Resources Policy 65 (2020) 101577

Available online 8 January 2020

0301-4207/© 2020 Elsevier Ltd. All rights reserved.

Efficiency change of coal used for energy production in Turkey

Yas¸ar Kasap, Cem S¸ens€o�güt

*, €Ozer €Oren

Kütahya Dumlupınar University, Department of Mining Engineering, Kütahya, Turkey

A R T I C L E I N F O Keywords:

Coal

Energy efficiency Energy policy

Malmquist productivity index Productivity

A B S T R A C T

A large part of the coal produced is consumed in thermal power plants in Turkey. Therefore, the energy policies focusing coal in the center is important for Turkey. Considering the lignite reserves of Turkey, as well as the effective use of these coal, a large part of the energy need will be met through local sources. Malmquist pro-ductivity index (MPI) has been utilized to analyse the effectiveness variation for the use of coal in Turkey, meeting an enourmous amount of its energy essentials through imports, in energy production between the years 2009–2018. As a result of the analyzes made; it has been determined that the efficiency change values of coal used in the production of electric energy increased by 16.4% due to the rise in the use of imported coal and asphaltite. In recent years, there has been no significant change in the use of lignite as it is determined that there is a 3.1% decrease in efficiency development due to the absence of new investments in hard coal -based elec-tricity generation.

1. Introduction

In the determination of the growth objectives of the countries, the availability and existence of energy sources take place a considerable weight. The unreliable resources may cause prices to change

uninten-tionally and the economic growth program to fail (Kasap and Duman,

2013).

Due to the existence of natural gas and oil resources in certain re-gions of the earth crust and the high degree of variation in prices, the waste coming from nuclear resources and the inconvenience of the environment in the event of an unexpected accident and the public re-flex against it, the high costs of new-renewable resources, the techno-logical developments not leading to new expansions, coal will continue to be an important actor as a source of energy because of economic and

strategic apprehensions (Kasap and Duman, 2013; Tamzok, 2005).

Considering the total coal production in the world in 2015, it is estimated that global coal reserves have a lifetime of about 116 years (Table 1). Likewise, the remaining life of lignite reserves with a calorific value of less than about 4000 kcal/kg is 222 years when global lignite production in 2012 is taken into account. However, in calculating the remaining life of coal reserves, a total of 861 billion tonnes of coal re-serves, which can be recovered from technical and economic consider-ations in today’s conditions, are taken as the basis. According to the German Federal Institute of Earth Sciences and Natural Resources, 17 trillion tons of hard coal and 4.2 trillion tons of lignite, which are not yet

available technically or economically, await the time for their usage as a

“source” in the earth (TCE (Turkish Coal Enterprises), 2016).

World coal production has almost doubled in the last thirty years. The increase in coal production is due largely to the demand for elec-tricity from Asia, especially China. In the last decade, the total increase in electric energy production in the Asia-Pacific region has been about 2 times, and it has been the most intensively used source of coal for

electricity generation (TCE (Turkish Coal Enterprises), 2016).

In recent years, with Turkey’s economic development, increase in crude oil and natural gas consumption was observed. However, Turkey has limited reserves of crude oil and natural gas. Therefore, almost all of the oil and gas supply for the country’s economy is imported with very high costs (Kaya and Kilic, 2015). In Turkey, lignite production has consistently decreased since 1998 and reached to the lowest value with 43.7 million tons in 2004 due to the increase in natural gas purchase agreements. After this date, the rising lignite production reached 76 million tons in 2008, but then regressed to 57.5 million tons in 2013. In line with the importance given to underground resources in recent years, lignite production was realized as 70.24 million tons in 2016, 71.46

million tons in 2017 and 101.5 million tons in 2018, respectively (TCE

(Turkish Coal Enterprises), 2018).

The hard coal production, which has been in a constant downward trend since the 1980s, declined to 1.9 million tons in 2004. After this date, re-mobilized salable hard coal production was 2.3 million tons in

2012. However, it fell to a level of 1.2 million tons in 2017 (TCE (Turkish

* Corresponding author.

E-mail address: cem.sensogut@dpu.edu.tr (C. S¸ens€o�güt).

Contents lists available at ScienceDirect

Resources Policy

journal homepage: http://www.elsevier.com/locate/resourpol

https://doi.org/10.1016/j.resourpol.2019.101577

Coal Enterprises), 2018).

Regarding the behavior of countries with rich coal reserves, it is understood that these countries mostly use their own coal resources at high rates in their electricity production, unless the dominant use of another domestic resource is concerned. Meanwhile, especially in recent years, it is observed that Turkey behaves very differently from the the countries in concern for the utilization of local coal sources in terms of electricity production. This case leads to increased electricity costs and

problems in electricity supply security in Turkey (Tamzok, 2005).

