OF Ä

'ГіШІЕСТ; OSIMQ LIMEÄiаді ï л f· ·2ΐ ЯНйчіг’Ьаі 'ía :Aтш

А THS'Sr! Íí'.^^e.· ' W W . 'ü i J d - - ·■'. . .»=■ t;, -r ^ .;!;.···«|·ί . "Л·,· «!»«». “И·... i VJ .'s^ i :% s : ¡aá Γώ. r: · T ‘it/ít !}'K. /f jW ·’· ,f ■· C ' t-vr'“ ,·*·'“·-'■■- і·’***^· В Y ' «ΐ· · ^ ttau Η», л* Μ ; . >*, Ä'.’M» я Í"í fc tAPPLICATION OF THE CRITICAL PATH METHOD TO THE PLANNING OF A TECHNOLOGY TRANSFER PROJECT USING LINEAR

PROGRAMMING

A THESIS

SUBMITTED TO THE DEPARTMENT OF MANAGEMENT

AND THE GRADUATE SCHOOL OF BUSINESS ADMINISTRATION OF BILKENT UNIVERSITY

IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF MASTER OF BUSINESS ADMINISTRATION

By

ELlF EMlRLl MAY, 1993

ı s

I certify that I have read this thesis and in my opinion it is fully adequate, in scope and in quality, as a thesis for the degree of Master of Business Administration.

Assoc. Prof. Erdal Erel

I certify that I have read this thesis and in my opinion it is fully adequate, in scope and in quality, as a thesis for the degree of Master of Business

Administration. _^ _

J

Assi^.Prof.Gillnur §engül

I certify that I have read this thesis and in my opinion it is fully adequate, in scope and in quality, as a thesis for the degree of Master of Business Administration

Approved for the

Administration

Prof. Sübidey Togan

Graduate School of Business

< w u

ABSTRACT

APPLICATION OF THE CRITICAL PATH METHOD TO THE PLANNING OF A TECHNOLOGY TRANSFER PROJECT USING LINEAR

PROGRAMMING

ELlF EMlRLl

Master of Business Administration Supervisor: Assoc. Prof. ERDAL EREL

May 1993, 132 pages

The main purpose of this thesis is to utilize

the critical path method in the planning of a

technology transfer project by using linear

programming. LINDO software is practiced in

establishing the linear programming formulation and a matrix generator is written in C language to input the

formulation into LINDO format. In this way, the

schedule of the project is created, the completion time of the project is calculated and the activities forming the critical path are determined. Also by applying a

parametric analysis to the right-hand sides of the

constraints (activity durations) for the noncitical

activities, the times when the critical activities

became critical are determined.

ÖZET

BÎR TEKNOLOJİ TRANSFERİ PROJESİNİN PLANLANMASINDA DOĞRUSAL PROGRAMLAMA KULLANILARAK KRİTİK YOL METODUNUN

UYGULANMASI

ELİF EMİRLİ

Yüksek Lisans Tezi, İşletme Enstitüsü Tez Yöneticisi: Assoc. Prof. Erdal Erel

Mayıs 1993, 132 sayfa

Bu çalışmanın amacı, bir teknoloji transferi

projesinin planlanmasında doğrusal programlama

kullanılarak kritik yol metodunun uygulanmasıdır.

Doğrusal programlama formülasyonunun oluşturulmasında

LINDO yazılımı kullanılmış ve formülasyonu LINDO

formatına çevirmek için de C dilinde bir program yazılmıştır. Bu şekilde, projenin aktivite zamanları, proje bitiş zamanı hesaplandı ve kritik yolu oluşturan

aktiviteler belirlenmiştir. Ayrıca kritik olmayan

aktivitelerin zamanlarına parametrik analiz yapılarak bunların kritik yola girme zamanları elde edilmiştir.

Anahtar Kelimeler: Kritik Yol Metodu, Proje Planlama ve

Aktivite Zamanlarını Belirleme, Teknoloji Transferi,

I would like to thank to Assoc. Prof. Erdal Erel for his guidance, suggestions and encouragement

for the preparation of this thesis. I am also thankful

to Assist. Prof. Dilek Önkal and Assist. Prof. Giilnur

Şengül for their helpful suggestions during the

completion of the thesis.

My thanks are also due to Mrs. Özge Savaş, Mr. Ergun Bora and my colleagues in ASELSAN for their supports and understanding throughout the thesis. I am indebted to ASELSAN Military Electronics Inc. for the facilities provided.

I would also like to express my deepest

gratitude to my family; Doğan, Nevin and Mustafa Emirli for their continuous supports not only during the thesis but also throughout my education in Bilkent University.

