UDCS’17

The Proceedings of Third International Iron and Steel Symposium (UDCS’17)

April 3-5, 2017, Karabuk University, Karabuk, Turkey.

Edited by

Dr. Mustafa YAŞAR (Chairman)

Copyright

ISBN 978-605-9554-0-60

© 2017, UDCS’17, Karabuk University Karabuk, Turkey

http://udcs17.karabuk.edu.tr/ udcs17@karabuk.edu.tr

This proceedings include the original papers submitted to UDCS’17. It is accessed in free of charge. All scientific and linguistic responsibilities of the published articles belong to their authors.

Symposium (IISS’17)

3-5 April 2017

Karabuk University, Karabuk, Turkey

HONORARY COMMITTEE

Dr. Refik POLAT, Rector of Karabuk UniversityDr. Erol ARCAKLIOĞLU, TÜBİTAK

Dr. Türkay DERELİ, İskenderun Technical University Dr. Arif KARADEMİR, Bursa Technical University

Ercüment ÜNAL, Kardemir A.Ş. Namık EKİNCİ, Steel Exporters Association

UDCS’17 CHAIRMAN

Dr. Mustafa YAŞARORGANISING COMMITTEE

Dr. Mustafa YAŞAR Dr. Yavuz SUN Dr. Yasin KANBUR Dr. Erkan KOÇ Dr. Engin CEVIK Dr. Betül USTA Dr. Ali GÜNGÖR Dr. Hayrettin AHLATCI Dr. Hüseyin ÇİMENOĞLU Dr. Mehmet Baki KARAMIŞDr. Veysel YAYAN Dr.Yunus TÜREN Dr. Erkan KOÇ Dr. Yasin KANBUR Dr. Engin ÇEVIK Dr. Betül USTA Alper İNCESU Yasin AKGÜL Fatih AYDIN M. Emre TURAN Fazıl HÜSEM Yüksel AKINAY Safa POLAT Savaş AĞDUK M. Yunus AŞKIN

SCIENTIFIC COMMITTEE

Dr. Ali ARSLANTAŞ Karabuk University

Dr. Ali GÜNGÖR Karabuk University

Dr. Ali KALYON Karabuk University

Dr. Anthony D. ROLLETT Carnegie Mellon University

Dr. Ali KONAK Karabuk University

Dr. Alper ERGÜN Karabuk University

Dr. Ali RAMAZANI University of Michigan-Ann Arbor

Dr. Bahattin TÜRETKEN Karabuk University

Dr. Behçet GÜLENÇ Gazi University

Dr. Betül USTA Karabuk University

Dr. Bilge DEMİR Karabuk University

Dr. Bülent Aydemir TUBITAK

Dr. Bülent Bostan Gazi University

Dr. Bülent KURT Nevsehir Hacı Bektas Veli University

Dr. Carl D. LUNDIN The University of Tenessee Knoxville

Dr. Cemal ÇARBOĞA Nevsehir Hacı Bektas Veli University

Dr. Cemal MERAN Pamukkale University

Dr. Cemil Hakan GÜR Middle East Technical University

Dr. Cihan MIZRAK Karabuk University

Dr. David K. MATLOCK Colarado School of Mines

Dr. Emrah DENİZ Karabuk University

Dr. Engin ÇEVİK Karabuk University

Dr. Enver OKTAY Istanbul University

Dr. Erhan DEMİRBAŞ Gebze Technical University

Dr. Erkan KOÇ Karabuk University

Dr. Ertugrul ESMERAY Karabuk University

Dr. Eyüp Sabri KAYALI Istanbul Technical University

Dr. Fatih HAYAT Karabuk University

Dr. Fatma MEYDANERİ TEZEL Karabuk University

Dr. Ferhat GÜL Gazi University

Dr. Filiz ERSÖZ Karabuk University

Dr. Fuat ŞİMŞİR Karabuk University

Dr. Hakan ATEŞ Gazi University

Dr. Hakan AYDIN Uludag University

Dr. Halil KULLUK Intekno Group of Companies Chairman of the Board

Dr. Hani HENEIN University of Alberta

Dr. Hasan GÖKKAYA Karabuk University

Dr. Hasan HASIRCI Gazi University

Dr. Hasan KARABULUT Karabuk University

Dr. Hatem AKBULUT Sakarya University

Dr. Hatice EVLEN Karabuk University

Dr. Hayrettin AHLATÇI Karabuk University

Dr. Hüseyin ÇİMENOĞLU Istanbul Technical University

Dr. Hüseyin DEMİREL Karabuk University

Dr. Hüseyin DEMİRTAŞ Karabuk University

Dr.Hüseyin KURT Karabuk University

Dr. Ivan Enrique Campos SILVA Instituto Politecnico Nacional

Dr.İdris KABALCI Karabuk University

Dr.İhsan KORKUT Gazi University

Dr.İhsan ULUER Karabuk University

Dr.İnan KESKIN Karabuk University

Dr. Irinei RADOMIR Transilvania University of Brasov

Dr.İsmail EKMEKÇİ Istanbul Commerce University

Dr. Jahan RASTY Texas Tech University

Dr.Kerim ÇETİNKAYA Karabuk University

Dr. Kiyotaka MATSUURA Hokkaido University

Dr. Mahdi MAHFOUF Sheffield University

Dr. M.Akif ERDEN Karabuk University

Dr.Mehmet AKBABA Karabuk University

Dr. Mehmet EROĞLU Fırat University

Dr. Mehmet Baki KARAMIŞ Erciyes University

Dr. Mehmet KARA Karabuk University

Dr. Mehmet KOBYA Gebze Technical University

Dr. Mehmet ÖZALP Karabuk University

Dr. Mehmet ÖZKAYMAK Karabuk University

Dr. Mehmet TÜRKER Gazi University

Dr. Melik ÇETİN Karabuk University

Dr. Metin ZEYVELİ Karabuk University

Dr. Mihai Alin POP Transilvania University of Brasov

Dr. Mihai CERNAT Transilvania University of Brasov

Dr. Muhammet KAYFECI Karabuk University

Dr. Muharrem DÜĞENCİ Karabuk University

Dr. Murat VURAL Istanbul Technical University

Dr. Mustafa ACARER Selcuk University

Dr. Mustafa AKTAŞ Karabuk University

Dr. Mustafa ANUTGAN Karabuk University

Dr. Mustafa AYDIN Dumlupınar University

Dr. Mustafa BOZ Karabuk University

Dr. Mustafa GÜNAY Karabuk University

Dr.Mustafa KURT Marmara University

Dr.Mustafa ÜRGEN Istanbul Technical University

Dr.Mustafa YAŞAR Karabuk University

Namık EKİNCİ Steel Exporters Union Chairman of the Board of Directors

Dr.Necmi Serkan TEZEL Karabuk University

Dr.Niyazi ÖZDEMİR Fırat University

Dr.Nizamettin KAHRAMAN Karabuk University

Dr.Oğuz BORAT Istanbul Commerce University

Dr. Oğuz KOÇAR Bulent Ecevit University

Dr. Oktay ERKOCA ArcelorMittal Global R&D

Dr. Ömer BUCAK Hochschule Furangewandte Wissenschaften Munchen

Dr.Özden İŞBİLİR Karabuk University

Dr. P. A. DEARNLEY University of Leeds

Dr.Raif BAYIR Karabuk University

Dr.Ramazan KAÇAR Karabuk University

Dr.Sakıp KÖKSAL Sakarya University

Dr.Salim ASLANLAR Sakarya University

Dr.Selami SAĞIROĞLU Karabuk University

Dr.Selçuk SELİMLİ Karabuk University

Dr.Serdar SALMAN Marmara University

Dr.Süheyla AYDIN Istanbul Technical University

Dr.Süleyman GÜNDÜZ Karabuk University

Dr.Süleyman YAŞIN Karabuk University

Dr.Şenol GÜRSOY Karabuk University

Dr.Tamila ANUTGAN Karabuk University

Dr.Tanju TEKER Adiyaman University

Dr. Tayfur ÖZTÜRK Middle East Technical University

Dr.Ulaş MATİK Karabuk University

Dr.Ulvi ŞEKER Gazi University

Dr.Veli ÇELİK Yildirim Beyazit University

Dr. Virgil GEAMAN Transilvania University of Brasov

Dr.Volkan KILIÇLI Gazi University

Dr. Yakup Kaya Karabuk University

Dr.Yavuz SUN Karabuk University

Dr.Yılmaz YILDIRIM Bulent Ecevit University

Dr.Yunus TÜREN Karabuk University

Dr.Yusuf ÖZÇATALBAŞ Gazi University

Dr.Zehra Şule GARİP Karabuk University

SYMPOSIUM SECRETARIAT

Tuğba AVŞAR Gözde GÜNEY Tuğba COŞKUNSYMPOSIUM SECTION COORDINATORS

Metallurgy Casting &

Materials Dr.Erkan KOC

Dr. Ali GÜNGÖR Dr.Kazım TUR Dr. Oncu AKYILDIZ

Dr. Necmi TEZEL

Dr. Fatma Meydaneri TEZEL

Heat

Treatment Coating & Corrosion

Dr. Mehmet EROGLU Dr. Yasin KANBUR Dr. Bilge DEMIR Dr.Hasan KOTAN

Dr. Hamza Yasar OCAK

Dr. M. Akif ERDEN

Welding Forming&Machining &

Cutting

Dr.Mustafa ACARER Dr.Cemal CARBOGA Dr. Fatih HAYAT Dr.Yavuz SUN Dr. Erkan KONCA Dr. Mustafa GUNAY

Dr.Harun CUG Dr.Engin CEVIK

Energy Forming &Machining &

Environment Dr. Mehmet YAZ

Dr. Mehmet OZALP

Dr. Harun CUG Dr. Suleyman YASIN

Materials Testing Tribology Machines

Dr.Engin CEVIK Dr.Nizamettin KAHRAMAN

Dr. Ulas MATIK Recycling

Dr.Yunus TUREN

Accreditation&Certification Marketing& Finance

Dr. Bulent AYDEMIR

Dr. Ali KONAK Dr. Filiz ERSOZ

KARABUK UNIVERSITY

Onur ALTAY Meral ERDIL Saime AÇIKGÖZ Elif SEYMEN Anıl İNCE Hilal TORUN Nurdan OZTURK Sakine OBUZ Sinan EKSİ Özgür DURGUN Gülcan CETİN Neslihan ERKEK Ceyda ALBAYRAK Cemre GOZUTOK Gamze ALTUNERUDCS’17 is organised by

