w w w . j m r t . c o m . b r

Availableonlineatwww.sciencedirect.com

Original

Article

Effect

of

dipped

cryogenic

approach

on

thrust

force,

temperature,

tool

wear

and

chip

formation

in

drilling

of

AZ31

magnesium

alloy

Ugur

Koklu

a,∗,

Himmet

Coban

baDepartmentofMechanicalEngineering,KaramanogluMehmetbeyUniversity,70100Karaman,Turkey

bNaturalandAppliedScience,KaramanogluMehmetbeyUniversity,Karaman,Turkey

a

r

t

i

c

l

e

i

n

f

o

Articlehistory:

Received11December2019 Accepted10January2020 Availableonline22January2020

Keywords:

Cryogenicapproach AZ31magnesiumalloy Drilling

Thrustforce Drillwear Temperature

a

b

s

t

r

a

c

t

Magnesiumalloystendtohaveinflammablenatureandchipself-ignitionathighcutting speedsunderdrymachiningcondition,althoughtheycanbeeasilymachinedwithgood surfacequality.Inthedrillingprocess,coolingandlubricationhaveacriticalimpactasit controlsheatgeneration,toolwear,surfacequality,andcuttingforce.Inthepresentstudy, drillingtestsonAZ31magnesiumalloywereperformedwithdryandcryogenicconditions atvariousfeedratesandcuttingspeeds.Theeffectofdippedcryogenicapplicationduring drillingonthrustforce,temperature,toolwear,andchipformationwereinvestigated.The resultsshowedthattheappliedcryogenicdrillingmethodprovidedlesstoolwear,smaller chipsandreducedamountofadhesions.Drillingtestsperformedinthecryogenic envi-ronmentincreasethethrustforcesby32%–39%comparedtodrycutting.Sparkandchip ignitionwerenotobservedevenathighcuttingspeedsduringdrycutting.

©2020TheAuthors.PublishedbyElsevierB.V.Thisisanopenaccessarticleunderthe CCBY-NC-NDlicense(http://creativecommons.org/licenses/by-nc-nd/4.0/).

1.

Introduction

Magnesium alloys attract significant attention in most engineeringapplicationssuchaselectronics,aerospace, auto-mobile,structuralandbio-medicalindustries.Mostofthefinal productsusedinmanyengineeringapplicationsare manu-facturedbymachiningprocesses[1,2].Itispossibletoeasily machine,andgoodsurfacefinishcanbeachieved.However, underdrycuttingcondition,inflammablenatureofthe mate-rial may cause self-ignition offinechip particles athigher cutting speeds. Built-up edge formation in metal cutting, whichresultsinpoorsurfacefinishanddimensionalaccuracy,

∗ Correspondingauthor.

E-mail:ugurkoklu@kmu.edu.tr(U.Koklu).

iscausedbylowmeltingpointofthesealloysandmaterial adhesiononthecuttingtool[1].Itisalreadyknownthatthe majorityoftheworkduringmachiningisconvertedtoheat andendsupwithariseinthetemperatureoftool,workpiece, andchip,whichhasanimportanteffectonchipformation, cuttingtoolwear,andmachinedsurfacefinish.Temperature isalwaysofconcerninmachining.Forthepurposeof decreas-ingthecuttingtemperature,applyingcryogenicsasacoolant isthegeneralproceduretoeliminatetheeffectofthe temper-ature,whichisknownascryogenicmachining[3,4].

Baloutetal.[5]investigatedtheeffectofsubjecting vari-ousmetallicmaterials(magnesium,aluminumandbrass)to pre-coolingandpreheatingonthedrillingprocess.The exper-imentalstudywascarriedoutatmanydifferenttemperature values(15, 10,5,0, –20,–30,–40,–50,and −60◦C)andthey stated thatthrustforce andtorquedecreasedwith increas-https://doi.org/10.1016/j.jmrt.2020.01.038

2238-7854/©2020 The Authors. Publishedby Elsevier B.V. This is anopen access articleunder the CC BY-NC-ND license (http:// creativecommons.org/licenses/by-nc-nd/4.0/).

ingmaterialtemperature.Kakinumaetal.[6],Mishimaetal. [7],andKakinumaetal.[8]experimentallyinvestigatedthe micro machinability offrozen polydimethylsiloxane elastic material.The materialwas machinedwhen the mold was filledwithliquidnitrogen.Theauthorsstatedthatmicro chan-nelsweremilledeasilyandaccuratelyusingthismethod.In addition,itwasemphasizedthattestsundercryogenic con-ditionyieldhighercuttingforcethanroomtemperaturetests. Songetal.[9]investigatedthedirectmechanicalmachiningof polydimethylsiloxaneusingcryogeniccooling.Themachined surfacewas analyzed using various machiningparameters such as spindle speed and feed rate, and their effects on thecutting temperaturewere examined.When the cutting temperatureroseabovethecriticalvalue,itwasnotedthat thesurface qualityofthepolydimethylsiloxane was signif-icantly degraded due to increased adhesion and reduced elasticmodulus.Dhokiaetal.[10]predictedby compensat-ingtheshrinkageofmidsolefoamedpolymerand ethylene vinylacetate which are widely used inthe manufacturing ofshoe,undercryogeniccondition.Theauthorsemphasized thatthecryogenicshrinkagefactorinthecryogenic process-ing was less than 1 % of the original CAD model. Dhokia et al.[11], inanother study,investigatedthe machinability ofEVA and neoprene elastomermaterialsunder cryogenic conditions. In the experimentalstudy, the glass transition temperatureataspecifictemperature andelasticity values ofthetwoselectedmaterialswerecharacterized.Kokluand Morkavuk[12]experimentallyinvestigateddrilling machin-abilityofcarbon fiber-reinforced compositematerialunder cryogeniccondition. Drillingtests werecarried out using a speciallydesignedthermallyisolatedmold.Theeffectsof dif-ferentcuttingconditionsonthrustforce,delamination,tool wear,andsurfaceroughnesswereinvestigated.Theauthors emphasizedthatthecryogenicmethodsignificantlyreduced toolwearandimprovedsurfacequality;however,itcausedto increasethethrustforce.