Turkey’s energy consumption showed an increase of 45.7% over the last decade. However, energy production in Turkey was increased by only 27.7%. Therefore, the rise in energy generation is heavily under the rate of rise in energy exhaustion in Turkey. For this reason, the com-pansation rate of domestic production to consumption fell from 27.3% (ten years ago) to 23.9% by the year 2015. The decline in equivalent petroleum-based coal production has been 7.2% in the last decade. While the rate of meeting the energy consumption by domestic coal production was 12.4% in 2005, it decreased to 9.9% in 2015, but rose to 10.37% in 2017. In 2015, 23.9% of the energy consumption in Turkey was obtained from domestic energy sources, while a significant portion of 76.1% was met from imported sources. In 2017, while 24.3% of the energy consumption in Turkey was obtained from domestic energy sources, 75.7% of the energy consumption was met from imported sources causing a little decrease in the dependency to importing sources.

(TCE (Turkish Coal Enterprises), 2016; TCE (Turkish Coal Enterprises),

2018).

In order to reduce the external dependency of energy, the right policies and long-term energy strategies should be determined first. While determining these strategies; the country’s energy resources po-tential should be determined in a healthy and scientific way at first; secondly, it is imperative that energy demand forecasts be made correctly. The main parameters that should be based on energy demand forecasts are economic growth, population, energy prices, technological developments, energy policies and consumer behavior towards energy saving. After determining the production and consumption potentials, one of the vital requirements in the process of determining energy pol-icies is the right planning. With this planning, the production and

con-sumption of resources are arranged for the needs (MENR_1 (Ministry of

Energy and Natural Resources-Turkey), 2018).

Reducing energy intensity (increasing energy efficiency) is one of the most important elements of energy policies. Developed countries, with a few times lower energy input, can achieve the gross product that the underdeveloped countries can create. One of the most important targets ahead of developing countries should be to put the measures that will reduce energy intensity at the forefront in energy policies which should

be integrated with industry and transportation policies (Pamir, 2005).

Considering the increase in energy costs, the importance of energy generation in terms of the environmental effects. and energy efficiency in production to ensure continuous and reliable supply of energy that

can compete in the free market, effectiveness (efficiency) change of the use of coal in electricity production in Turkey between the years 2009–2018 has been analyzed.

When it comes to productivity in energy production; Reliability and continuity,

Increasing the domestic ratio in primary energy sources,

The lowest primary resource losses in production, a price structure that is profitable for the investor and affordable for the consumer, Minimizing environmental and external costs,

The sector employees reaching the work and income satisfaction, It should be perceived as an improvement in the technological competence of the sector, high innovation capacity and management

quality (AEE (Association of Energy Efficiency), 2011).

Today, many different measurement methods have been in use since varying sources utilized for production, differing goods obtained through the use of these sources, and variations in input/output units cause a drawback for the estimation of the efficiency. The absence of standard, well-established safe and confirmed measurement methods to realize performance metrics that include measures such as productivity and efficiency have led to non-parametric linear programming methods becoming more prominent.

The nonparametric linear programming method analyzes the data of the decision units in a single time scale and does not take the event changes into consideration that may appear over the time. Therefore, the Malmquist productivity index (MPI) was used to examine the effectiveness exchange of the coal utilized for energy production in Turkey since it takes the time dimension into consideration for the years being analyzed.

In the literature, there are no studies on the effectivity variations of the resources used in energy production over time, but similar studies

are found in terms of the method considered. P�erez et al. (2017) in their

study, they examined the energy efficiency and greenhouse gas emis-sions in Chilean manufacturing industry by taking advantage of MPI, taking into consideration the time factor in terms of region and sector.

Guo et al. (2018) argued that improving coal consumption efficiency is

both important for China to address energy security and environmental pollution issues as well as for greenhouse gas emissions for the world. They used a data envelopment analysis (DEA) approach to assess coal consumption efficiency for six energy-intensive industries in China in

2015 utilizing total factor productivity in their work. Olanrewajua et al.

(2015) tried to examine the effectiveness of energy management policies

in food industry with the integration of index decomposition analysis (IDA), artificial neural network (ANN) and data envelopment analysis (DEA). As a result; It is determined that approximately 11% of the consumed energy can be saved.

Determining the efficiency change over time in the use of energy resources is important in terms of the strategies to be determined in meeting the increased energy demand. As a result of these analyzes; Increased rate of change in the use of imported coal and asphaltit for electrical power generation in Turkey was observed in the years 2009–2018 while no change in the use of hardcoal and a decrease in the use of lignite was determined. These reductions have been brought about as a consequence of the complications reasoned by imports, the commercial crises and the inability to utilize the existing installed powers effectively, and efforts have been made to draw attention to the use of domestic resources.

2. Methodology

Parametric efficiency measures take an assumption that the pro-duction parameters of fully active units are clear. Since propro-duction

functions are never practically known. Farrell (1957) pointed out that

the function be estimated by using the data in the sample. The first

suggestion was assessed by Charnes et al. (1978).