Iron and Steel Instıtute

Karabuk University

78050 Karabuk, Turkey

T: +90 370 433 88 33

F: +90 370 433 88 32

E-mail:

dce@karabuk.edu.tr

http://dce.karabuk.edu.tr

http://udcs17.karabuk.edu.tr

Third International Iron and Steel

Symposium (UDCS’17)

3-5 April 2017

Karabuk University, Karabuk, Turkey

PREFACE

The 3nd International Iron and Steel Symposium (UDCS’17) organised by Iron and Steel Institute, Karabuk University is held in April 3-5, 2017 in Karabuk, Turkey. The former symposium took place in April 1-3, 2015 (http://iiss15.karabuk.edu.tr). This succeeding symposium is aimed at bringing together academics, researchers and engineers, iron and steel manufacturers, exporters and importers, suppliers, technology producers and non-governmental organizations around the World to share and discuss their latest works and the new methodologies to improve the structure and properties of iron and steel products. The topics of UDCS’17 covered are Metallurgy and materials, Casting, Heat treatment, Coating and corrosion, Welding and cutting, Forming and machining, Energy and environment, Marketing and finance, Automation, Occupational health and safety.

Special panels from industry experts, “Heat Treatments In Iron Steel Industry” and “Simulation Solutions in Materials and Metallurgy”, and the panels from directors and CEOs, “Strategies On R&D, Accreditation, Certification, And Skilled Workforce Training In Iron & Steel Industry” and “Strategies On Increasing International Marketing And Competitiveness In Iron & Steel Industry” are organised. Thanks to NGO Associations and the companies work in iron and steel industry for their helps in making the panels are successful. The Symposium includes invited papers of national and international academicians and the papers submitted by academia in all aspects of the iron and steel industries. We would like to express our sincere thanks to those who spend great effort to make this event take place. We sent our special thanks to Prof. Dr. Refik Polat as the Rector of KBÜ, Ercüment ÜNAL, General Manager of KARDEMİR A.Ş. as being main sponsor of the UDCS17.

We would also like to thank to ERDEMİR Group and other sponsors of UDCS’17 as their names and company logos stated. We also express our gratitude to the members of Honorary Committee, Scientific Committee, Organizing Committee, Industrial Committee, Secretarial Assistance, and Student Association for their great effort to make the event successful. Last but not least, we would like to thank to academicians, practitioners, and the experts who were joined to UDCS’17 in order to share their knowledge.

With the wishes to see you all at the next International Symposium…

Editor

The Third International Iron and Steel

Symposium (UDCS’17)

3-5 April 2017

Karabuk University, Karabuk, Turkey

ACKNOWLEDGEMENTS

We wish to thank the following co-organisers Universities and associations as panellists for their contribution to the success of this symposium.

CO-ORGINISER UNIVERSITIES

PANELIST ASSOCIATIONS

The Third International Iron and Steel

Symposium (UDCS’17)

3-5 April 2017

Karabuk University, Karabuk, Turkey

ACKNOWLEDGEMENTS

KARDEMİR A.Ş. ERDEMİR GRUBU

http://kardemir.com

http://erdemir.com.tr

MARZINC ZEISS TÜRKİYE

http://marzinc.com.tr

http://zeiss.com.tr

ZİRAAT BANKASI

ANKA ANALİTİK MAK ELEKTRONİK

http://ankaanalitik.com.tr

http://makelektronik.com.tr

GALDABINI GNR

http://galdabini.it http://gnr.it

METALS JOURNAL OF THE BALKAN

http://mdpi.com

TRIBOLOGICAL ASSOCIATION

http://scibulcom.net

UDCS’17 SYMPOSIUM PROGRAMME

DAY 1 3 APRIL MONDAY LOCATION

8.30-10.00 Registration Hamit Çepni Conference Hall

10.00-10.15 Turkish National Anthem and Musical Notation

10.15-10.30 Presentation of Karabuk University and Iron & Steel Institute

10.30-10.45 Speech of Protocol

10.45-11.15 Oktay Elkoca: Abrasion Resistant Steels

11.15-11.45 Coffee Break

11.45-12.15

Young Pyun: Reduction of operation cost and improvement of production by utilizing advance surface modification technology "UNSM (Ultrasonic Nanocrystal Surface

Modification)"

12.15-12.45

Mehmet Eroglu: An innovative study: Developing of a continuous coating method for steel sheets or plates 12.45-13.30 Lunch 13.30-15.00 Oral Presentations 1

Majid Pouranvari: Metallurgical Challenges in Resistance Spot Welding of Advanced High Strength Steels

Panel 1

Research and Development, Human Resources in Iron and Steel Industry

Mehmet Ordukaya (Professional Qualification Institution) Didem Tunc (Professional Qualification Institution)

Hüseyin Soykan (MATIL Inc.) Oguz Gunduz (ERDEMIR Inc.)

Poster Presentations

1 Iron & Steel Institute

15.00-15.30 Coffee Break

15.30-17.00

Fatih Hayat: Steel Trend in Automotive Industry Presentations

Sponsor Companies

17.00-19.30 Touristic Travel – Bulak Mencilis Cave

19.30-20.30 Gala Dinner

DAY 2 4 APRIL TUESDAY LOCATION

9.00-10.30 Oral Presentations 2

Poster Presentations

2 Iron & Steel Institute 10.30-11.00 Coffee Break 11.00-12.30 Oral Presentations 3

Mehmet Baki Karamis: Tribological Damages On Projectile Steel Tip Surface After Ballistic Impact

Panel 2

Raw Material Markets Murat Demirci (ERDEMIR Inc.)

Nazım Çapraz (KAHDER)

Zeki Cizmecioglu (Istanbul Commerce University) 12.30-13.30 Lunch 13.30-15.00 Oral Presentations 4

Hüseyin Cimenoglu: Wear Characteristics of H13 Hot Work Tool Steel at Elevated Temperatures

Panel 3

Global Steel Industry and Expectations Ercument Unal (KARDEMIR Inc.) Ugur Dalbeler (Colakoglu Metallury Inc.)

Poster Presentations

3 Iron & Steel Institute

15.30-17.00

Presentations 5

Bülent Aydemir

Tensile Test for Metallic Materials according to ISO 6892-1:2016

17.00-19.30 Touristic Travel – Safranbolu Glass Terrace

19.30-20.30 Dinner

DAY 3 5 APRIL WEDNESDAY LOCATION

9.00-10.30 Oral Presentations 6

Iron & Steel Institute 10.30-11.00 Coffee Break 11.00-12.30 Oral Presentations 7 12.30-13.30 Lunch

13.30-17.00 Technical and Touristic Travel – KARDEMIR Inc. and Yenice Seker Canyon

ORAL PRESENTATIONS

1. SESSION

Parallel Session – Room : Hematite –- 03.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

127 EFFECT OF GRAIN BOUNDARY CHARACTERISTICS ON THE IMPACT PROPERTIES

OF THERMOMECHANICALLY ROLLED API X70 PIPELINE STEELS Semih ENGÜN 105 USE OF STEEL SLAG IN RUBBLE-MOUND MARINE STRUCTURES V.S. KIRCA

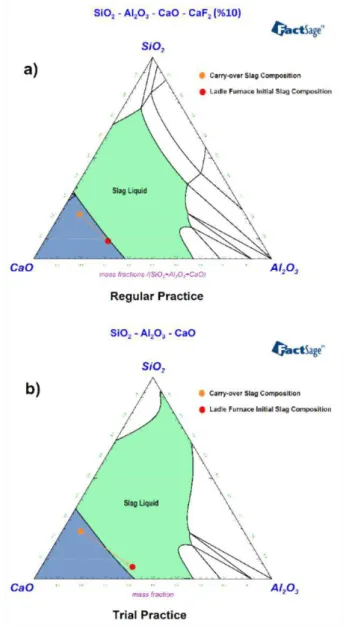

14 EFFECTS OF SLAG OPTIMIZATION ON STEEL CLEANLINESS IN SECONDARY

METALLURGY PROCESS Emre ALAN

125 PURE BENDING FATIGUE BEHAVIOUR OF 80 C STEEL CORD FLAMENTS Hüseyin KOYMATCIK 54 DYNAMICS STRESS ANALYSIS IN 120 MM SMOOTH BORE TANK BARREL Mehmet Fatih YAŞAR 88 INVESTIGATION OF GAS PRESSURE EFFECT ON POWDER CHARACTERIZATION OF

AL12SI ALLOY PRODUCED BY GAS ATOMIZATION METHOD Kamal Mohamed Em AKRA

Parallel Session – Room : Magnetite –- 03.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

39 EFFECT OF ION-NITRIDING PROCESS ON THE MECHANICAL PROPERTIES OF AISI

4140 LOW ALLOY STEEL M. Anıl KAYA

43 EFFECT OF HOMOGENIZATION HEAT TREATMENT ON MİCROSTRUCTURE,

HARDNESS AND TOUGHNESS PROPERTIES OF G18NICRMO3-6 STEEL Funda GÜL KOÇ 178 THE EFFECT OF THE SINTERING TEMPERATURE ON HARDNESS AND WEARING

BEHAVIORS OF THE STEEL Ramazan YILMAZ

138 INVESTIGATION OF STRAIN HARDENING IN AISI 430 FERRITIC STAINLESS STEELS Gökhan ARICI 247 EFFECT OF DEFORMATION ON THE MECHANICAL PROPERTIES OF HOT ROLLED

AISI 4140 STEEL Gökhan ATAY

65 PRODUCTION OF DUAL-PHASE STEEL USING VERY RAPID HEATING AND SHORT ANNEALING TIME

Parallel Session – Room : Wustite –- 03.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

