1st INTERNATIONAL BLACK SEA CONGRESS ON ENVIRONMENTAL SCIENCES (IBCESS) Giresun, Turkey • August 31 - September 03, 2016

IBCESS

FP81

651

ENERGY PRODUCTION FROM ORGANIC WASTE

Aysun Altikat

1, Sevtap Doğru

2, Yusuf Alparslan Argun

2and

Züleyha Bingul

31 Department of Civil Engineering, Engineering Faculty, Igdir University, Igdir, Turkey

aysun.altikat@igdir.edu.tr

2 Environmental Health Programme, Vocational School of Health Services, Igdir

University, Igdir, Turkey

3 Department of Environmental Engineering, Engineering Faculty, Igdir University,

Igdir, Turkey

ABSTRACT

The development level of the country is measured with the potential to meet the energy needs. In developed countries, wastes not only are undergone treatment, but also contributes to meeting the country’s energy needs by obtaining energy from them. Thermal and non-thermal techniques are used to generate energy from waste. Energy is obtained by burning waste in thermal technics, and by using anaerobic process in non-thermal technics. To obtain energy from organic waste is an issue that should be addressed seriously for global warming combat, the energy gap closure, effective waste management and sustainable development. In this study, it is discussed enable energy production techniques from organic waste in detail and demonstrated current situation of the world and Turkey comparatively and determined energy production potential of Turkey from waste and its proportion of the total energy need.

Keywords: Energy, environmental protection, organic waste, sustainable development, waste management.

FP81 652

INTRODUCTION

Energy is an essential factor for human life. All natural and artificial systems need energy to run. The need of additional energy has increased during the development process of humanity and the development level of the country has also measured with the potential to meet the energy needs. On the other hand modernization and urbanization, increasing human population and life quality have revealed the concept of waste which is need to focus cautiously. In particular, domestic and industrial solid waste lead to environmental pollution and affect surface-groundwater during production, transportation and storage/disposal and built landfills are harming natural habitats. For this reason, it is more need to reduce waste at the source, separated for recycling and the most important is to remove them rather than to collect for storage no longer. Energy production from waste is also a kind of disposal method. Now many developed countries in the world overlook to the waste as the raw materials for energy production not as rubbish. So that it was began to import waste depending on the raw requirement for energy production plants.

Energy Production From Waste

Production of energy from waste is a process that has a centuries-old history. Incineration process is the first used. Then different techniques have been developed because of increasing the priority of the energy requirements and waste disposal. In general, the process comprises the heat and/or electric power generation from the primary operation of waste. Many energy production from waste treatments can generate directly heat and/or electric power with combustion process and also produce flammable fuel products such as methane, methanol, ethanol or synthetic fuels. Pathway followed in the production of energy from waste shown in Figure 1.

FP81 653

The techniques used in the production of energy from waste are divided into thermal and non-thermal techniques. Detailed description of these techniques and used processes are given below.

Thermal Technics

Thermal technics refer to the high temperature treatment of the waste in general. The oldest methods used in the production of energy from waste is incineration. After this method which has about a hundred-year history some methods such as gasification, thermal depolymerization, pyrolysis, plasma gasification have been developed.

Incineration

Incineration, the burnout of organic matter for instance waste with energy retrieval, is the most common WtE (Waste to Energy( treatment. All OECD (Organisation for Economic Co-operation and Development( countries new WtE plants incinerating waste (residual MSW (municipal solid waste(, mercantile, industrial or RDF (refuse derived fuel(( should meet rigid emission standards, consisting of sulphur

dioxide (SO2(, nitrogen oxides (NOX(, dioxins and heavy metals. Therewith, current

incineration plants are distinct from old types, some of those neither retrieved energy nor materials. Newly builded incinerators decrease the size of the crude waste by 95-96 percent, relating on content and grade of recycle of materials such as metals from the ash for recycling.

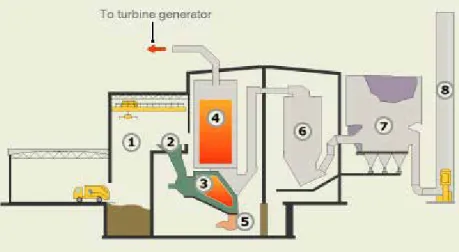

Figure 2. Basic process of a waste incinerator (Osorio Arce et al., 2015(

I

n Figure 2, the crude waste is taken to the waste incineration plant and spilled intothe storage (1(. The waste is then grasped and dumped into a feed hopper (2(. The waste is progressively fed into the incinerator (3(. This incinerator operates specific temperatures related to the type of waste. Incineration heat is then used for heating