Table 1

Coal reserves and reserve consumption periods of some countries (TCE (Turkish Coal Enterprises), 2018). Reserve (billion tons) Share in Total Reserve (%) Production Amount 2015 (million tons) Reserve/ Production (year) WORLD 891 100 7709 116 USA 237.3 26.6 813 291 Russia 157 17.6 349 450 China 114.5 12.9 3527 35 Australia 76.4 8.6 509 150 India 60.6 6.8 691 88 Germany 40.5 4.5 185 219 South Africa Republic 30.2 3.4 252 120 Turkey 9.4 1.1 58.4 161

In the nonparametric linear programming method used for comparative effectiveness analysis, there are firstly the enveloped sur-faces (effective bounds) which include the linear combinations and the effective observations of decision-making units (DMU: sources consid-ered) performing the similar production activities. Following that, the radial distances and the activity values of the inactive units remaining in

this enveloped surface are computed (Muniz, 2002; Aydagün, 2003).

The most important advantage of this method is that each decision- making unit can identify its ineffective amount and resources. With this feature, the method can guide decision makers on how much they can reduce their input and/or increase their output so that inactive units become effective.

The linear programming model with equations (1)–(4) is used to

asses the Technical Efficiency (TE) value of the kth DMU (the decision-

making unit in consideration).

In the objective function defined in equation (1), the inputs are kept

constant to try to maximize the outputs. Equation (2) gives the

constraint that maximizes the outputs of inactive DMU. Equation (3)

includes keeping non-parametric linear programming inputs constant under output maximization. The “i” input of each “j” DMU can be calculated with a lower input level than the weighted linear

combina-tion of inputs “i” used in all units. Equacombina-tion (4) is a sign constraint.

maxθk (1) Xn j¼1 λj⋅ Yrj srj¼θk:Yrk r ¼ 1; 2; :::::; s (2) Xn j¼1 λj⋅ Xijþsþij ¼Xik i ¼ 1; 2; :::::; s (3) λj;sþij;srj�0 8i; r; j (4)

For every DMU to be effective.

optimal θk should be 1 and

all slack variables must be zero (sikþ, srk- ¼ 0).

The parameters formulated in the of the nonparametric linear pro-gramming model are described below;

n number of decision-making units to be compared, s the number of outputs from production,

m the number of inputs utilized in production,

k ¼ (1, 2, …, n) the set of decision-making units considered, r ¼ (1, 2, …, s) set of all outputs,

i ¼ (1, 2, …, m) set of all inputs

y 2 Rþ

s vector of outputs (Y1, Y2, …,Ys) ¼ s � n

x 2 Rþ

m vector of inputs (X1, X2, …,Xm) ¼ m � n

λ the weight value of the decision unit “k”, which is measured in the output-oriented model according to the other units (j)

θk the scaler parameter (efficiency value) that tries to increase all

outputs of k DMU defined to get the best boundary,

Yrj the amount of rth output generated by decision unit j,

Yrk the amount of rth output generated by decision unit k,

Xij the amount of ith input generated by decision unit j,

Xik the amount of ith input generated by decision unit k,

t year studied and

t þ 1 the year after the studied year,

The nonparametric linear programming method is a static analysis and analyzes by using the data of decision units in a single time scale. After all, a decision-making unit may lose its effectiveness in later pe-riods as well as its feature to be reference. In this respect, the Malmquist total factor productivity index has been developed in order to examine the change that may occur in the course of the event evaluation process.

Malmquist total factor productivity index obtained by including

distance functions in technical efficiency measure (Farrell, 1957);

quantifies the variation in total factor productivity of the two units as a share of distance, which is a well-known technology, The distance function is utilized to determine multi-input, multi-output production methods with no specified purposes such as cost minimization or profit maximization, The input distance function, when given the output vector, specifies the production method depending on the input vector which is proportionally the most tapering, Accordingly, the output dis-tance function, when given the input vector, implies the production method depending on the input vector which is proportionally the most

expanding (Tarim, 2001; Coelli et al., 1998).

Grifell-Tatje and Lovell (1995) show that using the variable-valued

return assumption in calculating the distance functions necessitated for the Malmquist index does not accurately determine the variations in MPI (productivity gain or loss), Therefore, the index has to be calculated

under the belief of constant return to scale (Tarim, 2001; Kasap, 2008).

Output distance function; Diðx; yÞ ¼ min n θ : � x;y θ � 2LðxÞ o (5) The values of the distance function Di (x, y) are 1,0 if y is above the effective limit of L (x); If the technique in the x vector L (y) defines an ineffective point <1,0; and x is a non-possible point outside the vector L (y) > 1,0, The Malmquist total factor productivity change index (MPI), based on the interval between the period t and the following period (t þ 1), is in the framework of distance function;

MPI ¼ ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi Dt iðytþ1;xtþ1Þ Dt iðyt;xtÞ �D tþ1 i ðytþ1;xtþ1Þ Dtþ1 i ðyt;xtÞ s (6) where Dt

iðxtþ1;ytþ1Þ, gives the distance of t period to (t þ 1) period technology.