12 EFFECT OF NORMALIZATION PROCESS ON ADHASIVE WEAR BEHAVIOR OF

DUCTILE IRON Ferhat GÜL

46 AN INTEGRATED PROCESS DESIGN FOR MAGNESIUM ALLOY PART

MANUFACTURING IN TURKEY Ali Serdar VANLI

213 THE FLASH BUTT WELDING APPLICATION AND INSPECTION IN RAILWAY IN

KARABUK TRAIN STATION Mustafa DURSUNLAR

50 SOLIDCAST CASTING SIMULATION SOFTWARE REVISION OF SAMPLE PIECE

MOLD DESIGN BY SAND CASTING Mustafa ERCAN

52 SIMULATION INVESTIGATION OF EFFECTS ON PRODUCT QUALITY OF THE

ROUTING DESIGN PARAMETERS IN HIGH PRESSURE CASTING METHOD Mustafa ERCAN 133 DETERMINATION OF PHASE EQUILIBRIA IN HIGH ALLOY WHITE CAST IRONS Öncü AKYILDIZ

Parallel Session – Room : Limonite –- 03.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

123 THE IMPROVEMENT OF CORROSION RESISTANCE OF ZINC-COATED STEEL WIRES

BY CHROMATING PROCESS Ömer Faruk ÖZKAN

103 SYNTHESIS, CHARACTERIZATION AND TRIBOLOGICAL STUDIES OF

CHROMIUM-NANO DIAMOND COMPOSITE COATING Nima ZOGHİPOUR

25 WEAR BEHAVIOUR OF INDUCTION HARDENED 100CR6 STEEL Gülcan TOKTAŞ 18 VANADIUMBORIDE COATING OF A LOW CARBON STEEL BY PLASMA

TRANSFERRED ARC (PTA) METHOD

Yusuf DONAT

19 BORIDE COATINGS ON A LOW CARBON STEEL USING SHIELDED METAL ARC WELDING ELECTRODE WITH BORONCARBIDE

Mehmet EROĞLU 119 EFFECT OF ADDITIONAL BORON ON CORROSION RESISTANCE OF AISI4140

(42CRMO4)

Cemal ÇARBOĞA

Parallel Session – Room : Siderite –- 03.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

30 EFFECT OF MULTIPASS WELDING ON MICROSTRUCTURAL AND MECHANICAL

PROPERTIES OF AISI 2205 DUPLEX STAINLESS STEEL Alptekin KISASÖZ 38 X-RAY RADIOGRAPHY OF P460-ST52 STEEL COUPLES WELDED BY SUBMERGED

ARC WELDING Uğur ÇALIGÜLÜ

41 AN EFFECT OF STRESS RELIEF ANNEALING ON THE RESISTANCE SPOT WELDED

TRIP STEEL JOINT Hayriye Ertek EMRE

42 AN INVESTIGATION OF RESISTANCE SPOT WELDABILITY OF DP600/TRIP800

DISSIMILAR STEEL COUPLE Hayriye Ertek EMRE

45 JOINING GR2 AND GR5 TITANIUM ALLOYS WITH DIFFUSION BONDING METHOD

USING COPPER INTERLAYER Uğur ÇALIGÜLÜ

48 EFFECT OF PROCESS PARAMETERS AND PRODUCTIVITY OF WELDING

2. SESSION

Parallel Session – Room : Hematite –- 04.04.2017 – ( 09:00 – 10:30 )

Paper ID Title Speaker

256

INVESTIGATION OF THE EFFECT OF VANADIUM ADDITION AND CYCLING HEAT TREATMENT ON MECHANICAL PROPERTIES AND WEAR BEHAVIORS OF CASTING

STEEL

Harun ÇUĞ

115 COMPARİSON OF THE MECHANİCAL PROPERTİES OF DIFFERENT QUALITY

AUSTENİTİC STAİNLESS STEELS AFTER WİRE DRAWİNG Yılmaz YILDIRIM 9 INVESTIGATION OF DYNAMIC STRAIN AGING PROPERTIES OF HOT WORK TOOL

STEELS Demet TAŞTEMUR

91 DEVELOPMENT OF HIGH VALUE ALLOYS WITHOUT CRITICAL RAW MATERIALS

THROUGH HIGH ENTROPY ALLOYS Hakan YILMAZER

164

DESIGN AND SIMULATION OF AN APPARATUS FOR THE POST-WELD CONTROLLED ACCELERATED COOLING OF R350HT HEAD HARDENED RAIL

JOINTS

Nizar RAMADAN

210 CALCULATION OF (HKL) PLANE ENERGY OF BCC AND BCT IRON USING

ANALYTICAL METHOD Hamza Yaşar OCAK

Parallel Session – Room : Magnetite –- 04.04.2017 – ( 09:00 – 10:30 )

Paper ID Title Speaker

173 PARAMETER DETERMINATION OF YOSHIDA-UEMORI AND CHABOCHE

KINEMATIC HARDENING MODEL OF DUAL PHASE STEELS İlyas KAÇAR 174 COMPARISON OF YOSHIDA-UEMORI AND CHABOCHE KINEMATIC HARDENING

MODEL’S PREDICTION ABILITIES İlyas KAÇAR

185 MICROSTRUCTURAL EVOLUTION AND MECHANICAL PORPERTIES OF FRICTION

STIR PROCESSED TRIP780 STEEL İmren ÖZTÜRK YILMAZ

186

ACHIEVING ULTRAFINE GRAIN STRUCTURE WITH SUPERIOR MECHANICAL PROPERTIES BY FRICTION STIR PROCESSING OF INTERSTITIAL-FREE STEEL

(IF-STEEL) SHEETS

Mumun YILMAZ

163 AN INVESTIGATION INTO THE MACHINABILITY OF COLD WORK TOOL STEEL (DIN

1.2312) İbrahim ÇİFTÇİ

26 UTILIZATION OF FLUE DUST IN ZINC AND STEEL PRODUCTION PROCESSES AS

RAW MATERIALS Ömer ÖZAL

Parallel Session – Room : Wustite –- 04.04.2017 – ( 09:00 – 10:30 )

Paper ID Title Speaker

220 INVESTIGATION OF MACHINIBILITY OF HARDOX STEEL EXPOSED TO HEAT TREATMENT PROCESSES IN WEDM

Mehmet ALTUĞ

222 INCREASING COLD FORGING TOOL LIFE OF M10X1.25 WELDING FLANGE NUT BY USING FINITE ELEMENT SIMULATION

Sezgin YURTDAŞ

121

THE INVESTIGATION OF THE EFFECT OF TEMPCORE PROCESS ON STRUCTURAL FORM AND MECHANICAL PROPERTIES OF THE HOT ROLLED STEEL NPU AND

EQUAL ANGLE TYPE OF PROFILES

Tuna TOK

122 ANALYSIS AND OPTIMIZATION OF ROLLING PARAMETERS IN STEEL PROFILE HOT

ROLLING PROCESS Didem KILIÇ

10 THE EFFECT OF FUZZY LOGIC SPEED CONTROL OF SPINDLE MOTOR ON SURFACE

Parallel Session – Room : Limonite –- 04.04.2017 – ( 09:00 – 10:30 )

Paper ID Title Speaker

240 CORROSION BEHAVIOUR OF STEEL WIRE ROD Gülseher DOĞANCIK

100 INFLUENCE OF VARIOUS ZN COATING AMOUNT OF FORMED GALVANIZED

STEELS ON CORROSION PERFORMANCE Aras KARTUN

89 AFFECTING FACTORS ON GLOSS VALUE FOR GALVANIZED COLD ROLLED SHEETS Erkan PÜGE 64 FORMATON OF TRIANGLE SHAPED TIB2 BORIDES IN COATED SURFACE

PRODUCED BY GTAW Mehmet YAZ

31 ASSESSMENT OF MATERIAL SELECTION AND CORROSION PERFORMANCES FOR

PLATE HEAT EXCHANGERS Haluk ERDEMİR

62 THE WEAR PERFORMANCE OF TOOLS STEEL (AISI M2) COATED TIALN BY DC

REACTIVE MAGNETRON SPUTTERING TECHNIQUE Şengül DANIŞMAN

Parallel Session – Room : Siderite –- 04.04.2017 – ( 09:00 – 10:30 )

Paper ID Title Speaker

66 THE EFFECT OF NANO-SIZED ADDITIVES ON IGNITION TEMPERATURE OF

THERMITE WELDING Ömer GÜLER

67 WELDABILITY OF SIMILAR AISI 1040 MEDIUM CARBON STEELS USING FRICTION

WELDING İhsan KIRIK

85 AN INVESTIGATION OF THE INFLUENCE OF KEYHOLE LASER WELDING

PARAMETERS ON WELD BEAD SHAPE AND INTEGRITY Ömer EKİNCİ 96 INVESTIGATION OF WELDABILITY OF DP 1000-DP 1000 STEEL USING ELECTRON

BEAM WELDING Cihangir Tevfik SEZGİN

106

AN EXPERIMENTAL STUDY ON EFFECTS OF LASER WELDING SPEED AND LASER POWER ON WELD BEAD SHAPE AND HEAT AFFECTED ZONE IN KEYHOLE LASER

WELDING

Ömer EKİNCİ

128 THE EFFECT OF THE ELECTRODE TYPE ON TENSILE PROPERTIES OF THE

RESISTANCE SPOT WELDED JONCTIONS OF DP STEEL Öznur DİNÇEL

3. SESSION

Parallel Session – Room : Hematite –- 04.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

219 INVESTIGATION OF MACHINIBILITY OF THE HARDOX STEEL Mehmet ALTUĞ 206 APPLICATION OF TAGUCHI METHOD FOR OPTIMIZATION AWJ MACHINING OF

316 STAINLESS STEEL Fuat KARTAL

134 AN INVESTIGATION OF OPTIMUM INSERT DIAMETER / MOLDING DIAMETER

RATIO OF PARTS PRODUCED BY INSERTED POWDER INJECTION MOLDING Oğuz YILMAZ 137 MODELING OF THREE-DIMENSIONAL FRACTURE PROBLEMS USING FCPAS M. Faruk YAREN 156 AN INVESTIGATION INTO THE MACHINABILITY OF HOT WORK TOOL STEEL

