above conjecture, the variance of the pro-cessing time distribution was increased to 8 · 64 ( 40 % of mean) from the original value of6·48 (30% of the mean) and the simulation experiments were repeated under this new condition. Again, FCFS was used as the AGV rule. Utilization rates corresponding to the machines and the AGV system were 85 and 87 · 5 % , respectively.

As shown in Table 8, the performances of due-date assignment rules were quite different under the high variability. Not only the due-date assignment rules differed but the due-date scheduling rules EDD and MOD produced different mean tardiness performances.

Table 8. Mean tardiness performance (in minutes) of the due-date assignment rules when the coefficient of variance is 40 % .

Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWK NOP PPX

3 EDD 240·2 165·2 128·0 172 · 3 149 · 1 MOD 127·8 131 · 6 84·7 89·0 91 ·O 4 EDD 162·7 90·8 71 ·0 109·7 87·0 MOD 75·3 68 · 1 64· 1 67·1 64·8 5 EDD 101 · 7 44·3 35·2 67·8 44·9 MOD 42·4 34·2 27·7 25·2 44· 1 6 EDD 58·9 20·5 21 · 8 25·0 16 · 1 MOD 22·3 13·9 13·3 13·7 12·6

In general, TWK, NOP, and PPW were better due-date assignment rules than CON and SLK irrespective of the due-date scheduling rules. It is interesting to notice the crossover effect between TWK and PPW. While TWK was better than PPW at low values of flow allowances, PPW yielded slightly better mean tardiness than TWK at the loose due-dates. Between the two due-date scheduling rules tested, MOD always produced better mean tardi-ness performance. However, its superior performance over the EDD rule reduced as the due-date tightness decreased.

Case 4. Reducing the AGV load

Both the machines and AGV system control the material flow in an FMS. However, the degree of the control changes depending upon the current load levels of these subsystems. At one time machines may be highly loaded and therefore dominate the scheduling system. But at another time the AGVs may be a bottleneck and eventually drive the scheduling system. Thus, as the fourth condition, the AGV load was reduced to provide more opportunities for the machine scheduling rules ( or due-date scheduling rules) to dominate the due-date formance of the system. It was expected that the per-formance of due-date assignment and scheduling rules would begin to differ. To accomplish this, the AGV speed was increased to 75 from 60 ft/min. The resulting average AGV utilization was approximately 82 · 5 % .

As can be seen in Table 9, there was not much differ-ence between the performance of the due-date assign-ment rules. Even though TWK, NOP, and PPW produced slightly better mean tardiness than SLK and CON at the tight due-date (k = 3), their performances appeared to be very similar when the value of the due-date tightness parameter increased. Between the two due-date scheduling rules tested, MOD, which has SPT characteristics, resulted in a considerable mean tardiness

Table 9. Mean tardiness performance (in minutes) of the due-date assignment rules at reduced AGV load level.

Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWK NOP PPW

3 EDD 95·6 86·9 71·3 79·9 81 · 2 MOD 59·3 53·8 50·3 53·5 51 · 5 4 EDD 40·3 33·9 22·8 27 ·9 25·9 MOD 26 · 1 22·2 16·7 19·4 19·0 5 EDD 13·3 9·9 4·9 7·6 8·5 MOD 8·7 7·8 4·4 5·4 5·3 6 EDD 3·2 1 · 8 1·2 1 · 5 1 · 0 MOD 2·3 2 · 1 1·2 1 · 3 1 · 1

improvement over the EDD rule when k = 3. However, at the other values of tightness parameter, EDD per-formed competitively with the MOD rule. It produced the minimum mean tardiness with the CON and SLK due-date assignments rules.

Case 5. Simultaneously increasing the queue capacity and the vari-ance of processing time, and reducing the AGV load

For the last case, all the changes discussed before were applied simultaneously. Recall that this experimental condition was derived from the standard condition by increasing the queue capacity and the variance of the processing time and reducing the AGV load. These changes were made to test the difference in the perform-ance of due-date assignment rules.

