International Conference and Exhibition on Electronic, Computer and Automation Technologies (ICEECAT’14), May 9-11,2014

Konya, Turkey

Abstract - Conventional agricultural equipment and machinery have acquired a modern characteristic owing to technological transfers, which returns as profit in the meantime. Electronic and computer applications are becoming gradually widespread in agriculture. Agricultural mechanization is positively affected by this development. Using new technologies together with agricultural mechanization, results in more qualified crops in production stages. This study was carried out on an electronic module we designed to control the hydraulic lifting and unloading parts of a sugar beet harvester. For this purpose, we wrote a program in Peripheral Interface Controller (PIC). Processes have been automatised by means of this circuit. Our electronic circuits were tested in a workshop and then they were applied on a real sugar beet harvester. Its control system can communicate on cable via serial communication. The tests confirmed that this control system is applicable for sugar beet harvester. In this way, the system is controlled remotely via a wireless circuit designed as an addition to the electronic card.

Keywords - Serial Communication, Sugar Beet Harvester, PIC, Electronic Circuit, Software.

I. INTRODUCTION

Turkey is an agricultural country of high potential with its population, land size, and ecological advantages like climate and soil diversity. As an important nutrient for humans, sugar is produced from two sources. One is sugar cane and the other is sugar beet. Sugar producers are tending towards mechanization within the extent of their purchasing power. In recent years, agricultural equipment such as tractors, rotary cultivators, hoeing machines, and combined harvesters are increasing in number. Even those who cannot afford them use these machines on loan or by renting [1, 2].

Agricultural mechanization involves designing, developing, marketing, handling, and operating every kind of energy source and mechanical equipment that are used to develop agricultural areas and to produce and utilize every kind of crop. It is possible to reap more qualified crops in production stages as long as the agricultural mechanization is accompanied by new technologies. It also enables the production processes to be completed as soon as possible, prevents the yield loss resulting from delays and makes the rural labour conditions more convenient and secure. Agricultural productivity is enhanced and new employment opportunities are introduced with the industrial developments in agricultural machinery. Agricultural equipment and machinery are indispensable for completing work in due time. Since manual harvesting of sugar beet requires a vast number of workers and the cost of workmanship has

increased in recent years, producers are heading for mechanical harvesting. Mechanization brings about more cultivated areas and prolongs the harvest season (considering the weather and soil conditions) so that sugar beets become heavier. Furthermore, producers do not confront with workforce problems during their business plans [3, 4, 5].

In the 2010/2011 season, world sugar production was 152 million tons and the capacity settled by the board of sugar beet in Turkey is 3 million and 151 thousand tons. In Turkey, there are seven sugar beet-producing companies, one of which is publicly owned, and 33 active sugar factories with different capacities. Turkey’s share in world sugar production was 8 % in the 2010/2011 season. Turkey is the world’s fifth largest sugar producer after the USA, France, Germany, and Russia, and the fourth largest sugar producer in Europe after France, Germany, and Russia [6].

What lies behind the dominance of developed countries in the global economy is that they develop their agricultural machinery, they use this machinery efficiently, and their sale of agricultural products increases in this way. This accounts for why the developing countries fall one step behind the developed countries in terms of agro-based industrialization. Considering the trio of agriculture-trade-industry, agriculture has an active and positive role in industrialization, and as a matter of fact, developing countries have necessary infrastructure for agro-based industrialization [2, 7].

In parallel with the technological developments, agricultural machinery is developing in a positive way and the use of technology in agricultural equipment is rapidly increasing. Electronic and computer applications are becoming widespread in the sector, which impacts the agricultural mechanization. A modern approach to agricultural practices not only enhances agricultural productivity but also provides speed and ease of use. Designs of agricultural mechanization are affected by industrial developments and this leads to favourable outcomes. Multidisciplinary studies have paved the way for improvements in agricultural machinery and use of electronics and computer technologies in this sector. Moreover, these technological and electro-mechanical developments help people overcome the problems they encounter at workplace, providing them more comfort, more time, and more economic profit. Traditional agricultural machinery has acquired a modern characteristic owing to technological transfers, which returns as profit.

