Journal of Anatolian Environmental and Animal Sciences

(Anadolu Çevre ve Hayvancılık Bilimleri Dergisi)

Doi: https://doi.org/10.35229/jaes.655237

AÇEH

Yıl: 4, Sayı: 4, 2019 (674-678)

ARAŞTIRMA MAKALESİ RESEARCH PAPER

Gel Permeative Chromatography (GPC) Analysis of Polycaprolactone (PCL)

Based Biodegradable Composites through Laboratory Soil Test

Fatih MENGELOĞLU1 Engin Derya GEZER2 Kadir KARAKUŞ1

İlkay ATAR1* İbrahim Halil BAŞBOĞA3 Fatma BOZKURT1

1Kahramanmaraş Sutcu Imam University, Department of Forest Industry Engineering 46100 Kahramanmaraş, Turkey. 2Karadeniz Technical University, Department of Forest Industry Engineering 61080 Trabzon, Turkey.

3Kutahya Dumlupınar University, Simav Vocational School Simav-Kütahya, Turkey.

: https://orcid.org/0000-0002-2614-3662, : https://orcid.org/0000-0001-9657-7290, : https://orcid.org/0000-0001-7088-4364

: https://orcid.org/0000-0001-9527-1791, : https://orcid.org/0000-0002-3272-7269, : https://orcid.org/0000-0001-9323-6095

Received date: 05.12.2019 Accepted date: 23.12.2019

How to cite: Mengeloğlu, F., Gezer, E.D., Karakuş, K., Atar, İ., Başboğa, İ.H. & Bozkurt, F. (2019). Gel Permeative Chromatography (GPC) Analysis of

Polycaprolactone (PCL) Based Biodegradable Composites through Laboratory Soil Test. Anatolian Env. and Anim. Sciences, 4(4), 674-678.

Atıf yapmak için: Mengeloğlu, F., Gezer, E.D., Karakuş, K., Atar, İ., Başboğa, İ.H. & Bozkurt, F. (2019). Laboratuar Toprak Testi Uygulanmış

Polikaprolakton Esaslı Biyobozunur Kompozitlerin Jel Geçirgenlik Kromatografi Analizleri. Anadolu Çev. ve Hay. Dergisi, 4(4), 674-678.

Abstract: Biodegradability is an important asset for a polymer for their acceptance by the society due to the increased environmental

awareness of people over the years. In this study, Polycaprolactone (PCL) based biocomposites were produced using PCL, polyvinyl alcohol (PVA)/Starch mixture and polyethylene (PE) as a polymeric matrix and Turkish Red Pine Pruning waste flours (RPWF) a lignocellulosic filler. Biocomposites were manufactured through combination of extruder and injection molding processes. Forest soil was collected from arid regions of Konya and transferred to Laboratory. During 18 Months of soil test, degradation of PCL was monitored using Gel Permeative Chromatography (GPC). Results showed that major factor on GPC results were RPWF and degradation time. Especially at higher level of lignocellulosic filler use, there is a linear relation between filler and degradation time.

Keywords: Gel permeative chromatograph (GPC), polycaprolactone (PCL), polyvinyl alcohol (PVA), biodegradable, mechanical and physical

properties.

Laboratuar Toprak Testi Uygulanmış Polikaprolakton Esaslı Biyobozunur

Kompozitlerin Jel Geçirgenlik Kromatografi Analizleri

Öz: Yıllar içerisinde toplumun çevresel duyarlılığındaki artış dolayısıyla, polimerlerin biyolojik olarak bozunma özelliği onların