Therearemanyacademicpapersonthemachinabilityof magnesiumalloysinliterature.Themajorityofthese stud-ies arefocusedin theturning process.Onthe other hand, therearemanystudiesoncryogenicturningofmagnesium alloys [1,2,13–21]. But, limited study has been carried out ondrilling processesofmagnesium alloys undercryogenic condition.Kheireddineetal.[22]examinedtheinfluenceof cryogenic applicationon the surfaceintegrity ofmachined holesinAZ31BMgalloy.Intheexperimentalstudyconducted bythe authors,thrust force,torque, surfacehardness, and grainstructureweremeasured.Itwasreportedthatcryogenic applicationduringmachining resultedinimprovedsurface hardness of machined holes as compared with machined underdrycondition.Kheireddineetal.[23]investigatedthe effectof usingliquid nitrogenin drilling ofAZ31b magne-siumalloyontheholesurfaceintegrityusingaindexabledrill. Thrust force, torque,and surface hardnesswere examined bothexperimentallyandnumerically.Itwasstatedthatthe hardnessvaluewashigherinthetestsperformedunder cryo-genic condition. Finiteelement analysis withexperimental justificationhasbeendiscussed.Bhowmicketal.[24] investi-gateddryandminimumquantitylubricationdrillingofAM60 magnesiumalloy.Thrustforce,torque,cuttingtemperature, toollifetests, surfacetopography,chip,microhardnessand

toolwear were measured.Itisemphasized bythe authors thatuniformtorqueandthrustforce,smalland discontinu-ouschipsand smoothholesurfaceareobtainedbydrilling themagnesiumalloyunderMQLcondition.Wangetal.[25] studiedwearofHSStoolsduringdrillingofmagnesiumalloy. SEManalysisshowedthreetypesofwearmechanismsinHSS tools.Theseweartypesareadhesivewear,abrasivewearand diffusion wear. This wear mechanism map is indicated to be a good reference for selecting suitable drilling parame-tersfordrillingofcastmagnesiumalloys.Berzosaetal.[26] focused on cuttingtoolselection indrilling of magnesium workpieceunderdryandminimumquantitylubrication envi-ronments basedonsurfaceroughness.Intheexperimental study,twodifferentpointangles,cuttingspeeds,feedrates andMQLflowvariableswereselected.Foraeronautical sec-tor, the importance ofdeterminingthe tooland operation accordingtotherequirementofsurfaceroughnessvaluesof 0.8–1.6misemphasized.Gariboldi[27]investigateddrilling machinabilityofamagnesiumalloyusingPVDcoatedtwist drills. Thedrills werecoatedwithTiN,CrNand two differ-ent ZrN by PVD method. Tool life, tool wear and surface roughness wereinvestigated. Adhesivewearforms,cutting parameters, thepresenceand typeofcoatingare statedto berelated.KaracaandAksakal[28]studiedeffectoftheTiBN coating onHSSdrillindrillingMA8MMgalloy.The perfor-manceofHSSandTiBNcoateddrillbitsweredeterminedby performingtestsatvariousspindlespeedsandfeeds.Surface roughness,topographyandchipformationwereinvestigated. TheTiBN-coateddrillexhibitedpoorsurfacequality. Balamu-ruganetal.[29]investigateddrillingofMg/SiCcompositefor defenseapplications.Theeffectsofmachiningtemperature onchipmorphology,toolwearandsurfaceprofilewere inves-tigated.Ithasbeenobservedthatthemostimportanteffectin machiningtemperatureformationiscausedbyspindlespeed andalsobothabrasiveandadhesiveweartypeoccur.Sunil etal.[30]researchedinfluenceofaluminumcontentondrilling characteristicsofAZ31andAZ91magnesiumalloys.Drilling testswereperformedusingdifferentcuttingparameters. Cut-tingforcesandformedchipswereanalyzed.Itisstatedthat the presenceofsecondary phase(Mg17Al12) has a signifi-canteffectonthecuttingforcesandanincreaseincutting speed reducesthe resultingcuttingforce andload fluctua-tions.

As theliteraturereviewshows thatin thefield of cryo-genicmachiningofmagnesiumalloys,machinabilitystudies aregenerallyfocusedonturningprocess,andtherearevery fewstudiesondrilling.Inthemachiningundercryogenic con-dition,itisgenerallymadebysprayingthecryogenicliquid intothemachiningzonethroughanozzle.Inthisstudy,the magnesium alloyisdrilledinafixturewhichiscompletely filled withliquid nitrogen.By usingthis approach(dipping the workpiece into liquid nitrogen), drilling performance ofAZ31 magnesium alloywas experimentallyinvestigated. Two different cutting speeds (40 and 120m/min) and four different feed rates (0.1, 0.15, 0.2 and 0.25mm/rev) were chosenasdrillingparameters.Also,toolweartestswere per-formedunderbothdryandcryogenicconditionsatconstant 80m/min cutting speed and 0.08mm/rev and 0.16mm/rev feedrates.Theresultsoftheexperimentsdemonstratedthat cryogenic machiningtechnique proposed inthis study can

be applied in order to obtain less tool wear and smaller chips.