(TOOLOX 44)

Halil DEMİR

162 AN INVESTIGATION ON MACHINABILITY OF HARDENED AISI H10 STEEL WITH

Parallel Session – Room : Magnetite –- 04.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

221

THE EFFECTS OF HEAT TREATMENT ON THERMAL, MECHANICAL AND MICROSTRUCTURAL PROPERTIES OF AL BASED SB - 42.4% MG - 57.6% AL

EUTECTIC ALLOY

Fatma MEYDANERİ TEZEL 246 INVESTIGATION OF HOT ROLLED AISI 4140 STEELS SUBJECT TO LARGE STRAINS Sedef SiŞMANOĞLU 175 ASSESMENT OF THE AUSTEMPERING PROCESS PARAMETERS TO IMPROVE THE

WEAR RESISTANCE OF GG-25 GRAY CAST IRON

Abdulsamet YILDIRIM

255 BAINITIC RAIL STEEL PRODUCTION FROM PERLITIC RAILS IN EUTECTOID ALLOY

AND INVESTIGATION OF WEAR BEHAVIOUR Derya BULGAN

53 THERMAL STABILITY AND PHASE TRANSFORMATION OF NANOCRYSTALLINE

STAINLESS STEELS PREPARED BY MECHANICAL ALLOYING Hasan KOTAN 16 RAPID SURFACE HARDENING OF AISI 1045 STEEL FOR AUTOMOTIVE

APPLICATION BY ELECTROLYTIC PLASMA TREATMENT Gözdenur KURT

Parallel Session – Room : Wustite –- 04.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

11 OPTIMIZATION OF ABRASIVE WEAR BEHAVIOR OF BORON AND MILD STEEL BY

TAGUCHI METHOD Ferhat GÜL

110 EFFECT ON THE FORMATION OF BORIDE LAYER OF INCREASING AMOUNT OF

NIOBIUM IN PURE IRON Eyyüp Murat KARAKURT

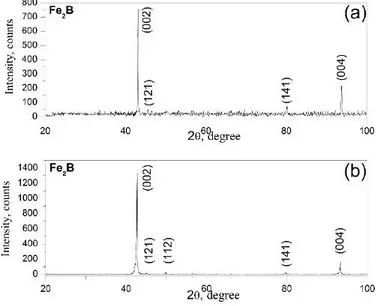

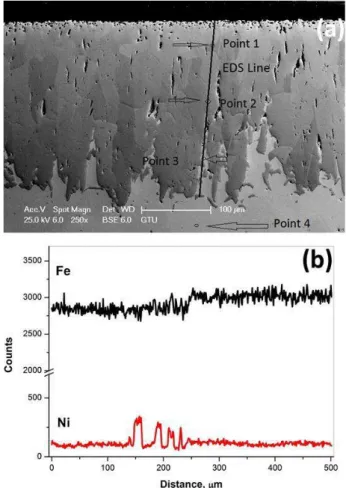

28 CHARACTERIZATION OF BORIDE LAYER FORMED ON FE-NI ALLOYS Naim Murat MAÇKAN 113

RELATION BETWEEN MICROSTRUCTURE AND HARDNESS IN HARDOX 450+FEW BASED COMPOSITE COATING FABRICATED BY PLASMA TRANSFERRED ARC

CLADDING

Eyyüp Murat KARAKURT

151 INVESTIGATION OF DRY SLIDING WEAR RESISTANCE OF AISI 52100 STEELS

UNDER DIFFERENT TRIBOLOGICAL CONDITIONS Merve YILMAZ 158 EXPERIMENTAL STUDY ON TRIBOLOGICAL PERFORMANCE OF SIC COMPOSITE

COATING LAYERS Koray KILIÇAY

Parallel Session – Room : Limonite –- 04.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

129 THE EFFECTS OF THE ELECTRODE TYPE ON MICROSTRUCTURE AND HARDNESS

OF THE RSW OF DP600 STEEL Muhammed ELİTAŞ

131 INVESTIGATING MECHANICAL PROPERTIES OF HARDOX 400 AND ST52 STEEL

COUPLE JOINED BY MIG/MAG WELDING Musa KILIÇ

142

AN INVESTIGATION INTO THE EFFECT OF WELDING PARAMETERS ON MECHANICAL PROPERTIES OF DISSIMILAR RESISTANCE SPOT WELDED DP1000–

QP1180 STEEL JOINTS

Abdullah Yasin BİLİCİ

211 MICROSTRUCTURE CHARACTERIZATION AND MECHANICAL PROPERTIES OF

9CR-1,2W WELD METAL Fikret KABAKÇI

193 INVESTIGATION OF CUTTING FORCES AND SURFACE ROUGHNESS IN HARD

TURNING OF BEARING RING WITH CBN INSERT Mehmet BOY 203 ACTIVATED FLUX TIG WELDING OF AUSTENITIC STAINLESS STEELS Ahmet İrfan YÜKLER

Parallel Session – Room : Siderite –- 04.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

51 BARKHAUSEN NOISE AS A MAGNETIC NONDESTRUCTIVE TESTING TECHNIQUE Oğuz KOÇAR 198 EFFECT ON CUTTING FORCES OF MINIMUM QUANTITY LUBRICATION METHODS

IN HARD TURNING OF 90MNCRV8 COLD WORK TOOL STEELS Nihat YILMAZ 90 DETECTION OF SURFACE RAIL DEFECTS WITH USING IMAGE PROCESSING

METHOD

Cihan MIZRAK

116 EFFECTS OF BIMETALLIC MATERIAL PROPERTIES ON APPLICATIONS FOR RELIABILITY OF DESIGN

Ahmet ÇETİN

176 PHASED ARRAY INDUSTRIAL APPLICATIONS OF IRON-ROAD ULTRASONIC INSPECTION METHOD

Ramazan YILMAZ

179 EFFECTS OF ALLOYING ELEMENTS (MO, NI AND CU) ON THE AUSTEMPERABILITY

OF GGG-60 DUCTILE CAST IRON Erkan KONCA

4. SESSION

Parallel Session – Room : Hematite –- 04.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

160 INVESTIGATION OF TRIBOLOGICAL AND MECHANICAL PERFORMANCE OF

CRYOGENIC TREATED MEDIUM CARBON STEEL, 38MNVS6 Esad KAYA 169 EFFECT OF CARBON CONTENT ON THE WEAR BEHAVIOUR OF EUTECTOID STEEL

WIRE ROD Melike BİRİNCİ

183 EFFECT OF THERMAL FACTORS ON ABRASIVE WEAR BEHAVIOR OF DIE CASTING

MOLD MATERIALS Ferhat GÜL

201 INFLUENCE OF GRAIN SIZE ON SUSCEPTIBILITY TO INTERGRANULAR

CORROSION OF AISI 316 AUSTENITIC STAINLESS STEEL Hüseyin ZENGİN 167 EXAMINATION OF SOLID STATE NITROGEN ABSORPTION FOR PRODUCTION OF

NICKEL FREE STAINLESS STEEL Oğuz Gürkan BİLİR

172 DETERMINING RETAINED AUSTENITE QUANTITY AND COMPOSITION WITH HEAT

TREATMENT PARAMETERS IN SAE52100 STEELS Ahmet Efe GEZMİŞOĞLU

Parallel Session – Room : Magnetite –- 04.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

177 GTAW WELDING OF AUSTENITIC STAINLESS STEEL AND ITS CORROSION

PROPERTIES Ramazan YILMAZ

182 USING A NICKEL-COATED MOLD WALL IN CONTINUOUS CASTING MACHINE Mehmet Fatih KAHRAMAN 215 AN INVESTIGATION ON MECHANICAL PROPERTIES AND MICROSTRUCTURE OF

AISI 304L AND 316TI STAINLESS STEELS WELDED BY TIG Gökhan Emre KÜKÜRTÇÜ 180 USE OF SUBMERGED ARC WELDING TECHNIQUE IN IRON AND STEEL INDUSTRY

FOR COATING Mehmet Fatih KAHRAMAN

237 MICROSTRUCTURAL AND MECHANICAL CHARACTERIZATION OF 9 CR - 1 MO - 1

W WELD METAL Emin SALUR

60

X-RAY DIFRACTION INVESTIGATION OF WELDING CHARACTERISTICS OF AISI304-HARDOX 400 STEEL COUPLES WELDED BY PLASMA TRANSFERRED ARC

WELDING

Parallel Session – Room : Wustite –- 04.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

199

EXPERIMENTAL INVESTIGATION OF EFFECT OF PROCESSING PARAMETERS ON THE SURFACE ROUGHNESS DURING THE BRASS ALLOY TURNING WITH

ABRASIVE WATER JET

Fuat KARTAL

200 OPTIMIZATION OF PROCESS PARAMETERS FOR ABRASIVE WATER JET OF CAST

ALUMINUM ALLOY A319 BY TAGUCHI METHOD Fuat KARTAL

124 THE IMPROVEMENT OF WEAR RESISTANCE OF STEEL DESCALING ROLLERS BY

BORIDING PROCESS IN WIRE DRAWING INDUSTRY Ahmet POLAT 228 EFFECT OF FRICTION STIR PROCESS ON ULTIMATE STRENGTH OF SHIP HULL

GIRDER STEEL PLATES ESTIMATED BY FEM APPROACH

Dursun Murat SEKBAN

209 EFFECT OF FORGING AND HEAT TREATMENT ON MICROSTRUCTURE AND

MECHANICAL PROPERTIES OF SAE 4140 STEEL Secarettin AKDI 181 EFFECT OF FRICTION STIR PROCESSES ON MECHANICAL PROPERTIES OF DP600

STEEL

Onur SAYAR

Parallel Session – Room : Limonite –- 04.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

