T.C.

Haziran-2018 KONYA

iv 2018, 63 Sayfa Prof. Dr. ERSOY ev tipi , ne, s deneysel olarak

ahip 0.50C olurken, eliptik kesitli borulara sahip 3.00C

d

Anahtar Kelimeler: Enerji verimi

v ABSTRACT MS THESIS

EXPERIMENTAL INVESTIGATION OF THE EFFECT OF THE

EVAPORATORS WITH ELLIPTICAL AND CIRCULAR CROSS-SECTIONAL PIPES ON PERFORMANCE IN A HOUSEHOLD REFRIGERATOR

THE GRADUATE SCHOOL OF NATURAL AND APPLIED SCIENCE OF VERSITY

THE DEGREE OF MASTER OF SCIENCE IN MECHANICAL ENGINEERING Advisor: Assist. Prof. Dr.

2018, 63 Pages Jury

ERSOY

Assist. Prof. Dr. Assist. Prof. Dr.

In the present study, it is purposed to experimentally determine the effect of two different types of heat exchangers in the evaporator of a household refrigerator using R600a on cooling capacity, coefficient of performance and indoor temperature of the refrigerator. The flow rate measured for the evaporator with the elliptical cross-sectional pipes is 10.70% less than the evaporator with the circular cross-sectional pipes at the first run time of the compressor and 12.94% less at the third run time. The COP value for the evaporator with the circular cross-sectional pipes is 4.25% higher than the evaporator with the elliptical cross-sectional pipes at the first run time and 5.96% higher at the third run time. Furthermore, while the effect of supercooling is 0.50C in the evaporator with circular section pipes, it is 300C in the evaporator with elliptical section pipes. However, the evaporator with the elliptical cross-sectional pipes has consumed less energy than the evaporator with the circular cross-cross-sectional pipes by considering the refrigeration of the same volume via both evaporator types in terms of power analysis. Furthermore, the compressor has brought the internal volume temperature of the refrigerator to the desired value by operating for a shorter period. It has determined that the electricity consumption of the compressor was 58.2W per hour for the evaporator with the elliptical cross-sectional pipes, 61.1W per hour for the evaporator with the circular cross-sectional pipes. It is thought that the caused this improvement use of elliptical pipe, the increase of the overheating temperature in the cycle, and together effects of the fixation elements between the pipes acting like the finned pipe.

Keywords: Evaporator, Refrigeration capacity, Thermal camera, Elliptical geometry, Energy efficiency.

vi

yerde

in

da ler

D Dr

ez konusunun belirlenmesinde projenin fikir sahibi olan ve bana ran,

H. AK

Ar-Ge ekibine rim.

vii ... iv ABSTRACT ... v ... vi ... vii ... ix ... 1 ... 2 ... 3 ... 4 ... 5 ... 6 ... 8 ... 10 ... 19 3.1.Bu ... 19 ... 20 ... 22 ... 23 ... 24 ... 24 3.5.2. Datalogger ... 25 3.5.3. Logger Utility ... 27 3.5.4. Wattmetre ... 27

3.5.5. Coriolis Tip Debimetre ... 28

... 30

... 31

3.6. Termo-Ekonomik Performans Deneyleri ... 32

3.7. Belirsizlik Analizi ... 36 ... 40 ... 41 ... 48 ... 50 ... 57 ... 58

viii

... 61

... 63

KAYNAKLAR ... 64

ix Simgeler A Alan (m2) h Entalpi (kJ/kg) msa (bar,kPa) s Entropi (kJ/kg.K) ( C) t Zaman (h,s) T0 ) (W,kW) Verim

x - 3 K 4 5 6 elektr Elektrik E Ekserji fizik Fiziksel ke Kinetik enerji kim Kimyasal enerji

kond Kondenser max Maksimum min Minimum ort Ortalama pe Potansiyel enerji sa

xi

PLC

.