2.

Material

and

methods

TheworkpieceusedintheexperimentalstudywasanAZ31 magnesiumalloyplate.Themechanicalpropertiesand chem-icalcompositionoftheAZ31magnesiumalloyareshownin Tables1and2,respectively.ThedimensionsoftheAZ31 mag-nesiumalloyworkpiecewas150×100×10mm.

Inthe experimentalstudy,twoflutehelical PVD(TiAlN) coateddrillswithadiameterof4mmwereusedascutting tools(Fig.1).Thepointangleofthedrillwas140◦.Anewdrill

Table1–MechanicalpropertiesofAZ31magnesium alloy[31]. Tensile strength (MPa) Yield strength (MPa) Elongation % Hardness HB Machinability % 290 220 15 73 100

wasusedforeachseriesofexperiments.Thefirstseriesof experimentswereconductedtodeterminetheeffectofthe cuttingparametersontheresults.Theexperimentswere car-riedoutindryandcryogenicconditionsat40and120m/min cuttingspeedsand0.1,0.15,0.2and0.25mm/revfeedrates.In thesecondseriesoftheexperiments,toolweartestswere

per-Fig.1–Drillusedintheexperimentalstudy.

Table2–ChemicalcompositionofAZ31magnesiumalloy[31].

Element Mg Al Zn Mn Si Ca Cu Fe Ni

Wt% 96 2.5–3.5 0.6–1.4 ≥0.2 ≤0.1 ≤0.04 ≤0.05 ≤0.005 ≤0.005

formedunderbothdryandcryogenicconditionsat80m/min cuttingspeedand0.08mm/revand0.16mm/revfeedrates.

Alldrilling testswere performed on3axisCNC vertical machining center (Quaser MV154C CNC). At the moment of experiments, thrust forces were measured by a force dynamometer(Kistler9257Btypeanddataacquisition equip-ment).Measurement oftemperature inmachining arevery difficultduetoclosedspace,chipobstacles,andthenatureof thecontactphenomenabetweentoolandchip[32].Therefore, thethermalcameraispositionedtoseethecuttingprocess inthe bestpossibleway. Temperaturemeasurementswere madebyathermalcamera(Flirsystem).Manyimageswere capturedwiththethermalcameraduringthedrillingprocess andthemaximumtemperatureobtainedfromtheseimages wasdetermined.Thethermal camera featuredobject tem-peratureranges from −25◦C to 380◦C withan accuracyof ± 1.5 % or 1.5◦C, a field of view 50◦×38.6◦, IR resolution of80×60pixelsandathermalsensitivity/NETDof<150mK. Theemissivityvaluewasselectedas0.6inthe experimen-talstudy.Thewearonthedrillsweremonitoredbyadigital microscope (Keyence VHX-900F). Thechips formed during experimentswere visualizedwithadigitalmicroscope.The experimentalsetupandmeasurementinstrumentsareshown inFig.2.AfixturewasmanufacturedtodrilltheAZ31 mag-nesiumalloyincryogenicenvironmentwithoutdamagingthe machineandcuttingforcemeasurementdevices.Thethermal insulatorfixturewaspositionedontheforcedynamometer. Polytetrafluoroethylenewasemployedasathermalinsulation materialtoavoidtheeffectofhigh-levelcoldcryogeniccoolant onthedynamometer.Asthecryogeniccoolant,liquidnitrogen wasemployedat−196◦C.Moredetailedinformationaboutthe experimentalset-upandthermalinsulationdiecanbefound inreference[12,33].Significantimprovementsin machinabil-ityandcuttingparameterscanbeachievedusingcryogenic processing[34].

3.

Results

and

discussion

Machinabilityisthefacilityordifficultyinmachininga mate-rialunderacertainsetofoperatingconditionsthatinclude cuttingdepth,feedrateand cuttingspeed.Thegeneral cri-teriacommonlyadoptedforassessingmachinabilityaretool life,powerconsumption,chipshape,surfacefinishand com-ponentforcesduringacuttingoperation[35,36].Inthisstudy thrustforce,temperature,toolwearandchipswere consid-ered.

3.1. Thrustforcecomparison

TheforcesintheXandYdirectionduringthedrilling opera-tionwereclosetozero.Ontheotherhand,themeasurement ofthrustforceisveryimportanttoanalyzemoreeffectively the machinability factors of AZ31 magnesium alloy under cryogenic and dry conditions. Each experiment series was

Fig.3–Theeffectoffeedratevariationonthrustforce.

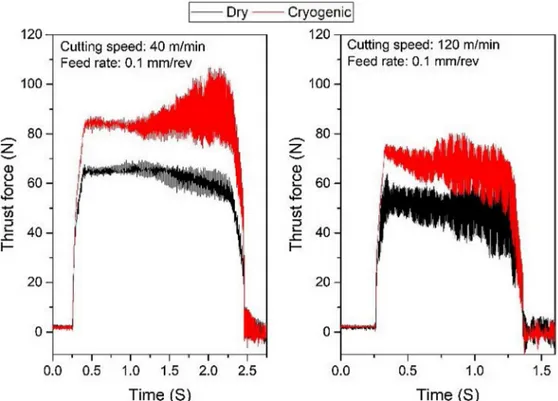

madewith3replicates,andthearithmeticaveragewastaken. Fig. 3shows a samplechartof the overall thrustforce for theexperimentscarriedoutatfourfeedrates(0.1,0.15,0.2 and 0.25mm/rev)and 40m/mincuttingspeed.Thrust force increasesasthefeed rateincreases.Theeffectsofdry and cryogeniccuttingconditionsonthethrustforcesoccurredat differentcuttingspeeds(40m/minand120m/min)and con-stantfeedrate(0.1mm/rev)areshowninFig.4.

