• W I T H L E i S L A B P S O S S J . ;

h, kS>.£ c<‘4·«L M C

t:

SUBMITTED TO THE

DS?.a-BTM®?T OT MAlIASffliiSilT

AHT THE C4'£ADUA.TS SCEOOL OF

*" BUSEiSSS AXiinMISTS-iTflGST

OF BIL'SSNT UHIYiSSITY

J£

PABTIAL FUUIIILMEMT OF

TSS EEaUIEEMENTS

w f^T>, T H S D S G f R E E O '·^'MABTIE

B Y .

LY'Y *

T'="rpW''';S''-?-i Tf^'^r. ^ ' r M « O i . W ' · 0 * f·AC3GREGATE PRODUCTIOh4 PLANNING WITH LINEAR PROGRAMMING : A CASE STUDY

A THESIS

SUBMITTED TO THE DEPARTMENT OF MANAGEMENT AND THE GRADUATE SCHOOL OF BUSINESS ADMINISTRATION

OF BILKENT UNIVERSITY

IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF

MASTER OF BUSINESS ADMINISTRATION BY

HALUK ALPERAT FEBRUARY,1 OQl

T s

^5В

* Ач^

\

53

к

I c e r t i f y t h a t I h ave r e a d t h i s t h e s i s , and i n my o p i n i o n , i t i s f u l l y a d e q u a t e i n s c o p e and i n q u a l i t y a s a t h e s i s f o r t h e d e g r e e o f M a ste r o f B u s in e s s A d m i n i s t r a t i o n . A s s i s t . P r o f . D i le k Y e ld a n I c e r t i f y t h a t I h a v e r e a d t h i s t h e s i s , and i n my o p i n i o n , i t i s f u l l y a d e q u a t e i n s c o p e and i n q u a l i t y a s a t h e s i s f o r t h e d e g r e e o f M a ste r o f B u s in e s s A d m i n i s t r a t i o n . A s s i s t . P r o f . Can gim ga I c e r t i f y t h a t I h av e r e a d t h i s t h e s i s , and i n my o p i n i o n , i t i s f u l l y a d e q u a t e i n s c o p e and i n q u a l i t y a s a t h e s i s f o r t h e d e g r e e o f M a ste r o f B u s in e s s A d m i n i s t r a t i o n . A s s i s t . P r o f . E r d a l E r e l

A p p ro v e d b y "Lhe Graduat/e S ch o o l of" B u s in e s s Adnd.rils'LrÄt/iori P r o f . S U b ld e y Togan

ABSTRACT

AGGREGATE PRODUCTION PLANNING WITH LINEAR PROGRAMMING : A CASE STUDY H aluk A l p e r a t M. B. A. S u p e r v i s o r : A s s i s t . P r o f . D i l e k Y e ld a n F e b r u a r y 190 1 , 61 p a g e s The aim o f A g g r e g a t e P r o d u c t i o n P la n n i n g i s t o b a l a n c e t h e e x p e c t e d denuind and s u p p l y f o r a company. I f demand i s g i v e n , p r o d u c t i o n r a t e s , w o r k f o r c e s i z e s , and i n v e n t o r y l e v e l s a r e d e te rm in e d f o r e v e r y p e r i o d i n t h e p la n n i n g h o r i z o n i n o r d e r t o m in im iz e t h e t o t a l p r o d u c t i o n c o s t . I n t h i s s t u d y . A g g r e g a t e P r o d u c t i o n P la n n i n g i s a p p l i e d t o a s m a ll company t h a t p r o d u c e s s p a r e p a r t s f o r T o fa ^ and F o rd f a c t o r i e s . L in e a r Progran u n in g i s on e a p p r o a c h t o s o l v i n g t h e A g g r e g a t e P r o d u c t io n P la n n i n g p r o b le m w it h l i n e a r c o s t f u n c t i o n s . T h is s o p h i s t i c a t e d t e c h n i q u e , w h ich i s v e r y s im p le t o a p p l y , y i e l d s a c c u r a t e r e s u l t s i n a r e l a t i v e l y s h o r t p r o c e s s i n g tim e . I n s o l v i n g t h i s p r o b le m , t h e r e q u i r e d d a t a f o r t h e com pany a r e c o l l e c t e d and p r o c e s s e d . The c o s t f u n c t i o n s a r e fo u n d t o b e l i n e a r w h ich e n a b l e s t h e u s e o f LP. F i n a l l y , s e n s i t i v i t y a n a l y s i s i s p e r fo r m e d t o f i n d t h e a l l o w e d r a n g e s f o r demand f o r e c a s t s a s w e l l a s r e g u l a r and o v e r t im e w o r k in g h o u r s . K ey w o rd s: A g g r e g a t e p r o d u c t i o n p l a n n i n g , l i n e a r p ro g ra m m in g , l i n e a r c o s t f u n c t i o n s , sh ad ow p r i c e s

ÖZET

E30ĞRUSAL PROGRAMA iL E GENEL ÜRETİM PLANLAMASI : VAKA AN A LİZİ

Hâl uk Al p e r a t YUksek L i s a n s T e z i

Tez Y ö n e t i c i s i : Y rd . Doç. Dr. D i le k Y e ld a n Ç^ubat l â Q l > 61 sa y T a

G en el Ü re tim p l a n l a m a s ı n ı n amacı ► b i r i'irm a i ç i n g e r ç e k le ş m e s i b e k le n e n a r z v e t a l e b i n d e n g e le n m e s id ir . E ğ e r t a l e p v e r i l m i ş i s e , to p la m lir e t im m a l i y e t i n i en a z a in d irm e k a m a c ı y la . Ü re tim m i k t a r ı , i ş gtlcU v e s t o k m ik t a r ı b e l ir ie n m e k t e d i r . Bu ç a lı ş m a d a , T o fa ş v e F o rd f a b r i k a l a r ı n a yedek p a r ç a Ü r e t e n b i r f i r m a i ç i n G enel Ü r e t im P la n la m a s ı u y g u la n m a k t a d ır . D o ğ r u s a l P ro g ra m la m a , d o ğ r u s a l m a liy e t f o n k s i y o n l a r ı n a s a h i p b i r G en el Ü re t im P la n la m a s ı p r o b le m in in çözUmlİ i ç i n k u l l a n ı l a n y a k l a ş ı m l a r d a n b i r i d i r . U y g u la m a sı çok b a s i t o l a n bu g e l i ş m i ş t e k n ik çok k ı s a s U r e i ç i n d e k e s i n s o n u ç l a r v e r i r . Bu p r o b le m i çözmek i ç i n , f ir m a y a g e r e k l i b i l g i l e r t o p la n m ış v e i ş l e n m i ş t i r . M a l i y e t f o n k s i y o n l a r ı n ı n d o ğ r u s a l o ld u ğ u n u n b u lu n m a s ı, p r o b le m i çözmek i ç i n d o ğ r u s a l p ro g ra m la m a n ın k u l l a n ı l m a s ı n ı o l a s ı k ı l m ı ş t ı r . Son o l a r a k , t a l e p t a h m i n l e r i , norm al v e ek ç a lı ş m a s a a t l e r i i ç i n o l a s ı i n t e r v a l l e r i bulmak a m a c ıy la d u y a r l ı l ı k a n a l i z i

ACKNOWLEDGEMENT

I w o u ld l i k e t-o thank A s s i s t . РгоГ. D i le k Y e l dan Гог h er s u p e r v i s i o n i n t h e d e v e lo p m e n t o f t h e t h e s i s . I w o u ld a l s o l i k e t o thank A s s i s t . P r o f . Can Şım ga and A s s i s t . P r o f . E r d a l Er e l f o r t h e i r h e lp . F i n a l l y * I w o u ld l i k e t o thank t o D e p a rtm e n t o f Management o f B i l k e n t U n i v e r s i t y f o r p r o v i d i n g me an i n v a l u a b l e MBA e d u c a t io n .