MPI, calculated from the distance function, examines the variations in productivity in consonance with two different components called technical efficieny change (TE) and technological change (TD), While technically efficieny change gives an assessment of the effective trans-boundary approach of decision-making units, technological change; indicates the change in effective limit over time, The technical efficiency here refers to the maximum amount of output produced by the inputs, The word technology taking place in technological change can be extended not only to production or machine technology, but also to the effects of policies, regulations and circulation of production processes, which will affect productivity (Grifell-Tatje and Lovell, 1995; Lorcu, 2010).

When equation (6) is rearranged:

MPI ¼D tþ1 i ðytþ1;xtþ1Þ Dt iðyt;xtÞ � ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi Dt iðytþ1;xtþ1Þ Dtþ1 i ðytþ1;xtþ1Þ � D t iðyt;xtÞ Dtþ1 i ðyt;xtÞ s (7) MPI¼ (Technical Efficiency Change) x (Technological Change)

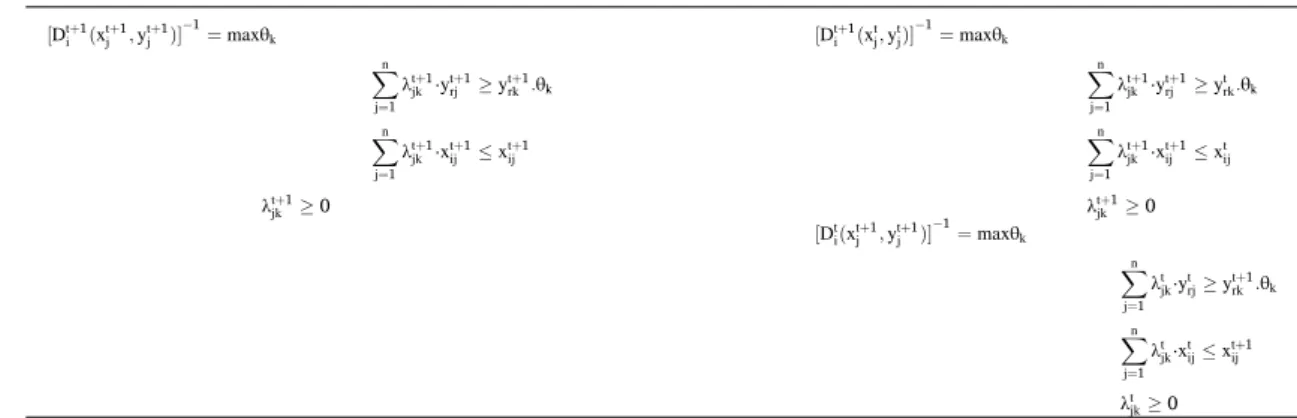

In short, MPI is the multiplication of TE and TD, The following four output distance functions are used in the calculation of MPI, These

functions are given in Table 2,

It requires a solution of nð3t 2Þ times linear programming models, which can be used to calculate these distance values for all periods and observations, to show the number of n DMUs and the number of t pe-riods (Tarim, 2001; F€are et al., 1994). In this study, 76 linear pro-gramming models have been solved in order to be able to carry out analysis because of 4 energy sources considered for 7 years.

3. Application

Malmquist total factor productivity index (MPI) has been utilized to analyse the progress of coal used for the production of electricity in

Turkey between the years 2009–2018, The data used in the analyzes have been taken from the statistics of Turkish Electricity Transmission Corporation, General Directorate of Energy Affairs, Chamber of Elec-trical Engineers in Turkey, Turkish Statistical Institute and Turkish

Ministry of Energy and Natural Resources (Table 3) (TETC (Turkish

Electiricity Transmission Corporation), 2018; TETC (Turkish Electiricity

Transmission Corporation), 2019; GDEA, 2019; TCEE (Chamber of

Electrical Engineers in Turkey), 2019; TSI (Turkish Statistical Institute),

2019; MENR_2 (Ministry of Energy and Natural Resources-Turkey),

2018). After 2009, the coal used for electricity production was

collected under four groups as hard coal, imported coal, asphaltite and lignite. For this reason, these four groups have been taken into consid-eration in the analysis.

The essence of the analysis is based on the effective bounds defined by input-output observations of all sources, and changes in these boundaries over time, The DEAP 2,1 computer program written by

Coelli (1996) was used to solve the models.

The examined parameters can be defined as follows;

n hard coal, imported coal, asphaltite, lignite

s the number of outputs obtained in production [shares of coal used

in electricity generation (%), amount of electric energy production (Gwh)],

m the number of inputs used in production [installed power of coal-

based power plant (MW)],

k ¼ (1, 2, 3, 4) the set of decision-making units considered, j ¼ (1, 2, 3, 4) all decision-making units’ set,

r ¼ (1, 2) set of all outputs, i ¼ (1) set of all inputs,

t ¼ (2009, 2010, … …, 2018) set of time periods considered.