toplum tarafından kabul edilmesinde önemli bir parametre haline gelmiştir. Bu çalışmada, polpolikaprolakton (PCL), polivinil alkol (PVA)/nişasta karışımı polimer matrisi olarak ve atık Kızılçam budama atık unları ise lignoselülozik dolgu maddesi olarak kullanılarak PCL esaslı biyolojik esaslı kompozitler üretilmiştir. Biyokompozitlerin üretimi ekstruder ve enjeksiyon kalıplama yöntemlerinin kombinasyonu ile üretilmiştir. Orman toprakları Konya’nın kurak alanlarından alınarak laboratuarlarımıza getirilmiştir. Jel Geçirgenlik Kromatografisi (GPC) yardımıyla belirlenmiştir. 18 ay boyunca gerçekleştirilen toprak testleri süresince, PCL’nin topraktaki bozunma oranı Jel Geçirgenlik Kromotografi (GPC) yardımıyla ölçülmüştür. Sonuçlar GPC değerleri üzerinde en etkili faktörlerin kızılçam odun unu miktarı ve bozunma süresi olduğunu göstermiştir. Özellikle yüksek dolgu maddesi oranına sahip örneklerde dolgu maddesi ile bozunma süresi arasında doğrusal bir ilişki tespit edilmiştir.

INTRODUCTION MATERIAL and METHODS

Petrochemicals driven non-biodegradable plastics cause serious environmental problems since they produce greenhouse gas during their manufacturing and wastes after their disposal. Even though they seem to be used for a long time due to newly add application areas, reliable and repeatable product quality and cost advantages, research towards finding alternative resources and using them continue.

That’s why past 30 years, biodegradable plastics and new manufacturing methods have been studied intensively (Van de velde & Kiekens, 2002; Kolybaba et al., 2003; Yu & Chen, 2009; Leja & Lewandowicz, 2010; Averous & Pollet, 2012;). Biodegradation is the decomposition of organic material to the carbon, hydrogen and oxygen by microorganisms. Most common biodegradable plastics are starch (Walenta et al., 2001a & 2001b; Laohakunjit & Noomhorm, 2004; Zhang & Han, 2006; Hanna & Xu, 2009; Inman, 2010), protein, polylactic asit (PLA) (Viera et al., 2011; Gorrasi & Pantani, 2013) and polyhydroxyalkonates (PHA), driven from renewable resource and polycaprolactone (PCL) (Viera et al., 2011), petroleum driven from petrochemicals. Among them, the most commonly used one is starch since it can be used as plastic matrix and also a plastic filler. However, its drawbacks prevent them from being good alternative to other synthetic plastics. That’s why they need to be combined with other biodegradable plastics for many application areas.

Biodegradable plastics are commonly used in the areas of packaging, agricultural mulch films and medical applications (Davis & Song, 2006). The usage of low density polyethylene (LDPE) based agricultural films are increasing in Turkey and in the World. After usage, these materials produce great amount of waste on the agricultural land. The use of biodegradable plastic instead, would be a better option. Biodegradable plastics are known for being environmental friendly and being used as an alternative to petroleum driven plastics. They are also known for medical applications like tissue engineering, surgery ropes and drug delivery systems. In those applications, they are taken advantage of biodegradability of plastics. There is a need to increase application areas of biodegradability of plastics beyond the packaging, agricultural mulch films and medical applications.

In our previous study, biodegradable composite materials using starch and wood flour were manufactured. However, this type of material still prone to hydrolyses in short time when in contact with water. That’s why the use of starch in combination with other biodegradable plastic is

Summary of the experimental design and description of the manufactured samples were presented in Table 1 and Table 2, respectively. PCL, PVA-Starch mixture and PE were used as thermoplastic matrix. Turkish red pine pruning waste (RPW) was used as lignocellulosic filler. Depending on the formulation given PCL, dried PVA-starch pellets, PE and RPW were dry-mixed in a high-intensity mixer to produce a homogeneous blend. These blends were compounded in a single-screw extruder at 40 rpm screw speed in the temperatures (barrel to die) of 170-175-180-185-190°C. Extruded samples were cooled in water pool and subsequently granulated into pellets. The pellets were dried in oven at 103±2°C for 24 hours. Dried pellets were injection molded using an HDX-88 Injection Molding Machine to produce standard test samples.