ThethrustforcerecordedduringdrillingoftheAZ31 mag-nesiumalloyispresentedinFig.5.Thrustforce indry and cryogenicenvironmentshowsdecreasingtrendwhencutting speed is increased. As cutting speed increases, the thrust force decreases byabout 16 %–27 %. This behaviorcan be ascribed to the reduction of the contact area at the drill-Mgalloyinterface andthe reductionofthespecificcutting energy.Furthermore,withanincreaseincuttingspeed,the cuttingtemperatureincreasedandsubsequentlyreducedthe materialhardness.Increasingthefeedrateinbothdry and cryogenicconditionsincreases(about34%–54%)thethrust force.Thisphenomenonstemmedfromthehigherfeedrates, whichcausedanincreaseintheamountofuncutchipand theenergyrequiredforcutting.Inaddition,drillingtests per-formed inthe cryogenic environment increased the thrust forcesby32%–39%comparedtodrycutting.Inthepresent study,dippedcryogenic drillingledto higherthrustforces, which was associatedwithincreasing Youngmodulus and tensile strength of AZ31magnesium alloy incaseexposed tocryogenicenvironment;andtherefore,higherthrustforces areobtainedincryogenicdrilling[33].Inpreviouslypublished studies, it was highlighted that tensile strength, hardness andyoungmodulusofthematerialsincreaseastemperature decrease[4,12,37–42].

Fig.4–Thrustforcevariationswithcuttingspeedunderdryandcryogenicconditions.

Fig.5–Variationofthrustforce(a)40m/mincuttingspeed(b)120m/mincuttingspeed.

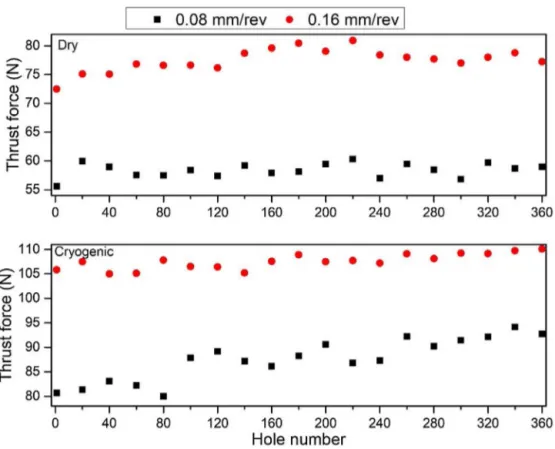

Toolweartestswere conductedtoexaminetheeffectof thesubsequentholenumberonthethrustforce.Atdifferent feedrates(0.08and0.16mm/rev)andaconstantcuttingspeed (80m/min),360holes weredrilledon theAZ31magnesium plate underdry andcryogenic conditions. Inthe toolwear experiments,thethrustforcewasmeasuredperiodicallyafter drilling20consecutiveholes.Thethrustforcegraphobtained fromthetoolwearexperimentsisgiveninFig.6.Inbothdry andcryogenicconditions,thethrustforcetendstoincrease

withincreasingnumberofholes.Thefundamentalreasonfor thissituationwassimplytoolwear.Indrydrillingcondition, lowerthrustforcewasgeneratedthanthoseinthecryogenic condition.

3.2. Temperaturecomparison

Surfacetemperaturesofthecuttingtoolatthetimeofdrilling weremeasuredbyathermalcamera.Inthedrillingtests

per-Fig.6–Comparisonofthethrustforceobtainedatdryandcryogenicconditions.

Fig.7–Temperaturesoccurredindrycuttingconditions.

formedundercryogeniccondition,thetemperaturewasnot measured since liquid nitrogenwas supplied continuously thereforethetemperaturesoftooland workpiecewas sup-posed−196◦C.Temperaturesgeneratedat40and120m/min cuttingspeedsanddifferentfeedratesindrycutting condi-tionaregiveninFig.7.Temperaturesinthedrillingprocess increasedlinearlywithincreasingbothcuttingspeedandfeed rate.Thetemperatureincreasedby20%withincreasingfeed rateatlowcuttingspeed,whileitincreasedby40%athigh cuttingspeed.Cuttingspeedhasadominanteffectonheat

for-mation.Sparkandchipignitionwasnotobservedevenathigh cuttingspeedsduringdrycutting.Thisisofvitalimportance formachiningsafety.

