The Profitable Cattle Fattening Operations Using Modern Technologiesfor

Turkey Red Meat Demand

Serap GÖNCÜ1*, Nazan KOLUMAN1

1 Department of Animal Science, Çukurova University, Turkey

*Corresponding Author: sgoncu@cu.edu.tr

Abstract

Modern technology provide beef industry with improved methods, management processes and accuracy. Technological applications have contributed to the beef sector such as nutrition and health management; information techniques, cattle management procedures and accurate cattle tracing.Fattening of animals is a highly profitable venture with return of premium to the farmer. The large scale beef farming must be meet economic criteria for sustainable production. It consists of buying healthy stock, feeding and fattening them to optimum carcass weight , and selling them at anytime of the year. They are handled in such a way that maximum growth is achieved at the lowest possible cost. The lifespan of operation is shorter and the return of investment is relatively higher. In beef farms which very high genetic value of breeding animals cannot be get the expected performance without the use of technology and automation systems. Beef herd management programs if can be used as effectively, farming will have many advantages for consumer, farmer and also animals. However, to obtain these advantages from this system required to have knowledge of the functions and effective use of the functions. The large amount of data in the obtained on many issues related to animals, herd management and an individual unless used in decisions about animals, ensuring the heavy data flow, record keeping or assessment will not give the expected results. In this study it has been aiming that the examined modern technologies for profitable cattle fattening for Turkey meat market.

Keywords:Automation, Intensive, Beef Farms, Herd management, profitability, red meat

Introduction

Due to the increase in the world population, the problem of nutrition is also rising up. Balanced nutrition, adequate animal protein intake has become a priority issue for developed countries. Therefore, the animal husbandry sector has maintained its strategic importance despite the developing technology and industrialization policies. According to Turkstat in Turkey, 14 million 222 thousand cattles raised in 2016, while there are 41 million 329 thousand sheep and goats. Around 30% of world meat production is supplied from cattle and 5% from sheep. In Turkey, 88% of meat production are supplied from cattle, and 12% fromsheep and goats. The use of technology during feedlot period is not common in Turkey. The human factor comes to the forefront in the studycarried out and the important decisions to be taken. The average daily weight gain and feed conversion ratioare not calculated in feedlot

period of imported culture animals. Persistence and profitability of livestock breeders continue to be fattening operations, but the technology of the infrastructure is found to be good. The managers of the fattening company decide to rely on their personal experience and knowledge in their fattening operational decisions.This situation adversely affects the profitability of fattening enterprises and their status in the world market. The sector is looking for support to develop with new and more advanced targets. For this purpose, using scientific and technological tools during production processoflivestock products, meet the demands of the country in the globalized world continues production. Turkey cattle breeders are looking for alternative profitable solutions to increase productivity of high feed prices, low daily live weight gain and management losses. It is stated that there is a loss of animal due to the lack of technology and animal care. Deficiencies experienced in vaccination are the most important reason. Especially with the importance of food safety, relevant regulations should be made in the sector. The process from fattening up to the processing of fattening animal meat businesses should take note of many issues. To ensure production at sustainable and profitable standards some factors such as, providing infrastructure incentives to the producer, to combat animal diseases, to eliminate deficiencies in our registration system, to promote livestock exchanges which are the correct marketing channels and to provide modernization of facilities of fattening farms should be emphasised.

Table 1. Turkey Livestock Population Trends in Last 15 years (TURKSTAT, 2019)

Year Cattle Buffalo Total Sheep Goat Total

2002 9.803.498 121.077 9.924.575 25.173.706 6.780.094 31.953.800 2003 9.788.102 113.356 9.901.458 25.431.539 6.771.675 32.209.214 2004 10.069.346 103.900 10.173.246 25.201.155 6.609.937 31.811.092 2005 10.526.440 104.965 10.631.405 25.304.325 6.517.464 31.821.789 2006 10.871.364 100.516 10.971.880 25.616.912 6.643.294 32.260.206 2007 11.036.753 84.705 11.121.458 25.475.293 6.286.358 31.761.651 2008 10.859.942 86.297 10.946.239 23.974.591 5.593.561 29.568.152 2009 10.723.958 87.207 10.811.165 21.749.508 5.128.285 26.877.793 2010 11.369.800 84.726 11.454.526 23.089.691 6.293.233 29.382.924 2011 12.386.337 97.632 12.483.969 25.031.565 7.277.953 32.309.518 2012 13.914.912 107.435 14.022.347 27.425.233 8.357.286 35.782.519 2013 14.415.257 117.591 14.532.848 29.284.247 9.225.548 38.509.795 2014 14.223.109 122.114 14.345.223 31.140.244 10.344.936 41.485.180 2015 13.994.071 133.766 14.127.837 31.507.934 10.416.166 41.924.100 2016 14.080.155 142.073 14.222.228 30.983.933 10.345.299 41.329.232 2017 15.943.586 161.439 16.105.025 33.677.636 10.634.672 44.312.308