TABLE OF CONTENTS PAGE ABSTRACT...ii Ö Z E T ... iv ACKNOWLEDGEMENTS... v TABLE OF CONTENTS... vi

LIST OF FIGURES ...ix

CHAPTER 1 : INTRODUCTION... 1

1.1. Scope of the Study... 1

1.2. An Overview of the Technology Transfer Concept... 2

1.2.2.Types of Technology Transfer Channels... 3

1.2.2.1. Trademark Transfer... 4

1.2.2.2. Patent/Patent License Transfer... 4

1.2.2.3. Technical Information (know-how) Transfer .. 5

1.3. An Overview of the Project... 8

1.3.1. License and Know-how Transfer Activities... 9

1.3.2. Hardware Supply Activities... 10

1.3.3. UTTE Supply Activities... 14

1.3.4.Sales Contract Activities with the Customer .... 14

1.3.5.Activities inside the company... 15

1.4. Purpose of the Thesis... 15

2.1 .Historical Background... 18

2.2.Overview of Project Management... 20

CHAPTER 3 : LITERATURE SURVEY...25

3.1. Project Scheduling Techniques... 25

3.2. Bar Charts... 25

3.3 .Logic-Diagram-Based Schedules... 26

3.3.1. Advantages/Drawbacks of CPM over Bar Charts .... 28

CHAPTER 4 : NETWORK MODELS IN SCHEDULING... 30

4.1. Critical Path Identification...30

4.2. Basic Definitions... 31

4.3. CPM Scheduling... 33

4.3.1 .Activity Relationship Methods... 33

4.3.1.1 .AOA M e t h o d ... 33

4.3.1.2 .AON M e t h o d ... 37

4.3.1.3.The Precedence M e t h o d ...38

4.4. Finding a Critical P a t h ... 39

4.4.1. Critical Path Identification with L P ... 39

4.4.2. Applying Linear Programming to the Schedule .... 41

4.4.3. Matrix Generators...43

4.5. Parametric Analysis... 44

4.5.1.Types of Parametric A nalysis... 45

CHAPTER 5 : APPLICATION OF CPM TO THE TECHNOLOGY TRANSFER PROJECT...4 6 5.1.Identifying Activities/Estimating Their Duration ... 46