As shown in Table 10, TWK, NOP, and PPW resulted in the better mean tardiness compared to CON and SLK, irrespective of the due-date scheduling rules. Furthermore, among these three rules, TWK minimized

Table 10. Mean tardiness performance (in minutes) of the due-date assignment rules at reduced AGV load level and increased

queue capacity and variances of processing times. Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWK NOP PPW

3 EDD 93·0 99·6 87·2 85·6 92·3 MOD 79·9 71·9 63·2 70·6 68·3 4 EDD 41·3 46·5 40·3 37·1 41 ·4 MOD 63·5 38·6 36·9 35·8 39·6 5 EDD 15·2 18 · 1 13·0 16·8 10·6 MOD 30·3 25·7 19·6 17·1 17·3 6 EDD 4·6 6 · 1 7·3 5·3 5·6 MOD 12·2 16·9 9·5 9·6 9·3

FMS due-date scheduling 141 the mean tardiness at varying levels of the tightness

par-ameter. The resulting mean tardiness improvements by TWK were greatest when the tightness parameter (k) was small.

The relative performance of the due-date scheduling rules were also quite different. In general, MOD outper-formed the EDD rule. Except for very loose due-dates

(k = 6), it provided a considerable mean tardiness improvement over EDD regardless of the due-date assignment rule and the tightness parameter used.

4. 2. A nary sis of due-date assignment rules using exponential()! distributed processing times

In the previous sections, the normal distribution was used to generate the processing times. However, the exponential distribution is also a commonly used pro-cessing time distribution in the literature. In fact, most of the experimental studies which investigated the due-date performances of scheduling rules assumed exponen-tially distributed processing times (Baker 1984, Baker and Kanet 1984 ). In general, the exponential distribution possesses very large variability. It is known from the earlier studies on the job-shop and the results obtained in the previous sections that the relative performance of the rules are more significant under high variability. Thus, the objective of this section is to repeat the simulation experiments using the exponential distribution, and to observe the differences in the performance of the due-date assignment due to the increased variability.

Under the standard experimental conditions, the mean operation times and the AGV speed were determined in such a way that the average machine and AGV utiliz-ation rates were kept at 85 and 87 · 5 % , respectively. However, during the initial simulation runs, the system was saturated for all rules under these conditions. The standard conditions were changed by reducing both the machine and AGV load. At the new conditions, the mean operation time was reduced from 20 · 60 to 19 · 03 min and the AGV speed was increased from 60 to 65 ft/min. This resulted in average machine and AGV utilizations of 7 5 and 82 % , respectively.

The FMS system was simulated under these con-ditions. Again, five due-date assignment rules were com-pared at varying levels of flow-alowances ( due-date tightness) by using the different due-date scheduling rules. Recall that the due-date scheduling rules refer to the machine scheduling rules in this study. FCFS was used as the AGV scheduling rule.

The relative performance of the rules against the mean tardiness measure are presented in Table 11. The results indicated that not only did the relative performance of the due-date assignment rules become more significant,

Table 11. Mean tardiness performance (in minutes) of different due-date assignment rules using FCFS as the AGV rule.

Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWK NOP PPW EDD 246·2 232·7 202·2 223·0 188·7 SLK 243·2 285·5 195·5 244·7 263·1 3 SCR 420·5 274·3 223·0 301·4 263·3 MOD 80·6 65·9 70·7 66 · 1 58 · 1 S/OPN 253·2 236·9 207·5 261·6 250·47 EDD 177·7 167·1 108· 1 157·7 145·5 SLK 174·3 214·9 124·5 186·6 165·1 4 SCR 312·6 168·6 132·9 257·2 170·2 MOD 53·3 40·2 37·2 48·4 37·7 S/OPN 199·3 171 · 5 100· 5 179 · 4 146·8 EDD 122·9 115 · 3 64·9 99·9 106·2 SLK 119 · 1 157·8 78·0 103 ·5 89·9 5 SCR 143·0 157·3 86·2 125·4 156·9 MOD 33·6 33·0 28·3 31 ·4 26·5 S/OPN 122·0 92·7 65·2 105·6 95 · 1 EDD 36·6 35·0 26·6 24·9 25·5 SLK 35·7 32·6 21 · 9 38·2 32·2 6 SCR 50·2 44·7 40·7 42·2 45·9 MOD 17·8 14·0 9·9 17·0 13·6 S/OPN 38·0 33 · 1 19·6 37·4 27·7

but also mean tardiness increased with exponentially dis-tributed processing times (refer to Figures 2 and 3 for comparison of normally and exponentially distributed cases). Recall that the system was lightly loaded in the exponential case but yielded higher mean tardiness than the normally distributed case. This is primarily due to the characteristics of the exponential distribution (high coefficient of variation).