Sanayi ve Ticaret Bakanl taraf ndan Ev Tipi Buzdolaplar , Derin Dondurucular, Buzdolab Derin Dondurucular ve Bunlar n Bile imlerinin Enerji Etiketlemesine Dair Y netmelik kart lm t r.

Bu Fakat veriml -itli ta 1.1. 2013 toplam

elektrik ener 'unun evlerde ekil 1.2).

Evlerde kul %28'ini ve

ekil 1.3).

1.3 lektr nda, lkemizde 2013 n 12,6 milyar kWh ktedir. jisi , 1.2. n ursa: hermetik turucu ve tamame . Kar yapmayan

eklinde biriken havadak yar 1.4 dol . 1.2 harcayan makinelerdir.

1.4

,

ri ve

H z kontrol yap lan kompres rlerde genellikle do ru ak m motorlar , ind ksiyon motorlar ve senkron motorlar kullan lmaktad r. Kompres r silindir hacmi, buzdolab hacmi ve kullan lan so utucu

ba l olarak 2 cm3 ve 10 cm3aras nda de i .

1.2.2

s

1.5

yo

buharl

evaporat n deneyleri . l 1.6 B lar genell . ar

dirde kanat su donarak,

hava hareketi azal yerine getirememektedir. Elektrik ile kar eritme en

iki ucuna ve elektrikli rezistanslar . 1.2. istenilen 1.7

Sisteme yeteri kadar ga

aplarda

A

n belirlenmesiyle birlikt belirsizlik analizleri de hesaplanabilir duruma

. daire ve elips in Oyedepo ve ark. (2017) -1.5 m sistemd

minde ekserji veriminin %6.7-Arshad (2017) 12, 22 ve R--12 ve R- de -407C maksimumdur. Solmaz ve ark. (2016) d enerji ve ekserji gereklili Dogan ve ark. (2015)

birbirinden borular ile kesitli silindirler -Fluent elips kesitli a

Jha ve ark. (2015) Sonucunda R600a anal performans kats

. Sag ve ark. (2015)

utma sistemi ile .

-12,87, ekserji verimi ise % 6.6 11.24 da r. Saravanakumar ve Selladurai (2014) . Selimli ve ark. (2014) veren ve perfo . tucu da . mektedir gibi ev

seviyesi, bir boyunca . ava No-ta , -ki

verimli ile yeni

bu ametrelerin (Durmaz ve ark., 2013). Lin ve Jang (2002) el - Saboya ve Saboya (2001)

Rocha ve ark. (1997) analizini dairesel silindir ve elips sili

1600 Tan ve ark. (2012) Yang ve ark. (2011) ise ve bu incelemeyi Romero- , Bouris ve

ark. (2001), Tiwari ve ark. (2003), ve Juncu (2008)

Juncu (2008) Bouris ve ark. (2001) Hasan (2005) - inde Li ve ark. (2006) Nagarani ve ark. (2012) elips kesitli

kondenserler -Chu ve ark. (2009) -Matos ve ark. (2004) L kesitli boru Tao ve ark. (2007) laminer Tablo 2.1 Yazarlar

Matos ve ark. (2004) %13- Azalma

Lin ve Jang (2002) %4 - %8 Rocha ve ark. (1997)

Sohal ve O'Brien (2001)

%25-Chu ve ark. (2009) %13- % 29,2 ile %40,6 azalma

Tao ve ark. (2007)

Bahaidarah ve ark. (2006) Horvat ve ark. (2006) e Berbish (2011) Re<14100 ortalama %

Borrajo- ara sahip elips

Tala ve ark. (2012)

performans i

er

bir tanesi Porkhial ve ark. (2006)

r rejimde

rejimde

Melo ve ark. (1999) boru

-12, 134a ve

Hepbasli (2007) ekonomik analizidir.

dayanan EXCEM metodu R-314a kullanan ev tipi

ila 20 ekonomik hususlar

etik verimin %13,68 ile % Stegou-Sagia ve Paignigiannis (2005)

-404A, R-410A,

vriminde meydana gelen tersinmezlikleri

alizi olsa da

t

cihaz . Gerekli veriler datalogg

e

tma kapasitesi . Bu

l .