FP81 654

the working fluid (usually water( in the boiler (4(. The steam from this process is carried with pipes to a turbine to generate electricity. The residual burnt trash and weighty ash spills to a collection area (5(. An electromagnet can be used to recover any left over metals in this discarded part. The flue gases probably found fine ash and other toxic vapors are sent to a scrubber reactor (6(. This unit is used to purify

the flue gases from acidic pollutants such as SO2 and dioxins. The gases then pass

through a fine particulate removal system and reduce their toxicity (7(. Finally the flue gases are released from the chimney (8(. Generally approximately 400 to 700 kWh of electricity can be generated with one tonne of MSW in a incineration plant. But there are significant local variations depend on the magnitude of the plant, steam parameters and degrees of steam utilisation and mainly on the calorific value of the trash (European Commission, 2006(

Gasification

Gasification, is a thermochemical process, consists of two stages: pyrolysis and char gasification reactions. In the first stage, a char consisting of fixed carbon and the inorganic compounds in the feed is remained after the volatile components of the organic compounds are released at temperatures below 600°C (1112°F(. In the second stage, the carbon in the char is reacted with steam, air, or pure oxygen. Gasification with steam results in a “synthetic” gas (syngas( which is rich in hydrogen and carbon

dioxide. Gasification with air produces a high-N2, low Btu fuel gas. When the proses is

operated with oxygen occurs a high Btu mixture of carbon monoxide and hydrogen. The exothermic reaction between carbon and oxygen provides the thermal energy needed to perform the pyrolysis and char gasification reactions. A schematic image of MSW Gasifiation and Power Generation Plant was given in Figure 3.

FP81 655

Thermal depolymerization

Thermal Depolymerization is a process using hydrous pyrolysis for the reduction of complex organic materials into light crude oil. These materials are usually waste products often known as biomass and plastic. It imitates the natural geological processes producing of fossil fuels. Long chain polymers of hydrogen, oxygen, and carbon turn into short-chain petroleum hydrocarbons with a maximum length of around 18 carbons under pressure and heat thanks to this process.

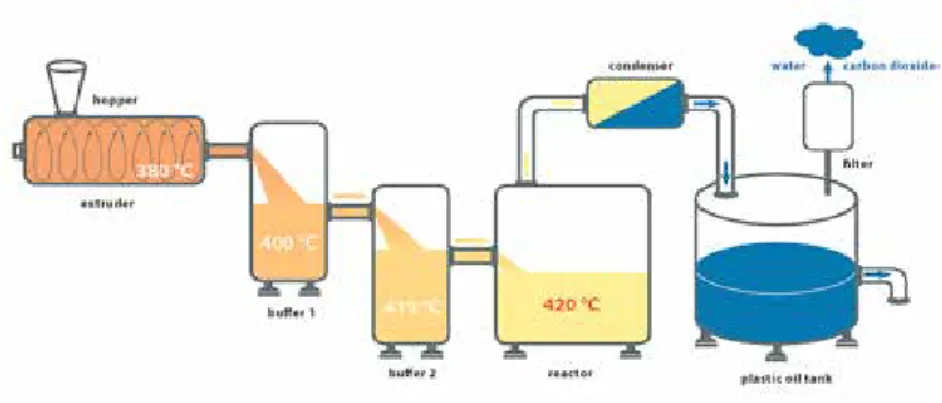

Figure 4. A thermal depolymerization scheme (Leitner, 2016(.

Thermal Depolymerization Plant can infer transformation of biomass to oils using superheated water, although it more usually is implemented to fuel production by way of pyrolysis (Figure 4( (Wikidoc, 2012(.

Pyrolysis

Pyrolysis is the thermal decomposition of a matter in the absence of oxygen. This process involves an exterior heat source to ensure required temperature continuity. Generally, lower temperatures of between 300°C to 850°C are used for pyrolysis of MSW (Figure 5(.

FP81 656

Figure 5. A pyrolysis scheme

Crude municipal waste is usually inappropriate for pyrolysis because of glass, metals and inert materials such as rubble. They must be preparated and separated before processing the leftover waste. Generally pyrolysis technics need consistent feedstocks so there are very few commercial scale pyrolysis plant processing municipal derived wastes in the world. The products of pyrolysing materials are a solid residue (named char( and a syngas. Char is a composition of noncombustible substance and carbon. The syngas is a mixture of combustible gases (such as carbon monoxide, hydrogen, methane and other volatile organic compounds( (DEFRA, 2013(.

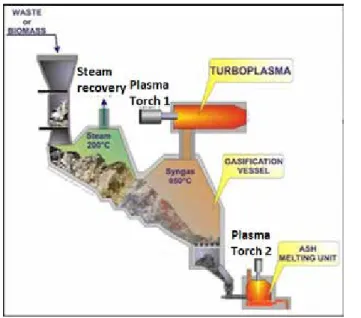

Plasma gasification

Plasma arc gasification or plasma gasification process (PGP( produces hydrogen and carbon monoxide-rich syngas. It is utilizable for fuel cells or generating electricity (Figure 6(. Compared with mostly used combustion technics for waste treatment, thermal plasma advantages are;

1( High energy production and temperatures, and fast reaction times, provide a large productivity with a small oven.