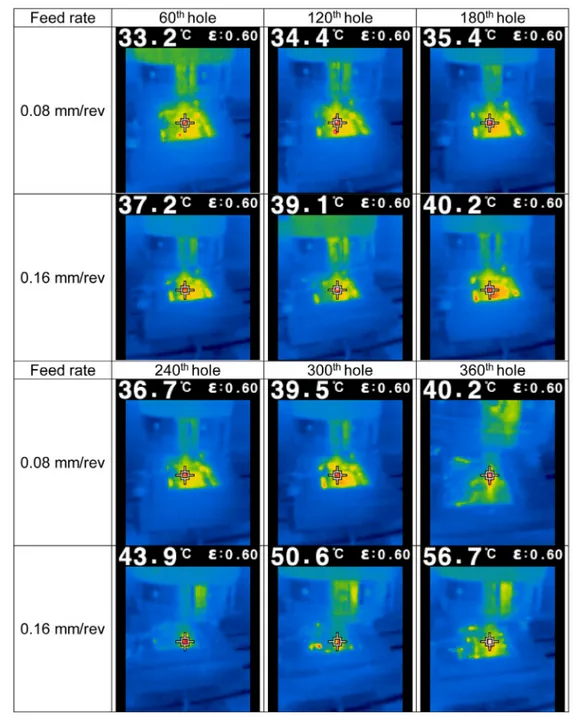

Inthetoolweartestscarriedoutwithaconstantcutting speed (80m/min)andtwo differentfeedrates(0.08mm/rev and0.16mm/rev)underdrydrillingcondition,temperatures measuredforeach60holes.Imagesfromthethermalcamera areshowninFig.8.Ascanbeshown,anincreaseinthe num-berofholesincreasesthetemperature.Atbothfeedrates,as thenumberofholesincreases,thetemperatureincreasesas

Fig.8–Temperaturechangewithnumberofholes.

well.At0.08mm/revfeedrate,thetemperaturemeasuredas 40.2◦Cinthe360thhole,whileatthefeedrateof0.16mm/rev, thetemperaturewas56.7◦Cinthe360thhole.

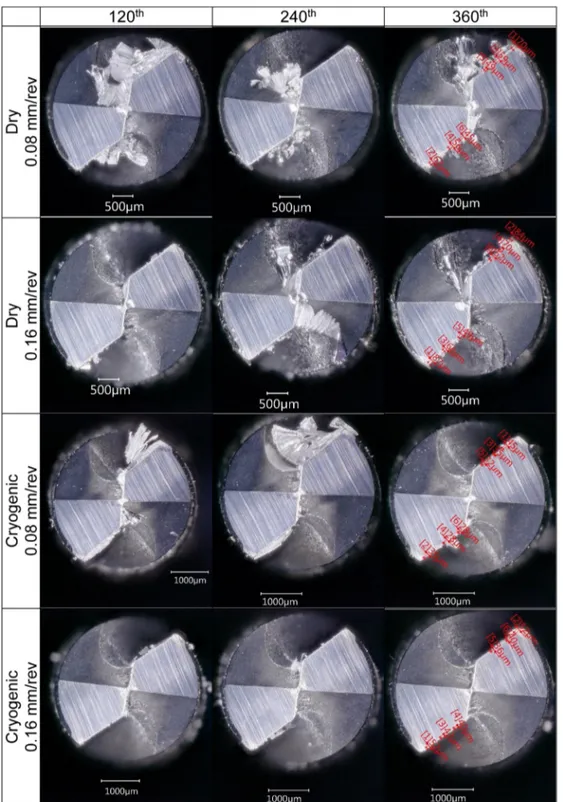

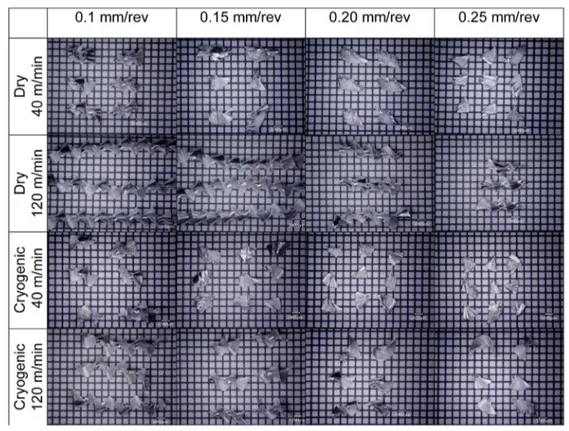

3.3. Toolwear

Becauseofrapidwearandfailureofcuttingtool,itis possi-bletoencountersomeproblemslikeshortlifecycleoftool, poorhole quality,low cuttingefficacy,and high machining costs[37].Inthetoolweartestsperformedatdryand cryo-genicconditionsataconstant80m/mincuttingspeedand0.08 and0.16mm/revfeedrates,thewearonthedrillisvisualized withadigitalmicroscope.Animagewastakenfrom adrill inevery120holes(Fig.9).Indrydrillingcondition,excessive adhesionofAZ31magnesiumalloyonthedrillwasobserved. Intestsperformedundercryogeniccondition,theadhesionis

verylow,whileathighfeedratestheadhesionisalmost negli-gible.Toolweartestsconductedunderdryconditionresulted ingreater wearthan thoseincryogenic condition.In addi-tion,athigherfeedratesinbothcuttingconditions,morewear occurredcomparedtothetestsconductedatlowfeedrate.

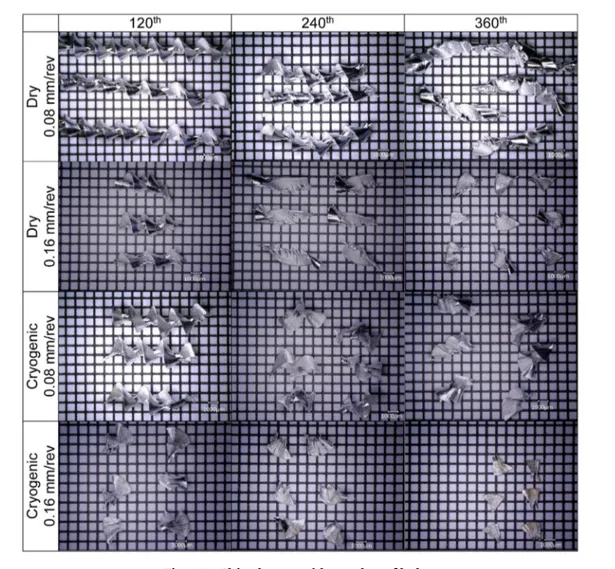

3.4. Chipmorphology

Chipshapeisthemostsignificantfactoraffectingthe smooth-nessofametalcuttingprocess.Theprocesswillbesmoothas long aschipsare brokenand fragmentedinto smallpieces. However,asthechipsgetlarger,theycannotmovewellvia theflutesofthedrill,andthisincreasestorquerequirements. Moreover,itmaycausethedrillbittobreak.Yet,many duc-tilematerialsdonotbreakbutformcontinuouschipsduring drilling.Inordertoshowthechipshapedependingoncutting