Deneylerde daire ve oval(elips)

deneyle . n mevcut olan - )`dur. Bu eksik olmas . Buhar Daha ta

proseslerden (Yamankaradeniz ve ark.,

1

So utma evr evrimi referans

. S k t izentropik oldu u

. K s lma prosesi de s ge i adyabatik

olarak kabul edilmektedir. Buharla t r c ve yo u turucuda bas n kay plar . 3.2. ve burada ta , . Bu proseslerin -s diyag -.

(a), T-P- -n 1- 2- 3- 4-h ortam . Y linde ak a sonra buharl ak ve kom

enerji ve ekserji

analizlerinde, P-h ve T- .

-3 ve 4-, 1-2 ve

3-evrimi

edilmektedir nin sabit entalpide

3.3

3 -s ve P-h

Ge

-e i

-

edir.

borularda boru boy

. ortamdan acmini . entropiyi etkilem . . Bun , s .

bu durum ihmal edilmektedir.

hacimden daha fazla .

.

3 sabit

basma valfinde, silin . 3.5. TS EN ISO 15502 deney sisteminde materyallerin 3.5.1. performans kadar test oda . deneylerin enerj 4

%1 . hassasi r. veriler veya i toplan halinde ki

veya uzaktan bilgisayar,

Tablo 3.1 acmi 54 m3 -%0,1 (25-98)%RH/ (20-Nem hassasiyeti %1

PLC, bilgisayar, harici harddisk

3.5.2. Datalogger

Datalogger aydeden

de kaydeden

eri, saha

Kaydetm

30

datalogger sayesinde veriler saniyelik olarak kaydedilmektedir.

.

5

Datalogger

z her andaki verinin .

9600Bd

RS232 , 15 m.PC ile veya hat modem veya GSM

KORUMA IP20

9-3.5.3. Logger Utility

6

Program sayesinde her bir

a periyotlarda ortalama veriler

3.5.4. Wattmetre

yon

7 0-4000W -10V analog veriye Tablo 3.3 Wattmetre Montaj Panel AC 0- -Frekans 58-62Hz 0-5Aac

3.5.5. Coriolis Tip Debimetre

no

lmektedir. A cihaz

ile Do

8 Coriolis tip debimetreler

kullanmakta ve Ne

ler vibrasyon

akan

. kuvvetler ndaki fark

hareket . mektedir. ma, U cak etkilememektedir.

9 Coriolis Coriolis Tablo Tablo 3.4 Hacim 125 bar -204 ile 204 25 1sn 3.5. Seebeck

10

Deney sisteminde K

3.5.

Deney sisteminde Mesens marka MPS500 tipi, 10 bar ve

0-olan, 12- ve 4-20 mA

.

11

3.6. Termo-Ekonomik Performans Deneyleri her iki deneyler ; a) Dairesel b) Elips c) d)Deney son Tez incelenecek ki -olarak , . TSEN-15502 iklimlendirilmi hangi edilmektedir.

13.

deney sistemindeki noktalar ilmektedir. Belirtilen noktalar

Burada h5

gerekmektedir. Bu

5= h4 (izentalpik)

kond) denklemi

ilk olarak k 2

2) aha sonra da kondenser

4 . Sistemde kondens 1, h2) bulun (3) (1) (2)

Sistemdeki evap) (4) Sistemdeki kompres belirten STKelektr (5) -(6) 3.7. Belirsizlik Analizi ; deneyi zlik ve den kaynaklanan ;

hatalar etki sayesinde fark edilebilir. ; deneyi

A olan (commonsensebasis) ve belirsizlik analizi (uncertaintyanalysis e . (Bilen, 2011). elirsizlik R etki eden n x1, x2, x3,...,xn belirsizlikler); , , ,..., ise, R wR ise;

olarak ifade edilebilir.