2( Only a slight amount of oxidant is necessary to generate syngas.

3( High heat flux densities at the oven walls lead to fast achievement of steady state conditions. This leads rapid start-up and shutdown times compared with other thermal technics. (Byun et al., 2012(.

FP81 657

Figure 6. A plasma gasification process (Waste Management, 2010( Non-thermal Technics

Non-thermal techniques express the biological decomposition of waste in general. Basic non-thermal processing techniques are presented below.

Anaerobic digestion

Anaerobic digestion (AD( is defined as the decomposition of carbonous substances by microorganisms in nature without oxygen. This process already occurs naturally in landfills containing organic matter. One of its main products is methane (EPA, 2015(. An anaerobic digestion process scheme was given in Figure 7.

FP81 658

Plants containing anaerobic digestion process greatly provide to maximize the yield of methane production for generating energy, simultaneously lowering greenhouse gas emissions from landfills. Additionally, this situation results in better landfill management, reducing tipping fees for businesses and addressing odor control issues (Naik et al., 2013(.

Fermentation production

The fermentation process can be performed under aerobic or anaerobic conditions, wherein the formation of final products such as ethanol, lactic acid, hydrogen and methane.

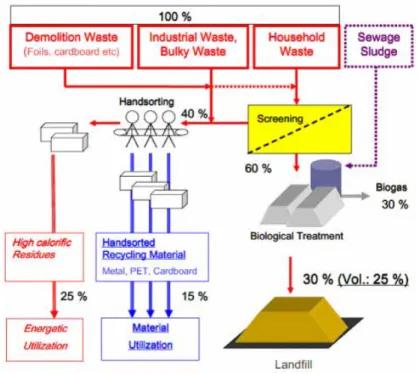

Mechanical biological treatment (MBT)

The Mechanical Biological Treatment Plant (MBT( is comprised of two systems. A MBT Plant is comprised of Municipal Solid Waste Separation Plant coupled with Dry Anaerobic Digester Plant. By MBT recycling technologies, almost all the household waste is converted into electrical energy, heat energy, organic fertilisers, refuse and other sustainable resources (Figure 8( (Advaitaa, 2012(.

FP81 659

Worldwide and Turkey Energy Status

Among the G20 members with data available (see Table 1(, Japan reported the most frequent use of incineration to treat municipal waste and Mexico and Turkey the most frequent use of landfill. In South Korea, more than half of the municipal waste was recycled, with the share in Australia (41 %( the next highest, Turkey was not recycled.

The amount of municipal waste generated in 2012 ranged from 295 kg per inhabitant in Brazil to 407 kg per inhabitant in Turkey, with the EU-28, Russia, Australia and the United States above this range and China and Indonesia below it.

Methods used applied in EU-27 countries for collection and disposal of solid waste between 1995-2014, the amount of landfill by 54% and other methods by 52% reduced, incineration, recycling and the compositing process increased by 100%, 166% and 170% respectively. The processed waste amount of per capita decreased 57% in landfill and 64% in other methods, and increased in incineration, recycling and compositing process 90%, 152% and 158% respectively (Eurostat, 2016(.

Table 1. Municipal Waste, Latest Year (Eurostat, 2015(.

Latest year Generated (million tonnes) Treated

Landfilled Incinerated Recycled Composted (% of total treatment) EU-28 2013 243.3 31 26 28 15 Australia 2009 14.0 58 : 41 : Brazil 2007 51.4 : : : : Canada (1( 2010 13.8 72 4 18 7 China 2009 157.3 80 18 : 2 India 2001 17.6 : : : : Indonesia 2008 9.6 : : : : Japan 2010 45.4 1 76 19 : Mexico 2012 42.1 95 : 5 : Russia 2012 80.6 : : : : South Korea 2011 17.9 17 24 58 1 Turkey 2010 29.7 99 0 : 1 United States 2010 226.7 54 12 26 8

Among the G20 members, the largest net exporters of energy in 2012 were Russia and Saudi Arabia, while Mexico and South Africa also recorded smaller net exports. The largest net importer was the EU-28, followed by China, Japan and the United States.

FP81 660

Between 2002 and 2012, Argentina moved from being a net exporter of energy to a net importer. During the same period, the United States’ net imports declined, while the net imports of China increased greatly as did those of India, South Korea, the EU-28 and Turkey.