Due to population growth, the number of animals and red meat production is increasing every year. Red meatcontains very valuable nutritional factors for human health. The red meat consumption per capita in Turkey is lower than in developed countries as shown in Table 2.

Table 2. Turkey meat production trends in Last 30 years (TURKSTAT, 2019)

Sheep Goat Cattle Buffalo

Year (head) Meat (ton) (head) Meat (ton) (head) Meat (ton) (head) Meat (ton) 1991 7 926 513 128.626 1.198.008 19.570 2.162.860 309.563 59.913 8.803 2000 6.110.853 111.139 1.166.169 21.395 2.101.583 354.636 25.518 4.047 2001 4.747.268 85.661 879.127 16.138 1.843.320 331.589 12.514 2.295 2002 3.935.393 75.828 757.465 15.454 1.774.107 327.629 10.110 1.630 2003 3.554.078 63.006 607.006 11.487 1.591.045 290.455 9.521 1.709 2004 3.933.973 69.715 570.512 10.301 1.856.549 364.999 9.858 1.950 2005 4.145.343 73.743 688.704 12.390 1.630.471 321.681 8.920 1.577 2006 4.763.394 81.899 803.063 14.133 1.750.997 340.705 9.658 1.774 2007 6.428.866 117.524 1.256.348 24.136 2.003.991 431.963 9.534 1.988 2008 5.588.906 96.738 767.522 13.752 1.736.107 370.619 7.251 1.334 2009 3.997.348 74.633 606.042 11.675 1.502.073 325.286 4.857 1.005 2010 6.873.626 135.687 1.219.504 23.060 2.602.246 615.584 15.720 3.387 2011 5.479.546 107.076 1.254.092 23.318 2.571.765 644.906 7.255 1.615 2012 4.541.122 97.334 926.799 17.430 2.791.034 799.344 7.426 1.736 2013 4.958.226 102.943 1.340.909 23.554 3.430.723 869.292 2.403 366 2014 5.197.289 98.978 1.570.239 26.770 3.712.281 881.999 2.176 526 2015 5.008.411 100.021 1.999.241 33.990 3.765.077 1.014.926 1.391 326 2016 4.083.620 82.485 1.756.360 31.011 3.900.307 1.059.195 1.499 351 2017 5.134.338 100.058 2.068.866 37.525 3.602.115 987.482 6.123 1339

As seen in Table 2 livestock populationdecrease in Turkey. Local breeds which are low production level , not suitable for intensive production.The social, economical and technical farctors limited profitability in animal production of Turkey. Cattle fattening is carried out with the aim of make the animals to the cutting maturity in order to obtain high meat and quality meat with proper care and feeding. The aim in fattening studies is to achieve the highest live weight in the shortest time,in the most economical way. Live weight gain and feed efficiency ratio in fattening is stated as Fattening Performance. This is the main problem

for Turkish beef farmers. A total cattle number is 1.972.923 heads in Turkey for 1991. The only

group of culture breed cattle with a rapid increase in the last 30 years. In the period in question, the number of culture cattle breeds increased by almost 6 times.One of the important factors affecting the amount of meat produced in a population is the carcass weight obtained per unit animal.