5.2 . Preparing the Schedule... 48

5.3. Identifying the Critical Path Activities... ..50

5.4. Applying Parametric Analysis to the Activities... 51

5.5. Discussion and Evaluation of the Implementation .... 53

CHAPTER 6 : CONCLUSION AND RECOMMENDATIONS... 55

6.1. Conclusion...55

6.2.Suggestions for Further Research... 63

LIST OF REFERENCES...66

APPENDICES A. LINDO COMPUTER PACKAGE...68

B. MATRIX GENERATOR PROGRAM FOR LINDO FORMULATION... 73

C. ACTIVITY L I S T ... 75

D. LINDO FORMULATION... 105

E. PARAMETRIC ANALYSIS RESULTS OF THE NONCRITICAL PATH ACTIVITIES...119

LIST OF FIGURES

PAGE

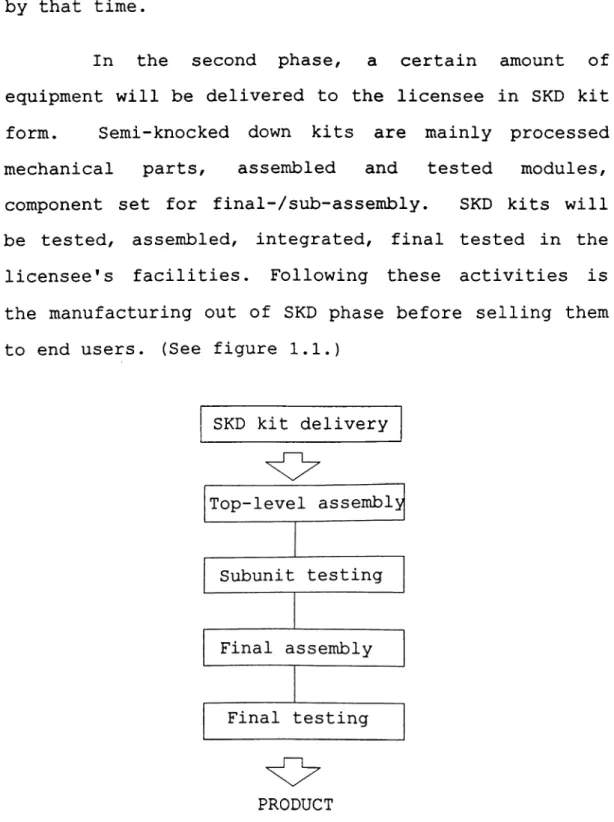

Figure 1.1. Flow chart of SKD phase production... 11

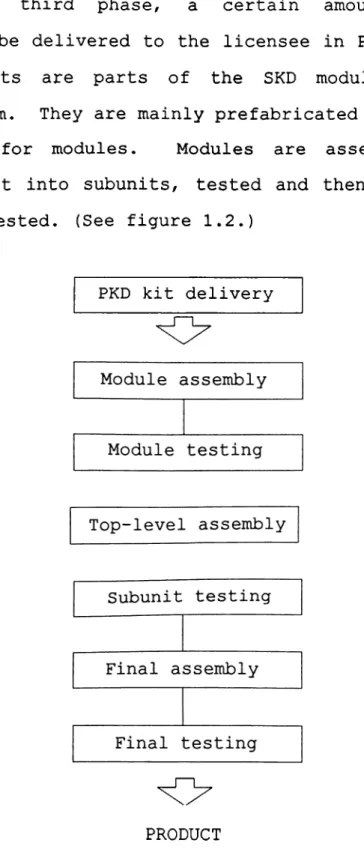

Figure 1.2. Flow chart of PKD phase production... 12

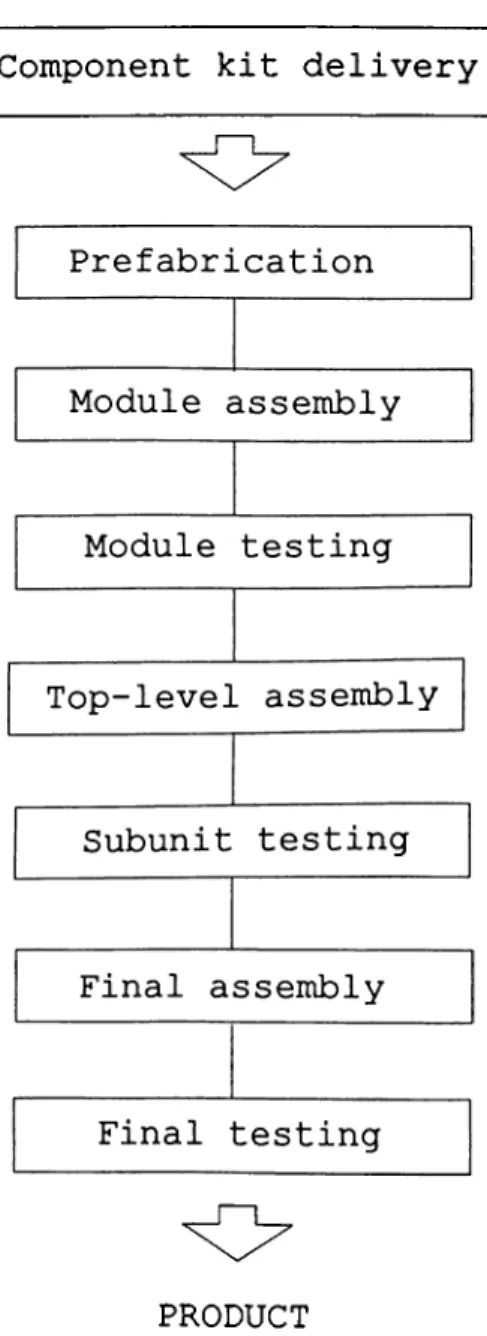

Figure 1.3. Flow Chart of Production from Component... 13

Figure 4.1. Single activity in AOA format...34

Figure 4.2. Activities with a Dummy Constraint... 35

Figure 4.3. Violation of Rule 5 ...36

Figure 4.4. Use of Dummy Activity... 37

Figure 4.5. AON format...37

CHAPTER I

INTRODUCTION

1.1.Scope of the Study

"Project management is not only a science but

also an art. It is a science because it makes use of

scientific techniques that have been proven to enhance

management processes. It is an art because it relies

on the judgment, expertise and personal intuition of the project management people." (Whitehouse,1973,1989)

Leaving the art side of the project management aside, the emphasis is on science part of it in this thesis.

Most of the scientific techniques available to project management people are handled with the help of

computer hardware and software. Although project

management makes use of computers in many areas such as

project planning and organization, project

coordination, project control, budget analysis and

project communications; activity scheduling and

resource allocation are the areas where computers are utilized most.

And the scope of this study is limited to project scheduling with critical path method (CPM) by

making use of linear programming software LINDO. The

discussions are also applied to a technology transfer project as an illustration.

1.2.An Overview of the Technology Transfer Concept

The fast development of global

industrialization has brought a new approach to the

concept of ownership in law in the last centuries and consequently besides tangible rights, intangible rights

also emerged. Technological knowledge, which is gained

either as a result of experience or as a result of systematic research, had become something that is sold

in return of money. It has long been a very common

behavior to buy the results that some other company developed by paying a suitable fee which is called

transfer of technology. The transfer of technical

information related with the design, engineering,

manufacturing, and production techniques for hardware systems using recorded and/or documented information of a scientific or technical nature is called technology

transfer. (the Defense Systems Management College

Publications,1987)

With the rapid widening of the technological gap between the developed and developing countries, the

transfer of technology has become a matter of decisive

importance. This importance is not restricted to the

developing countries alone, but to the developed ones

as well, since no industrial, trade or cultural

relations can be built up and maintained between the two, without bridging, or at any rate reducing this

gap. (Bhattasali,1972) Hence, although technology

transfers may be among companies from different

countries or among companies from the same country, the most common type is the one which includes different

countries. In other words, transfer of technology is

an integral part of national development.

Technology transfer is indeed an extremely

broad subject and it is perceived as an increasingly important ingredient in the development of industrial

resources and wealth. Technology transfer enables

companies to make better use of their scarce resources of research and development for donor companies in that it provides additional income to be derived from R & D. On the other hand, it represents a source of new and improved products in an increasingly competitive world for the recipient companies.

1.2.2.Types of Technology Transfer Channels

Although technology transfers vary in their

transfer, patent/patent license transfer and technical information (know-how) license transfer for them.

1.2.2.1.Trademark Transfer

Trademark is a sign which is put onto a product or to its package in order to distinguish it from the

similar products. Trademarks are registered by the

government to hinder unfair competition by

counterfeiting. (Milli Prodüktivite Merkezi, 1975) Any

other company can obtain the rights to use the

registered trademark of a company by paying a suitable fee to the owner of the trademark.

Contracts are made between the companies for

the transfer of trademarks. These contracts should

also be approved by the government office which

registered the trademark. In these contracts there

exists issues such as the term of the agreement, the products for which the trademark can be used and whether the trademark is transferable or not.

1.2.2.2.Patent/Patent License Transfer

Patent is a grant of specific monopoly rights given by a government to an inventor for his invention that is valid for a certain period of time and only within the territorial limits of the country in which

it is granted, (the Defense Systems Management College

Publications,1987) These rights can be transferred in

return of a fee which is called patent transfer. If

only the rights to use the patent but not the rights to transfer, are transferred then this is called patent

license transfer. (Milli Prodüktivite Merkezi

Yayınları, 1975)

In patent/patent license transfer contracts , there exists topics such as what portion of the patent is transferred, if the licensee is given the right to transfer and whether the developments, if any, will also be transferred to the licensee.

The monopoly granted to the patentee rules the others out from using the particular invention in the sense that it provides redress by giving the right to bring suit but it cannot prevent the direct violations.

1.2.2.3.Technical Information (know-how)

Transfer

Know-how is an American term which is receiving growing acceptance in international contracts. It is a

generic term and it includes trade secrets,

manufacturing procedures and techniques,

specifications, charts, formulae, drawings and graphs, marketing techniques and professional advice and the

like except patents and trademarks. Actually know-how can be anything which is not readily known or available to the public.