In this study, we developed an electronic circuit to control the hydraulic system by which sugar beet harvesters do lifting and unloading, and for this purpose, we wrote a program in Peripheral Interface Controller (PIC). By means of this circuit, processes were automatised. The system was 1

The Design and Implementation of a Sugar Beet

Harvester Controlled via Serial Communication

Adem GOLCUK1, Sakir TASDEMIR2, Mehmet BALCI2

1Higher School of Vocational and Technical Sciences, Karamanoğlu Mehmetbey University / Karaman,

Turkey

ademgolcuk@kmu.edu.tr

2 Higher School of Vocational and Technical Sciences, Selçuk University / Konya, Turkey stasdemir@selcuk.edu.tr, mehmetbalci@selcuk.edu.tr

remote-controlled via a wireless circuit designed as an addition to the electronic card. In this way, cables were eliminated and the system was made remotely operable.

II.MATERIALAND METHOD

Sugar beet harvester is a machine used to uproot beets. It is attached to the tractor drawbar and runs by the power take-off (PTO). Self-lubricant machines do not require anything but tractor PTO and 12-volt accumulator electricity. This combined machine picks up the sugar beets, separates their stems and leaves, removes their dirt, takes them to the ground or the bunker, and finally unloads them. Like manual lifting, sugar beets are picked up cleanly by this machine without giving any detriment to them. All of its units except the star drum are driven hydraulically. It adjusts the digging height and range automatically with its electronic-hydraulic control system and accomplishes the lifting and loading processes easily and in a short time [8, 9].

Using PicBasic Pro, we wrote microcontroller software for the serially communicating sugar beet harvester we designed. Printed circuits were prepared in Ares Professional inside the Proteus Professional software package. We used two-sided printing technique while plotting these printed circuits. In addition, before transferring the circuits into printed circuits, working principles of the used codes and ICs were tested on the simulation program of Isis Professional. During the tests, our printed circuits were prepared by the method of ironing in a workshop environment. As the tests yielded positive results, the printed circuits were churned out by professional firms.

2.1 Serial Communication Technique

Serial communication technique is preferred by business organizations, automation systems, and factories with a number of machines and engines, in order to minimize the complexity, reduce the cost, and make the control easier. It is easily and as required programmed and removes the need for an additional data link when new devices are added to circuit.

Nowadays, serial communication has a wide area of utilization. Microprocessors and the devices such as modem, printer, floppy disc, hard disc, and optical drives communicate in a serial way. In addition to these, serial communication is used in cases that the number of links are wanted to be reduced. In serial communication, data are conveyed unidirectionally or bidirectionally on a single channel. As the number of links is reduced, its data signaling rate is low as well [10, 11].

2.2. The Systemic Structure

Our system is made up of two modules in essence. The circuit we developed for the first module is the “mainboard” part mounted to the sugar beet harvester, enabling the lifting and unloading operations of the machine. This module conducts the sugar beet harvester according to the data transmitted from the remote control. The second module consists of the remote control system. Users control their sugar beet harvesters by this system. Figure 1 shows the structure of this system.

Figure 1: Block Structure of Automation for Sugar Beet Harvester

In the system shown in Figure 1, all the data exchange between the control module and the mainboard on the sugar beet harvester takes place on two cables with serial communication. This system is safer and easier to install. Also, troubleshooting becomes easier and the cost is cut down as the number of cables is reduced by serial communication. However, hardware cost increases to a certain extent because there are two circuits to ensure serial data communication in the control system. One of these circuits is placed inside the control device, conveying the user commands to the sugar beet harvester. The other one is placed in the sugar beet harvester, guiding the sugar beet harvester according to the commands coming from the control unit to open and close the valves.

2.2.1 The Control Keypad and Its Functions

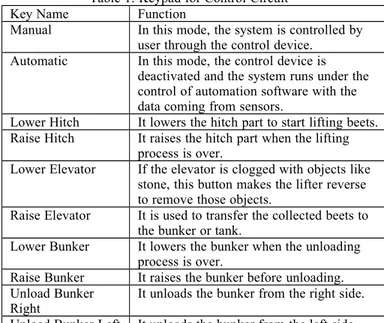

There are control buttons on the control system designed to control the sugar beet harvester by a tractor driver. Table 1 shows these buttons and their functions.

In the system we designed, all the data exchange between the control device and the mainboard takes place either on two cables with serial communication.

Table 1: Keypad for Control Circuit

Key Name Function

Manual In this mode, the system is controlled by user through the control device.