TABLE OF CONTENTS

S u b J e e t P a g e

CHAPTER 1 - INTRODUCTION 1

CHAPTER 2 - LITERATURE SURVEY 7

LI n e a r D eci s i on R u le 8 2 _ 2 _ Management C o e r f i e i e n t s Model 12 2 _ 3 _ L i n e a r Pr o g r ammi ng 13 S i m u la ti on M o d els 15 2 _ A _ 1 _ P a r a m e t r ic P r o d u c t i o n P la n n i n g 15 2 _ 4 _ 2 _ S e a r c h E J ecision R u le 16 2 _ S _ P r o d u c t io n S w i t c h i n g H e u r i s t i c 17 CHAPTER 3 - INFORMATION ABOUT THE COMPANY IQ 3 _ 1 _ G e n e r a l In T o r m a t io n IQ 3 _ 2 _ C om pan y's P r o d u c t i o n P o l i c y 21 CHAPTER A - METHODOLOGY 23 C h o ic e o f LP 23 LP Model 25 -4_3_ D a ta C o l l e c t i o n 28 D a ta P r o c e s s i n g 30

-i_ 7 _ I n t e g e r Program m ing w it h B ra n e h -a n d -B o u n d T e c h n iq u e CHAPTER S - RESULTS 5 _ 1 _ S o l u t i o n o f t h e LP 5 _ 2 _ S e n s i t i v i t y A n a l y s i s S _ S _ 1 _ R ig h t Hand S i d e R an ges S _ 2 _ £ _ Shadow P r i c e s CHAPTER 6 - CONCLUSION REFERENCES APPENDIX - A APPENDIX - B 39 39 39 40 43 45 48 50

37

LIST OF TABLES

Number Name P a g e

1 EJemand F o r e c a s t s i n U n i t s App. A 51 2 P r o d u c t io n i n U n i t s App. A 51 3 I n v e n t o r y L e v e l s i n U n i t s App. A 52 4 P r o d u c t io n R eq u ire m e n t i n M an-H ours App. A 52 S F ix e d C o s t s o f P r o d u c t s App. A 52 6 A v a l 1a b l e Wor k i ng Hour s App. A 53 7 A v a i 1a b l e Over t i me Hour s App. A 53

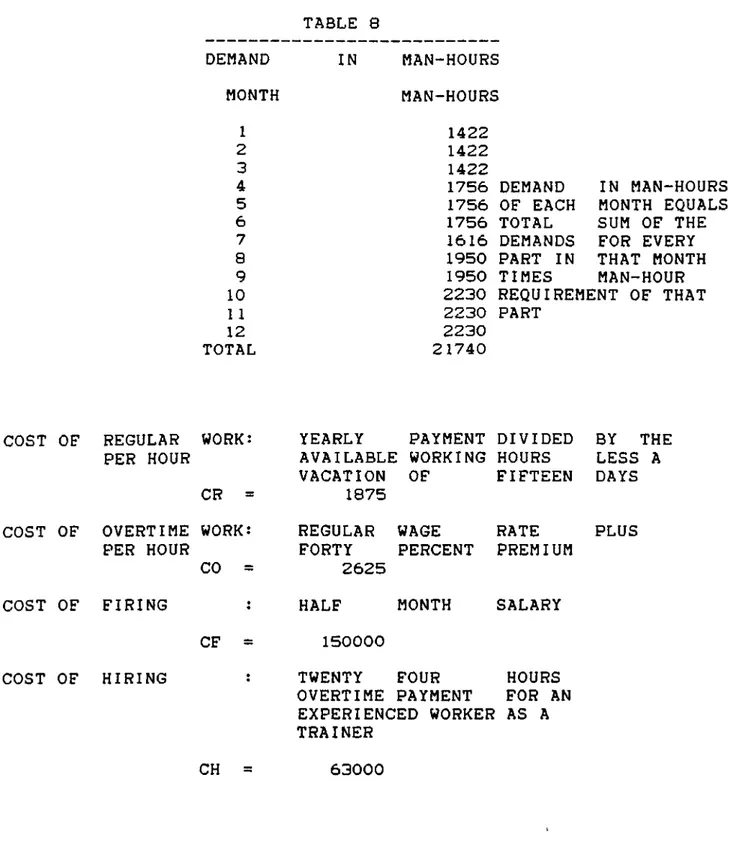

8 CJemand i n M an-H ours App. A 54

3 C o s t s p e r Y e a r App. A 55 10 C o s t o f t h e E x i s t i n g P o l i c y App. A 56 11 S o l u t i on o f LP 33 12 Demand F o r e c a s t S e n s i t i v i t y 40 13 R e g u la r W o rk in g H ours S e n s i t i v i t y 41 14 O v e rtim e W o rk in g H ours S e n s i t i v i t y 42 I S Demand F o r e c a s t s Shadow P r i c e s 43 16 R e g u la r W o rk in g H ours Shadow P r i c e s 44

LIST OF SYMBOLS

Ai. : A v a i l a b l e r e g u l a r w o r k in g h o u rs f o r e a c h w o rk e r i n month i C hour 'J Bi : A v a i l a b l e o v e r t im e w o r k in g h o u rs f o r e a c h w o rk e r i n month i C hour 'J C : T o t a l p r o d u c t io n c o s t f o r t h e e n t i r e p la n n i n g p e r i o d CTLDDi. : IDemand i n m an -h o u rs i n month i Chour D

I t : H ours o f p r o d u c t io n k e p t i n i n v e n t o r y i n month i C hour

XFi : Number o f w o r k e r s f i r e d i n month i XHi : Number o f w o r k e r s h i r e d i n month i

XOi : O v e rtim e w o rk in g h o u r s u s e d f o r p r o d u c t i o n i n month i ChourD

XRv : R e g u la r w o rk in g h o u r s u s e d f o r p r o d u c t io n i n month i Chour D

XWi : Number o f w o r k e r s i n month i c f : C o s t o f f i r i n g on e w o rk e r

Cl Ck Co : C o at o f h i r i n g one w o rk e r CTLD : T o t a l p r o d u c t io n c o s t i n month i CTLD

: I n v e n t o r y h o l d i n g c o s t t o k eep one hour p r o d u c t io n i n i n v e n t o r y

CTL / hourD

: O v e rtim e wage r a t e p e r hour CTL / hourD

: R e g u la r wage r a t e p e r hour CTL / hourl)

IN T R O D U C T IO N

A g g re g a t-e p la n n i n g i s m e d iu m -ra n g e e a p a e i t y p la n n i n g t h a t t y p i c a l l y c o v e r s a tim e h o r i z o n o f an y w h ere fro m 3 t o I S m onths. I t s g o a l i s t o e f f e c t i v e l y u t i l i z e t h e o r g a n i z a t i o n 's r e s o u r c e s t o s a t i s f y e x p e c t e d demand. P la n n e r s must d e c i d e on o u t p u t r a t e s , em ploym ent l e v e l s and c h a n g e s , i n v e n t o r y l e v e l s and c h a n g e s , b a c k o r d e r s and s u b c o n t r a c t i n g .