The Restatement of Torts defines know-how as

"any formula, device or compilation of information

which is used in one's business and which gives an opportunity to gain an advantage over competitors who do not know or use it." (the Defense Systems Management College Publications, 1987)

Therefore, know-how can be similar to a patent in the sense that it grants some kind of monopoly by preventing those who do not posses it from using it. But it is also differentiated from patents in the

following issues (the Defense Systems Management

College Publications, 1987) :

. The monopoly is de facto as opposed to de jure.

. The monopoly is maintained indefinitely unless the know-how is made public.

. What is essential to the value of know how is some extent of secrecy.

There is a current trend of switching from

patent system to know-how rights to protect the

recent years. Furthermore, know-how is generally

necessary to utilize the patents licensed in an

agreement. As a result of this, another common behavior in this area has been to contain only know-how without patents in the licensing agreements.

The companies that are successful in

transferring technologies to other companies have a

common belief in general. This belief is that the

beginning of a successful local production is not at the time of contract signature between two parties, but it is as early as the time the design goals for a new product or system to be transferred later are being

defined. One design goal of such a product is that it

must be producible in foreign countries autonomously,

free of bottlenecks and hindrances. In order to do

this, the product should be designed taking the

availability of components in the world market into

consideration. Furthermore, the local manufacturing

philosophy should be structured in a modular way to enable the company receiving the technology to increase the local manufacturing content step by step thus

achieving the implementation of the full know-how

transfer to a 100% autonomy in subsequent modules, parts and components at the earliest time possible.

1.3.An Overview of the Project

The Project is mainly a license and know-how transfer of a defense product from a European company and subsequent manufacturing of it in the licensee's facilities and then selling it to a customer in Turkey. The licensee company is a Turkish company and the

project duration is 7 years. The overall project

involves 3 agreements and a contract, namely License

and Know-how Transfer Agreement, Hardware Supply

Agreement, Unique to Type Test Equipment (UTTE)

Agreement and Sales Contract. While the three

agreements are between the licenser which is a

multinational company and the licensee ; the contract

is between the end customer and the licensee.

In this program, the licenser is selected by the customer from a number of foreign companies which are manufacturing the product the customer desires to buy. The licenser possesses some specific proprietary rights, manufacturing rights and certain engineering and production know-how essential to or helpful in the manufacturing the product. Following the selection of the licenser, the customer has opened a domestic tender for the local production and delivery of the product. It obligated the bidders for the tender to locally

product and provide the necessary support.

A contract is signed between the customer and the winner of the domestic tender. The licensee has

been nominated by the customer for the local

manufacturing of the product and had obtained the

rights to use, to manufacture, to sell and to provide maintenance for the product and subassemblies of the product in accordance with the License and Know-how Transfer Agreement.

Although the validity of the agreements in consideration lasts 7 years, only the activities of the first 3 years will be studied in this thesis due to the

data available at hand. Besides, activities after the

third year will be a repetition of the first 3-year activities.

Since the project is in the defense industry, confidentiality agreements are made between the two parties to protect the proprietary rights. And because of these agreements, the name of the licenser and the licensee, the name of the product any other information about it will not be disclosed within the thesis.

1.3.1.License and Know-how Transfer Activities

These are the activities of the License and Know-how Transfer Agreement signed between the licensee

and the licenser company. They mainly consist of training courses at different phases of the project, technical assistance programs and delivery of technical

and manufacturing data package activities. This

technology transfer is planned be completed by the end of 1997. In order for the licensee to be able to manufacture the product in its own facilities, the timing of the activities in the technology transfer must be closely monitored. Namely, the success of the project depends on the timely and successful progress of technology transfer activities.

1.3.2.Hardware Supply Activities

These are activities of the Hardware Supply Agreement signed between the licensee and the licenser

company. While the license and know-how transfer

continues between the two parties, the procurement of necessary kits and components from the licenser also continues according to the provisions of the Supply Agreement.

In general, they consist of procurement

programs of ready made units (RMU), semi-knocked down

kits (SKD) , partly knocked down kits (PKD) and

components. In the early phases of the program, a

number of RMUs will be procured from the licenser and will be sold to the customer without giving any

additional value to them since necessary technology will not be present in the facilities of the licensee by that time.

In the second phase, a certain amount of

equipment will be delivered to the licensee in SKD kit

form. Semi-knocked down kits are mainly processed

mechanical parts, assembled and tested modules,

component set for final-/sub-assembly. SKD kits will

be tested, assembled, integrated, final tested in the licensee's facilities. Following these activities is the manufacturing out of SKD phase before selling them to end users. (See figure 1.1.)

SKD kit delivery

O

O

PRODUCT

In the third phase, a certain amount of equipment will be delivered to the licensee in PKD kit

form. PKD kits are parts of the SKD modules in

unassembled form. They are mainly prefabricated parts,

component set for modules. Modules are assembled,

tested and built into subunits, tested and then final assembled and tested. (See figure 1.2.)

PKD kit delivery

O

PRODUCT

In the last phase of the supply program, some must-buy items will be procured from the licenser and other material will be procured from other vendors.

Items delivered in this phase are mainly raw material for prefabricated parts and modules and some component kits.

Component kit delivery

O

PRODUCT

Component kits delivered in this phase are

prefabricated and built into modules. Then the same

operations as in PKD phase are performed from this stage onwards. (See figure 1.3)

When the term of the agreements expired, the complete purchasing of materials will be done by the

licensee. The received material from the suppliers

will be tested in the incoming inspection department of

the licensee. But the scope of this thesis covers only

the activities during the first 3 years of the

agreement. However, the success of this independent local production phase depends on the timely and

successful transfer of technology satisfying the

requirements of the original product.

1.3.3.UTTE Supply Activities

These are the activities of the Unique to Type

Test Equipment Agreement. They mainly consist of the

procurement of the special equipment which are not components of the product but are specially used in the manufacturing and testing of the product.