Fig.9–Comparisonofthetoolwearobservedatdryandcryogeniccuttingprocess.

parameters(cuttingspeedandfeedrate),numberof subse-quentholes,dryandcryogenicconditions[43],thechipswere collectedandvisualizedinadigitalmicroscope(Keyence VHX-900F)aftereachexperiment.Specimenswererepresentedby digitalmicroscope by selecting samplesfrom the collected chips.Chipsformedat40and120m/mincuttingspeedsand 0.1,0.15,0.2and0.25mm/revfeedrateindryandcryogenic conditionsare giveninFig.10.Bothcuttingspeedandfeed rateshaveadominanteffectonchipformation.Asthe cut-tingspeedincreases,chipsareformedlongerinbothdryand

cryogenic cuttingconditions. Withincreasingfeedrate, the chipsbecomeshorterinbothcuttingconditions.Thechips formedincryogenicconditionareshorterthanthoseinthe drycuttingcondition.Inthetestscarriedoutunderdrycutting condition, withthe cuttingspeed increasedfrom 40m/min to120m/min, moretemperature wasgeneratedduring the cuttingprocess (Fig.7).Inthe testsperformedathigh cut-tingspeed,theincreasedtemperatureduringcuttingcaused thechiptoemergeinalongerform.Thefactthatthechips are longer shows that the chips is in ductile form.

Previ-Fig.10–Photographsofchipsobtainedatdifferentdrillingconditions.

ously,similarfindings arereportedinthe literature[30,43]. Becausethecuttingtemperaturedidnotgreatlyincreaseinthe testsperformedundercryogenicconditionatcuttingspeedof 120m/min,thechipsweregeneratedinamuchshorterform comparedtothoseformedinthedrycutting.Althoughitis mentionedintheliteraturethatmagnesiumalloyhasa ten-dencytoigniteathighercuttingspeed,nosuchsituationhas beenobservedinthisstudy.

360holeswasdrilledonAZ31magnesiumplateata con-stantcuttingspeedof80m/minand0.08and0.16mm/revfeed rate.Chips were collectedineach 120holes. Thisseriesof experimentswereperformedunderbothdryandcryogenic cuttingconditions. Thechipsformedafterthe experiments arecategorizedandgiveninFig.11.Withanincreaseinthe numberofholes,shapeofthechipsalsochanges.Thechip shapeforthefirst240holesindrycuttingconditionwasin theformofaspiral conewhichwas moreeasilyremoved. Afterthe240thhole,dependingonanincreaseinthethrust forceandwear,thechipthicknessdecreasedasthechippitch increased,thusribbonchips wereformed. Inthetests per-formedincryogenicenvironment,shorterchipsare formed becausethematerialbecomesbrittle.Toolwearwasthe fun-damentalreasonforthevariationofchipshapebasedonthe increaseinthenumberofholes[43].Undercryogenic condi-tion,asmallamountofdiscolorationwasobservedinthechips formedat0.16mm/rev feedrateforthe 360thhole.By per-formingdrillingtestsinacryogenicenvironment,thematerial changesfromductilemode tobrittlemode.Brittlematerial becomesmorerigidandharder.Muchmorepowerisneededto drillthehardermaterial.InSection3.1itwasmentionedthat testscarriedout undercryogenicconditiongeneratedmore thrustforcethanunderdrycutting.Moreplasticdeformation

occurredduringdrillingofthehardenedmaterialunderthe cryogenicprocess.Thishighplasticdeformationwasreflected intheformofthechip.

4.

Conclusion

Theeffect ofdippedcryogenic approachanddry condition on thrustforce,temperature, toolwearand chipformation indrillingofAZ31magnesiumalloywasinvestigated. • Inthetestsperformedunderbothdryandcryogenic

con-ditions,thethrustforcedecreases(about16%–27%)with increasing cutting speed; and the thrust force increases (about34%–54%)withanincreaseofthefeedrate.Drilling testsperformedinthecryogenicenvironmentincreasethe thrustforcesby32%–39%comparedtodrycutting.Intests performedunderdryandcryogenicconditions,inaddition, thethrustforcetendstoincreasewithincreasingnumber ofholes.

• Temperaturesinthedrillingprosesincreasedlinearlywith increasingbothcuttingspeedandfeedrate.Cuttingspeed hasadominanteffectonheatformation.Sparkandchip ignitionwerenotobservedevenathighcuttingspeeds dur-ingdrycutting.Anincreaseinthenumberofholesincreases thetemperature.

• Indrydrillingcondition, theAZ31magnesium alloyisin anexcessiveamountofadhesionstothedrill.Intests per-formedundercryogeniccondition,theadhesionisverylow, whileathighfeedratesitisalmostnegligible.Toolwear testsconductedunderdryconditionresultedingreatertool

Fig.11–Chipchangewithnumberofholes.

wear.Inaddition,athigherfeedratesinbothcutting con-ditions,morewearoccurred.