S p e c i f i c a l l y , t h e a g g r e g a t e p r o d u c t i o n p l a n n i n g p ro b le m c a n b e sum m arized a s f o l l o w s :

The demand f o r e c a s t Ft i s o b t a i n e d b y some a p p r o p r i a t e f o r e c a s t i n g t e c h n iq u e f o r e a c h d i s c r e t e p e r i o d t i n t h e p l a n n i n g h o r i z o n w h ich e x t e n d s o v e r T p e r i o d s . The p r o d u c t i o n l e v e l Pt, i n v e n t o r y l e v e l I t , and work f o r c e l e v e l Wt a r e d e t e r m in e d f o r p e r i o d s t = l , 2 , . . . , T w h ich m ininvize r e l e v a n t c o s t s o v e r t h e p la n n i n g h o r i z o n . A g g r e g a t e p r o d u c t i o n p l a n n i n g s o l v e s t h e p ro b le m a s a w h o le . P la n n e r s t r y t o a v o i d f o c u s i n g on i n d i v i d u a l p r o d u c t s o r s e r v i c e s . T h e r e f o r e , t h e p r o d u c t i o n sy ste m i s c o n s i d e r e d t o b e a s i n g l e p r o d u c t i o n f a c i l i t y t h a t p r o d u c e s a s i n g l e p r o d u c t C m u lt i - p r o d u c t f i r m s a r e t r e a t e d b y a g g r e g a t i n g i n d i v i d u a l p r o d u c t s t o some common u n i t su c h a s c o s t , c o n t r i b u t i o n , o r d i r e c t m ach in e h o u rsD . The c o n c e r n s o f a g g r e g a t e p l a n n e r s a r e t h e q u a n t i t y and

t im in g o r t h e f o r e c a s t e d CexpectedZ? demand. T h e ir p u r p o s e i s t o b a la n c e t h e e x p e c t e d demand and s u p p ly . They must b e a p p r o x im a t e ly e q u a l o v e r t h e e n t i r e p e r i o d » how ever t h e r e may b e d i f f e r e n c e s b e tw e e n them i n an y d i s c r e t e p e r i o d due t o f l u c t u a t i o n s i n demand.

I n r e s p o n s e t o f l u c t u a t i o n s i n demand* management may i mplement one o f t h e f o l 1owi ng s t r a t e g i e s :

Si^Hax>& a s t a t i c p r o d u c t i o n p ro g ra m ^ c o u p le d w it h an i n v e n t o r y l a r g e enough t o s a t i s f y t h e f l u c t u a t i n g demand. The i n v e n t o r y l e v e l w ou ld f l u c t u a t e a c c o r d in g t o t h e demand p a t t e r n * r e p le n is h m e n t b e i n g p r o v i d e d b y a c o n s t a n t f l o w fro m t h e p l a n t . T h is method i s g r e a t l y f a v o u r e d b y t h e p r o d u c t io n d e p a rtm e n t* s i n c e i t s i m p l i f i e s p la n n in g * e n s u r e s h ig h e r m achine u t i l i s a t i o n * a l l o w s b e t t e r s u p e r v i s i o n and c o n t r o l * and p ro m o tes a s e n s e o f s e c u r i t y among t h e w o rk e rs . H ow ever* t h e a v e r a g e s t o c k l e v e l i s h ig h * th u s t y i n g up a c a p i t a l and i n v o l v i n g h ig h c a r r y i n g c o s t s .

bD H avo a f l u e t u a t i n g p r o d u c t i o n p ro g ra m ^ t o c a t e r f o r t h e c h a n g in g demand* and k e e p a c o n s t a n t i n v e n t o r y l e v e l t o p r o v i d e a s a f e t y c u s h io n b e tw e e n p r o d u c t io n and m a rk e tin g . Any c h a n g e i n t h e demand p a t t e r n r e q u i r e s a c e r t a i n tim e l a g b e f o r e p r o d u c t io n can f o l l o w i t * and t h e s a f e t y s t o c k e n a b l e s management t o s a t i s f y demand i n t h e i n t e r i m p e r i o d . The s t o c k l e v e l d o e s n o t* s t r i c t l y s p e a k in g * rem a in c o n s t a n t * b u t t h e f l u c t u a t i o n s and t h e a v e r a g e s t o c k l e v e l a r e f a i r l y lo w *

comparefd wi+-h t h e p r e v i o u s method.

c:^ Wove o corn b irtcit icun o f tK& e y etem e, s o e s t o b r i n g t h e t o t a l o o s t s t o a minimum. The p ro b le m i s , t h e r e f o r e , t o a c h i e v e a p r o p e r b a la n c e b e tw e e n t h e amount oT f l u c t u a t i o n s i n t h e p r o d u c t io n p ro g ra m and t h o s e o f t h e s t o c k l e v e l . C o s t m in im iz a t io n i s t h e most im p o r t a n t f a c t o r i n s e l e c t i n g t h e a p p r o p r i a t e s t r a t e g y . C o st m in im iz a t io n i s a t t a i n e d b y o b t a i n i n g t h e r i g h t c o m b in a t io n o f c a p a c i t y - d e t e r m i n i n g f a c t o r s . T h e se f a c t o r s a r e e x p l a i n e d a s f o l 1o w s : iZ> O v e rtim e a l l o w s m a in t a in in g a s t e a d y b a s e o f e m p lo y e e s . W ith o v e r t im e , t h e need t o h i r e and t r a i n new w o r k e r s i s e l i m i n a t e d . The l e a r n i n g c u r v e e f f e c t i s u t i l i z e d . O v e rtim e i s m o s t ly u s e f u l when d e a l i n g w it h s e a s o n a l den^nd p e a k s . The w o r k e r s can b e more e f f i c i e n t i f t h e y a r e s a t i s f i e d w it h t h e i n c r e a s e i n t h e i r e a r n i n g s . On t h e o t h e r h an d , t h e r e may b e l e g a l o r u n io n r e s t r i c t i o n s w h ich p r e v e n t t h e w o r k e r s fro m w o r k in g l o n g h o u r s . O v e rtim e may a l s o r e s u l t i n lo w e r p r o d u c t i v i t y , p o o r q u a l i t y , and i n c r e a s e s i n a c c i d e n t s . i i D H i r i n g a n d F i r i n g o f ¡✓ orAier'S, o r t h e ch an ge i n t h e l e v e l o f work f o r c e , a l t e r s t h e c a p a c i t y i n d i s c r e t e te rm s. H i r i n g h a s r e c r u i t m e n t and t r a i n i n g c o s t s . T ra i,n in g c o s t s may i n c r e a s e d e p e n d in g on t h e d i f f i c u l t y o f t h e Job. The com pany I n c u r s f i r i n g c o s t s , w h ich a r e paym ents made t o t h e e m p lo y e e s

1 2l1 d off. M o re o v e r» l a y i n g ot'f* h a s b ad m o r a le e f 'f ’e c 'L s on "Lhe

r em ai n i n g wor k e r s .

i l l I) P c L T t - t i m ^ W or'h& rs can b e h i r e d f o r s i m p le t a s k s . They a r e p a i d l e s s th a n t h e r e g u l a r w o rk e rs i n b o t h h o u r l y w ages and f r i n g e b e n e f i t s . H ow ever» p a r t - t i m e w o r k e r s a r e n o t s u i t a b l e f o r J o b s r e q u i r i n g t r a n i n g and s k i l l . iv2) IiTL\>&intori&:s a l l e v i a t e t h e n e c e s s i t y o f im m e d ia te p r o d u c t io n . H ow ever» t h i s a l t e r n a t i v e a d d s s t o r a g e and i n s u r a n c e c o s t s » o p p o r t u n i t y c o s t o f money» d e t e r i o r a t i o n » b r e a k a g e and s p o i l a g e . v2) S u b c o n tr c L c t i Yi ^ i s a t e m p o r a r y c a p a c i t y i n c r e a s e » a make o r bu y q u e s t i o n . I t may c a u s e p ro b le m s o f h ig h c o s t and p o o r q u a l i t y .