1.3.4.Sales Contract Activities with the

Customer

between the licensee and the customer. They mainly consist of the deliveries of the product in batches

beginning in 1992, ending in 1994, and operator

training, field level maintenance training and depot level maintenance training programs that will be given to the customer.

1.3.5.Activities inside the company

These are the insider activities that will be performed by the licensee in addition to the other agreement and contract activities. They mainly consist of the procurement of standard equipment, procurement from the other vendors, building SKD production set-up,

building PKD production set-up, building local

production set-up, building UTTE production set-up and local production phase.

1.4.Purpose of the Thesis

Technology transfer projects, like other

projects, consists of a number of activities. But the

feature that differentiates technology transfer

projects from others is the existence of strict

deadlines to be satisfied. Therefore, they necessitate

close monitoring. For example, in order to complete

the technology transfer project subject to this thesis and to perform the subsequent local manufacturing phase

on time and with success, bottlenecks and potential problem areas should be identified before they occur.

For this concern CPM is one of the useful and

economical methods in scheduling. The purpose of this

thesis is to show how CPM using linear programming can be applied to the scheduling of a technology transfer project.

1.5.Outline of the Thesis

In this chapter, first of all, technology

transfer concept is explained and then some brief information is given about the particular technology

transfer project. Following this chapter, project

management concept is explained including its

functions. One of these functions which is project

scheduling is the subject of the third chapter giving

the literature survey on the different scheduling

methods such as bar charts, PERT and CPM in a

comparative way. In the fourth chapter, network models

in scheduling is explained with emphasis on Activity on

Arc (AOA) method which is the one used in CPM. These

led the discussion in chapter four to finding a

critical path by making use of linear programming. In

the fifth chapter, the methodology used in the

particular application is explained. The critical path

on the schedule is conducted in this chapter. Conclusion and recommendations are given in the sixth chapter.

CHAPTER 2

PROJECT MANAGEMENT

2.1.Historical Background

Although project management has been used in industrial capital projects for more than 50 years, it

gained widespread usage in many areas such as

construction, banking, manufacturing, marketing,

healthcare, sales, transportation, and research and

development as well as academic, legal, political and government establishments in the recent 10 years of time due to the successful results obtained in the capital projects field.

Project management applications were initially

concentrated on defense-related and construction

projects and many of the important developments in project management area occurred during and immediately after the World War II. One of the first publicized successes of the project management was the famous Manhattan project. It started early in the 1940s to develop the atom bomb under the direction of General Leslie Groves who is qualified as the first project

manager. (Ritz, 1990)

Following World War II, substantial

improvements on the capital projects side are realized both in size and monetary value. This was nothing but a result of the post-war economical boom which is seen all over the world. As a result of the trials to

reconstruct Europe and to meet restrained demand

because of wartime restrictions, capital project

investment spending is increased substantially.

Consequently, project management studies accelerated in order to meet the huge demand for new plants.

The 60s was the period which had taken the most of capital project increases of the post-war era especially with the construction of office buildings,

airports, power plants, chemical plants, holiday

centers and the like. Whereas in the 70s, the

economical expansion continued with runaway inflation

added to the trend. Also there was a growth in overseas projects of US. (Project Management Institute, 1981)

This era of super- and mega projects faded with the recession of 1981-82 and industrial plant usage declined to 70% from 85%. Nevertheless, the most important advantage gained from this era was that the top management people accepted the need for project management. (Cleland, 1983)

In the 80s, market expansion is observed in

high-tech field which includes electronics, foreign

autos, foods, biotechnology and the like. Accordingly, the size of capital markets lessened and the subject of

them became much more specialized. Hence they

necessitated more detailed project scheduling methods and expertised manpower.

The historical background of project managers indicates that the subject of project management is

subject to sudden changes. Thus it requires a

continuous awareness toward change and sufficient

flexibility in order to adapt to the environment on time.

2.2.Overview of Project Management

Project management is the process of managing, allocating, and timing resources in order to achieve a given objective in a expedient manner. The objective may be in terms of time, monetary or technical results. The term project involves several functions within itself such as project planning, project scheduling, resource management and project control.

Project planning is the first step in a

systematical project management study. It involves the

of a baseline plan. (Kerzner, 1984) During the preparation phase, this baseline plan is subject to many changes until it satisfies the overall objectives of the project. Project planning is performed in three organizational levels consecutively which are strategic planning, operational planning and planning by the line

and stuff personnel. (Cleland, 1983) Strategic

planning involves the high level selection of the project objectives by the top management or whoever the

strategic planners in the company. Operational

planning involves the detailed planning required to

meet the strategic objectives. Finally planning by the

line and stuff personnel puts the operational plan on a time scale by the strategic objectives enabling the execution of the project.

Project scheduling is the establishment of a

timetable to do work. It puts all the work activities

onto a timeline beginning at the project start date and

ending at the completion date. (Ritz, 1990; Levine,

1986) In order to achieve this objective, the schedule

should contain not only the list and duration of tasks but also the dependency relationship among tasks.

Experienced project management people favors

the top down approach in scheduling. In top down

approach first of all the list of major activities in

are broken down into sub macro activities and finally these sub macro activities are split into individual tasks forming the overall project.

Top down approach in scheduling is very

advantageous especially when there is a substantial amount of activities in the project because it helps people manage the overall project in a modular way

without getting lost in the sea of tasks. Furthermore,

it prevents people from missing some details while trying to cope with the whole bunch of activities at the same time.

After the project schedule is created, the

sequence of tasks in the project is established taking the planned duration of tasks and their dependency

relationships into consideration. Before doing this,

it is quite helpful to determine the immediate

predecessors and successors of the individual tasks.

Following the determination of the immediate

predecessor and successor relationships, all these are

connected in order to form the overall project

schedule.