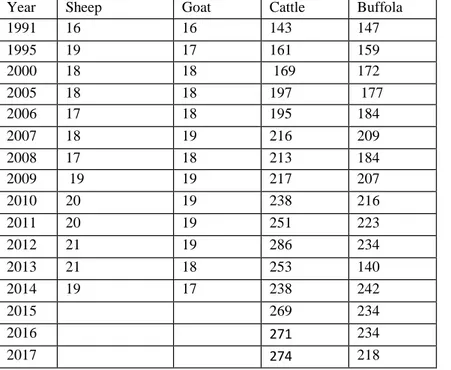

Table 3. Turkey red meat carcass weight (kg) values (TURKSTAT, 2019)

Year Sheep Goat Cattle Buffola

1991 16 16 143 147 1995 19 17 161 159 2000 18 18 169 172 2005 18 18 197 177 2006 17 18 195 184 2007 18 19 216 209 2008 17 18 213 184 2009 19 19 217 207 2010 20 19 238 216 2011 20 19 251 223 2012 21 19 286 234 2013 21 18 253 140 2014 19 17 238 242 2015 269 234 2016 271 234 2017 274 218

Sheep carcass weight in Turkey variated as seen in Table 3. While there was a significant change in carcass weight in cattle that of increased from 143 kgto 218 kg. Due to the relative increase in the average carcass weight of cattle slaughtered in recentyears, the ratio of cattle in total meat production has increased. But still there is big gap for consumer demand.Population of Turkeyhas increased from67,743,000 to 78,741,000 during the last 10 years and demand for meat products has led to an increase in meat prices in Turkey. Moreover, regional differences in animal production are very high. Not all regions have the same characteristics.The province with the highest number of cattle is Konya, followed by Erzurum, İzmir, Balıkesir and Kars, respectively. This constitutes 20% of the Turkey cattle population. Van province is the most abundant animal species, then Konya, Sanliurfa, Agri and Mersin respectively. This constitutes 22% of the Turkey ovine livestock. According to TURKSTAT data, in 2017, the average price of beef meat increased by 7% compared to the previous year and was realized as 38.42 TL. In 2017, it increased by 8% compared to the previous year. In 2017, the price of veal consumers increased by 8% compared to the previous year and rose by 41.63 TL / kg. While Calfcarcass prices were also 18,07 TL / kg in 2014, it increased by 45% in 2017, and the price of lamb carcass increased by 38% to 27,28 TL / kg.

It is a very important advantage that it can be used in rapid decision-making and instant decision making with technological applications.Also to access instant information of all animals in the enterprise and to use them in decisions to prevent immediate intervention and loss. In addition, these calculations are very important for making profitability and sustainability calculations. In addition, it is advantageous that herd management programs which isflexible,easily expand and compatible with other automations. The reports used here have the advantage of being broad and flexible according to user demands and possible

developments forthe future.Turkey eliminate the shortage of red meat in the coming years with possible profitable and sustainable farming system. The improvements in beef cattle production cannot be attributed to single technology. However, incorporation of multiple technologies in several segments has transformed to the beef industry.

The large amount of obtained data on many issues related to animals, herd management and an individual unless used in decision makingfor animal farming. Ensuring the heavy data flow, record keeping or assessment will not give the expected results. In this study it has been aiming that determine modern technologies for profitable cattle fattening for Turkey meat market

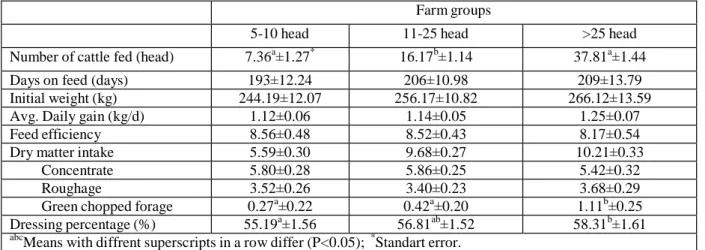

Beef farm performances

Beef farming is an important animal production sector and has significant role inTurkish economy. Flocksize is mainly (80%) 1-20 head cattles. In Turkey, fedlotcattle are aged between 12-24 months and are ready to be slaughtered ehile they reach 300kg. Turkish producers typically do not castrate their feedlot cattle since they believe that customers prefer to consume lean meat.Turkey, is the main importer of fedlotcattle and if necessary measures are not taken will likely continue to need to import live cattle in order to maintain feeder cattle herds, so long as the structure of the industry remains the same.The imported breeds are mainly crosses of beef breeds asAngus, Hereford, Limousine and Charolaise. Brahman breeds and their crosses are also seen in meat type farms. Cattle producers are concerned imported feed prices which is so high due to the currency devaluation that the subsidy doesn’t cover the increased costs of production. Also the unstable economic situation is making it more difficult for producers to plan for future production. The average fattening period is 244 days in Turkey and total weigth gain is 253 kg, and the daily weight gain 981-1.056 g. Fattening performances differ depending on the farm size and their management conditions (Table 4).