Table 1. Summary of the experimental design.

Analysis Type: Response Surface Method Variance (nm) Desing Model: Quadratic Levels:2

Factors Type Low Actual High Actual

A RPW(%) Numeric 4.39 25.61

B PE (%) Numeric 1.46 8.54

Table 2. Description of the manufactured samples.

ID Neat PCL (%) RPWF (%) PE(%) PVA-Starch (%)

PCL0 55.00 15.00 0.00 30 PCL1 64.15 4.39 1.46 30 PCL2 42.93 25.61 1.46 30 PCL3 65.00 0.00 5.00 30 PCL4 50.00 15.00 5.00 30 PCL5 35.00 30.00 5.00 30 PCL6 57.07 4.39 8.54 30 PCL7 35.85 25.61 8.54 30 PCL8 45.00 15.00 10.00 30

Forest soil was collected from arid regions of Konya and transferred to Laboratory. Samples were put into the flowerpots and covered by forest soil. They were watered up to field capacity (Figure 1).

Figure 1. Samples were put under soil (a) and watered up to the

field capacity (b).

For GPC Analysis; samples were taken out of soil, cleaned and weighed before testing. Before running test GPC was cleaned with 2-propanol for 120 min. Flow was 1ml/h. Later eluent THF was run for 180 min. GPC was calibrated.

temp. One agilent brand Polargel-M guard 50 x 7.5 mm column and 2 agilent brand Polargel-M 300 x 7.5 mm column were used for analysis (Figure 2).

Figure 2. Samples were cleaned from dirt (a), granulated with IKA

(b), diluted in THF (c) and tested in GPC (d).

RESULTS and DISCUSSION

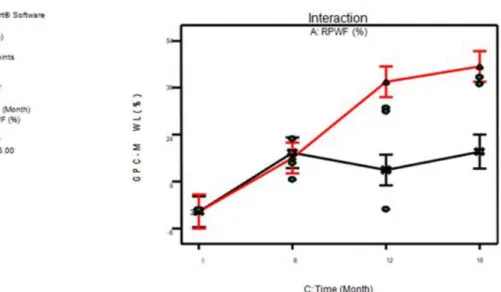

After soil burial test, maximum molecular weight loss of the samples were determined and results were analyzed. Statistical analysis showed that both RPWF loading and degradation time had significant effect on molecular weight of the PCL matrix. Interaction graph of the result is presented in Figure 3. In first 6 month period, samples with low and high RPWF loading have provided similar molecular weight degradation (10%). After 6 months, on the other hand, high RPWF loading samples lost more molecular weight. After 18 months of burial test, samples with high RPWF loading lost around 40% of its molecular weight. However, it was still around 10% for samples having low RPWF loading. Arvanitoyannis et al. (1998) reported that there is close relation between degradation and excess of the microorganism to lignocellulosic materials. We believe that at high RPWF loading, water and microorganism had a better chance of excessing the lignocellulosic materials resulting in increased molecular weight reduction of the PCL matrix.

Figure 3. GPC- Maximum Weight Lost (GPC-MWL).

Produced composite materials were buried under soil which is collected from Konya region. Tensile, flexural and impact samples were kept under soil over 18 months of period. Samples were taken out every six months and weight losses were measured. Weight loss percentage interaction graphs of tensile, flexural and impact samples were shown in Figure 4, Figure 5 and Figure 6, respectively. Based on the statistical analysis, RPWF loading had no significant effect on weight loss for tensile and flexural samples (P=0.1268,

P=0.2108, respectively). In the case of impact samples, it had significant effect on weight loss (P=0.0039). Even though PE amount had some effect on weight loss, degradation time has the most important effect on weight loss for all samples (P<0.0001). Among them, impact samples had the highest weight loss compared to tensile and impact samples. It is believed that higher surface area of the impact samples (being in almost half the size of other samples) increased the wear of the samples under soil.