Upon establishing the project schedule, some

milestones are defined on the schedule. Milestones are

zero duration tasks showing the beginning or end of

indicators of the achievements in the project and help the project management people evaluate the progress or

delay of the overall project. (DOD and NASA Guide,

1972)

Resources are the people and equipment needed

to get the tasks of the project done. And resource

management is the process of assigning and allocating resources to the individual tasks so as to meet the functional requirements of the project objectives.

(Badiru, 1989) While doing this, not only currently available resources but also the resources to be

procured must be identified. After that, the time-

based availability of resources should be specified so that resources could be allocated in a timely manner with no overloads or deficiencies.

Resource management plays a very important role especially in resource-driven projects and should be

closely monitored because in such projects the

structure and hence the performance of the project is

determined by the resources. (Fleming, 1987; Badiru,

1989)

Ensuing the schedule establishment and resource allocation, the costs of the tasks and resources in the

project is determined. Unexpected costs, in case of

consideration while making the budget of the project.

After all these phases are completed, the

project plan is reviewed. After this review, the ideas

and approvals of the related personnel is taken. Final

stage in project management involves the project

control activities.

This chapter has given a summary of project management and its functions in order to reveal where this particular study stands in the overall project

management subject. Narrowing down the topic, a

literature survey on project scheduling techniques is

CHAPTER 3

LITERATURE SURVEY

3.1. Project Scheduling Techniques

Two basic project scheduling techniques are bar

charts and logic-diagram-based schedules. Both methods

have their own advantages and disadvantages.

Therefore, selecting which technique to use is a very important decision since it also affects the success of the controlling phase of the project.

3.2. Bar Charts

Bar charts first came into use on capital

projects in the early twenties. The forerunner to the

bar chart was developed by an industrial engineer, Henry L. Gannt for scheduling production/operations

during World War II. Therefore, bar chart are the

oldest and the simplest of the scheduling techniques.

One of the advantages of the bar charts is their being cheap and simple to prepare, easy to read

and update. People with a little schedule training can

disadvantage is their inability to show enough detail to cover all the activities and their interaction on

larger, complex projects. That is the reason why they

become unmanageable on projects with as few as 100 activities. (Ritz, 1990)

Furthermore, bar charts cannot show clearly the interaction between early start and late finish dates of activities and the resulting float of non critical

activities. Hence, there is no clear identification of

the critical path through the project.

3.3.Logic-Diagram-Based Schedules

Although bar charts are simple and effective progress reporting tools, they are weak in planning. This, along with the fact that the size and complexity of the projects grew in the late fifties and sixties

obliged project management people add logical

relationships to Gannt charts. DuPont Company together

with Remington Rand (Univac) developed CPM (Critical Path Method) in 1957-1958 for planning and scheduling of plant maintenance and construction programs where the dominant emphasis was on controlling cost and

having schedule flexible. (Ritz, 1990/ Project

Mangement Institute, 1981)

of PERT (Program Evaluation and Review Technique) was invented by the Special Projects Office of the US. Navy in 1957-1958, and developed by Booz, Allen and Hamilton in conjunction with Lockheed Missiles Systems Division

on the Polaris Fleet Ballistic Missile Program.

(Project Mangement Institute, 1981) The dominant

emphasis in this program was on meeting closely

determined schedules for internationally strategic

reasons and taking a rather flexible view of cost control.

Today, the distinction between PERT and CPM had been disappeared and the two became nearly identical methods with slight variations in network format and

activity duration estimation. In the PERT, the

duration of an activity is calculated by assessing an optimistic and a pessimistic time and then calculating

the average of the two. (Moder,1983) Whereas in CPM,

there is only one value for each activity duration and it is the most likely time for the activity duration. Therefore, estimating the activity duration is a very important part in CPM scheduling since it directly

affects the critical path and the slack times. This

indicates the importance of getting the most

sophisticated estimates from the most experienced

specialists. Activity duration estimates should

this would skew the schedule too far one way or to the other.

3.3.1 .Advantages/Drawbacks of CPM over Bar

Charts

CPM is capable of handling many work activities

on complex projects. However, one should not use more

activities than necessary just because it is easy to do

so. In such a situation, the scheduler might get lost

in the details and use the activities in a less

efficient way. (Busch, 1991) Actually, this was the

trap that almost killed CPM in its early years. One

way to get rid of this may be to use bar-charts for less complicated areas in the schedule.

Another advantage of CPM is that it establishes an intangible force on the project team to divide the project into all its working parts and form an early analysis of the individual work activities as early as possible. (Moder,1983)

Disadvantages of CPM are a few in number and

can be avoided if proper attention is paid to. One of

these disadvantages is the necessity of the project people be trained in CPM techniques which is something

costly. All the people in the project team should

training includes all project management team including people from various functional departments.

On top of this, CPM generates more data than

bar charting. That means unit cost of the data in CPM

is low. However, if the data are not used or are being

improperly used, then the unit cost of the data is not low any more and the. project team is not getting the

worth from the particular investment on CPM.

(Ritz,1990)

This chapter has given a comparative literature

survey on the project scheduling techniques. Next

chapter further narrows down the topic to give activity

relationships in scheduling. It also introduces how LP

can be relevant in a project scheduling study in finding the critical path and performing parametric analysis.

CHAPTER 4

NETWORK MODELS IN SCHEDULING

4.1.Critical Path Identification

Identifying the critical path of a project is actually nothing but an optimization problem because the aim here is to minimize the time project takes to

finish. Most of the optimization problems can best be

analyzed by making use of a network representation. Among these network models are shortest route problems, maximum flow problems, minimum spanning tree problems, CPM-PERT project scheduling models.