Automatic In this mode, the control device is deactivated and the system runs under the control of automation software with the data coming from sensors.

Lower Hitch It lowers the hitch part to start lifting beets. Raise Hitch It raises the hitch part when the lifting

process is over.

Lower Elevator If the elevator is clogged with objects like stone, this button makes the lifter reverse to remove those objects.

Raise Elevator It is used to transfer the collected beets to the bunker or tank.

Lower Bunker It lowers the bunker when the unloading process is over.

Raise Bunker It raises the bunker before unloading. Unload Bunker

Right It unloads the bunker from the right side. Unload Bunker Left It unloads the bunker from the left side.

Open Bunker It opens the bunker door. Close Bunker It closes the bunker door. Signal On/Off It switches the signal on or off.

Light On/Off It switches the headlight on when work is done by night.

2.2.2 Electronic Circuit for Control

The circuits in Figures 2 and 3 are for the control device. Keys were mounted to the circuit in Figure 2. The circuit shown in Figure 3 serially transmits the data from the pressed key to the circuit on the sugar beet harvester through RX and TX cables.

Figure 2: The Printed Circuit for Control Keypad

Figure 3: Control Transmitter Circuit

The program running on the PIC 16F84A microcontroller [12, 13] used in the control circuit was developed in PICBASIC PRO [12, 13]. This software regulates the way the system runs either wired or wireless. If RF signals are to be used through the wireless control system, the data regarding the key pressed by the user is calculated as 4 bits by the program codes. Afterwards, it sends this data to the inputs of PT2262 IC (Figure 4) to be transmitted in turn to the RF signals. This 4-bit data is conveyed by using 0, 1, 2, and 3. bits of PortA. In addition, this microcontroller memories in which mode the sugar beet harvester is running. When there is no electricity in the circuit unless a key is pressed, the power of microcontroller is off as well. The data regarding the mode of the sugar beet harvester is stored in the internal EEPROM of the microcontroller. Thus, even if the power is cut off, the information is kept by the microcontroller without being erased.

PicBasic code writing the mode information to internal EEPROM:

WRITE 0,modd ‘this command writes mode information to address 0.

PicBasic code reading the mode information from internal EEPROM:

READ 0,modd ‘this command reads mode information than address 0.

If the wired system will be used, the instruction to send the control information to the sugar beet harvester via serial communication is as follows:

SEROUT2 VERIOUT,188,["P","M",TusBilgisi]

This instruction conveys data at the rate of 4800 baud. It conveys “P” and “M” letters before sending the key information.

Figure 4: PT2262 and ATX-34 transmitter module [10, 14]

BC327 NPN transistor used in the diagram of the control circuit in Figure 4 prevents the circuit from dispending battery unless the button is pressed. When any button is pressed, the base of PNP transistor is grounded and the transistor starts to transmission. The circuit is electrified in this way. Then, the instruction for a pressed key is conveyed wirelessly to the control panel.

2.3 Control and Electronic Card of the Sugar Beet Harvester Figure 5 shows the circuit we prepared for the sugar beet harvester. This circuit guides the machine according to the data coming from the control device.

Figure 5: Sugar Beet Harvester Circuit

PIC16F84A opens and closes the valves on the sugar beet harvester in accordance with the data coming from the control device. The machine is controlled by an electronic circuit and software. If the wired control system is to be used, the instruction for reading the data serially is as follows:

SERIN2 VERIIN,188,100,ATLA,[WAIT ("PM"), TusBilgisi]

This instruction reads the data sent at the rate of 4800 baud and conveys the data sent after the regularly conveyed “P” and “M” letters to the key information variable. If the control system is to communicate via RF signals, a control receiver circuit is placed in the sugar beet harvester with the help of a header socket and these two circuits run like a single circuit. 12 volt power from the tractor accumulator is reduced to 5 volt with the 7805 regulator. The valves used in the sugar beet harvester are driven by the TIP55 power transistor. This transistor is preferred because its high collector current (Ic=15A).