sistemlerinde en fazla hataya sebep olan parametr edilm

hesaplanan parametrelere) ili

belirsizlikler tespit edilebilir.

evap (7) (8) (9) (10) (11) (12) (13) evap ve (14)

evap ve

ve iklimlendirme o a b 4.1 a. Dairesel lips , es lips Seri imalatta borular

Dairesel tip boruda da

9 metre 9 metre 15mm 15mm 1 3,25 4.1. Deneyler 6 4.2

saniyede (5 saat 13 dakika lk

dakika 54 saniye 15 dakika

4.2 4.

ekil 4.4

4.3

4

4.5

4. 4.7 4. -25.48 -24.84 -26.29 -25.73 C 4.8

4.9 .

4.10 kondensere

4.1

4.11 Kondenser

-17.04 -20.54

se -20

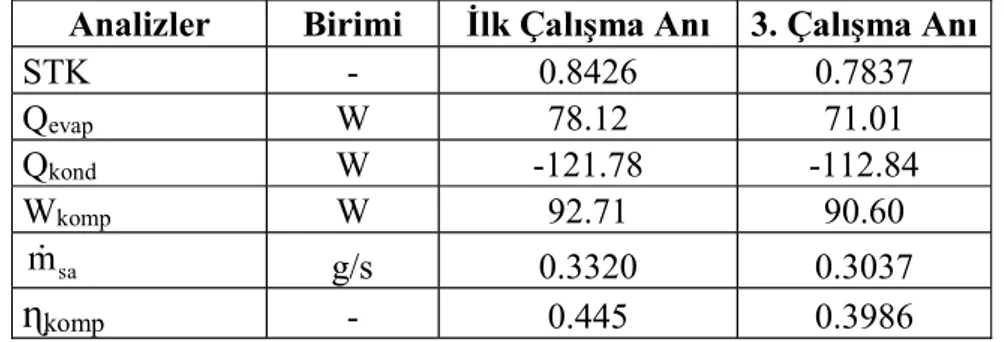

No-imini 18780 ortalama saatte 59.3 kWh, larak ise 535 kWh Tablo 4.2 Birimi 30.33 21.60 62.13 64.29 37.75 36.79 36.36 36,24 -25.48 -26,29 -25.62 -26,38 -18.32 -20,98 -18.41 -21,10 -18.37 -21,04 -19.27 -21,61 -19.43 -21,79 -19.35 -21,70 5,53 4,77 3,89 3,37 3,08 1,80 -0,13 0,34 3,03 2,43 3.08 2,54 0,38 0,38 bar 5,25 5,10 Kondenser bar 5,11 4,95 bar 5,13 4,96 bar 0,57 0,57 bar 0,53 0,51 26,09 25,88 No- -17,04 -20,54 kg/saat 1,20 1,09 W 106,11 104 53,37 56,51 -25,13 -26,09 -24,84 -25,73

4.1.1 Tablo 4.2 -Bu noktalardaki entalpi -4.13 Tablo 4.3 Belirlenen Parametreler 1 2 2s 3 4 5 7 21.60 64.29 92.87 36.79 36.24 -26.29 -25.73 P (bar) 0.38 5.1 5.1 4.95 4.96 0.57 0.51 h (kj/kg) 595,74 657,3 714,7 287,9 285,73 285,73 519,57 S ile bulunabilir.

kapasitesini ve

alt- ortalama 90.60W olarak

genel

komp =

komp =0,3986

Tablo 4.4 Analizler Birimi 3 STK - 0.8426 0.7837 Qevap W 78.12 71.01 Qkond W -121.78 -112.84 Wkomp W 92.71 90.60 g/s 0.3320 0.3037 komp - 0.445 0.3986 4.2. k borular ile 19980 saniye (5saat 33 dakika