2 REVISION OF THE ROLLING MILL ROLLER BEARING Bilal ÇOLAK

5 THE EXPERIMENTAL INVESTIGATION OF SPRINGBACK PHENOMENON IN DP600

SHEET METAL MATERIAL AND ESTIMATION WITH FUZZY LOGIC Tahsin ÖNEL 32 HYDROFORMABILITY OF ADVANCED HIGH STRENGTH STEELS THROUGH FEA Doğan ACAR 69 COMPARISON OF VARIOUS CRITICAL PLANE APPROACHES UNDER

PROPORTIONAL AND NON-PROPORTIONAL MULTIAXIAL STRESS STATES Tuğçe LEBLEBİCİ 75 COMPARISON OF ENERGY ABSORBING MEMBERS FOR PASSENGER COACHES Ramazan ÖZMEN 76 STRESS DISTRIBUTION ANALYSIS AND TOPOLOJI OPTIMIZATION FOR

SEMI-TRAILER Şükrü ŞEN

Parallel Session – Room : Siderite –- 04.04.2017 – ( 13:30 – 15:00 )

Paper ID Title Speaker

6 INVESTIGATION OF HEAT RECOVERY AND SAVING POTENTIAL OF HOT STOVES IN

BLAST FURNACES Erhan KAYABAŞI

36 ENERGY SAVING IN INDUSTRIAL ANNEALING FURNACES Durmuş KAYA

44 EVALUATION OF ENERGY SAVING POTENTIAL IN INDUSTRIAL FURNACES USED IN

IRON-STEEL SECTOR Şaban PUSAT

47 ELECTRICITY GENERATION WITH ORGANIC RANKINE CYCLE FROM WASTE GASES Emrecan ERCAN 120 THE EXPERIMENTAL INVESTIGATION OF THE EFFECTS OF IRON STEEL PLANT

WASTE (SLAG) IN BIOGAS PURIFICATION Nuri TUNÇ

188

INVESTIGATION OF THE EFFECT OF IMPROVED WASTE FUSEL OIL USING IN A SPARK IGNITED ENGINE TO DETERMINE THE ENGINE PERFORMANCE AND

EMISSIONS

5. SESSION

Parallel Session – Room : Hematite –- 04.04.2017 – ( 15:30 – 17:00 )

Paper ID Title Speaker

77 THE INFLUENCE OF TOOL HELIX ANGLE ON TOOL WEAR WHEN END MILLING

AISI 8640 STEEL İbrahim ÇİFTÇİ

82 MECHANICAL CHARACTERIZATION OF THIN SHEET METALS FOR SUSPENSION

SYSTEM FORMING DESIGN Ali Murtaza RUTCI

87 THE INVESTIGATION OF TRIBOLOGICAL PROPERTIES OF THERMAL AGED

CUAL10FE ALLOYS Anıl IMAK

95 INVESTIGATION OF SHEET METAL FORMING PROCESS BASED ON FINITE

ELEMENT SIMULATION Ali Murtaza RUTCI

101 2D MODELING OF RESIDUAL STRESSES IN HARD TURNING OF AISI 4140 STEEL Mehmet Erdi KORKMAZ 102 MODELLING OF ROUND ROLLING PROCESS BY USING FINITE ELEMENT METHOD Emre EROL

Parallel Session – Room : Magnetite –- 04.04.2017 – ( 15:30 – 17:00 )

Paper ID Title Speaker

194 AN APPLICATION EXAMPLE FOR ELECTRIC POWER PRODUCTION WITH ORGANIC

RANKINE CYCLE FROM WASTE HEAT OF BASIC OXYGEN FURNACE PROCESS Aytaç AYDIN 195 AN APPLICATION EXAMPLE FOR DEMINERALIZED WATER PRODUCTION FROM

WASTE HEAT OF BASIC OXYGEN FURNACE PROCESS Aytaç AYDIN 204 IMPROVING THE ENERGY EFFICIENCY IN IRON AND STEEL INDUSTRY BY

ELECTRIC MOTOR RETROFIT Mehmet AKBABA

244 IRON POWDER RECOVERY FROM STEEL PLANT RED MUD Çağıl KOYMATÇIK

218 HEAT TRANSFER ANALYSIS OF A REHEAT FURNACE IN IRON AND STEEL

INDUSTRY Hüseyin YAĞLI

234 PRECIPATING OF SINTER POWDER BY ESP AND EFFECTS OF SINTER POWDER ON

ESP EFFICIENCY Muhammed Esad ÇAYIR

Parallel Session – Room : Wustite –- 04.04.2017 – ( 15:30 – 17:00 )

Paper ID Title Speaker

205 FROM WASTE MANAGEMENT IN IRON AND STEEL SECTOR TO ZERO WASTE Esma YILMAZ

98 INDUSTRIALIZATION AND CANCER RISKS; A REVIEW Kasım YILMAZ

17

AN EXAMPLE IMPLEMENTATION FOR THE LOWEST REDUCTION OF ENVIRONMENTAL EFFECTS OF CHEMICAL ORIENTED DISASTERS: THE REACH

SYSTEM

Gazanfer ERBAY

94

AN OBSERVATION ON NATURAL WEATHERING EFFECT ON COLOR AND GLOSS PROPERTIES OF PPG COILS BASED ON DÖRTYOL HATAY TURKEY REGION

COMPARED WITH FLORIDA

Tuğçe TOP

80 A RESEARCH ON BUSINESS SATISFACTION LEVELS OF OCCUPATIONAL HEALTH

AND SAFETY SPECIALISTS IN OCCUPATIONAL HEALTH AND SAFETY PRACTICE Volkan SANCI 93 REMOVAL AND ABSORPTION OF AMMONIA BY AN AIR STRIPPING PROCESS

Parallel Session – Room : Limonite –- 04.04.2017 – ( 15:30 – 17:00 )

Paper ID Title Speaker

49 THE EFFECTS OF REAL EXCHANGE RATES ON IRON & STEEL INDUSTRY Ömer Faruk ÖZYALÇIN

81 LONG-TERM STEEL CONSUMPTION IN TURKEY Hüseyin KARAMELİKLİ

139 ESTIMATION OF STRENGTH PROPERTIES IN CONCRETE STEEL BARS BY MULTIPLE

REGRESSION METHOD Hande VURŞAN

84 A FORECASTING ANALYSIS OF EXPORTS OF RAIL AND RAIL EQUIPMENTS IN

TURKEY BY GREY PREDICTION AND EXPONENTIAL SMOOTHING Ahmet Ziyaeddin BULUM 154 THE NUMERICAL SIMULATION OF THE FATIGUE ANALYSIS OF UIC60 AND 49E1

RAILS FOR HIGH SPEED MOVING TRAINS Mehmet Akif KOÇ 108 THE DEVELOPMENT OF A DECISION SUPPORT SYSTEM FOR IRON AND STEEL

INDUSTRY IN TURKEY Muharrem DÜĞENCİ

Parallel Session – Room : Siderite –- 04.04.2017 – ( 15:30 – 17:00 )

Paper ID Title Speaker

238 ENERGY BALANCE RELATION FOR A BATCH TYPE FURNACE, A THEORETICAL STUDY

Selçuk SELİMLİ

243 ENHANCEMENT OF ENGINE OIL LIFE WITH VACCINATION METHOD İsmail TARAKÇI 55 INVESTIGATION OF NANOCRYSTALLINE STAINLESS STEELS AS A FUNCTION OF

MILLING TIME Ahmet Burçin BATIBAY

223 EXPERIMENTAL INVESTIGATION ON SELF-LOOSENING OF PRELOADED STAINLESS STEEL FASTENERS

Barış TANRIKULU

259 THE INTEGRATION OF PLATE HEAT EXCHANGERS TO HEATING SYSTEM IN AN

IRON & STEEL PLANT Mutlucan BAYAT

8 INVESTIGATION OF PHYSICAL, CHEMICAL AND METALLURGICAL PROPERTIES OF DOMESTIC AND IMPORTED PELETS

Neslihan ATALAY

6. SESSION

Parallel Session – Room : Hematite –- 05.04.2017 – ( 09:00 – 10:30 )

Paper ID Title Speaker

37

FATIGUE STRENGTH ASSESSMENT USING FINITE ELEMENTS AND INTERNATIONAL STANDARDS: APPLICATION EXAMPLES FROM RAILWAY WAGON

CERTIFICATION

Emin SÜNBÜLOĞLU

59 INTERLABORATORY COMPARISONS OF TENSILE TEST FOR REINFORCING STEEL

RELATED TO TS EN ISO 6892-1 Alper INCESU

68 ANALYSIS OF ACCREDITED LABORATORIES IN THE STEEL SECTOR IN TURKEY Murat KAVRUK 126 MEASUREMENT UNCERTAINTY CALCULATION FOR CHARPY IMPACT TEST OF

S275JR QUALITY STEEL Alper INCESU

208 THE LIMITATIONS FOR PLANE-STRAIN FRACTURE TOUGHNESS TEST OF STEEL COMPACT TENSION SPECIMENS

Oğuzhan DEMİR

79 INTERLABORATORY COMPARISONS OF CHARPY IMPACT TEST FOR S275JR STEEL

Paper ID Title Speaker 225 RESEARCH AND DEVELOPMENTS IN IRON AND STEEL INDUSTRY Aslan ÜNAL 241 A LITERATURE REVIEW TO DESIGN OF 60 METRES AERIAL WORK PLATFORM Yasin YAMAN 148 DETERMINATION OF THE INDIVIDUAL LEVEL OF FINANCIAL LITERACY: A STUDY

IN KARDEMIR INC. Murat YILDIRIM

149 A STUDY ON THE FINANCIAL BEHAVIOR OF KARDEMIR INC. EMPLOYEER Gülay GÜNAY 155 THE EUROPEAN COAL AND STEEL COMMUNITY AS A TRIVET FOR PEACE AFTER

THE SECOND WORLD WAR Umut KEDİKLİ

147 STEEL AND DEFENSE: SUCCESS TO THE SUCCESSFUL Bahar AŞÇI

Parallel Session – Room : Wustite –- 05.04.2017 – ( 09:00 – 10:30 )

Paper ID Title Speaker

157 SIMULATION AND ANALYSIS OF THE SOLIDIFICATION CHARACTERISTICS OF A

CAST AUSTENITIC STAINLESS STEEL Gülşah AKTAŞ ÇELİK 171 ANALYSIS OF THE EFFECT OF THE CONTINUOUS SLAB CASTING PARAMETERS ON