As can be seen from the results in Table 4, the geometric average of

the efficiency change values of the coal used in electricity generation is calculated as 1.164 (>1). This result suggests that the sources examined show a 16.4% increase in productivity changes between the years 2009–2018. The increase in MPI is due to the increase in the use of imported coal and asphaltite in electricity generation. The increase of 4.2% (1.042 if 1 ¼ 100) determined in technological change indicates a increase in the efficiency limit measured over the years considered. An increase of 11.7% in the technical efficiency value of coal in this group has occurred depending on the increase in the amount of electricity and production shares it produces according to the existing installed capacities.

Between 2009-2018, a decrease of 3.1% (0.969) was observed in MPI value of hard coal, while an increase of 38.6% (1.386 > 1.000) of the share of imported coal and 35.8% (1.358 > 1.000) of asphaltite were detected in the share of imported coal. The share of lignite in electricity

production (0.1007 ffi 1.000) was not significantly changed (Fig. 1).

At the beginning of the 1980s when coal imports started to rise, almost 70–80% of the country’s total hard coal consumption and 45% towards the end of the period were covered by domestic resources. Only 3.63% of the hard coal consumption, which was 36 195 000 tons in 2016 was met by Turkish Hard Coal Enterprises (THCE) and production in

basin (THCE, 2017).

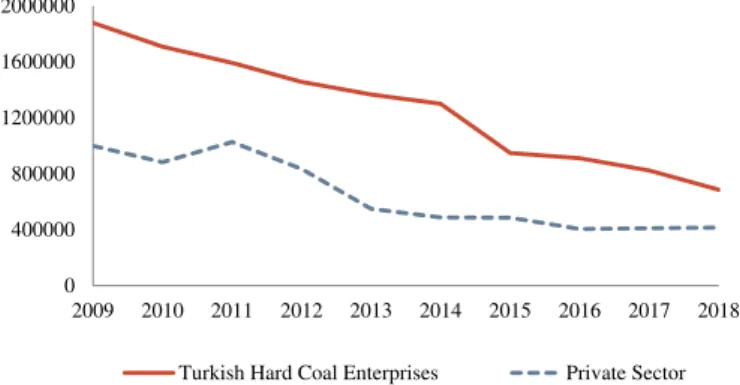

The average share of hard coal in electricity production during the period 2009–2018 is around 1.4%. Between 2009 and 2010, the share of hard coal in electricity production was around 1.7%. It decreased to 1.6% in 2011 and to 0.97% in 2018. It is possible to see the effect of this decline on the analysis results (Fig. 2).

Table 2 Distance functions. ½Dtþ1i ðxtþ1j ;ytþ1j Þ� 1¼ maxθk Xn j¼1λ tþ1 jk ⋅ytþ1rj �ytþ1rk :θk Xn j¼1 λtþ1jk ⋅xtþ1ij �xtþ1ij λtþ1jk �0 ½Dtþ1i ðxtj;ytjÞ� 1¼ maxθk Xn j¼1λ tþ1 jk ⋅ytþ1rj �ytrk:θk Xn j¼1 λtþ1jk ⋅xtþ1ij �xtij λtþ1jk �0 ½Dt iðxtþ1j ;ytþ1j Þ� 1¼maxθk Xn j¼1 λt jk⋅ytrj�ytþ1rk:θk Xn j¼1 λt jk⋅xtij�xtþ1ij λt jk�0 Table 3

Statistical outline of the input and output values of the sources used in the production of electric energy between the years 2009 and 2018.

Share in Electricity Production (%) Electricity Production (Gwh) Installed Power (MW)

HARD COAL Average 1.38 3390.61 341

Standard

deviation 0.25 273.08 7.75

Max. 1.70 3765.40 350

Min. 0.97 2915 335

IMPORTED

COAL Average Standard 13.38 34855.04 5344.60 deviation 4.85 16768.72 2295.99 Max. 22.00 66115.40 8794 Min. 6.60 12813.20 1921 ASPHALTITE Average 0.55 1419.47 243 Standard deviation 0.30 965.91 139.43 Max. 1.05 3065 405 Min. 0.20 447.60 135 LIGNITE Average 15.03 37090.60 8525.10 Standard deviation 2.39 4338.72 523.48 Max. 20.10 44838 9448.50 Min. 12 30262 8108.20 Table 4

Mean changes of the indices of MPI and its components obtained as a result of the analysis. TEa TDb MPIc Hard coal 0.927 1.046 0.969 Imported coal 1.330 1.043 1.386 Asphaltite 1.310 1.037 1.358 Lignite 0.965 1.043 1.007 Average 1.117 1.042 1.164

a TE: Technical Efficiency Change. b TC: Technological Change. cMPI: Malmquist Productivity Index.

The efficiency change of hard coal use in electricity production of Turkey started to decline in 2010–2011 and became 0.877 in 2011–2012. While the share of hard coal in electricity production was 1.4% between 2012 and 2015, the amount of electricity production increased with the increase of the installed capacity from 335 MW to 350 MW in 2015. However, after 2016, the decrease in the share of hard coal in electricity production resulted in a decrease in MPI.