In general, TWK outperformed the other due-date assignment rules irrespective of due-date tightness and the due-date scheduling rule. PPW produced the second best mean tardiness performances in most of the con-ditions tested. However, its relative performance, com-pared to SLK and NOP, changed with different combinations of the scheduling rules at varying levels of due-date tightness. CON performed poorly compared to the other rules.

Among the scheduling rules tested, MOD yielded the best tardiness performance. The superior performance of the MOD rule was due to its SPT characteristic under the tight due dates. While the SCR rule performed very poorly, the relative performance of SLK, EDD, and S/OPN changed with the due-date assignment rules at the varying levels of the due-date tightness.

The due-date assignment rules were further tested by using different AGV scheduling rules. First, LQS was used as the AGV rule. The simulation results (Table 12)

142 ~ -250 M e

a

200 n t 150a

r

d

i

100 n es

50s

4 5 6 Due-date tightness (k)Figure 2. Mean tardiness performance of CON( x ), SLK('), TWK( 0 ), NOP( I) and PPW( +) with EDD machine scheduling rule (normally distributed case).

250

M

e

a

200n

t

150a

r

d

i 100n

e

s

50s

0 3 ·-z.+-._

4 --.:--. . ,..

_ 5 6 Due-date tightness (k)Figure 3. Mean tardiness performance of CON( x ), SLK( · ), TWK( 0 ), NOP( I) and PPW( +) with EDD machine scheduling rule (exponentially distributed case).

show that the mean tardiness performance of all the rules were improved with the LQS rule compared to FCFS (Table 11 ). Among the due-date assignment rules, TWK achieved the minimum tardiness in most of the con-ditions tested. PPW yielded the second best performance and this was followed by the NOP and SLK rules. The CON rule performed poorly compared to the other rules. On the other hand, MOD was still the best due-date scheduling rule since it improved the mean tardiness

sig-nificantly. SCR performed poorly. The performance of the other scheduling rules, EDD, SLK, and S/OPN, changed with the different combinations of scheduling rules at the varying values of tightness.

Finally, the simulation experiments were repeated using the due-date scheduling rules as the AGV rules. Under this condition, the same due-date scheduling rule was used both for the machine and AGV scheduling rule. As shown in Table 13, TWK minimized the mean

tardi-FMS due-date scheduling 143

Table 12. Mean tardiness performance (in minutes) of different due-date assignment rules using LQS as the AGV rule.

Due-date assignment rules Flow-allowance Due-date

parameter k rules CON SLK TWK NOP PPW

3 4 5 6 EDD SLK SCR MOD S/OPN EDD SLK SCR MOD S/OPN EDD SLK SCR MOD S/OPN EDD SLK SCR MOD S/OPN 170·2 172·3 196·5 76 · 1 188·7 110 · 3 110·5 154·4 41 ·9 121 ·4 66·0 65·0 90·0 27·9 64·2 36·6 35·7 50·2 17·8 37 ·9 158·9 165·3 181 · 7 59·3 171 ·6 101 · 7 103·3 121 · 9 34·5 103 · 7 65·9 59·9 73·2 20·2 54·0 35·0 32·6 44·7 14·0 33 · 1 116·3 152 · 1 155·8 55·6 137·2 70·3 66·3 94·3 32·2 62·2 35 · 1 42·7 53·5 19·8 33·5 26·6 21 ·9 40·6 9·9 19·6 160·5 170·4 199·4 56 · 1 173·0 92·7 102·5 128 · 1 34·5 106·3 53·6 60·8 66·2 23·4 56·2 24·9 38·2 42·2 17·0 37·4 141 · 1 163·2 189·6 52·7 157·3 105·5 93·9 109·5 30·5 99·7 43·5 50·0 72·5 20·4 62·4 25·5 32 · 1 45·8 13·6 27·7

Table 13. Mean tardiness performance (in minutes) of the due-date assignment rules using the due-due-date scheduling rules as the

AGV rules. Flow-allowance Due-date parameter k 3 4 5 6 rules EDD SLK SCR MOD S/OPN EDD SLK SCR MOD S/OPN EDD SLK SCR MOD S/OPN EDD SLK SCR MOD S/OPN