CONCLUSION

Energy production from organic waste is a method based on an old history. In particular, the collection of solid waste in landfills is now completely abandoned in developed countries, producing energy from waste is used for recycling. Methods are used for less storage space, volume, quantity, waste which has minimum harmful effect to environment, recycling of waste with economic value, and disposing of waste as a result of accelerated catalytic reactions that occur in the natural process and finally for positive effect on both country’s economy and on global effect of waste. Optimization works on these methods are still continuing.

The results observed in this study suggest that the generation energy from waste is development indicators in the world. Countries are taken seriously to save energy for prevention of global warming, reduction of carbon footprint, building and protection of the world’s healthy future. Measures taken not be limited to a single country, the necessity of taking common measures in the shared world is giving sense to the

concept of globalization. The following recommendations are offered for Turkey’s

place of residence that has been earned in this picture:

Energy-based projects should be supported, given priority in every project calls.

It should be considered for inclusion process about generation energy from these waste to the projects while planning solid waste management of new developing urban.

It should be provided informing of public, promotion of energy projects and

provision support for energy converting of agricultural and animal waste which

is rich in organic content as public or private in rural areas as well as urban solid waste management.

Energy regulation should be considered not only newly established landfills, but also the transformation of the old plant for the production of energy should be provided.

It should be provided scientists turned to energy in academic terms, promotion rates of energy based R & D projects should be increased.

FP81 661

REFERENCES

1. Advaitaa (2012(, Mechanical Biological Treatment Plant, http://advaitaa.in/green_ energy/mbt_plant.html, Date of Access 29 May 2016.

2. Byun Y., Cho M., Hwang S.M. and Chung J. (2012(, Thermal Plasma Gasification of Municipal Solid Waste (MSW(, Gasification for Practical Applications, Yun Y. (Eds.(, InTech Publisher, Rijeka, Croatia.

3. DEFRA (Department for Environment, Food & Rural Affairs( (2013(, Advanced Thermal Treatment of Municipal Solid Waste, PB13888, Kew, London, UK.

4. ECORP (Environment & Energy Corporation( (2012(, MBT Mechanical-Biological Waste Treatment, http://www4.ecorpbg.com/en/content/mbt-mechanical-biological-waste-treatment, Date of Access 29 May 2016.

5. EPA (US Environmental Protection Agency( (2015(, Inventory of US Greenhouse Gas Emissions and Sinks: 1990-2013, EPA 430-R-15-004, Washigton DC, USA.

6. European Commission (2006(, Integrated Pollution Prevention and Control Reference Document on the Best Available Techniques for Waste Incineration.

7. Eurostat (2015(, The EU in the World, 2015 edition, Eurostat Statistical Books, ISSN 2315-1870, Belgium.

8. Eurostat (2016(, Municipal waste landfilled, incinerated, recycled and composted in the EU-27, 1995 to 2014, http://ec.europa.eu/eurostat/statistics-explained/index.php/ File:Municipal_waste_landfilled,_incinerated,_recycled_and_composted_in_the_EU-27,_1995_to_2014.png, Date of Access 29 May 2016.

9. Klein A. and Themelis N.J. (2003(, Energy Recovery from Municipal Solid Wastes by Gasification, North American Waste to Energy Conference (NAWTEC 11(11 Proceedings, ASME International, Tampa FL, 241-252.

10. Leitner (2016(, Technologies, Plastics to oil transformation diagram, http://www. leitnertechnologies.sk/en/technologie/, Date of Access 29 May 2016.

11. Naik N., Tkachenko E. and Wung R. (2013(, The Anaerobic Digestion of Organic Municipal Solid Waste in California., CHEMISTRY C234, University of California, Berkeley, USA. 12. Osorio Arce L.M., Satir M., Pujari S. and Nag R. (2015(, Design of an integrated waste

management facility in the republic of Ireland, Waste to Energy Process & Technology, School of Biosystems & Food Engineering, Agriculture and Food Science Department University College Dublin, Belfield Dublin.

13. Scarlat N., Motola V., Dallemand J.F., Monforti-Ferrario F. and Mofor L. (2015(, Evaluation of energy potential of Municipal Solid Waste from African urban areas, Renewable and Sustainable Energy Reviews, 50, 1269-1286.

14. Waste Management (2010(, Methods of Waste Disposal 1, http://www. wastemanagement.in/methods-of-waste-disposal-1.html, Date of Access 29 May 2016. 15. Wikidoc (2012(, Thermal depolymerization, http://www.wikidoc.org/index.php/

Thermal_depolymerization, Date of Access 29 May 2016.

16. Zafar S. (2009(, Gasification of Municipal Solid Waste, http://www.altenergymag.com/ content.php?issue_number=09.06.01&article=zafar, Date of Access 29 May 2016.