4.14 coriolis debimetreden okun 4.15

4.15

4.16

dakika 36

saniye 105.29 dakika 43 saniye

ve ortalama

ortalama 29.06 ma 25.94 olarak , 4.17 4.18 4.18

4.19

4.20

ortalama -25.06 -22.45

-30.51 olarak girmekte, -27.08

4.21 girmekte 0.48 bar 4.21 4.22 62.23 65.05 36.13 . 4.22

5.14

4.23

- -21.43

periyot boyuncaki buz -21.2

No-Tablo 4.5

aliz sonucun saniyede

509 ir. Tablo 4.5 Birimi 29,06 25,94 62,23 65,05 37,19 36,13 33,30 33,67 -25,06 -30,51 -26,59 -27,90 -18,94 -21,86 -19,05 -22,00 -19,00 -21,93 -19,68 -22,52 -20,05 -22,85 -19,86 -22,69 5,37 4,60 3,75 3,15 3,09 1,63 0,15 0,31 3,18 3,06 3,11 2,55 0,38 0,37 bar 5,45 5,26 bar 5,33 5,14 bar 5,36 5,16 bar 0,58 0,54 bar 0,51 0,48 25,22 25,22 No- -17,96 -21,43 debisi kg/saat 1,08 0,97 W 105,29 100,86 53,52 57,56 -25,84 -27,05 -22,45 -27,08

Qevap W 74.27 64.69 Qkond W -112.15 -101.93 Wkomp W 91.89 87.46 g/s 0.2999 0.2689 komp - 0.4073 0.3820 lity 4.25 il 4.25 te

da derece fazla , dairesel elips %10.70 Hes cmini bir periyot boyunca -21.20 -20

, elips kesitli evapor

4.4.

26

27

100-

-100-120 elene kadar birinci ve ikinci susturucu

Bu

28 Elips kesitli evapora n -22 ile -13 -26 4.5. Belirsizlik Analizi ve Wkomp llikleri de Tablo 4.7 de ve Wkomp Qevap ve ST %5 Tablo 4.7 K tipi termoeleman -PT 100 -Mesens MPS500 0-6 bar %0.5

Debimetre Emerson H-PDS Seri 0.5-3000 kg/m3 %0.15

D70420N model

kondenser, gen

-dairesel Daha sonra tasarlanan elips

TS EN ISO 15502

,

ve son olarak 24 saa

dairesel kesitli borulara sahip 0.500C olurken, eliptik kesitli 3.00 borulu eva , %9.76 Hesaplanan STK eli , re i dairesel o-minimum 1 W --21.37 -20.30 1.396 kWh, y ise 509 . Dairesel, yani mevcut 1.466 kWh, 535 kWh enerji

5.2.

her yer

geom enerji tasarrufu

KAYNAKLAR

Arshad, M. O., 2017, Comparison of Second Law Efficiency and Exergy Analysis of Refrigerants R-12, R-22, R-407C Influenced by Evaporator Temperature for Vapour Compression Refrigeration System.

Bahaidarah, H. M., Ijaz, M. ve Anand, N., 2006, Numerical study of fluid flow and heat transfer over a series of in-line noncircular tubes confined in a parallel-plate channel,

Numerical Heat Transfer, Part B: Fundamentals, 50 (2), 97-119.

Berbish, N. S., 2011, Heat transfer and flow behavior around four staggered elliptic cylinders in cross flow, Heat and Mass Transfer, 47 (3), 287-300.

, 11-13.

Borrajo-

-drop characteristic of heat exchangers with elliptical tubes and smooth fins, , 15 (3).

Bouris, D., Papadakis, G. ve Bergeles, G., 2001, Numerical evaluation of alternate tube configurations for particle deposition rate reduction in heat exchanger tube bundles,

International Journal of Heat and Fluid Flow, 22 (5), 525-536.

Chu, P., He, Y., Lei, Y., Tian, L. ve Li, R., 2009, Three-dimensional numerical study on fin-and-oval-tube heat exchanger with longitudinal vortex generators, Applied Thermal

Engineering, 29 (5-6), 859-876.