MOULD FRICTION Hakan KAPUSUZ

229 UNPRESSURIZED GATING SYSTEM DESIGN AND SIMULATION IN SAND CASTING

OF DUCTILE IRON Ali Serdar VANLI

7 INVESTIGATION OF THE WETTING BEHAVIORS OF SAC305 AND SAC405 TERNARY LEAD-FREE SOLDER ALLOYS ON CU SUBSTRATE

Hasan ABUT

258 CLIMATE CHANGE EFFECT BY ROAD TRANSPORTATION IN KARABUK PROVINCE Ali CAN 3 ALUMINUM INGOT FEEDING SYSTEM DESIGN FOR BASIC OXYGEN FURNACE Ahmet KAYRAK 239 FEEDER DESIGN OPTIMIZATION FOR ALUMINUM SAND CASTING Mustafa ERCAN

7. SESSION

Parallel Session – Room : Hematite –- 05.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

153 INFLUENCE OF COOLING CONDITIONS ON FRACTURE TOUGHNESS OF 1040

QUALITY STEEL Fazıl HÜSEM

248 INFLUENCE OF AGING ON RESIDUAL STRESS, WEAR AND HARDNESS

BEHAVIOUR IN AL-CU-NI HEUSLER ALLOYS Fazil HÜSEM

197 INVESTIGATION OF THE EFFECT OF YTTRIA CONTENT ON THE MECHANICAL

PROPERTIES OF THE ALUMINUM/TIC COMPOSITES Yasin AKGÜL 135 NANO-SIZED IRON OXIDE PRODUCTION AND CHARACTERIZATION BY ARC

DISCHARGE METHOD Safa POLAT

152 INFLUENCE OF HEAD HARDENING PROCESS ON FRACTURE TOUGHNESS IN

RAILS Fazıl HÜSEM

196 FABRICATION AND MECHANICAL BEHAVIOR OF ALUMINUM-MATRIX

Parallel Session – Room : Magnetite –- 05.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

227 THE OPTIMIZATION OF THE COATING PROCESS PARAMETERS BY ELECTRO-SPARK

DEPOSITION (ESD) TECHNIQUE USING STEEL/INCONEL COUPLE Mustafa Safa YILMAZ 166 THE EFFECT OF PRIOR AUSTENITE GRAIN SIZE ON MICROSTRUCTURE OF

MEDIUM CARBON DUAL PHASE STEELS Özge ARARAT

214 INVESTIGATION OF RESISTANCE SPOT WELDING CONNECTION IN DP600 STEEL Burak Emre YAPANMIŞ 27 EFFECT OF CHROMIUM ON THE BORONIZING BEHAVIOR OF IRON Mehmet TARAKÇI

29 CHARACTERIZATION OF BIODEGRADABLE FE-CO ALLOYS Mehmet TARAKÇI

230

EFFECT OF NB CONTENT ON MICROSTRUCTURE TENSILE STRENGTH PROPERTIES OF NB-V ADDED MICROALLOYED STEEL PRODUCED BY POWDER

METALLURGY METHOD

Ferhat KAHVECİGİL

232 THE MECHANICAL PROPERTIES OF CARBURIZED AND UNCARBURIZED AISI 8620

STEEL BY POWDER METALLURGY METHOD Özcan TOPÇU

Parallel Session – Room : Wustite –- 05.04.2017 – ( 11:00 – 12:30 )

Paper ID Title Speaker

143 EFFECT OF TEMPERING TIME AND TEMPERATURE ON WEAR PERFORMANCES OF CR-W STEELS

Fatih AYDIN

184 TRIBOLOGICAL BEHAVIORS OF NITRIDED AND NITROXED TOOL STEELS M. Emre TURAN 1 INFLUENCE OF STRAIGHTENING PROCESS ON MECHANICAL PROPERTIES OF

PRE-STRAIN PEARLITIC STEELS Alper INCESU

191 THE INFLUENCE OF HEAT TREATMENT ON STRUCTURAL TRANSFORMATIONS OF

NITI ALLOY Yüksel AKINAY

146 DRY SLIDING AND CORROSIVE WEAR PERFORMANCES OF HEAD HARDENED

RAILS M. Emre TURAN

136 ENHANCED SYNTHESIS AND FUNCTIONALIZATION OF BORON NITRIDE

POSTER PRESENTATIONS

1. SESSION

Location : Poster Hall - 03.04.2017 - ( 13:30 – 17:00 )

Paper ID Title Presenter

4 CORROSION-RESISTANT HIGH ENTROPY STAINLESS STEELS — A PERSPECTIVE Burak DİKİCİ 86 INVESTIGATION FRICTION WELDING PROCESS OF HIGH SPEED STEEL TO SPRING

STEEL İhsan KIRIK

20 FRICTION STIR SPOT WELDING FOR DIFFERENT METALS: A REVIEW Melike ŞAŞMAZ 33 HIGH PERFORMANCE COPPER AND COPPER ALLOYS FABRICATED BY SEVERE

PLASTIC DEFORMATION Aslıhan GÖKDUMAN

34 HIGH PRESSURE TORSION APPLICATIONS ON DILUTE COPPER ALLOYS Hasan KÖKLÜ 57 A METHOD FOR ASSESMENT OF RUST PREVENTIVE OIL ON GALVANIZED STEEL Özgür KARAKAŞ 63 THE CHANGES IN ISO 6892-1:2016 METALLIC MATERIALS TENSILE TESTING

STANDARD Bülent AYDEMİR

70 A NEW HARD COPPER ALLOY ALTERNATIVE TO CUCONIBE ALLOY FOR STEEL

WIRE MESH WELDING Tuba ÖZEREN

71 AN INVESTIGATION ON CUTTING BEHAVIOR OF CONIAL SHAPE MEMORY ALLOY

BY ABRASIVE WATER JET Ali GÜNEN

72 APPLICATION OF DIFFERENT COATING METHODS TO EXTERNAL COOLING

ROLLER AND CHARACTERIZATION OF APPLIED COATINGS Ali GÜNEN 78 IMPORTANCE OF FORCE MEASUREMENTS AND THEIR TRACEABILITY IN STEEL

INDUSTRY Haldun DİZDAR

74 DETERMINING THE CORROSION BEHAVIOUR OF EN 1.4462 DUPLEX STAINLESS

STEEL IN FECL3 MEDIA FOR VARIOUS SOLUTION TREATMENT CONDITIONS Alptekin KISASÖZ

2. SESSION

Location : Poster Hall - 04.04.2017 - ( 09:00 – 12:30 )

Paper ID Title Presenter

92 CHANGE IN CHLORIDE CONTENT OF REGENERATED RED IRON OXIDE PARTICLES

IN ACCORDANCE WITH PARTICLE SIZES Alper AKÜN

97 AGING OF A356 ALUMINUM BILLETS PRODUCED BY SEMI-SOLID METAL

PROCESSING Rıdvan GECU

99 SAFE BEHAVIOR CHANGE TO RELEASE OF OHS CULTURE IN THE IRON AND STEEL

SECTOR Cumhur KOCAMAN

107 EFFECT OF REDUCTION RATE IN FORMABILITY OF TITANIUM + NIOBIUM

ALLOYED IF STEEL Muhammed Mustafa ERŞEN

114 EFFECT OF HEAT TREATMENT PARAMETERS APPLIED TO AA7075 ALLOY ON

CORROSION BEHAVIOR Gökhan ÖZER

117 MAGNESIUM METAL PRODUCTION WITH MAGNETERM PROCESS BY USING

ALUMINIUM Yahya BAYRAK

130 INVESTIGATION OF MECHANICAL PROPERTIES OF PIPES USED IN OIL AND GAS

PIPELINES Osman AKTAŞ

132 ELECTROSTATIC POWDER PAINTING PLANT CONVEYOR SYSTEM AND ENERGY

EFFICIENCY Demet TAŞKAN

140 ENERGY SAVING BY USING BLAST FURNACE TOP PRESSURE RECOVERY TURBINE

(TRT) SYSTEM Selcuk KUŞOĞLU

141 THE INVESTIGATION OF MICROSTRUCTURE OF DUBLEX STAINLESS STEEL

WELDED BY FCAW METHOD Mustafa TÜMER

144 INVESTIGATION OF DETERMINATION THE NON-RECRYSTALLIZATION

TEMPERATURE (TNR) BY THERMO-MECHANICAL SIMULATION METHODS Ekrem AKÇA 189 THE TRIBOLOGICAL CHARACTERISTICS OF ELECTROLESS NI-P COATED AISI1020

CARBON STEEL Ulaş MATİK

251 RECYCLING AND REUSE POTENTIAL OF SOLID WASTES PRODUCED IN IRON AND

3. SESSION

Location : Poster Hall - 04.04.2017 - ( 13:30 – 17:00 )

Paper ID Title Presenter

150 TURKEY'S MAGNESITE FOR PRODUCTION OF FUSED MAGNESIA, PROPERTIES

AND USES IN REFRACTORY APPLICATIONS Asım BİLGE

165 THE EFFICIENT USE OF NOISE PRODUCED IN ENERGY FACILITIES OF INTEGRATED

IRON AND STEEL PLANTS Hasan KAHRAMAN

187 STUDY OF THE COMPACTING AND PRE-SINTERING OF DENTAL ZIRCONIA WASTE

POWDERS Handan TURAN MATİK

192 EFFECT OF SIC PARTICLE SIZE ON THE TRIBOLOGICAL PROPERTIES OF

AA6061-SICP COMPOSITE PREPARED BY HOT PRESSING Mert YAKIŞIK 145 RESIDUAL STRESS DISTRIBUTION IN R220 AND R260 GRADE GROOVED RAILS M. Emre TURAN 216 IMPROVEMENT OF 16MNCR5 STEEL WEAR RESISTANCE BY DEFORMATION Hüseyin DEMİRTAŞ 231