If the duration of each activity is known with certainty, CPM can be used to determine the length of

time required to complete a project. CPM can also be

used to determine how long each activity in the project can be delayed without delaying the completion of the

project. If the duration of the activities is not

known with certainty, PERT can be used to estimate the probability that the project will be completed by a given deadline. (Winston,1991)

critical path in a project, CPM-PERT project scheduling

methods can be used. Furthermore, as the duration of

the activities in this particular project can be estimated quite certainly, CPM is chosen as the more appropriate method to utilize in scheduling the project activities.

Before discussing the CPM project scheduling, some basic terms used in describing network models will be explained.

4.2.Basic Definitions

Activity : A project operation or process that

requires resources and consumes some amount of time to complete.

Critical Path ; The sequence of activities

which determines the total completion time for the project.

Dummy Activity : A logical link or a constraint

representing no specific operation. It is an activity

which absorbs neither time nor resources.

Duration : The estimated or actual time

required to complete an activity.

Event : The completion of an activity, or a

Finish-to-start (F-S) : The condition that the start of an activity depends on the finish of its predecessors.

Finish-to-finish (F-F) : The condition that the finish of an activity depends on the finish of its predecessors.

Float : A time available for an activity or

path in addition to its duration. It is the difference

between the time necessary and the time available for an activity.

Network : The set of all project activities

graphically interrelated through the precedence

relationships.

Path : A series of connected activities between

two events.

Predecessor : A set of activities that must be completed before an activity begins.

Successor : A set of activities which can only

begin after an activity ends.

Start-to-start (S-S) : The condition that the start of an activity depends on the start of its predecessors.

4.3.CPM Scheduling

After identifying the list of activities that make up the project and their duration, it is time to

begin scheduling part of the baseline plan by

establishing activity relationships. Precedence

diagrams and precedence matrix are two of the methods

used to show these relationships. The activity

relationship method affects the schedule times to a

great extent. Hence, choosing which activity

relationship method to use in scheduling is an

important decision.

4.3.1. Activity Relationship Methods

There are three basic activity relationship methods which are AOA (activity on arc), AON (activity

on node) and the precedence method. CPM makes use of

AOA method in scheduling. Since the objective of this

thesis is to utilize CPM in project scheduling, AOA method will be discussed in more detail.

4.3.1.1. AOA Method

In the AOA, activities are represented by

directed arcs, and nodes are used to depict the

completion of a set of activities. In the arrow

event. The events are numbered sequentially and the activity is identified by the beginning and ending

event numbers. These numbers are designated as the i-j

number. (Lockyear,1984) With these definitions, a

single activity in AOA is as in figure 4.1.

O

Activity A DurationEvent(i ) Event(j)

Figure 4.1. Single activity in AOA format

Each activity has an elapsed time necessary to

accomplish the work involved. The estimated elapsed

time for the activity must consider the scope of the

activity and any historical data available from

previous similar activities. If there are no

historical data on the activity to estimate the

activity duration, then scheduling is done by using the estimates of the people experienced in performing the activity.

In the AOA format any activity may either precede, succeed, or be performed concurrently with any

other activity. A more complex situation depicted in

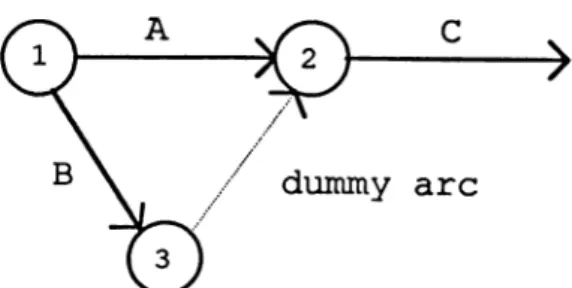

figure 4.2. specifies that A and B are prerequisites for activity D, but that only A is required to start

activity C. A dummy activity is drawn between event 3

constraints.

0

- ^0

- ^Figure 4.2. Activities with a Dummy Constraint

In figure 4.2. there are four real activities, indicated as 1-3, 2-4, 3-5, and 4-6, plus one dummy

activity, designated 3-4. A, B, C, and D are just

activity descriptions. Dummy activities are usually

indicated by a dotted line on the precedence diagram.

The following rules apply to the construction of a project network or precedence diagram in AOA format :

1. Node 1 represents the start of the project. An arc should lead from node 1 to represent each activity that has no predecessors.

2. A node representing the completion of the project should be included in the network.

3. Number the nodes in the network so that the node representing the completion of an activity has a larger number than the node representing the beginning

of an activity.

4. An activity should not be represented by more than one arc in the network.

5. Two nodes can be connected by at most one arc. (Winston, 1991)

Another use of dummy activities is to avoid the

violation of rules 4 and 5. For example, suppose that

activities A and B are both predecessors of activity C

and can begin at the same time. In the absence of rule

5, activity representation could be as in figure 4.3. However, since nodes 1 and 2 are connected by more than one arc, figure 4.3. violates rule 5.

Figure 4.3. Violation of Rule 5

By using a dummy activity as in figure 4.4., A and B both can be represented as the predecessors of C. Figure 4.4. guarantees that activity C cannot begin until both activities A and B are completed without violating rule 5.

Figure 4.4. Use of Dummy Activity

4.3.1.2.AON Method

In AON method the nodes of the network are used

to represent the activities. This method is widely

preferred in the recently developed project management programs prepared for microcomputers. (Levine, 1986)

Having activities represented in the nodes in AON format eliminates the need to use dummy activities

for unique relationships. Figure 4.5. illustrates the

same relationships that were shown in figure 4.2., but this time in AON format without any dummy activities.

4.3.1.3.The Precedence Method

The Precedence method is more complex than the

AOA and AON methods. Nevertheless, it permits a more

precise description of activity relationships in that it supports two additional types of relationships in

addition to the traditional finish-to-start (F-S)

relationships. These are start-to-start (S-S) and

finish-to-finish (F-F). (Bennett, 1977) Besides this,

the precedence method adds an element called ” lag ”, which is the time duration for the relationship itself.