Due-date assignment rules CON SLK TWK NOP PPW 226·9 230·0 387·2 71·5 222·1 159·5 160·2 191 ·O 45·9 173·0 105·4 105·3 137·1 27 ·O 98·7 65·2 66·4 86·0 15·2 59·5 187·4 225·2 315·7 60·8 198·9 123·5 155·9 179·6 37·6 128·2 76·5 101 ·4 102 · 7 19·0 89·7 43·9 62·8 88·4 11 · 8 38·3 163·6 188·6 198·2 56·2 170·4 105·7 114· 5 111 ·8 29·5 81 ·6 55·5 54·9 84·7 21 ·O 43·4 24 · 1 40·4 52·2 9·6 38·2 186·5 208·2 298·8 60·0 210·7 140 · 1 164·3 199·5 37·7 158·6 90·4 91 ·9 123·2 24·5 86·4 60·7 57·8 87·3 19·6 47·3 213·4 225·3 245·4 57·0 219·4 127·3 130·2 178·6 31 · 2 119 ·9 82·2 80·2 119 · 1 16·7 81 · 5 50·9 48·5 61 · 4 10·6 51 · 5

ness with any due-date scheduling rule at any value of due-date tightness parameter. Similarly, MOD outper-formed any other due-date scheduling rule irrespective of the due-date assignment method and the value of tightness parameter. While the CON due-date assign-ment rule and the SCR due-date scheduling rule resulted in the poorest mean tardiness, the relative performances of the other rules changed with the level of due-date tightness. It appears that EDD performed well with the SLK due-date assignment rule. Also, PPW is a very effective due-date assignment method when used with the MOD scheduling rule.

5. Conclusions and directions for future research

In this paper, the performances of several due-date assignment rules and machine/ AGV scheduling rules were studied usmg an FMS simulation model. The results indicate that none of the due-date assignment or due-date scheduling rules exhibited dominating perform-ance with normally distributed processing times. As the variance of the processing time distribution or the queue capacity increased, or the AGV load was reduced, the relative performances of the rules differed.

In the exponential case, the TWK due-date assign-ment rule minimized the mean tardiness for most of the conditions tested. PPW produced the second best per-formance and this was followed by NOP and SLK. The CON rule was the worst of all the rules tested. The superior performance of TWK is quite reasonable since it is more sensitive to the mean and variance of the total processing time than the other due-date assignment methods. Accentuated differences for due-date perform-ances of the due-date assignment and scheduling rules in the exponential case indicated that the variance of the operation time was the major factor in separating the performance of the rules.

The flow-allowance level ( or due-date tightness) was also a very important factor in evaluating the rules. As the flow-allowance decreased, the differences among the performances of the rules became significant. There was also some evidence that improving the mean flow-time also improved due-date performance. This was noticed when LQS was used as the AGV rule. Moreover, with the tight due-dates, the rules which minimized the flow-time, also resulted in better due-date performances.

Among the machine due-date scheduling rules tested, MOD produced better mean tardiness. Among the AGV rules tested, LQS outperformed the other rules. Even though LQS did not use the due-date information, it pro-duced the best results, indicating that the mean tardiness could be improved significantly by minimizing the mean flow-time.

144

The resulting performances of TWK due-date assign-ment rule and the MOD scheduling rule in the exponential case also confirmed the previous job-shop studies (Kanet and Christy 1988, Baker 1984, Baker and Kan et 1984).

While there are a number of other assignment and scheduling rules that could have been studied in this paper, those that were selected had been shown to be effective in other studies. The results presented in this paper are valid under the experimental conditions described. Hence there is a need for further research to develop new rules and continue to test the existing ones under different experimental conditions against the various criteria. Such research should address the impact of varying system parameters such as arrival rates, pro-cessing time parameters, and the different FMS configurations.

References

BAKER, K. R., 1984, Sequencing rules and due-date assign-ments in a job shop. Management Science, 30, 1093-1104. BAKER, K. R., an<l BERTRAND,

J.

W. M., 1981, Aninvesti-gation of due-date assignment rules with constrained tightness. journal of Operations Management, 1, 109-120. BAKER, K. R., and KANET

J.

J.,

1984, Improved decisionrules in a combined system for minimizing job tardiness.