EFFECT OF CR CONTENT ON MICROSTRUCTURE AND TENSILE STRENGTH PROPERTIES OF NONALLOYED STEEL PRODUCED BY POWDER METALLURGY

METHOD

Rıfat GÜNDÜZ

233

EFFECT OF GRAPHITE CONTENT ON MICROSTRUCTURE AND MECHANICAL PROPERTIES OF MO ADDED STEEL PRODUCED BY POWDER METALLURGY

METHOD

Mehmet Akif ERDEN

236

RESIDUAL STRESS MEASUREMENT IN EN ISO / IEC 17025 STANDARD AND HARDNESS-RESIDUAL STRESS RELATIONS IN HOT ROLLED SQUARE AND ROUND

SHAPED PROFILES

Tolga TURANLI

245 ACCELERATED COOLING HEAT TREATMENT OF EQUILATERAL ANGLE AND

HEA-HEB PROFILES Fatma KÖZ

249 INVESTIGATION OF WEAR AND MECHANICAL BEHAVIORS OF DAMASCUS STEELS Eren SALİS 56 ECONOMIC CRISES IN TURKEY AND IN THE WORLD AND THEIR EFFECTS ON

Influence of Straightening Process on

Mechanical Properties of Pre-Strain Pearlitic

Steels

Alper INCESU

1, Yasin AKGUL

1, Muhammet Emre TURAN

1, Ahmet GULLU

21

Karabuk University, Iron and Steel Institute

2Gurmak Çelik

correspond e-mail: yasinakgul@karabuk.edu.tr

ABSTRACT

In this study, effect of straightening process on mechanical properties of pre-strain pearlitic

steels was investigated. The material employed in this study has 0,83 % Carbon content. Tensile

test, Vickers hardness test and Wear tests under load of 10N and 20N were performed for

samples (straightened and non-straightened) to determine mechanical properties. Also,

Scanning Electron Microscope (SEM) was used for microstructure characterization. Tensile

test results revealed that yield strength and tensile strength increased with straightening process.

2

Revision of The Rolling Mill Roller Bearing

Bilal ÇOLAK

*, Ahmet EREN

+, Naci KURGAN

*#Karabuk University, Eskipazar Vocational School

Bahcepinar Mah. Hastane Cad. No:37 Eskipazar, Karabuk, Turkey bilalcolak@karabuk.edu.tr

Ondokuz Mayis University, Engineering Faculty Kurupelit Kampusu, Atakum, Samsun, Turkey

naci.kurgan@omu.edu.tr +aerena@gmail.com

Abstract— Generally, 4-row cylindrical roller bearings

are used as roll neck bearing in rolling mills. The inner ring of these bearings must be fitted as a tight fit to the roll neck according to the structure of the bearing. This concomitantly requires a great deal of labor, time and equipment. In addition to this hardship, roller bearing damages and time lost are in question because of difficulties encountered when mounting the chock to the roll. It was provided an improvement in bearing life and an increase in production speed and quantity by being eliminated these problems with the use of tapered roller bearings instead of cylindrical roller bearings.

Keywords— 4-high, rolling, roller bearing, rolling

force, axial force, radial force, chock I. INTRODUCTION

This revision has been performed in the finishing mill of a hot rolling mill producing flat rolled products in Turkey. The finishing mill consists of 7 stands finishing train, side guides and with looper tables between each pair of stands (Fig. 1). Finishing mill is equipped with the high technology systems to achieve proper surface condition, narrow dimension tolerances and good shape. There are AGC (Automatic Gauge Control), roll bending and roll shifting systems in this mill. Each stand reduces strip thickness according to calculated setup to produce ordered dimensions at the exit of last stand. Each stand has a 4-high rolling mill with two work rolls and two support rolls [1] (Fig. 2). The revision has been held on the last three stands (F5, F6, F7) of the finishing mill.

Fig. 1 Finishing mill

Fig. 2 4-high rolling mill [2]

4-row cylindrical roller bearing (Fig. 3a) is used on work roll in the mill. These bearings have high stiffness and can accommodate only radial loads. For this reason, they are mounted together with double row tapered roller bearing shown in Fig. 3b.

a. Radial bearing b. Thrust bearing Fig. 3 Original roller bearings [1]

Roll barrel surfaces are deteriorated during rolling. They are ground to remove residual work hardening wear and minor damage. After grinding of the barrel surfaces, chocks must be remounted on the roll neck. Assembled chocks are fitted to the roll neck via chock mounting device shown in Fig. 4 and operating principle of this device is schematized in Fig. 5. This process is performed many times in every shift. It is important to make the settlement process as soon as possible to prevent interruption of production.

Fig. 4 Chock mounting device

Fig. 5 Main steps for dismounting and mounting of chocks [3]

II. AVAILABLEROLLERBEARING

TROUBLES

A.

Inner Race Mounting ProblemThe inner ring of the 4-row cylindrical roller bearings illustrated in Fig. 3a can be completely separated from the bearing. The cylindrical roller bearing inner rings are mounted on the roll neck with tight fit (Fig.6). In this process, the selection of the fitting temperature is important so that the properties of the ring material are not adversely affected. The size difference between the roll neck and the bearing inner race varies between 0.084 mm and 0.143 mm [1]. For mounting the inner races on the necks, they must be heated to approximately 100 to 120°C. The races are dimensionally stable up to 160°C, i.e. this temperature must not be exceeded, not even partly. A temperature presetting device is available so that the maximum temperature not to be exceeded. The heated races are centrically pushed onto the roll until they abut. They should be left on the roll to cool down and shrink on. While cooling down, the races must on no account be axially adjusted [4]. The work roll before mounting is shown in Fig. 7a and it is shown after mounting in Fig. 7b.

During mounting, physical damage of the ring depends on the degree of mastery of the person. The ring mounting is another disadvantage of the cylindrical roller bearing when it is remembered that the life of the roller bearing depends largely on the mounting conditions.

a. Heating of the rings b. Mounting of the rings Fig. 6 Mounting process of the rings

4

a. Before mounting b. After mounting Fig. 7 Work roll [1]

Inner rings must be finish ground after mounting on the roll neck to minimize eccentricity of the roll neck to the roll body (Fig.8.). Thanks to this skin grind, bearings have extended useful life in the mill.

Fig. 8 Ring grinding

Sturdy rings on scrap rolls are removed by an induction heater and remounted to new rolls (Fig. 9). But in this reheating operation, the bearing material may be impaired and result in physical damage to the bearing. This process also causes labor and time loss.

a) Heating of the ring b) Extracting of the ring Fig. 9 Dismounting of the ring

B.

Roller DropRolls that have been ground in certain periods need to chock with the aid of the chock mounting system shown in Fig. 4. This process is as shown in Fig. 10.

The four-row cylindrical roller bearings are provided with a double pronged brass cage that cannot properly control the roller drop during the bearing life cycle. With high roller drop, the mounting process can be very tricky. Due to the tight dimensions, care must be paid to avoid damaging bearing components. In fact, by hitting the inner ring, the resulting tilting moment on the rollers can

damage the cage or outer ring integral ribs as shown in Fig. 11 [3]. Besides the bearing damage, the installation time is also extended. Repeatedly performing this assembly process in a busy working environment can cause the production to be interrupted.

Fig. 10 Mounting of the CRB to the roll (Original type bearing) [1]

Fig. 11 Roller drop [3] III. REVİZYON

Although cylindrical roller bearings take only the radial loads, tapered roller bearings have the inherent ability to carry combinations of radial and thrust

loads, depending on the angle of the rollers. This angle is indicated by the K factor (Fig. 12). The bearing with small K factor has high thrust load rating, low radial load rating; the bearing with large K factor has high radial load rating and low thrust load rating [5]. The selected tapered roller bearing in this revision has been chosen to have high K factor (K = 1.89) to accommodate as a radial bearing.

K = dynamic radial load rating / dynamic thrust load rating

a. Shallow angle for heavy radial loads b. Steep angle for heavy thrust loads

(K=1,5-2,2) (K=0,6-1,2) Fig. 12. K factor [6]

The radial load carriage capacity of tapered roller bearings is lower than the radial load carriage capacity of the same-sized CRBs. A tapered roller bearing of the same size was needed to carry the same amount of radial load. To find the most suitable bearing to meet the need, the theme was passed with Timken regional sales manager. In making bearing selections for the hot strip mill chock, Timken representatives have assisted us in load and life calculation methods that have taken full advantage of tapered roller bearing operating characteristics. In this stage rolling loads (radial, axial, bending), operating speed, working temperature, material type, lubrication condition, environmental factors, bearing and roller dimensions and tolerances have been considered. This information required in the calculation and selection of the bearing is given in Table I, Table II and Table III.

TABLEI WORKINGCONDITIONS[1] Stand Max. Radial Force (kN) Max. Bending Force (kN) Max. Rolling

Speed (m/sec) Lube

F5 5.000 800 4,57-11,43 Grease

F6 5.000 800 6,03-15 Grease

F7 5.000 800 7,22-15 Grease

The forces given in Table 1 are the forces per bearing. TABLEII Distanc e (mm) Barrel Width (mm) Bearing Temp. (0C) Internal Clearan ce (mm) Max Min F5 1860 1150 50 0,28 460 410 F6 1860 1150 50 0,28 460 410 F7 1860 1150 50 0,28 460 410 TABLEIII

INFORMATIONOFROLLEDMATERIAL[1]

Stand Max. Width of Rolled Material (mm) Max. Reduction (Δh) (mm) Rolling Temp. (0C) Material Grade F5 1000 1 900-1000 Low carbon steel F6 1000 1 900-1000 F7 1000 1 900-1000

As a result of the evaluations, it is concluded that the TQOW type 4-row tapered roller bearing shown in Fig. 13 is the most suitable bearing in the present conditions. The type TQOW is particularly suited to roll necks not having a separate fillet ring, where the cone is backed directly against the roll shoulder [6].

Fig. 13 4-row tapered roller bearing (New type bearing) (TRB) The static and dynamic load ratings of the old and new type bearings are given in Table 4.