Table 4. Fattening perfromances and carcass characteristics of Turkish beef farms (Demircan et al. 2007)

Farm groups

5-10 head 11-25 head >25 head

Number of cattle fed (head) 7.36a±1.27* 16.17b±1.14 37.81a±1.44

Days on feed (days) 193±12.24 206±10.98 209±13.79

Initial weight (kg) 244.19±12.07 256.17±10.82 266.12±13.59

Avg. Daily gain (kg/d) 1.12±0.06 1.14±0.05 1.25±0.07

Feed efficiency 8.56±0.48 8.52±0.43 8.17±0.54

Dry matter intake 5.59±0.30 9.68±0.27 10.21±0.33

Concentrate 5.80±0.28 5.86±0.25 5.42±0.32

Roughage 3.52±0.26 3.40±0.23 3.68±0.29

Green chopped forage 0.27a±0.22 0.42a±0.20 1.11b±0.25 Dressing percentage (%) 55.19a±1.56 56.81ab±1.52 58.31b±1.61

In livestock production is very low and the global red meat sector is an advanced industry.Meat production costs are extremely high in Turkey. Thus, there is no chance to compte to global market.Meat trade between countries; different resource structure of each country, consumer choice in meat selection, domestic industry structure determines. Countries that produce low-cost meat have the advantage of competing in world trade. Turkey has forced the effectiveness of the country's meat imports fall in cattle breeding. Thus, Turkey became one of the countries with the most expensive meat.

Vast majority of Turkey's red meat supply isprovided by fattening enterprises. As a result of the researches it could be seen that turkish fattening enterprises can not work efficiently because of various problems. Our country's cattle breeding was carried out mainly as a family business until the 1980s. In recent years, the number of modern cattle farms with large capacity increased rapidly as a result of the increase in government subsidies.To improve the breeding of cattle in Turkey is mainly focused genotype, environmental and marketing with efforts to improve, create new businesses, conducted in association etc. Animal production is strategic in terms of nutrition demand and food safety and its only source is nature.

Technologic oppurtunities

Technologic devices that can be integrated inside the body of animal, patched under its skin, or remain in its stomach give animal owner's useful information regarding their behavior and medical conditions. These electronic devices are expected to be used for the medical treatment of animals, detection of heating and cooling needs, iontophoretic drug delivery. Sensors and wearable technologies can be implanted on animals to detect their sweat constituents (Glennon ety al. 2016) measure body temperature (Selliereta l. 2014) observe behavior and movement (Van Nuffel eta l. 2015), detect stress Lee et al. (2015) analyze sound (Kim et al. 2015; Ferrari et al. 2008; Berckmans et al. 2015; Fontana et al. 2015), Exadaktylos et al., (2013) detect pH (Kim et al. 2016), prevent disease (Rutten et al. 2013), detect analytes and detect presence of viruses and pathogens (Mungroo and Neethirajan 2014; Ayyar and Arora 2013; Mungroo et al. 2016; Posthuma-Trumpie et al.2009; , Kizil et al. 2015) Wearable sensors help farmers catch disease early, and thereby prevent deaths of animals. Farmers can also cull diseased animals in time to prevent the spread of disease in whole cattle herds through prediction. Another important use of biosensors is antibiotic detection. With the unhampered and frequent use of antibiotics in the animal industry, antibiotic resistance has become a major threat for farmers. Ecological instability is caused by the uncontrolled use of sub-therapeutic antibiotics in concentrated animal feeding operations (CAFOs), which in turn causes antibiotic resistance in animals. Maximum Residue Limits (MRLs) have been set up for those antibiotics that are still allowed to be administered in animals in the United States and European countries. MRL is that amount of pharmacologically active substances, and their derived metabolites, which is legally acceptable. Biosensors have been identified as being helpful in this regard; they can easily detect antibiotic levels and warn the farmer if the antibiotics level exceeds a maximum range (Mungroo and Neethirajan 2014).

Beef cattle producers use technologies to improve animal performance and well-being and to increase the profitability of their enterprises.Many beef cow management strategies, genetic improvement technologies, exogenous growth promoting compounds, vaccines, antibiotics, and feed processing strategies and many software programs.