A lt h o u g h » i n most c a s e s » c o s t mi ni n\i z a t i on i s t h e most im p o r t a n t d e t e r m in a n t o f a g g r e g a t e p r o d u c t i o n p l a n n i n g » t h e r e may b e o t h e r f a c t o r s i n v o l v e d . For e x a m p le » a com pany» w h ich m in im iz e s c o s t s w it h a c e r t a i n l e v e l o f i n v e n t o r y » may m a in t a in a h ig h e r l e v e l a s a s a f e t y c u s h io n i n o r d e r t o a v o i d s t o c k - o u t s » t h u s p r e v e n t i n g t h e l o s s o f f u t u r e o r d e r s .

I n t h i s s t u d y » a g g r e g a t e p r o d u c t i o n p la n n i n g i s a p p l i e d t o a company t h a t h a s e i g h t w o r k e r s . T h is company p r o d u c e s s p a r e p a r t s f o r T o fa ^ and F o r d f a c t o r i e s . The p e r i o d o f one y e a r i s d i v i d e d i n t o t w e l v e e q u a l i n t e r v a l s CmonthsD» and f o r e a c h i n t e r v a l » p r o d u c t i o n r a t e » work f o r c e s i z e and i n v e n t o r y l e v e l a r e d e te rm in e d . The g o a l i s t o m in im iz e t h e v a r i a b l e

p r o d u c t i o n c o s t . I n t h o c u r r e n t s i t u a t i o n , g e n e r a l m anager makes a l l th e p r o d u c t io n d e c i s i o n s . He d o e s n o t u s e h i r i n g o r f i r i n g o f w o rk e rs and k e e p s a s t a b l e w o r k fo r c e . He p r e f e r s o v e r t im e h o u rs t o meet t h e e x c e s s i v e demand w it h o u t an y J u s t i f i c a t i o n . C o n c lu s io n o f t h i s s t u d y com pares h i s s t r a t e g y w it h t h e recommended p la n o f a c t i o n . T h e re a r e s e v e r a l m ethods t o s o l v e t h e a g g r e g a t e p r o d u c t i o n p l a n n i n g p ro b le m . The b a s i c o n es a r e L i n e a r D e c i s i o n R u le , Management C o e f f i c i e n t s M o d e l, L i n e a r P rogram m in g, P a r a m e t r ic P r o d u c t i o n P la n n i n g , S e a r c h D e c i s i o n P u l e and P r o d u c t io n S w i t c h i n g H e u r i s t i c . I n t h e s e c o n d c h a p t e r , t h e s e a l t e r n a t i v e m ethods a r e e x p l a i n e d . When t h e p r o b le m i s d e f i n e d , one o f t h e a l t e r n a t i v e s w i l l b e s e l e c t e d f o r a p p l i c a t i o n . I n C h a p te r 3 , t h e p r o b le m i s d e f i n e d b y I n t r o d u c i n g t h e com pany, i t s p r o d u c t s , and p r o d u c t io n p r o c e s s e s . The c o m p a n y 's r e s o u r c e s , t h e demand f o r i t s s p a r e p a r t s and i t s e x i s t i n g p r o d u c t io n p o l i c y a r e g i v e n i n A p p e n d ix A. I n C h a p te r 4 , l i n e a r p rogran u n in g i s J u s t i f i e d a s t h e most a p p r o p r i a t e method f o r t h i s a g g r e g a t e p r o d u c t i o n p la n n i n g p ro b le m . A c c o r d i n g l y , t h e LP model i s c o n s t r u c t e d an d t h e u n d e r l y i n g a s s u m p t io n s a r e e x p l a i n e d . The o b j e c t i v e f u n c t i o n o f t h e model h a s n u m e r ic a l c o s t c o e f f i c i e n t s f o r r e g u l a r and o v e r t im e h o u r s . I n v e n t o r y h o l d i n g and h i r i n g and f i r i n g o f w o r k e r s . I n o r d e r t o f i n d t h e s e v a l u e s , t h e

r e q u i r e d d a t a a r e d e t e r m in e d and c o l l e c t e d i n t h e D ata C o l l e c t i o n s e c t i o n and p r o c e s s e d i n t h e D a ta P r o c e s s i n g s e c t i o n . H ence, a l l t h e i n p u t s a r e fo u n d . Tlie p a c k a g e p ro g ra m HYPERLINEX3 i s c h o se n f o r s o l v i n g t h e LP p ro b lem . T h is p ro gram u s e s B ra n c h -a n d -B o u n d t e c h n iq u e t o s o l v e p ro b le m s t h a t c o n t a i n i n t e g e r v a r i a b l e s a s i s t h e c a s e i n t h i s s t u d y . The B r a n c h -a n d -B o u n d t e c h n iq u e i s e x p l a i n e d a t t h e end o f C h a p t e r 4. I n C h a p te r S , t h e s o l u t i o n o f HYPERLINEXI) i s d e m o n s t r a t e d . S e n s i t i v i t y A n a l y s i s i s p e rfo rm e d t o d e te rm in e t h e sh ad o w p r i c e s and t h e r i g h t hand s i d e r a n g e s i n w hich t h e s o l u t i o n i s u n ch an ged.

I n t h e l a s t c h a p t e r , t h e r e s u l t s o f t h e a n a l y s i s a r e com p ared w it h t h e c o s t o f t h e e x i s t i n g p o l i c y and t h e c o n c l u s i o n s o f t h e s t u d y a r e d e l i n e a t e d .

2 LITERATURE SURVEY

R ôco^ni L i on o r Lhô w id osp roâid o x is L o n o ^ of* â.oorocfâ.Lâ p la n n i n g p ro b le m h as l e d t o p u b l i c a t i o n o f a number o f d i f f e r e n t a p p ro a c h e s f o r s o l v i n g i t . I n t h i s c h a p t e r * t h e s e a p p r o a c h e s a r e a n a ly z e d i n o r d e r t o s e l e c t t h e most a p p r o p r i a t e one f o r t h i s s t u d y . An e a r l y a p p ro a c h t h a t h as become a s t a n d a r d f o r c o m p a ris o n i s t h e l i n e a r d e c i s i o n r u l e CLDRD p r o p o s e d b y Hoi 11 Modi g l i an i » Muth and S i mon C1 Ô552). A 1 i n e a r p r o g r ammi ng

a p p r o a c h CLPD h as been a d v a n c e d b y Hansmann and H ess C1Ô60D. E x t e n s io n s t o t h e l i n e a r program m ing a p p r o a c h h a v e i n c l u d e d a t r a n s p o r t a t i o n f o r m u l a t i o n b y Bown^n C1Ô562) and* more r e c e n t l y * g o a l program m ing f o r m u l a t i o n s p r o p o s e d b y L e e and M oore C1Ô7AI) and Goodman C1Ô7G^. El mal eh and E i l o n C1Q74D h a v e s u g g e s t e d a s w i t c h i n g p r o c e d u r e f o r u s e i n i n d u s t r i e s i n w h ic h p r o d u c t io n i s l i m i t e d t o d i s c r e t e l e v e l s . O th e r a p p r o a c h e s w hich h ave b e e n p r e s e n t e d i n c l u d e t h e management c o e f f i c i e n t s model CMCMD d e v e lo p e d b y Bowman <I1063D* p a r a m e t r i c p r o d u c t io n p la n n i n g CPPPD b y J on es C1Ô67D and t h e s e a r c h d e c i s i o n r u l e b y T a u b e r t C1S68D.