III. CONCLUSION AND DISCUSSION

This study deals with the design and use of an electronic circuit to control the hydraulic parts of an agricultural machine, namely sugar beet harvester. A program was written in PIC for its electronic circuit. Designed electronic circuits were applied on a real sugar beet harvester after they were tested in our workshop. Possible hardware and software failures were detected and resolved during the tests. After the final revision, the system has been tested continually for two months. The tests have shown that the control system which can communicate on cables with serial communication and wirelessly with RF signals is applicable for sugar beet harvester machines. After the tests yielded the desired results, our printed circuits were serially produced by professional firms.

Using electronics and computers in agricultural mechanization applications is a modern approach. This approach not only enhances agricultural productivity but also provides a quick and easy use. Furthermore, these technological and electro-mechanical developments help people overcome the problems they encounter at workplace, providing more comfort, more time, and more economic profit.

Number of cables is reduced and troubleshooting becomes easier with the serial communication technique. This technique also provides an easier installation and a safer working environment. The system is remote-controlled with a wireless RF circuit designed additionally to the electronic card. By this way, cables are eliminated and the system is made remotely operable The system we have developed can be used and improved further by being adapted to the other parts of sugar beet harvester or to the other kinds of machines.

REFERENCES

[1] Unal H.G., Research on Mechanization Conditions and Agricultural Applications of Sugar Beet Producers in Kastamonu, Journal of Agricultural Sciences Ankara University Faculty of Agriculture, 13 (1) 9-16, 2006. [2] Arısoy H. “Tarımsal Araştırma Enstitüleri Tarafından Yeni Geliştirilen Buğday Çeşitlerinin Tarım İşletmelerinde Kullanım Düzeyi ve Geleneksel Çeşitler İle Karşılaştırmalı Ekonomik Analizi -Konya İli Örneği” Yayın No: 130, ISBN:975-407-174-8, 2005.

[3] Eryilmaz T., Gokdogan O, Yesilyurt M. K., Ercan K., Properties of Agricultural Mechanization of The Nevsehir Province, Journal of Adnan Menderes University Agricultural Faculty,10(2):1-6, 2013.

[4] Şeker Pancarı Hasat Makineleri, http://www.ziraatciyiz.biz/seker-pancari-hasat-makineleri-t1528.html?

s=00c338ed6fd8fd245dbc150440ddd34a&t=1528 [Ziyaret Tarihi: 24 Mart 2014]

[5] Tarımsal Mekanizasyonun Faydaları, http://www.birlesimtarim.com/bilgi-TARIMSAL.MEKANIZASYONUN.FAYDALARI-2-tr.html [Ziyaret Tarihi: 24 Mart 2014]

[6] Türkiye Cumhuriyeti Şeker Kurumu,

http://www.sekerkurumu.gov.tr/sss.aspx [Ziyaret Tarihi: 24 Mart 2014] [7] Guzel S., Yerel Kalkınma Modeli: Afyon-Sandıklı’da Tarıma Dayalı Sanayileşme, Karamanoğlu Mehmetbey University Journal of Social and Economic Science, 133-143, May 2007.

[8] Kombine Pancar Hasat Makinasi,

http://www.ozenistarimmak.com/pancar-hasat-makinasi-pancar-sokme-makinesi-pancar-toplama-makinesi_1_tr_u.html [Erişim Tarihi: 13 Mart 2014]

[9] Milli Eğitim Bakanlığı, Mesleki ve Teknik Eğitim Programlar ve Öğretim Materyalleri, Tarım Teknolojisi Programı, Traktörle Kullanılan Özel Hasat Makineleri Modülü, 2014.

[10] Golcuk A, 2010. Design And Actualisation Of The RF-Controlled Lift System, M.Sc. thesis, Graduate School of Natural and Applied Sciences, Selcuk University, 75 P. Konya, Turkey.

[11] Mikrodenetleyici İle Tek Hat Seri İletişim (Hazırlayan Akif Canbolat), http://320volt.com/mikrodenetleyici-ile-tek-hat-seri-iletisim-pic16f84 [Ziyaret Tarihi: 24 Mart 2014]

[12] Microchip Technology Inc., http://www.microchip.com [Ziyaret Tarihi: 24 Mart 2014]

[13] Altınbaşak, O., Mikrodenetleyiciler ve PIC Programlama, Altaş Yayıncılık, İstanbul. 2004.

[14] AN-ASKTX-PT2262, Udea Elektronik, http://www.udea.com.tr/dokumanlar/AN-ASKTX-PT2262.PDF, [Ziyaret Tarihi: 13 Mart 2014]