In parallel with the developments in computer technology, the use of (GIS) Image Processing Systems in the field of animal husbandry, more production period, storage and pre- consumption health and quality audits, examination of growth and development, determination of morphological characteristics, evaluation, grading or standardization according to the color characteristics of animal products focuses on issues. It is also possible to use GIS in determining body development and growth through examination of dimensions and shape. If such a system is used, grouping of animals according to their developmental status, separate care and feeding of the grouped animals are necessary for the economy of business as well as scientific studies where the growth event is examined.

An increase in per animal productivity provides benefits for producers (fewer cattle to manage to obtain the same amount of output), consumers (potentially increased beef supply), and the environment.However management of production is still the decisive factor in profitability. Many farms have the scope to dramatically improve profitability using latestv technology developed country.Some technologies provide beef sector with improved methods, management processes and accuracy. Greenwood et al (2016) reported that the schematic representation of efficiency at pasture phenotyping network for grazing livestock meat (and fibre) production.

Genetic

World beef industry invests in new genetic and reproductive knowledge and technologies aimed at improving production, optimising herd quality, performance and health and creating lines of cattle optimally adapted to diverse climatic conditions. Many climatic conditions required different animal phenotypes that are adapted to different conditions. Cattle breeds are very heterogeneous in nature, consisting of pure breeds and crosses whichreflecting the diversity of environments.Hybrid vigour (heterosis) is the advantage of crossbreds over the average of the parent breeds. Research shows that the advantage expected from using a cross- bred cattle as opposed to a purebred in terms of kg of calf weaned per cow put to the bull is about 13%. In addition, using a sire from a third breed (i.e. a breed not in the cow breed type) increases the weight of calf weaned per cow bred by approximately a further 8 % (literatür). The latest cattle breeding schemes are only economically viable when combined with of artificial reproduction technologies, to ensure that elite genetics are multiplied widely (Archer et al. 2004). Genes from the bull are mainly transferred to multiplier herds and to the commercial herds by the using technoloies more faster for better breeding results. Genetic evaluation using best linear unbiased prediction (BLUP) technology is almost universal in beef nucleus herds, principally via the Australian BREEDPLAN system (Johnston et al. 1999) although some other providers are also used. These genetic evaluation systems cover a many production traits of economic importance across major beef production systems. Genetic technologies requiring co-operative arrangements between herds, such as across-herd genetic evaluation, tend to be administered by breed societies and consequently genetic comparisons in beef cattle are restricted to within-breed comparisons (Morris and Archer 2007).

Feeding

Livestock feed costs are the main source of expense and the smallest savings on this issue can create significant differences in the profits of enterprises. At this stage, feed preparation

machines, mixers and dispensers with electronic precision measurement system in feed preparation are the first applications that come to mind. Many software adjusts automatically the daily intensive feed consumption level of the animals according to the criteria defined by the user, controls the amount to be given and the frequency of the meal at a meal and also determines the amount not consumed from the daily total amount determined for each animal (Spahr, 1989). Here, the electronically defined animals can be taken to the feeders containing automatic weighing scales and the records are taken when they eat the feed, how long they have been in the feeder, and how much time the feed is at seven hours. The antennas to read the electronic definition are mounted in the immediate vicinity of the feeder and continuously record the data.

The accumulated use of technology in the beef industry has improved cattle and enterprise efficiency and has decreased the resource inputs of feed and land. Important technologies that have been adopted include antibiotics, implants, ionophores, parasiticides, genetics, vaccines, physiological modifiers, and nutrition (Lawrence and Ibarburu 2008). Buty many pharmaceutical products not allowed in finishing cattle. But examination of these technologies appeared to show performance advantages for treated cattle relative to cattle in negative control groups. Average daily gain in feeder cattle given metaphylaxis on arrival was 0.11 kg/d (P < 0.01) greater relative to cattle that did not receive metaphylaxis on arrival. Implanting heifers increased ADG by 0.08 kg/d compared with nonimplanted controls (P = 0.09). Implants had no effect on G:F (P = 0.14) in heifers or on DMI (P = 0.44) relative to nonimplanted control heifers. Implanting steers was associated with greater ADG, by 0.25 kg/d (P < 0.01), and DMI, by 0.53 kg/d (P < 0.01), relative to nonimplanted control steers. Implants also improved G:F in steers relative to nonimplanted steers, by 0.02 (0.17 vs. 0.15; implanted vs. controls, P < 0.01; n = 21 studies.