2 _ 1 _ L i n e a r D e c i s i o n R u le

T h is a p p ro a c h i s p r o p o s e d b y H o l t , M o d i g l i a n i , Muth and Sim on C1S55I). C T h e r e f o r e , t h e m ethod i s c a l l e d t h e HMMS d e c i s i o n r u l e . 3 They h av e s u g g e s t e d t h a t t h e r e a r e f o u r c o s t f a c t o r s t h a t s h o u ld b e a c c o u n t e d f o r . ID R e g u la r p r o d u c t io n c o s t s i n p e r i o d t ctClD = Cl Wt The a s s u m p tio n h e r e i s t h a t t h e c o s t i s l i n e a r l y r e l a t e d t o t h e s i z e o f t h e work f o r c e Wt. An a d d i t i o n a l f i x e d c o s t te rm can b e a d d e d , b u t t h a t w o u ld n o t a f f e c t t h e s o l u t i o n . 2D H i r i n g and f i r i n g c o s t s i n p e r i o d t The c o s t o f i n c r e a s i n g o r d e c r e a s i n g t h e work f o r c e i s assum ed t o t a k e t h e fo rm o f t h e q u a d r a t i c f u n c t i o n ctC2D = C

2

CWi-Wt-iD* w h e re Wt-Wt-i i s t h e c h a n g e i n t h e l e v e l o f' t h e work f o r c e fr o m I n t e r v a l t - 1 t o t . H e r e , t h e c o s t i s assum ed t o b e s y m m e t r ic a l, n am ely anm c r e fa s e o r a. d e c r e a s e i n t h e work f o r c e b y a g i v e n amount i n c u r s t h e same c o s t . AsyTnmetry i n t h e c o s t f u n c t i o n can b e i n t r o d u c e d , b u t HMMS s t a t e t h i s a d d i t i o n a l c o n s t a n t p r o v e s t o b e i r r e l e v a n t i n o b t a i n i n g o p t im a l d e c i s i o n s . 33 C o s t o f O v e rtim e I t i s assum ed t h a t f o r a g i v e n p r o d u c t i o n l e v e l t h e r e i s a c o r r e s p o n d i n g d e s i r a b l e l e v e l o f l a b o u r r e q u ir e m e n t and t h a t t h e c o s t o f o v e r t im e and u n d e r t im e i s ctC33 = ca CPt-c^W O^ + c s Pt - co Wt 43 C o s t o f I n v e n t o r y I f t h e i n v e n t o r y l e v e l a t t h e end o f p e r i o d t i s I t th e n I t = It-4 + Pt - St w h e re I t - i : I n v e n t o r y l e v e l a t t h e end o f p e r i o d t - 1 Pt : P r o d u c t i o n i n p e r i o d t St : S a l e s o r sh ip m e n t i n p e r i o d t The t o t a l c o s t o f i n v e n t o r y , i n c l u d i n g h o l d i n g c o s t s and r u n o u t c o s t s , a r e th e n assum ed t o t a k e t h e q u a d r a t i c fo r m : Q

ctCl4-? = C7 CI tC

^'

S o l u t i o n : The t o t a l c o s t f o r p e r i o d t i s th e n Cl = ctCl 2)+ciC 22)+ctC 3D+ctC and o v e r T p e r i o d s T^

The p ro b le m p o s e d b y t h e HMMS model i s a s f o l l o w s : F in d t h e v a l u e s o f Pt and Wt t h a t w i l l m in im iz e t h e t o t a l c o s t f u n c t i o n . When d e r i v a t i v e s o f t h e q u a d r a t i c c o s t f u n c t i o n a r e t a k e n , l i n e a r e x p r e s s i o n s a r e o b t a i n e d and t h e s o l u t i o n ca n f i n a l l y b e re d u c e d t o t h e f o l l o w i n g fo rm : Pt = a o F t+ a iF t+4+ a2Ft+2+ . . . + g4Wt-i—h i l t - i + e iWt = boFt+biFt-M +b2Ft+2+. . . +giW t-4—h il t-4+e2

T h e s e a r e t h e p r o d u c t i o n and employment d e c i s i o n r u l e s , w h e re a l l t h e l o w e r c a s e l e t t e r s a r e c o n s t a n t s . Each e x p r e s s i o n c o n s i s t s o f a s e r i e s o f te rm s t h a t i n c l u d e t h e

i'or&cast/S f a r a g i v e n number a f fu t ,u r e p e r i o d s and t h e p r e s e n t l e v e l s ol' employment and i n v e n t o r y .

T h e r e a r e s e v e r a l c r i t i c i s m s o f t h i s method. For e x a m p le , Samuel E i l o n C1Q763 s a y s : "What i s t h e J u s t i f i c a t i o n f o r a ssu m in g t h a t t h e c o s t o f f i r i n g and h i r i n g i s a q u a d r a t i c f u n c t i o n ? HMMS Cl 9601) s u g g e s t t h a t t h e p l a u s i b i l i t y o f t h i s a s s u m p tio n r e s t s on t h e argum en t t h a t " r e o r g a n i z a t i o n c o s t s a r e more th a n p r o p o r t i o n a t e l y l a r g e r f o r l a r g e l a y o f f s th a n f o r s m a ll l a y o f f s ; and s i m i l a r l y t h e e f f i c i e n c y o f h i r i n g , m easured i n term s o f t h e q u a l i t y o f t h e e m p lo y e e s h i r e d , may f a l l when a l a r g e number o f p e o p le a r e h i r e d a t one t im e " Cp. 535; b u t why s h o u ld t h i s i n c r e a s e c o s t s ? Such an argum ent d e f e a t s t h e n o t io n o f e c o n o m ie s o f s c a l e , w h ich i s i n t u i t i v e l y f a r more p l a u s i b l e . A p a r t fro m t h a t , t h e r e i s no r e a s o n why t h e o v e r t im e c o s t s h a v e a q u a d r a t i c f u n c t i o n . I n most c a s e s t h e y a r e c l e a r l y l i n e a r . " Cp. 1225 Samuel E l i o n C l 9765 a d d s : "A n o th e r o b j e c t i o n i s t h a t t h e c o s t o f u n d e r t im e , n am ely t h e c o s t o f t h e work f o r c e b e i n g i d l e , i s a l s o e x p r e s s e d i n t h e c o s t f u n c t i o n . I t may b e a r g u e d t h a t t h e c o s t o f t h e l a b o u r f o r c e , w h eth er i t i s g a i n f u l l y em ployed o r n o t , i s a l r e a d y i n c lu d e d i n t h e p a y r o l l an d t h a t t o Im p o se a f u r t h e r p e n a l t y f o r u n d e rtim e i s n o t a p p r o p r i a t e . " Cp. 1225 ,

11

2 _ 2 _ Management C o e f f i c i e n t s Model

T h is method i s due t o Bowman C1S63:) and s e e k s t o e s t a b l i s h c o e f f i c i e n t s t h a t d e s c r i b e t h e m an agem en t's d e c i s i o n - m a k i n g b e h a v io u r i n a g i v e n e n v iro n m e n t. U s in g s t a t i s t i c a l r e g r e s s i o n a n a l y s i s t h e s c h e d u l i n g r u l e s a r e f i t t e d t o s im p le r e g r e s s i o n , su c h a s Pt = a iF t+ a a W t-i-a a lt-i+ a -t Wt - b iF t+ b a W i-i-b a l t - i+ b * w h e re t h e a * s and b * s a r e d e r i v e d fro m t h e r e g r e s s i o n s .