• Itisobservedthatthecuttingspeedisdominantonthechip formationandthechipsformedincryogenicconditionare shorterthanthechipsformedindrycuttingcondition.

Conflict

of

interest

Theauthorsdeclarenoconflictofinterest.

Acknowledgments

This work was supported by Commission of Scientific Research Projects of Karamanoglu Mehmetbey University, Karaman-Turkey(ProjectNo.04-YL-17).

Appendix

A.

Supplementary

data

Supplementary material related to this article can be found,intheonlineversion,atdoi:https://doi.org/10.1016/j. jmrt.2020.01.038.

r

e

f

e

r

e

n

c

e

s

[1]DineshS,SenthilkumarV,AsokanP,ArulkirubakaranD. Effectofcryogeniccoolingonmachinabilityandsurface qualityofbio-degradableZK60Mgalloy.MaterDes 2015;87:1030–6.

[2]DineshS,SenthilkumarV,AsokanP.Experimentalstudieson thecryogenicmachiningofbiodegradableZK60Mgalloy usingmicro-texturedtools.MaterManufProcess 2017;32(9):979–87.

[3]DillonOW,DeAngelisRJ,LuWY,GunasekeraJS,DenoJA. Theeffectsoftemperatureonthemachiningofmetals.J MaterShapTechnol1990;8(1):23–9.

[4]ZhaoZ,HongSY.Coolingstrategiesforcryogenicmachining fromamaterialsviewpoint.JMaterEngPerform

1992;1(5):669–78.

[5]BaloutB,SongmeneV,MasounaveJ.Anexperimentalstudy ofdustgenerationduringdrydrillingofpre-cooledand pre-heatedworkpiecematerials.JManufProcess 2007;9(1):23–34.

[6]KakinumaY,YasudaN,AoyamaT.Micromachiningofsoft polymermaterialapplyingcryogeniccooling.JAdvMechDes SystManuf2008;2(4):560–9.

[7]MishimaK,KakinumaY,AoyamaT.

Pre-deformation-assistedcryogenicmicromachiningfor fabricationofthree-dimensionaluniquemicrochannels.J AdvMechDesSystManuf2010;4(5):936–47.

[8] KakinumaY,KidaniS,AoyamaT.Ultra-precisioncryogenic machiningofviscoelasticpolymers.CIRPAnnManuf Technol2012;61(1):79–82.

[9] SongK,GangMG,JunMB,MinBK.Cryogenicmachiningof PDMSfluidicchannelusingshrinkagecompensationand surfaceroughnesscontrol.IntJPrecisEngManuf 2017;18(12):1711–7.

[10]DhokiaVG,NewmanST,CrabtreeP,AnsellMP.A methodologyforthedeterminationoffoamedpolymer contractionratesasaresultofcryogenicCNCmachining. RobotComputIntegrManuf2010;26(6):665–70.

[11]DhokiaVG,NewmanST,CrabtreeP,AnsellMP.Adiabatic shearbandformationasaresultofcryogenicCNC machiningofelastomers.ProcInstMechEngPartBJEng Manuf2011;225(9):1482–92.

[12]KokluU,MorkavukS.Cryogenicdrillingofcarbon fiber-reinforcedcomposite(CFRP).SurfRevLett 2019;26(09):1–11.

[13]PuZ,DillonOW,JawahirIS,PuleoDA.Microstructural changesofAZ31magnesiumalloysinducedbycryogenic machininganditsinfluenceoncorrosionresistancein simulatedbodyfluidforbiomedicalapplications.In:ASME 2010InternationalManufacturingScienceandEngineering Conference.AmericanSocietyofMechanicalEngineers. 2010.p.271–7.January.

[14]PuZ,OuteiroJC,BatistaAC,DillonOW,PuleoDA,JawahirIS. SurfaceintegrityindryandcryogenicmachiningofAZ31B Mgalloywithvaryingcuttingedgeradiustools.ProcediaEng 2011;19:282–7.

[15]PuZ,OuteiroJC,BatistaAC,DillonOW,PuleoDA,JawahirIS. EnhancedsurfaceintegrityofAZ31BMgalloybycryogenic machiningtowardsimprovedfunctionalperformanceof machinedcomponents.IntJMachToolsManuf 2012;56:17–27.

[16]PuZ,UmbrelloD,DillonOW,JawahirIS.Finiteelement simulationofresidualstressesincryogenicmachiningof AZ31BMgalloy.ProcediaCirp2014;13:282–7.

[17]PuZ,UmbrelloD,DillonOW,LuT,PuleoDA,JawahirIS. Finiteelementmodelingofmicrostructuralchangesindry andcryogenicmachiningofAZ31Bmagnesiumalloy.J ManufProcess2014;16(2):335–43.

[18]OuteiroJC,RossiF,FromentinG,PoulachonG,GermainG, BatistaAC.Processmechanicsandsurfaceintegrityinduced bydryandcryogenicmachiningofAZ31B-Omagnesium alloy.ProcediaCirp2013;8:487–92.

[19]NasrMN,OuteiroJC.Sensitivityanalysisofcryogeniccooling onmachiningofmagnesiumalloyAZ31B-O.ProcediaCirp 2015;31:264–9.

[20]BertoliniR,BruschiS,GhiottiA,PezzatoL,DabalàM.The effectofcoolingstrategiesandmachiningfeedrateonthe corrosionbehaviorandwettabilityofAZ31alloyfor biomedicalapplications.ProcediaCirp2017;65:7–12. [21]SivaiahP,ChakradharD.Influenceofcryogeniccoolanton

turningperformancecharacteristics:acomparisonwithwet machining.MaterManufProcess2017;32(13):1475–85. [22]KheireddineAH,AmmouriAH,LuT,DillonOW,HamadeRF,

JawahirIS.Anexperimentalandnumericalstudyofthe effectofcryogeniccoolingonthesurfaceintegrityofdrilled holesinAZ31BMgalloy.IntJAdvManufTechnol

2015;78(1–4):269–79.