International Journal of Production Research, 22, 917 - 921. BAKER, K. R., and SCUDDER, G. D., 1990, Sequencing with

earliness and tardiness penalties: a review. Operations Research,

38, 22-36.

CHOI, R. H., and MALSTROM, E. M., 1988, Evaluation of traditional work scheduling rules in a flexible manufacturing system with a physical simulator. Journal of Manufacturing Systems, 7, 33-45.

CONWAY, R. W., 1963, Some tactical problems in digital simulation. Management Science, 10, 47-61.

KANET,

J. J.,

1982, Toward understanding lead times in MRP systems. Production and Inventory Management, 23, 1-14. KANET, j.J.,

and CHRISTY, D. P., 1989, Manufacturing systems with forbidden early shipment: implications for setting manufacturing lead times. International Journal of Pro-duction Research, 27, 783 - 792.KUSIAK, A., 1986, Scheduling flexible machining and assembly system. Proceedings of the Second ORSA/TIMS Confer-ence on Flexible A1anufacturing Systems: Operations Research Models and Applications (Elsevier Science Publishers, Amsterdam) pp. 521-526.

KUSIAK, A., and CHEN, M., 1988, Expert systems for plan-ning and scheduling manufacturing systems. European journal of Operations Research, 34, 113-130.

MIYAZAKI, S., 1981, Combined scheduling system for reducing job tardiness in a job shop. International Journal of Production Research, 19, 201-211.

MONTAZERI, M., and WASSENHOVE, L. N. V., 1990, Analysis of scheduling rules for an FMS. International journal of Production Research, 28, 785-802.

PEGDEN, C. D., 1985, Introduction to SIMAN (Systems Model-ing Corporation, State College, PA).

RAMAN, N., TALBOT, F. B., and RACHAMADUGU, R.

v.,

1986, Simultaneous scheduling of machines and material handling devices in automated manufacturing. Proceedings of the Second ORSA/ TIMS Conference on Flexible Manufacturing Systems.· Operations Research Models and Applications, (Elsevier Science Publishers, Amsterdam pp. 321-332.RANK Y, P. G., 1986, Computer Integrated Manufacturing,

(Prentice-Hall, Englewood Cliffs).

RANKY, P. G., 1983, A real-time, rule-based FMS operation control strategy in CIM environment-Part I. International Journal of Computer Integrated Manufacturing, 1, 55- 72.

Ro, I., and KIM,

J.,

1990, Multi-criteria operational control rules in fexible manufacturing systens (FMSs). International Journal of Production Research, 28, 47 -63.SABUNCUOGLU, I., and HOMMERTZHEIM, D., 1989a, An investigation of machine and AGV scheduling rules in an FMS. Proceedings of the Third ORSA/ TIMS Conference on Flexible Manufacturing Systems: Operations Research Models and Applications (Elsevier Science Publishers, Amsterdam), pp. 261-266.

SABUNCUOGLU, l., and HOMMERTZHEIM, D., 1989b, Expert simulation systems: recent developments and applications in flexible manufacturing systems. Computers and Industrial Engineering, 16, 575-585.

SABUNCUOGLU, l., and HOMMERTZHEIM, D., 1992, Exper-imental investigation of FMS machine and AGV scheduling rules against the mean flow-time criterion. Internationaljournal of Production Research, 30, 161 7 -1635.

SABUNCUOGLU, l., and HOMMERTZHEIM, D., 1993, Exper-imental investigation of an FMS due-date scheduling pro-blem: evaluation of machine and AGV scheduling rules.

International Journal

~f

Flexible Manufacturing Systems, 5,301-323.

SINGHAL, K., FINE, C. H., MEREDITH,

J.

R., and SURI, R., 198 7, Research and models for automated manufacturing.Interfaces, 17, 5-14.

SMITH, M. L., RAMESH, R., DUDEK, R. A., and BLAIR, E. L., 1986, Characteristics of U.S. flexible manufacturing systems-a survey. Proceedings of the Second ORSA/TIMS Con-ference on Flexible Manufacturing Systems: Operations Research

Models and Aplications (Elsevier Science Publishers, Amsterdam), pp. 477-486.

SMITH, M., and SEIDMANN, A., 1981, Due-date selection procedures for job shop simulation. Computers and Industrial Engineering, 7, 199-207.