Hard coal mining in Turkey, working with the royalty method in Zonguldak coal basin by THCE and THCE’s concession area is carried out by private sector firms. The complex geological structure of the Zonguldak deep hard coal-mine basin, prevents the use of full mecha-nization, and hard coal production is predominantly carried out by labor-intensive mining methods. In recent years, however, pilot exca-vation equipment has been applied in accordance with basin conditions and successful results have been obtained. Although the maximum value of 5 million tonnes of salable production in 1974 declined from time to time, the value of production achieved was not preserved in the basin, where a significant production uptrend was caught and unfortunately the amount of production decreased under 4 million tonnes after the year 1982. The royalty method, which normally took place in 1991, has been started to be operated by private companies since the year 2004, so that the reserves that can not be worked by THCE. Hard coal production

in Zonguldak basin for years 2009–2018 is given in Fig. 3 (THCE, 2017;

THCE, 2018a; THCE, 2018b).

Over the years, there has been a significant change in sales of THCE hard coal to iron - steel and energy sector. After 1982, the capacity rise in the iron and steel manufacturing premises and the inability to meet the coking coal demand by the THCE have led to heading towards to

imported coal resulting in a decrease in the sales of THCE (Fig. 4) (THCE,

2017).

With the Law no, 4628, which came into force in 2001, withdrawal of the state owned companies from the production investments and private sector oriented investments of power plants based on imported coal has reduced the usage of the hard coal in the energy sector. The Çatala�gzı Power Plant, which uses the locally produced hard coal in the Zonguldak Basin, also has imported coal license. Nevertheless, the use of domestic coal is declining every year, and it is considered to be more appropriate to evaluate the power plant in concern in imported coal

power plants in the coming years (TCE (Turkish Coal Enterprises),

2016).

The significant increase in demand for coal to be used for electricity generation has recently been the most important reason for the increase

in coal imports. Fig. 5 shows that the MPI value is 1.000 and above 1.000

during the years 2009–2018, indicating an increase in the rate of use of imported coal over time.

Asphaltite, a petroleum-based solid fuel, is estimated to have over 80 million tons of reserves in Turkey. The first unit of 135 MW of Sirnak Silopi Power Plant which is the first power plant in Turkey using as-phaltites as fuel was commissioned in 2009. By the end of 2015, three

units increased the installed capacity to 405 MW (EI (Energy Institute),

2018). The share of asphaltite in electric energy production has been

around 0.4% in 2009–2018 years. According to the results obtained from the analysis, there was a decrease in efficiency change in the years 2011, 2013 and 2017 due to the decline in the share of asphaltite in electricity generation. However, with the third unit, which started production in 2015, it was found that this ratio increased in an

impor-tant scale (Fig. 6). In 2010, 2014, 2016 and 2018, due to the increase in

the share of asphaltite in electricity generation compared to the previous year, MPI variation values are over 1.000.

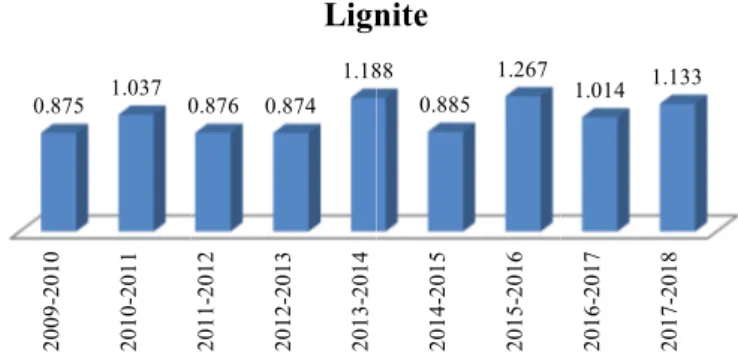

As it can be examined from Table 4, no significant changes were

found in lignite use between the years 2009–2018 (MPI ¼ 1.007). Although the reduction in technical efficiency value (0.965) was observed, MPI value remained at 1.000 levels due to the increase in Technological Change (1.043). The increase in technological change shows that the best production limit determined according to the input- output observations progresses over time. The decline in the value of technical efficiency implies that in the considered years the production of the source in question has declined in production quantities and production shares despite the existing installed capacities.

It can also be seen from Fig. 7 that the least MPI value (0.874) is

between 2012 and 2013. The cause of this decline has been determined to be a decrease in the share of lignite used in electricity generation when the given data are evaluated. Additionally, the highest MPI value (1.188) was found to be between 2013 and 2014. When these years’ data are analyzed, it is determined that the share of lignite in electricity

Fig. 1. MPI values of resources used in electricity generation.

Fig. 2. Variation of MPI for hard coal use in the production of electric energy.