Dogan, S., Ozgoren, M., Solmaz, O. ve Ozseker, G., 2015, Investigations of Flow around Cylinders having Circular and Elliptical Geometries for Multiple and Staggered Arrays via PIV Method. International Ege Energy Symposium & Exhibition. Afyonkarahisar, Turkey.

Durmaz, G., Uras, E. ve Erek, A., 2013, No-Ekin, A. B. v

Hasan, A., 2005, Thermal-hydraulic performance of oval tubes in a cross-flow of air, Heat

and mass transfer, 41 (8), 724-733.

Hepbasli, A., 2007, Thermoeconomic analysis of household refrigerators, International

journal of energy research, 31 (10), 947-959.

Horvat, A., Leskovar, M. ve Mavko, B., 2006, Comparison of heat transfer conditions in tube bundle cross-flow for different tube shapes, International Journal of Heat and

Mass Transfer, 49 (5-6), 1027-1038.

Jha, B. K., Khandelwal, N., Singh, P., Chaudhary, N. ve Ali, H., 2015, Performance of Refrigerator Using R-600a as Refrigerant, proceedings of 2015 2nd international

conference on recent innovations in science, engineering and management. JNU convention center, New Delhi.

Juncu, G., 2008, Unsteady heat transfer from an elliptic cylinder, International Journal of

louvered fin-and-tube heat exchangers having circular and oval tube configurations,

International Journal of Heat and Mass Transfer, 44 (22), 4235-4243.

Li, B., Feng, B., He, Y.-L. ve Tao, W.-Q., 2006, Experimental study on friction factor and numerical simulation on flow and heat transfer in an alternating elliptical axis tube,

Applied Thermal Engineering, 26 (17-18), 2336-2344.

Lin, C.-N. ve Jang, J.-Y., 2002, A two-dimensional fin efficiency analysis of combined heat and mass transfer in elliptic fins, International Journal of Heat and Mass Transfer, 45 (18), 3839-3847.

Matos, R., Vargas, J., Laursen, T. ve Bejan, A., 2004, Optimally staggered finned circular and elliptic tubes in forced convection, International Journal of Heat and Mass

Transfer, 47 (6-7), 1347-1359.

Melo, C., Ferreira, R., Neto, C. B., Goncalves, J. ve Mezavila, M., 1999, An experimental analysis of adiabatic capillary tubes, Applied Thermal Engineering, 19 (6), 669-684. Nagarani, N., Mayilsamy, K. ve Murugesan, A., 2012, Experimental Heat Transfer Analysis

on Annular Elliptical Fins and Comparison with Circular Fins, European Journal of

Scientific Research, ISSN, 143-156.

Oyedepo, S. O., Fagbenle, R., Babarinde, T. O., Odunfa, K., Leramo, R., Ohunakin, O., Ajayi, O., Babalola, P., Kilanko, O. ve Oyegbile, A., 2017, A COMPARATIVE STUDY ON THE PERFORMANCE OF THE DOMESTIC REFRIGERATOR USINGR600A AND LPG WITH VARYING REFRIGERANT CHARGE AND CAPILLARY TUBE LENGTH, International Journal of Energy for a Clean

Environment, 18 (4), 287-302.

Makine Teknolojileri Elektronik Dergisi.

Porkhial, S., Khastoo, B. ve Razavi, M. M., 2006, Transient response of finned-tube condenser in household refrigerators, Applied Thermal Engineering, 26 (14-15), 1725-1729.

Rocha, L., Saboya, F. ve Vargas, J., 1997, A comparative study of elliptical and circular sections in one-and two-row tubes and plate fin heat exchangers, International

Journal of Heat and Fluid Flow, 18 (2), 247-252.

Romero- ng, K. ve McClain, R., 2000, Effect of fin spacing on convection in a plate fin and tube heat exchanger, International Journal of Heat and

Mass Transfer, 43 (1), 39-51.