The a s s u m p tio n h e r e i s t h a t m a n agem en t's d e c i s i o n s a r e m a in ly g o v e r n e d b y t h e c u r r e n t work f o r c e , t h e f o r e c a s t f o r demand i n p e r i o d t , and t h e i n v e n t o r y l e v e l . The a x io m a t ic n o t i o n o f t h i s a p p ro a c h i s t h a t , a s Bowman C1S635 t h i n k s t h a t e x p e r i e n c e d m anagers a r e q u i t e a w a r e o f and s e n s i t i v e t o t h e c r i t e r i a o f a s y ste m and m a n a g e r ia l d e c i s i o n s a r e n o t b i a s e d . He p r o c e e d s t o a r g u e t h a t m a n a g e r ia l d e c i s i o n s a r e b a s i c a l l y so u n d and what i s n eed ed i s t o e l i m i n a t e t h a t e r r a t i c e le m e n t b y m aking them more c o n s i s t e n t .

One c r i t i c i s m f o r t h i s model i s t h a t t h e r e g r e s s i o n model r e l i e s on d e c i s i o n s made b y a m anager o r b y a g r o u p o f

m^iriagera. Changes i n p e r s o n n e l may r e n d e r t h e model i n v a l i d . S eco n d argum ent i s t h a t t h e m o d e l's fu n d a m e n ta l a s s u m p tio n i s t h a t m anagers a r e good d e c i s i o n m akers and what i s n eed ed i s t o e l i m i n a t e i n c o n s i s t e n c i e s i n t h e i r b e h a v io u r . H ow ever» i t i s r a t h e r q u e s t i o n a b l e i f a l l t h e m an agers a r e go o d d e c i s i o n m akers.

L i n e a r Program m ing

Hansmann and H ess C1Q60D d e v e lo p e d a s im p le x model t h a t i s s i m i l a r t o L in e a r D e c i s i o n R u le . I n t h e i r c o s t model t h e y u s e t h e p r o d u c t io n r a t e and t h e work f o r c e a s in d e p e n d e n t v a r i a b l e s . T h e ir main d i f f e r e n c e i s t h a t t h e i r c o s t f u n c t i o n s a r e l i n e a r r a t h e r th a n q u a d r a t i c . For p e r i o d t » e le m e n ts o f t h e c o s t f u n c t i o n s can be r e p r e s e n t e d a s f o l l o w s :

R egu la r Payment etc ID erWt

O ve rtim e Payment ctC2D = coCkPt-WO

Hi p i ng ctC3D = chCWt-Wt-±D

F i r i n g etC 45 = cfCWt-Wt-iD

I n v e n t o r y ctCSD = ciC Io ·*·

S h o rta g e ctC6D = c iiC I O "

w h e re ctCiD : u n i t c o s t k : c o e f r i c i e n t t h a t c o n v e r t s p r o d u c t io n i n p i e c e s t o m an -h ou rs r e q u i r e d f o r t h a t p r o d u c t io n : work f o r c e i n p e r i o d t : p r o d u c t io n i n p e r i o d t : i n v e n t o r y l e v e l i n p e r i o d t X when X > 0 0 when X <= 0 O when X > = O -X when X < O Wt Pt I t CTJ'*' cx:) C N o te t h a t i n a b o v e e q u a t i o n s X i s n o t a v a r i a b l e ; i t i s g i v e n a s an e x a m p le t o show what t h e v a l u e o f a v a r i a b l e i n p a r e n t h e s i s w i l l b e , when t h e p a r e n t h e s i s i s f o l l o w e d b y a " + " o r s i g n . r ) Then t h e c o s t f u n c t i o n f o r p e r i o d t I s Cl = ctC1 3 +ctC2:)+ctC3 5 +ctC43+ctC5:)+ctC65 and th e t o t a l c o s t f o r T p e r io d s i s C =

= K-.

ctT h is o b j e c t i v e f u n c t i o n , w hich i s t o be m in im iz e d , i; s u b j e c t t o t h e f o l l o w i n g c o n s t r a i n t s : I t = I t - i + P t - F t P t> = O Wt>= O f o r t = l t o T w h e re Ft= s a l e s f o r e c a s t f o r month t

The a b o v e f o r m u l a t i o n can b e m o d if ie d i n s e v e r a l w ays. Mew c o n s t r a i n t s can b e a d d e d , su ch a s s t a t i n g a s p e c i f i c minimum l e v e l o f work f o r c e .

M ain a d v a n t a g e s o f L in e a r Program m ing a p p r o a c h a r e t h e s h o r t n e s s o f t h e c a l c u l a t i o n tim e and s i m p l i c i t y o f t h e f o r m u l a t i on.

H ow ever, J o n es C1Q67I) c r i t i c i z e s t h e model b e c a u s e t h e c o s t f u n c t i o n h a s n o t t o b e l i m i t e d t o l i n e a r f u n c t i o n s , q u a d r a t i c f u n c t i o n s o r an y s i n g l e t y p e . 2 4 S i m u la t i o n M o d els 2 _ 4 _ 1 _ P a r a m e t r ic P r o d u c t io n P la n n in g P a r a m e t r ic P r o d u c t io n P la n n in g i s a method d e v e lo p e d b y

15

C u r t i s Jones C1967J. He h as tw o d e o i s i o n r u l e s , one f o r t h e work f o r c e , t h e o t h e r f o r t h e p r o d u c t io n r a t e . A s e a r c h r o u t i n e i s u se d t o e v a l u a t e an o b j e c t i v e f u n c t i o n f o r t h e optimum s e t o f v a lu e s f o r tw o d e c i s i o n r u l e s . 2 _-4 _2 _ S e a r c h D e c i s i o n R u le T h is method i s d e v e lo p e d b y T a u b e r t C196SJ. I n t r i a l p o i n t s , he u s e s a com puter a i d e d optimum s e e k i n g p r o c e d u r e t o s y s t e m a t i c a l l y e v a l u a t e t h e c o s t f u n c t i o n . T h e re i s no g u a r a n t e e t h a t t h e optimum v a l u e w i l l b e fo u n d . I n t h i s d i r e c t s e a r c h method t h e c o s t f u n c t i o n i s e v a l u a t e d a t a p o i n t , th en t h e r e s u l t i s com pared t o p r e v i o u s r e s u l t s . T h is p r o c e d u r e i s r e p e a t e d u n t i l e i t h e r a lo w e r c o s t c a n n o t b e fo u n d o r t h e p r e d e t e r m in e d com puter tim e l i m i t i s e x c e e d e d .

The c o s t c r i t e r i o n f u n c t i o n r e p r e s e n t s t h e c o s t t o b e m in im iz e d o v e r t h e p la n n in g h o r i z o n and i t can b e e x p r e s s e d a s a f u n c t i o n o f p r o d u c t io n r a t e s and t h e work f o r c e l e v e l s i n e a c h p e r i o d o f t h e p la n n i n g h o r iz o n . T h e r e f o r e , e a c h p e r i o d r e q u i r e s t h e a d d i t i o n o f tw o d im e n s io n s t o t h e c r i t e r i o n f u n c t i o n , one f o r t h e p r o d u c t i o n r a t e and on e f o r t h e work f o r c e l e v e l . The s e a r c h p ro g ra m u s e d b y T a u b e r t h a n d le s a maximum o f t w e n t y in d e p e n d e n t v a r i a b l e s and t h e r e f o r e , t h e p la n n in g h o r i z o n I s l i m i t e d t o t e n months.