TABLEIV LOADRATINGS Bearing Type Static Load

Rating

Dynamic Load Rating

Original Roller Bearing (CRB)

(C0) (kN) (C) (kN)

5220 2030

New Kind of Bearing (TRB)

– Timken 090

C (kN) C90(kN)

98,8 648

IV. LOADDISTRIBUTION

The distribution of load in each work roll bearing is dependent not only on the magnitude of radial and axial loads but also their relative values. That is, when the radial load is relatively large compared to the axial load, then all the four rows will be loaded, to differing values. If the axial load is significant

6

if the thrust loads increase, the new type radial bearing (TRB) will not carry thrust loads. Because bearing in which has the least internal clearance takes the load. Due to the structure of the tapered roller bearings, the radial and axial clearances can be adjusted during mounting. Axial clearance of the radial TRB (Fig. 13) is set larger than axial clearance of the 2-row tapered roller bearing (Fig. 3b) in the same chock. Thus, the radial TRB only carries radial loads. Because of this, axial loads were not considered in life calculation of the TRB.

Due to the plastic deformation of the material, the pressure distribution occurred between the work roll and the material is shown in Fig. 14. It is assumed that the resultant force of this pressure distribution (Fr) acts from the neutral point (N) where there is no

relative motion between the roll and the material. This whole resultant force isn't taken by the radial TRB. This force is divided into vertical (Fv) and

horizontal (Fh) components at varying rates

depending on the ф angle. Since the horizontal component is taken by the radial TRB, only this component has been considered in the life calculation.

Fig. 14 The components of the rolling force

The maximum radial force is 5.000kN in the mill (Table 1). The horizontal component of this force (F ) is taken by the TRB. The maximum value of h this component (

max h

F

) occurs when the angle ф is maximum. This means that the diameter of the roll is the smallest (410 mm) (Table II) and the reduction is the largest (Δh=1 mm) (Table III). The roll bite angle (α) is calculated as 40 with the aid of trigonometricrelations as shown below.

0 1 4 205 5 , 0 205 2 cos R h R

The angle Φ is theoretically 25% of angle α. 0 1 4 25 , 0 25 , 0

Here the angle is 10 and the force max h

F

is 87kN.kN F

Fhmax rsin5.000sin187

The vertical component of the radial load (Fv) is

transmitted to the back-up roll barrel over the work roll barrel and then to the back-up roll bearings (Fig. 15).

Fig. 15 Transmission of the separating force [7] The main forces acting on the work roll bearings are the bending forces which are occurred by the bending system (Fig. 16). This rolling mill is equipped with a positive bending system and bending forces are around 800kN per bed (Table I). The bending force (Fb) is perpendicular to the

horizontal component of the radial force (Fh). With

the help of trigonometric relations, the compound of these two forces (F) is found to be 805kN as shown below. k N Fhmax 87 kN Fb800 (Table I)

F F

kN F h b 87 800 805 2 2 2 2 max Fig. 16 Bending system [8]

There is also a horizontal component of the roll force caused by the offset of the work roll to the backup roll. This force, as well as the friction force between the roll and the material, is neglected in the bearing lifetime calculation.

A.

Bearing Life CalculationAccording to ISO and AFBMA (Anti-Friction Bearing Manufacturers Association), the dynamic load ratings used in bearing life calculation are given for 1 million cycles. Table 4 shows the number of dynamic load ratings of the original CRB for 1 million cycles. However, for Timken bearings this value is given for 90 million cycles (500rpm, 3000h) [5]. The life calculation that has been made considering this difference is given below.

1) Original Bearing (CRB) Life Calculation

cycle

x

x

F

C

L

3 6 6 10 6 3 1010

.

8

,

21

10

805

2030

10

2) Life Calculation of the New Kind Bearing (TRB)

cycle

x

x

F

C

L

3 6 6 10 6 3 10 9010

.

6

,

43

10

.

90

805

648

10

.

90

Although the dynamic load rating of the TRB is lower than that of the CRB, the life of the Timken bearings is higher than that of 90 million rpm.

When the speed reaches 2 times in the roller bearings, the life is reduced to about half [5]. Since the life of Timken bearings is given for 500rpm and the current bearing speeds are also approximately the same with this speed, negative impact of speed on bearing life isn't in question.

V. CONCLUSIONS

As a result of this revision, the disadvantages in using cylindrical roller bearings have been abolished by the use of tapered roller bearings. The advantages

problem encountered in cylindrical roller bearing assembly is not experienced in tapered roller bearing assembly. So, the mounting process is performed more quickly and efficiently, with a low incidence of bearing damages.

2) Since there is no ring mounting in the use of tapered roller bearings, there are no ring mounting-disassembly problems experienced with the use of cylindrical roller bearings. 3) As roller bearings work, their rollers are worn

out and their diameter gets smaller. Thus, load distribution in the bearing does not show homogeneity and the bearing life is reduced. This problem can be solved using tapered roller bearings. In the case of tapered roller bearings, when the rollers are worn, the spacer rings between the cones are grinded to ensure that all the cones and rollers are evenly loaded. So, that the actual life of the bearings has prolonged. 4) With the commence using of tapered roller

bearings, damage to the bearings was largely avoided and a considerable reduction in bearing costs was seen. In addition, shortening of the chock assembly duration leads to reduce downtime, thus contributing to increase the annual production volume.

5) Rolling mills need bearings to perform effectively at high speeds, under heavy loads, and in severely contaminated environments. At the same time, there’s constant pressure to increase production while reducing cost-per-ton rolled. Maintenance budgets are often being reduced, allowing for less time and resources available for bearing maintenance.

6) Because of its tapered construction and hard wearing surfaces, the Timken bearing has the capacity to tolerate a reasonable amount of dirt. This results from a tendency for the dirt along with the lubricant to be worked through the bearing, minimizing the lapping effect that would otherwise be created by dirt trapped in the bearing [6].

7) The on-apex construction that assures true rolling motion of a Timken baring, combined with its fine surface finish, keeps friction to a minimum. This is of significance on machines that are continually started and stopped under heavy loads [6].

8) Timken bearings can be depended upon to deliver their full rated capacity because the rib-guided rollers are positively aligned, permitting them to carry load over the full length of the rollers. Even with a significant amount of deflection and misalignment, the roller in a Timken bearing line up squarely. The cage doesn’t guide the rollers. Its only operating

8

REFERENCES [1] Rolling Mill Manuals

[2] (2017) [Online]. Available www.aptint.com/ [3] RKB Multi-Row Roller Bearing Brochure

[4] Made by SKF, Mounting and Maintenance Instructions for 4-row Taper Roller Bearing, SKF Gmbh, Schweinfurt [5] Timken Tapered Roller Bearing Guide

[6] Rolling Mill Equipment Supplement, The Timken Company

[7] Morgoil Symposium, Sept. 2004

Aluminium Ingot Feeding System Design for BOF

Ahmet Kayrak

*, Mesut Tutal

+, İsa Keskin

*#Eregli Iron and Steel Works Co., Steelmaking and Casting Tech. R&D Zonguldak, Turkey

{akayrak, ikeskin}@erdemir.com.tr

+ Erdemir Engineering, Portfolio and Project Management Dept. Hatay, Turkey

mtutal@erdemir.com.tr

Abstract— Aluminium is usually used for de-oxidation of

liquid-steel production in Basic Oxygen Furnaces. For this process, Aluminium ingots that have 5 kg nominal weight are feeding manually in a ladle for this kind of Plant. This situation can lead to some problems such as quality error and loss of efficiency. The problem was solved by designing automatic aluminium ingot feeding system. Hereby feeding system performance variables had improved considerably and also risks caused by occupational health and safety aspects have been eliminated.

Keywords— Basic Oxygen Furnace, Aluminium ingot,

De-oxidation, automatic feeding

I. INTRODUCTION

During the tapping process of steel from converter to ladle in steel making shop, due to the deoxidation of liquid steel defined amount of aluminium is added to stream. The aim of ideal deoxidation practices is preventing the CO gas formation during casting by binding free oxygen in liquid steel and removing oxide inclusions which are formed in deoxidation during tapping and increasing the efficiency of deoxidant materials. For being supplied easily, high affinity to oxygen and cost advantage reasons, aluminium is one of the most common used deoxidizer in steelmaking process. The amount of soluble oxygen can be measured between 400 – 1400 ppm at the end of blowing process in converter. According to affinity diagram the soluble oxygen amount can be decreased till 5 ppm levels in steel [1].

Figure 1: Tapping Pocess [2]

As seen in figure 1, the shape of aluminium added for steel deoxidation can be ingot, pyramit and granulated. Although material additon system is used for feeding the pyramit and granulated aluminium, the ingot aluminium is fed by manually in steelmaking processes. In this study, the deoxidation efficiency and cost optimization of ingot aluminium’s amount of 5 kg, fed by automated feeding system or manually was investigated. Moreover, during the startup of automated aluminium feeding system the ratio of work accidents and operation risks were aimed least as possible.

In steelmaking process, deoxidizers are always used to decrease the dissolved oxygen in liquid steel [1]. Dissolved metal reacts with the dissolved oxygen according to the precipitation reaction to generate metal oxide and this deoxidation product Al2O3 not only can affect the cleanness of

steel, but also is the main cause for nozzle clogging during continuous casting. The most common used deoxidation agents are FeSi and Aluminum [3]. According to Ellingham diagram, the commercial element which has the highest affinity to oxygen is aluminium [4]. The deoxidation product of process can be FeO. Al2O3 when the aluminium activity is lower or

Al2O3 when Al activity is higher. The FeO. Al2O3 and Al2O3

phases are in equilibrium condition at the spesific temperature on the equilibrium lines of FeO. Al2O3 and Al2O3 (Figure 2).

![Fig. 10 Mounting of the CRB to the roll (Original type bearing) [1]](https://thumb-eu.123doks.com/thumbv2/9libnet/5391677.101693/30.892.494.789.233.617/fig-mounting-crb-roll-original-type-bearing.webp)

![Fig. 4 Appearance of the welds after the first step and the second step [19].](https://thumb-eu.123doks.com/thumbv2/9libnet/5391677.101693/76.892.458.832.452.1008/fig-appearance-welds-step-second-step.webp)