Saboya, S. M. ve Saboya, F. E., 2001, Experiments on elliptic sections in one-and two-row arrangements of plate fin and tube heat exchangers, Experimental Thermal and Fluid

Science, 24 (1-2), 67-75.

Sag, N. B., Ersoy, H., Hepbasli, A. ve Halkaci, H., 2015, Energetic and exergetic comparison of basic and ejector expander refrigeration systems operating under the same external conditions and cooling capacities, Energy conversion and

management, 90, 184-194.

analysis of an ejector expansion refrigeration system, International Journal of

Exergy, 24 (2-4), 201-215.

Saravanakumar, R. ve Selladurai, V., 2014, Exergy analysis of a domestic refrigerator using eco-friendly R290/R600a refrigerant mixture as an alternative to R134a, Journal of

Selimli, S., Recebli, Z. ve Gorken, M., 2014, Evaluation the effects of used refrigerants R134a and R600a in cooling systems on the system performance, Sigma, 32, 290-295.

Sohal, M. ve O'Brien, J., 2001, Improving air-cooled condenser performance using winglets and oval tubes in a geothermal power plant, Geothermal resources council

transactions, 25 (7), 1-7.

Solmaz, O. ve Ozgoren, M., 2012, Prediction of hourly solar radiation in six provinces in turkey by artificial neural networks, Journal of energy engineering, 138 (4), 194-204.

Solmaz, O., Karatas, M., Dogan, S., Ozgoren, M. ve Ozseker, G., 2016, Energy and Exergy Analyses of a Refrigerator Having Circular Cross Section Tube Bundle Evaporator. 8th International Ege Energy Symposium & Exhibition. Afyonkarahisar, Turkey. Stegou-Sagia, A. ve Paignigiannis, N., 2005, Evaluation of mixtures efficiency in

refrigerating systems, Energy Conversion and Management, 46 (17), 2787-2802. Tahseen, T. A., Ishak, M. ve Rahman, M., 2015, An overview on thermal and fluid flow

characteristics in a plain plate finned and un-finned tube banks heat exchanger,

Renewable and Sustainable Energy Reviews, 43, 363-380.

Tala, J. S., Bougeard, D., Russeil, S. ve Harion, J.-L., 2012, Tube pattern effect on thermalhydraulic characteristics in a two-rows finned-tube heat exchanger,

International Journal of Thermal Sciences, 60, 225-235.

Tan, X.-h., Zhu, D.-s., Zhou, G.-y. ve Zeng, L.-d., 2012, Experimental and numerical study of convective heat transfer and fluid flow in twisted oval tubes, International Journal

of Heat and Mass Transfer, 55 (17-18), 4701-4710.

Tao, Y., He, Y., Wu, Z. ve Tao, W., 2007, Three-dimensional numerical study and field synergy principle analysis of wavy fin heat exchangers with elliptic tubes,

International Journal of Heat and Fluid Flow, 28 (6), 1531-1544.

Tiwari, S., Biswas, G., Prasad, P. ve Basu, S., 2003, Numerical prediction of flow and heat transfer in a rectangular channel with a built-in circular tube, Journal of heat

transfer, 125 (3), 413-421.

. Yang, S., Zhang, L. ve Xu, H., 2011, Experimental study on convective heat transfer and

flow resistance characteristics of water flow in twisted elliptical tubes, Applied

: :

Yeri ve Tarihi : KADINHANI/01.06.1991

Telefon : 05068534038 Faks : 0332 8464171 e-mail : mehmetemrekaratas@hotmail.com Derece Lise : 2009 : 2014 : - Doktora : - Kurum 2014 2015 2015 UZMANLIK ALANI

Hidrolik, Malzeme Bilimi, Cnc teknolojileri

YAYINLAR

Energy and Exergy Analyses of a Refrigerator Having Circular Cross-Section Tube Bundle Evaporator 8th International Ege Energy Symposium and Exhibition 2016