The -two m o d e ls , PPP and SDK, h a v e common d i s a d v a n t a g e s . T h ey b o th need lo n g c a l c u l a t i o n tim e and t h e r e i s no g u a r a n t e e t h a t t h e o p t im a l s o l u t i o n w i l l b e r e a c h e d .

2 _ 5 _ P r o d u c t i o n S w it c h in g H e u r i s t i c

D. O rr C l 9622) h as s u g g e s t e d t h a t an i m p l i e d g o a l o f management i n p r o d u c t i o n p l a n n i n g i s t o a v o i d r e s c h e d u l i n g t o o f r e q u e n t l y . T h us, a s l o n g a s demand i s b e in g met, C l . e . , a s l o n g a s s t o c k o u t s do n o t o c c u r t o o f r e q u e n t l y and i n v e n t o r y l e v e l s do n o t I n c r e a s e d r a s t i c a l l y ! ) , m an agers a r e o f t e n i n c l i n e d t o m a in t a in t h e same p r o d u c t i o n and work f o r c e l e v e l s , m aking m inor a d ju s t m e n t s when n e c e s s a r y .

T lie se i d e a s d i r e c t e d O rr t o p r o p o s e t h e random w alk a p p r o a c h t o a g g r e g a t e p r o d u c t i o n p la n n in g . A f t e r w a r d s , E lm a le h and E i l o n C l 9742) a d a p t e d t h e f o r m u l a t i o n a s f o l l o w s : S p e c i f y t h r e e i n v e n t o r y l e v e l s , a > b > c , and t h r e e p r o d u c t i o n l e v e l s , H>N>L, w it h t h e f o l l o w i n g o p e r a t i n g I n s t r u c t i o n s : - H i f I i - i p a s s e s c fro m a b o v e C i f I t - i > c and Ii<c2) Pt= -N i f I t - i p a s s e s b

C l f I t - i > b and I t < b o r It-4 < b and It>b2) L i f I t - i p a s s e s a fro m b e lo w

C i f I t - i < a and It> a 3

V a lu e s f o r a » b , c and H ,N ,L a r e o b t a i n e d b y s i m u l a t i n g v a r i o u s c o m b in a t io n s o f t h e s e c o n t r o l p a r a m e t e r s o v e r a h i s t o r i c a l demand s e r i e s and c h o o s in g t h e s e t f o r w h ich c o s t s a r e minimum.

E l l o n C l 0675 a r g u e s : "F o r a s im p le c o n t r o l p r o c e d u r e . I n v o l v i n g one o r tw o c o n t r o l l e v e l s , t h i s s i m u l a t i o n model i s an e f f e c t i v e t o o l , b u t t h e o b v io u s d a n g e r i n t h e s y s te m i s when a d r a s t i c c h an ge i n demand t a k e s p l a c e C f o r e^camρle, f o l l o w i n g an upw ard o r downward t r e n d s , p r o d u c t i o n w i l l lo c k i n t o a s i n g l e lo w o r h ig h l e v e l w h ich may p r o v e t o b e in a d e q u a t e t o d e a l w it h a p e r s i s t e n t l y d e p l e t e d o r s o a r i n g s t o c k l e v e l . To g u a r d a g a i n s t su ch e x tre m e s i t u a t i o n s , a d d i t i o n a l m o n it o r in g i s n eed ed t o t e l l management when t h e tw o l e v e l p r o d u c t io n sy ste m c e a s e s t o b e e f f e c t i v e and n e e d s t o b e r e p l a c e d C f o r e x a m p le , by new p r e s c r i b e d l e v e l s ^ . " Cp. 1305 A t t h i s p o i n t , a l l t h e m ajor a p p r o a c h e s f o r s o l v i n g a g g r e g a t e p r o d u c t io n p ro b le m h av e b een e x p l a i n e d . F o r e a c h d i f f e r e n t e a s e , a d i f f e r e n t a p p r o a c h may b e s u i t a b l e . I n t h e n e x t c h a p t e r , our c a s e i s exam in ed i n o r d e r t o c h o o s e t h e most a p p r o p r i a t e a p p ro a c h .

3 INFORMATION ABOUT THE COMPANY

3 _ 1 _ G e n e r a l I n f o r m a t i o n

The company w orks i n t h e p r o d u c t i o n o f s p a r e p a r t s f o r T o fa ? and F o rd f a c t o r i e s . The f o u r p a r t s p ro d u c e d f o r T o fa ? and t h e i r r e q u i r e d p r o d u c t io n p r o c e s s e s a r e l i s t e d b e lo w .

A : Ki ng P i n

R e q u ir e d P r o c e s s e s : S a w in g , Hot S ta m p in g , R ear H o le D r i l l i n g and T h r e a d in g , T u r n in g Copy, End T h r e a d in g , H eat T re a tm e n t, C e n t e r l e s s G r in d in g B : Gear S h i f t Rod R e q u ir e d P r o c e s s e s : S a w in g , T u r n in g , M i l l i n g , I n d u c t i o n , C e n t e r l e s s G r in d in g C : G ear Shi f t L e v e r R e q u ir e d P r o c e s s e s : S a w in g , Hot S ta m p in g , T u r n in g , T h r e a d in g , H eat T re a tm e n t, C a r b u r i z a t i o n , Hot B e n d in g , P a l n t i ng D : Cab B o l t R e q u ir e d P r o c e s s e s : S a w in g , Hot S ta m p in g , T u r n in g , Thr e a d i n g , G a l v a n l z i ng F or F o r d , t h r e e p a r t s a r e p ro d u c e d . E : K in g P in

19

R e q u ir e d P r o c e s s e s : S a w in g , C h a m p e rin g , T u r n in g , T h r e a d in g , M i l l i n g , I n d u c t i o n , C e n t e r l e s s G r i n d i n g F : G ear S h i f t Rod R e q u ir e d P r o c e s s e s : S a w in g , T u r n in g , M i l l i n g , I n d u c t i o n , C e n t e r l e s s G r i n d i n g G : G ear S h i f t L e v e r R e q u ir e d P r o c e s s e s : S a w in g , Hot S ta m p in g , T u r n in g , T h r e a d i n g , H eat T re a tm e n t, C a r b u r i z a t i o n , Hot B e n d in g , P a i n t i n g

The company owns t h e r e q u i r e d m a c h in e ry ; 1. e. l a t h e s , d r i l l i n g m a c h in e s, m i l l i n g m a c h in e s , t h r e a d r o l l i n g m ach in e, g r i n d i n g m ach in e, w e ld in g e q u ip m e n t, p i p e b e n d in g m ach in e s, h y d r o l i c p r e s s e s and s a w in g m achine. T h e re a r e a t o t a l o f 2-d s u c h m ach in es.

The em p lo y ee p r o f i l e i s made up o f one fo re m a n and s e v e n w o r k e r s . Each o f t h e s e w o r k e r s can a c c o m p lis h a n y o f t h e a b o v e p r o c e s s e s b e c a u s e t h e r e i s no n eed f o r s p e c i a l i z a t i o n i n t h e p r o d u c t i o n . I t i s assum ed t h a t e v e r y w o rk er can c o m p le t e t h e same t a s k i n an e q u a l amount o f tim e . P r o d u c t io n p r o c e s s d o e s n o t r e q u i r e a n y p r e p a r a t i o n , th u s s e t - u p c o s t i s n e g l i g a b l e .