0 400000 800000 1200000 1600000 2000000 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 Turkish Hard Coal Enterprises Private Sector

production is increased by 1.9% (TCME (Chamber of Mining Engineers

in Turkey), 2015). With the importance given to domestic resources in

recent years, the share of lignite in energy production has increased. As a result of this, it can be seen that MPI values are over 1.000 as of 2015 from Fig. 7.

After the 1999 earthquake, a contraction in total energy consump-tion (0.58%) were confronted with in Turkey. Yet the earthquake wounds were not recovered. Turkey had the greatest decline (6.33%) in its history during the global crisis experienced in 2001. Çanakkale 18 Mart Çan and Afs¸in-Elbistan B plants became operational in the years of 2004–2005, the share of lignite production in these years has been increased. The share of lignite in electricity generation declined from 20.1% in 2009 to 12% in 2015 due to the inability to make new in-vestments in this area in the following years. In 2018, this value increased to 15%.

4. Conclusions and policy implications

Energy demand of Turkey in 1980 is observed to increase rapidly due to especially population growth and increase in the industrialization. It is important lowering of high energy intensity compared to developed countries and making improvements in the energy efficiency field for

Turkey in terms of sustainable development. In this context, the Energy Efficiency Strategy Document (2012–2023), which came into force in 2012, sheds light on the works to be done in the field of energy effi-ciency. In this study, it was tried to investigate the efficiency variation of coal use as an energy source. It has been determined that the efficiency change values of coal used in the production of electric energy increased by 16.4%. It is also determined that the reason for this increase is the increase in the share of electricity production of imported coal and asphaltite. In addition, it is determined that the share of lignite in electricity production increased after 2015. Between 2009 and 2018, it was found that the imported coal had an increase of 38.6% in MPI value and 35.8% in MPI value of asphaltite. The MPI value of lignite was found to be 1.007 (ffi 1.000).

In recent years, a decrease of 3.1% in the MPI value of hard coal was detected due to the inability to make new investments to increase the share of hard coal use in electricity generation. It has been determined that there is no change in the MPI value of lignite.

Turkey’s economy can possibly grow fast and stable by evaluating local sources throughly for energy production. Coal in Turkey is the most reliable energy source with its abundance compared to other fuels produced from fossils, durable order of supply and price structure in meeting the rising energy demand with the developing economy of Turkey. Increasing the utilization of this source for domestic and in-dustrial purpose for electricity generation is also important in terms of contributing to economy as well as energy security. In addition, as it is in a significant part of the world, the implementation of technologies developed in coal mining in Turkey ensures that low production costs are important in the electricity market.

References

AEE (Association of Energy Efficiency), 2011. Turkey’s Energy and Energy Efficiency Study. AEE Iconomy Vezir Consultancy, _Istanbul, Turkey, pp. 33–35. July.

Aydagün, A., 2003. Data Envelopment Analysis. T.R. Air Force Academy Institute of Aeronautics and Astronautics Year - end Seminar (in Turkish).

Charnes, A., Cooper, W., Rhodes, E., 1978. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 2 (6), 429–444. https://doi.org/10.1016/0377-2217(78) 90138-8.

Coelli, T.J., 1996. A Guide to DEAP Version 2.1: A Data Envelopment Analysis (Computer) Program. Center for Efficiency and Productivity Analysis (CEPA)

Working Paper 96/08. University of New England.

Coelli, T.J., Rao, D.S.P., Battese, G.E., 1998. An Introduction to Efficiency and Productivity Analysis. Kluwer Academic Publishers, Boston, pp. 67–74.

EI (Energy Institute), 2018. Accessed January 21. http://www.enerjienstitusu.com/2013 /03/18/termik-santrallerin-yeni-gozdesi-asfaltit/.

F€are, R., Grosskopf, S., Norris, M., Zhang, Z., Productivity Growth, 1994. Technical progress and efficiency changes in industrialized countries. Am. Econ. Rev. 84, 66–83. https://www.jstor.org/stable/2117971.

Farrell, M.J., 1957. The measurement of productivity efficiency. J. R. Stat. Soc. 120, 253–290. https://doi.org/10.2307/2343100.

GDEA, 2019. General directorate of energy Affairs. Accessed February 7. www.eigm.gov. tr/tr-TR/Denge-Tablolari/Denge-Tablolari.

Grifell-Tatje, E., Lovell, C.A.K., 1995. A note on the malmquist productivity index. Econ. Lett. 47, 169–175. https://doi.org/10.1016/0165-1765(94)00497-.

Guo, P., Qi, X., Zhou, X., Li, W., 2018. Total-factor energy efficiency of coal consumption: an empirical analysis of China’s energy intensive industries. J. Clean. Prod. 172, 2618–2624. https://doi.org/10.1016/j.jclepro.2017.11.149.

Fig. 6. MPI variation of asphaltit used in the production of electric energy.

Fig. 7. MPI variation of lignite used in the production of electric energy. Fig. 4. Sectoral variation of hard coal sales (tonnes).