Figure 4. Weight loss of tensile samples (TWL).

CONCLUSION

Biodegradable composites were successfully manufactured and 18 months of soil burial test were conducted. Based on the GPC analyses following conclusions were reached;

RPWF concentration and degradation time have a significant effect on GPC molecular weight.

Especially at high RPWF loading, there is a linear correlation between degradation amount and filler loading.

GPC can be used to monitor degradation of polymers but needs further studies to compare and correlate them to standard weight loss methods.

ACKNOWLEDGEMENTS

This research was supported by The Scientific & Technological Research Council of Turkey (Project # TOVAG 113O254). Thanks to graduated student Merve ARAS ERDOĞAN for her help during GPS Analysis.

REFERENCES

Arvanitoyannis, I., Biliaderis, C.G., Ogawab, H. & Kawasaki, N. (1998). Biodegradable films made

from low-density polyethylene (LDPE), rice starch and potato starch for food packaging applications: Part 1. Carbohydrate Polymers, 36, 89-104.

Averous, L. & Pollet, E. (2012). Biodegradable polymers,

environmental slicate nano-biocomposites. Springer-Verlag London.

Inman, H. (2010). Who said Potato? Starch-Based

Thermoplastics, 66(4), 42-44.

Hanna, M.A. & Xu, Y. (2009). Starch-fiber composites,

Biodegradable polymer blends and composites from renewable resources. Hoboken-New Jersey.

Davis, G. & Song, J.H. (2006). Biodegradable packaging

based on raw materials from crops and their impact on waste management. Industrial Crops and

Products, 23, 147-161.

Gorrasi, G. & Pantani, R. (2013). Effect of PLA grades and

morphologies on hydrolytic degradation at composting temperature: assessment of structural modification and kinetic parameters. Polymer

Degradation and Stability, Doi: 10.1016/j.

polymdegradstab.

Kolybaba, M., Tabil, L.G., Panigrahi, S., Crerar, W.J., Powell, T. & Wang, B. (2003). Biodegradable

polymers: past, present, and future. CSAE/ASAE Annual Intersectional Meeting Sponsored by the Red River Section of ASAE Quality Inn & Suites 301 3rd Avenue North Fargo, North Dakota, USA October 3-4.

Laohakunjit, N. & Noomhorm, A. (2004). Effects of

plasticizers on mechanical and barrier properties of rice starch film. Starch/Staerke, 56, 348-356.

Leja, K. & Lewandowicz, G. (2010). Polymer

biodegradation and biodegradable polymers – a review. Polish J. of Environ. Stud., 19(2), 255-266.

Van de velde, K. & Kiekens, P. (2002). Biopolymers:

overwiev of several properties and consequences on their applications. Polymer Testing. 21(4), 433-442.

Viera, A.C., Viera, J.C. Ferra, J.M., Magalhaes, F.D.,

Guedes, R.M. & Marques, A.T. (2011).

Mechanical study of pla-pcl fibers during in vitro degradation. Journal of the Mechanical Behavior of

Biomedical Materials, 4(3), 451-460.

Walenta, E., Fink, H.P., Weigel, P. & Ganster, J. (2001).

Structure - property relationships in extruded starch, 1 supermolecular structure of pea amylose and extruded pea amylose. Macromolecular Materials

and Engineering, 286, 456-461.

Yu, L. & Chen, L., (2009). Polymeric materials from

renewable resources, Biodegradable polymer blends and composites from renewable resources, Ed: Yu, L., Wiley Hoboken, New Jersey.

Zhang, Y. & Han, J.H. (2006). Mechanical and thermal

characteristics of pea starch films plasticized with monosaccharide and polyols. Journal of Food

Science, 71( 2), E109-118.

*Corresponding author’s:

İlkay ATAR

Kahramanmaraş Sutcu Imam University, Department of Forest Industry Engineering, 46100, Kahramanmaraş, Turkey

E-mail : iatar@ksu.ed.tr