(Moder, 1983) Lag is used either to indicate a delay

between the finish of one activity and the start of

another, or the delay between two starts or two

finishes.

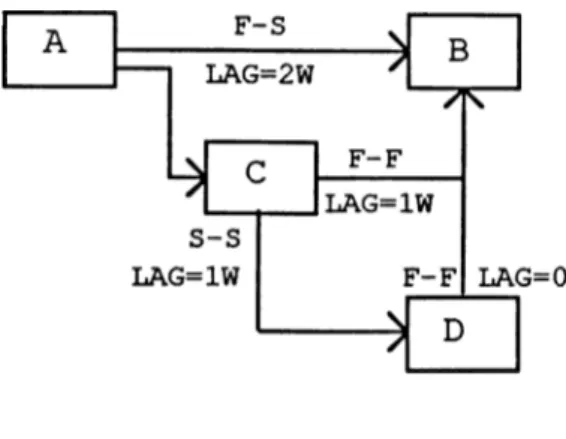

In the precedence diagram shown in figure 4.6., the start of task B is delayed for two weeks after task

A is completed. Task C can start after task A is

completed, but must be completed one week before task B

can be finished. Task D can start one week after task

Figure 4.6. PDM Format

4.4.Finding a Critical Path

Now that the list of activities making up the project is identified and AOA is chosen as the activity relationship method as a requirement of CPM, it is time to establish the project schedule, and find the critical path.

4.4.1.Critical Path Identification with LP

One of the ways of determining the length of the critical path in a project is by making use of

linear programming. Linear programming (LP) is a

mathematical decision-making procedure for determining

optimal allocation of resources. It has found

practical application in many areas of business.

In all LP problems the maximization or

there are also some restrictions or constraints that limit the degree to which the objective can be pursued. For most of the LP problems, there are two important

types of objects. The first type is limited resources

which can be time, money or labor and the second type

is set of activities. Each activity consumes some

amount or contributes additional amounts of resources. The problem in LP formulation is to determine the best combination of activity levels and which does not use more resources than actually available. (Schräge, 1991)

The problem to be solved is defined as the objective function, z in LP formulation and it can be either a minimization or a maximization situation as

explained above. The objective function is defined

using variables which are called decision variables.

These variables are all restricted to nonnegative

values. The activities consuming resources and the

scarcity of the resources are given as the constraints.

The solutions that satisfy all the constraints are referred to as feasible solutions and the best one among the feasible solutions is the optimal solution. The standard format of LP formulation is as follows :

Min (or Max) z = objective function subject to (s.t.)

constraint2 constraint^

all variables are nonnegative

LP applies only to situations in which the effects of the different activities which are engaged

in are linear. Linearity requirements are as follows :

1. Proportionality : Contribution of each

variable in the objective function or its usage of resources are directly proportional to the level of the activity.

2. Additivity : There should be no cross-

product terms in the formulation.

3. Certainty : All the parameters are known

constants.

4. Activity units can be divided into any fractional levels. (Schräge ,1991 ; Winston , 1991)

4.4.2.Applying Linear Programming to the

Schedule

While applying linear programming, first of

all, a variable called Xj is defined where Xj is the time that the event corresponding to node j occurs. For each activity (i,j), we know that before node j occurs, node i must occur and activity (i,j) must be

completed. This implies that for each arc (i,j) in the project network ,

Xj >= Xi + tij where t^j is the duration of

activity (i,j).

Above relationships are defined for each

activity and these constitute the constraints in the

linear programming model. Since the goal is to

minimize the time required to complete the project, the objective function in this linear programming model would be as follows :

z = X f - where X f is node that represents

the completion of the project.

Hence the complete linear programming model would be in the following form :

Min Z = X f - x^ st

Xj >= Xi + tij

for i=l to n, j=l to n & i not equal to j where n = number of events(nodes)

All variables integer

After including all of the project activity relationship constraints and the objective function into the linear programming model, it is time to solve

finding the critical path requires a large number of calculations for projects with hundreds of activities. Therefore, instead of manual calculation the model is run on a computer using a linear programming software.

In this thesis, LINDO is utilized as the linear

programming software package. (See Appendix A)

After the model is executed on a computer, the results of the model are used to determine the critical

path. Dual prices column of constraints is examined to

find the critical path. The critical path for a

project network consists of a path from the start of the project to the finish in which each arc in the path corresponds to a constraint with a dual price of -1. As explained in Appendix A, for each constraint with a

dual price of -1, increasing the duration of the

activity corresponding to that constraint by X days will increase the duration of the project by X days. Decreasing the activity duration will do the reverse effect as long as the activity remains critical.

4.4.3.Matrix Generators

Many linear programming models contain

thousands of decision variables. In such large LPs, it

is impractical to manually enter all the coefficients

and constraints of the LP. Instead of manual entering,

program called a matrix generator to simplify the

inputting of the LP. This program reads the problem

description in an arbitrary format from either a file

or from the terminal and then generates the

corresponding LP formulation depending on the given

information. There are two approaches in writing a

matrix generator program :

a. to use a general purpose programming

language such as FORTRAN, PASCAL or C.

b. to use a special purpose language designed

for generating LP formulations. These special purpose

languages are frequently available from vendors of LP optimization packages.

4.5.Parametric Analysis

After determining the critical path depending upon the solution of the LINDO formulation, performing parametric analysis may be quite helpful during the planning stage since it helps visualize the situation when assumptions upon which the model is based, is

changed. Parametric analysis or parametric programming

is the term applied to tracing out how the solution

changes as a specific coefficient (the parameter)

changes over a wide range.(Schräge, 1991) Most of the