[23]KheireddineAH,AmmouriAH,LuT,JawahirIS,HamadeRF. AnFEManalysiswithexperimentalvalidationtostudythe hardnessofin-processcryogenicallycooleddrilledholesin MgAZ31B.ProcediaCirp2013;8:588–93.

[24]BhowmickS,LukitschMJ,AlpasAT.Dryandminimum quantitylubricationdrillingofcastmagnesiumalloy(AM60). IntJMachToolsManuf2010;50(5):444–57.

[25]WangJ,LiuYB,AnJ,WangLM.Wearmechanismmapof uncoatedHSStoolsduringdrillingdie-castmagnesiumalloy. Wear2008;265(5-6):685–91.

[26]BerzosaF,deAgustinaB,RubioEM.Toolselectionindrilling ofmagnesiumUNSM11917piecesunderdryandMQL conditionsbasedonsurfaceroughness.ProcediaEng 2017;184:117–27.

[27]GariboldiE.DrillingamagnesiumalloyusingPVDcoated twistdrills.JMaterProcessTechnol2003;134(3):287–95. [28]KaracaF,AksakalB.EffectoftheTIBNcoatingonaHSSdrill

whendrillingtheMA8MMgalloy.MaterTehnol 2016;50(1):75–9.

[29]BalamuruganK,UthayakumarM,KumaranST,SamyGS, PillaiUTS.DrillingstudyonlightweightstructuralMg/SiC compositefordefenceapplications.DefTechnol2019. [30]SunilBR,GaneshKV,PavanP,VadapalliG,SwarnalathaC,

SwapnaP,etal.Effectofaluminumcontentonmachining characteristicsofAZ31andAZ91magnesiumalloysduring drilling.JMagnesAlloy2016;4(1):15–21.

[31]http://www.matweb.com/search/datasheet.aspx?matguid= d1e286e1ac0742358544b953bbf3c2e9&ckck=1.

[32]AydınM,KarakuzuC,Uc¸arM,CengizA,C¸avus¸luMA. Predictionofsurfaceroughnessandcuttingzone temperatureindryturningprocessesofAISI304stainless steelusingANFISwithPSOlearning.IntJAdvManuf Technol2013;67(1-4):957–67.

[33]MorkavukS,KöklüU,Ba ˘gcıM,GemiL.Cryogenicmachining ofcarbonfiberreinforcedplastic(CFRP)compositesandthe effectsofcryogenictreatmentontensileproperties:a comparativestudy.ComposPartBEng2018;147:1–11. [34]KaraF,TakmazA.OptimizationbytheTaguchimethodof

effectonthesurfaceroughnessofcryogenictreatment appliedtocuttingtools.MaterialTesting2019;61(11):1101–4. [35]EzugwuEO,BonneyJ,YamaneY.Anoverviewofthe

machinabilityofaeroenginealloys.JMaterProcessTechnol 2003;134(2):233–53.

[36]SeahKHW,SharmaSC.Machinabilityofalloyed austemperedductileiron.IntJMachToolsManuf 1995;35(10):1475–9.

[37]BasmaciG,YorukA,KokluU,MorkavukS.Impactof cryogenicconditionanddrilldiameterondrilling performanceofCFRP.ApplSci2017;7(7):667. [38]XiaT,KaynakY,ArvinC,JawahirIS.Cryogenic

cooling-inducedprocessperformanceandsurfaceintegrity indrillingCFRPcompositematerial.IntJAdvManufTechnol 2016;82(1–4):605–16.

[39]HongSY,DingY,JeongWC.Frictionandcuttingforcesin cryogenicmachiningofTi–6Al–4V.IntJMachToolsManuf 2001;41(15):2271–85.

[40]Uc¸akN,C¸ic¸ekA.Investigationoftheeffectsofcryogenic coolingondrillingperformanceindrillingofInconel718 superalloy.JFacultyEngArchitectGaziUniv

2019;34(3):1242–52.

[41]KumarD,GururajaS.ExperimentalinvestigationofCFRP/Ti stackdrillingundercryogeniccondition.In:International ConferenceonCompositeMaterialsandStructures-ICCMS. 2017.Hyderabad,27–29thDecember.

[42]KaraF,C¸ic¸ekA,DemirH.MultipleregressionandANN modelsforsurfacequalityofcryogenically-treatedAISI 52100bearingsteel.JBalkanTribologAssoc

2013;19(4):570–84.

[43]KokluU,MorkavukS,UrtekinL.Effectsofthedrillflute numberondrillingofacastedAZ91magnesiumalloy.Mater Test2019;61(3):260–6.

![Table 1 – Mechanical properties of AZ31 magnesium alloy [31]. Tensile strength (MPa) Yield strength(MPa) Elongation% HardnessHB Machinability% 290 220 15 73 100](https://thumb-eu.123doks.com/thumbv2/9libnet/4582512.84351/3.918.470.839.144.227/mechanical-properties-magnesium-tensile-strength-elongation-hardnesshb-machinability.webp)

![Table 2 – Chemical composition of AZ31 magnesium alloy [31].](https://thumb-eu.123doks.com/thumbv2/9libnet/4582512.84351/4.918.473.849.118.503/table-chemical-composition-az-magnesium-alloy.webp)