Fig. 5. MPI variation of imported coal used in the production of

Kasap, Y., 2008. Coal Mining Efficiency and Productivity Growth in Turkey: Data Envelopment Analysis. PhD Thesis. Eskisehir Osmangazi University (in Turkish with English Abstract), 159.

Kasap, Y., Duman, F., 2013. Use efficiency of primary energy resources in Turkey. Energy Explor. Exploit. 31 (6), 937–952. http://pdf/10.1260/0144-5987.31.6.937.

Kaya, D., Kilic, F.C., 2015. New markets for renewable industries: developing countries - Turkey, its potential and policies. J. Energy South. Afr. 26 (1), 25–35.

Lorcu, F., 2010. Malmquist total factor productivity index: Turkish automotive industry application. Istanbul University. J. Bus. Adm. Fac. 39 (2), 276–289 (in Turkish with English Abstract).

MENR_1 (Ministry of Energy and Natural Resources-Turkey), 2018. http://www.eigm. gov.tr/File/?path¼ROOT%2f4%2fDocuments%2fEnerji%20Politikas%C4%B1%2f1. 13%20Yerli%20Kaynaklara%20Dayal%C4%B1%20Enerji%20%C3%9Cretim%

20Program%C4%B1%20Eylem%20Plan%C4%B1.pdf. (Accessed October 2018).

MENR_2 (Ministry of Energy and Natural Resources-Turkey), 2018. http://www.enerji. gov.tr/File/?path¼ROOT%2f1%2fDocuments%2fMavi%20Kitap%2fMavi_kitap _2016.pdf. (Accessed 24 January 2018).

Muniz, M.A., 2002. Separating managerial inefficiency and external conditions in data envelopment analysis. Eur. J. Oper. Res. 143, 625–643. https://doi.org/10.1016/

S0377-2217(01)00344-7.

Olanrewajua, O.A., Munda, J.L., Jimoh, A.A., 2015. Assessing possible energy potential in a food and beverage industry: application of IDA-ANN-DEA approach. J. Energy South. Afr. 26 (1), 74–85. https://doi.org/10.17159/2413-3051/2015/v26i1a2223.

Pamir, N., 2005. Energy Policies and Global Developments. Strategic Analysis. December, pp 68-74. (in Turkish).

P�erez, K., Gonz�alez-Araya, M.C., Iriarte, A., 2017. Energy and GHG emission efficiency in the Chilean manufacturing industry: sectoral and regional analysis by DEA and malmquist indexes. Energy Econ. 66, 290–302. https://doi.org/10.1016/j. eneco.2017.05.022.

Tamzok, N., 2005. The choice of sources for electricity generation in the coal reserve-rich countries and Turkey’s position. In: Proc. Of Vth Energy Symposium, Chamber of Mining Eng. of Turkey, Ankara-Turkey, pp. 279–291 (in Turkish with English abstract).

Tarim, A., 2001. Data Envelopment Analysis: Mathematical Programming Based Relative Efficiency Measurement Approach. Court of Accounts Publication Directorate. Research/Analysis/Translation Series 15, Ankara (in Turkish).

TCE (Turkish Coal Enterprises), 2016. Coal (lignite) sector report-2015. In: 2016 Annual Report of Turkish Coal Enterprises, Ankara, Turkey, pp. 1–90.

TCE (Turkish Coal Enterprises), 2018. Coal (lignite) sector report-2017. In: 2018 Annual Report of Turkish Coal Enterprises, Ankara, Turkey, pp. 1–90.

TCEE (Chamber of Electrical Engineers in Turkey), 2019. Accessed. http://www.emo.

org.tr/genel/bizden_detay.php?kod¼88369. (Accessed 7 February 2019).

TCME (Chamber of Mining Engineers in Turkey), 2015. Energy and Coal Report, pp. 1–128. Ankara, Turkey.

TETC (Turkish Electiricity Transmission Corporation), 2018. http://www.teias.gov.tr/t r/iv-turkiye-termik-santrallarinda-kullanilan-yakit-miktarlari-isil-degerleri-ve-koj enerasyon. (Accessed 22 January 2018).

TETC (Turkish Electiricity Transmission Corporation), 2019. www.teias.gov.tr/tr/turk iye-elektrik-uretim-iletim-istatistikleri. (Accessed 7 February 2019).

THCE (Turkish Hard Coal Enterprises), 2017. Hard coal sector report – 2016. In: 2017 Annual Report of Turkish Hard Coal Enterprises, Zonguldak, Turkey, pp. 1–50.

THCE (Turkish Hard Coal Enterprises), 2018. Hard coal sector report – 2017. In: 2018 Annual Report of Turkish Hard Coal Enterprises, Zonguldak, Turkey.

THCE (Turkish Hard Coal Enterprises), 2018. 2018 Monthly Statistic Report (Zonguldak, Turkey).

TSI (Turkish Statistical Institute), 2019. http://tuik.gov.tr/UstMenu.do?metod¼temelist. (Accessed 7 February 2019).