The company h as a d e f i n i t e a d v a n t a g e i n demand f o r e c a s t i n g . T o fa $ and F o rd f a c t o r i e s d e v e lo p p r o d u c t i o n p l a n s f o r o n e y e a r a h e a d . The company d e d u c e s fro m t h e s e p l a n s t h e number o f s p a r e p a r t s t h a t i t l>as t o p ro d u c e .

Historically, the forecast and the actual requirement of

Tofa^

and

Ford have always

been

equal,

hence,

demand

forecasts are reliable. For year 19Q0, monthly forecast in

units is given in

Ta.bl& i .C Tables 1 to lO which show the

collected and processed data can be found in Appendix - A.5

The company can meet the demand by regular and overtime

production or by inventory.

Backlogging is not possible

because the demand should completely be met in time.

A

shortage in the supply of these parts may disrupt the

production of Tofa^ and Ford factories. Consequently, these

two costumers factories may decide against using the company

as a supplier, which in turn, would damage its future sales.

The company has suitable idle space, hence there is no

storage problem. Therefore, inventory holding cost is the

opportunity cost of money tied up in production.

There are no union restrictions for hiring and firing of

workers, and new workers are always available.

3 _2_ Con^any*s Production Policy

The management of the company makes all the decisions

based on intuition. In the existing production policy of the

company, there are three rules which are explained below.

12) There is no hiring and firing. The level Pf work force is

kept constant.

iil) All available regular working hours must be used fully

and if there is excessive demand it should be met by overtime

wor

k .

iii3 25

‘/iof next month's demand should be kept in

i nventory.

The third rule has a relatively low priority indicating

that the inventory level can fall below 25

of the next

month's demand if the available regular and overtime work

hours can Just meet the demand.

The company has no initial inventory and management does

not want to have a final Inventory at the end of twelve

months.

The company decided to produce the amounts given in

T a b l& £ .

The resulting inventory levels are in Ttible

3.Note

that the 25 % requirement is not met in months 10 and 11.

After

finding

the

cost

coefficients,

the

total

production cost for the existing policy are calculated in

Ta.hl& iO .

Characteristlcs of the problem are defined so that the

appropriate aggregate production planning approach can

be

chosen now. Next chapter presents the methodology with which

the problem is solved.

4 METHODOLOGY

Choice

o tLP

ATLer Lhe problem definibion and analysis of all Lhe

approaches, linear programming is selected as the solution

procedure for this problem. The underlying assumptions are

valid for LP rather than for the other approaches. LP is very

simple to apply and gives accurate output if the inputs are

correct and the assumptions are valid. If an input changes,

the new result can be obtained very rapidly.

There are two basic criticisms of LP which prevent its

use in certain applications. These two criticisms and the

arguments against them for this study are explained below.

Mel 11 champ and Love Cl9782) argue :

"For one thing, the

analytical

models

all

incorporate

various

simplifying

assumptions which limit their applicability. For example, the

mathematical programming approaches require that all cost

functions be linear. Unfortunately, actual cases in industry

are rarely like that and we might expect to observe in the

same situation some costs which are linear and some costs

which are of higher order. A second example« of unrealistic

assumptions

involves

the

way

demand

is

treated

in

mathematical

programming approaches.

These

methods

all

incorporate the assumption that demand forecasts are accurate

and equally weighted over the planning horizon. The result is

that the production level for the forthcoming period can be

significantly affected by forecasts of future periods even

though forecasts for distant periods are less reliable than

the forecasts for the immediate future. **Cp. 12431)

However* in our case* all the cost coefficients are

shown below to be linearly related to the variables.

iD Regular work hours :

The wages are predetermined *

hence wage cost increases linearly with the number of workers

hi red.

iiD Overtime hours :

There is a direct linear relationship

between overtime hours and payment as there are no special

arrangements under different conditions. CFor example* there

is no additional payment for national holidays.!)

iiiD

Cost

of

firing

:

The

management

always

pays

half-month salary to the fired workers. There are no union

r

es

tr

i cti ons.

ivD Cost of inventory :

There is no storage costs because

of the small scale of production and large size of idle

space. Moreover* the company does not pay insurance and does

not have a problem with spoilage* deterioration or breakage.

Therefore* the inventory cost increases linearly with money

tied up in the production. CThere is no bank paying interest

with quadratic propertionality^

the interest is certainly

1 i near .

2

)

v!) Cost of hiring :

New entrants are trained by the

experienced

workers.

The average

training

time

is

approximately 2-d hours. Since the standard deviation is not

large» the cost function is linear. Clf the company hired 30

more workers» the cost could change quadrat!cal1y or more

however

the

company cannot

increase

the

worker

number

drastically due to demand constraints.!)

The second criticism given by Mellichamp and Love C1S7S2)

was about demand forecasting» but our model is deterministic.

The company takes the production plans of the two automobile

factories» Tofa^ and Ford» and bases its forecasts on these

plans.

Historically» these factories have always strictly

followed their plans and ordered accordingly. Therefore» the

forecasts have always been quite accurate.

Counter-arguments in our

study eliminate these two

criticisms and enable our utilization of LP. In the next

section» the model will be constructed and its assumptions

will be explained.

^ 2 LP Model

The LP model has a linear objective function which is to

be minimized.

This objective function consists of five

elements for every month i , for i= 1 to 12.

L'J

Cost of regular work

crXRi

iil)

Cost of overtime work

coXOi.

iiiD Cost of hiring

chXHi.

ivD

Cost of firing

cfXFi

vD

Cost of inventory

ckl i

The total production cost for month i Is:

ci. — crXRi+coXOi+chXHi+cfXFi.+ckI i

.

where

ct

:

Total production cost in month i

CTL3

cr ;

Regular wage rate per hour

CTL / hour

2)

,

XRi :

Regular working hours used for production in month 1

Co

:

Overtime wage rate per hour

CTL / hourD

XOi :

Overtime working hours used for production in month i

C

hour

D

ch

:

Cost of hiring one worker

CTLD

XHi :

Number of workers hired in month i

cf

Cost of firing one worker

CTLD

XFv :

Number of workers fired in month i

ck

:

Inventory holding cost to keep one hour

production in inventory

CTL

hour:?

li

:

Hours of production kept in inventory in month i

C

hour

D

The model has the following assumptions :

aZ) The cost function is

linear. This assumption enables

using linear programming

because simplex method requires a

linear objective function.

bZ) The inventory li is taken as the end-of-month Inventory

and this inventory level is assumed to be constant for the

whole month.

cZ) Hiring is made in such a way that the worker

completes

the training and is ready to work at the beginning of the

month.

dD A worker can only be fired at the beginning of a month.

1

There is no initial and final inventory.

fD Backlogging and subcontracting are impossible.

g2) The set-up cost is zero for switching from producing one

product to another because preparation is not necessary. In

the next two sections , the cost coefficients cr, co, ch, cf

and ck of the constructed model will be determined to solve

the problem.

4_3_ Data Collection

In order to find the numerical values of the cost

coefficients,

the required

data

have

to be

collected.

Consultation with management and historical data analysis are

used to determine the availability of the necessary inputs.

Direct observation is also used for data collection.

In the factory, seven different products are produced

with each of them having different production processes. The

sequence of the processes are listed in section 3_1; for

example,

in the production of the king pin,

sawing is

followed by hot stamping. For the existing demand, there is a

machinery will not generate extra profit .

Each production process for every part is carefully

examined and the processing times are determined. The results

are in

Т а Ы & 4.Fixed cost data are obtained from the management. These

data consist of three parts

:

material»

machinery and

external cost which are given in

Т а Ы & Б.It is assumed that

these costs will be constant throughout the year.

The company pays 300»000 TL per month to the workers and

AO