Biosecurity

Healthy animals are is an essential component of animal production. The disease reduce animal production and profitability aspectsand cause many problems in herd operations. Subclinical disease, where there are no obvious signs or symptoms, may also be present in the herd. Animal performance may be only slightly reduced, so sub-clinical diseases detection is difficult but the hidden cost couldbe larger. The livestock activities need to be carried out in a sustainable manner, as well as in a flock-oriented way beyond individual animal treatments in order to ensure high yield per animal.It is important to review the practices and management and to establish a business structure free from infectious diseases. Implementing a herd- specific health programme is the best way to address potential health problems and is essential if optimum profitability to be achieved. A veterinarian should always be consulted with regard to specific animal health problems and farm bio-security.The sector maintains high standards of animal health through livestock industries. Biosecurity has become a major concern to the beef sector as a result of foreign and emerging disease issues, the globalization of agriculture and increasing public concerns over food safety. Individual farms are less isolated and inputs are entering the farms of today from further away, often from other countries.

Every year since 2010, when the importation started, especially during the sacrifice period, a few diseases are determined. It is not a coincidence that diseases emerged in the period of the victim festival. Both the state and the private sector are importing intensively to reduce

domestic animal prices during the sacrifice period. Because of this each beef producer is responsible for developing a biosecurity plan for their own property.

Technology can help reduce that number and transform the way the industry identifies sick animals. Initially developed for the feedlot industry, tags fastened to an animal’s ear collect and perform analysis of an animal’s biometric and behavioral data. Continuous, noninvasive monitoring of cattle behavior using various technologies have potential to be powerful health management tools in beef feedlot (Wolfger et al., 2015a)Proprietary algorithms flag any animal showing signs of illness or disease and alert you through a smartphone, tablet, email, SMS, or a secure website. An LED light on the tag flashes to easily identify the sick cow. More recently, cattle behavior has been quantified objectively and continuously using advanced technologies to assess animal welfare, indicate lameness or disease, and detect estrus in both production and research settings. The recent rise in mobile phone use and increased signal coverage has created opportunities for growth of the mobile Health sector in many low resource settings (Beyene et al. 2017). Biosensing technologies provides promise to improve the performance, cost, and productivity in the area of disease management in livestock. Development and deployment of reliable, rapid tests will allow earlier and more specific treatment of diseases, potentially resulting in reduced antimicrobial usage and improved animal welfare.

Autmation systems

The animal husbandry account and the general status of animals, fattening decision and profitability are determined. The weighing process, which will provide important information, is hampered by the difficulty and done in very important situations. Because, live animal weighing is a very risky and difficult element in the animal. However, it has been automated in weighing after electronic identification systems. The system to be installed in a suitable area on the farm, automatic measurement of the weights of animals during the transitions and recording to the computer system provides a great advantage to the business.

The most important information about the individual's identity information, pedigree information, insemination, health control results, diagnosed diseases and applied treatments. Some animals in the herd must be subjected to this distinction because of weight loss during fattening, sick appearing or no eating problems such as lameness. Separation process becomes stressful, time-consuming, risk-taking, a lot of high-error management work. This task is one of the most demanding jobs.

Grouping of cattle with electronic numbers is possible with these electronic systems. For this purpose, depending on the characteristics of the system used in some way for a reason to be separated from the number of cows to be manually entered into the system or the system according to the specified criteria automatic segregation of cattle is also possible.

Research and development based innovations that are used in developing technology, comprehensive individual animal information collection and herd for efficient decision making offer technological products to growers (Göncü et al. 2008; Göncü et al. 2015). In this way, breeders can use information systems, marketing management, health.

It offers the widest range of tools, solutions and expertise in the areas of nutrition program management and individual animal monitoring. Cattle Technologies have provided a great advantage in individual animal identification and traceability since 1980s (Göncü et al. 2016;

of animals increases, the margin of error and workload increase. For these purposes, mechanization and automation systems offer options in front of the user in an intensive competition in the market.Also advanced software options provide farmers to save time, improve record keeping and allow for more coordinated efforts across all stages of production.Latest technologic aplications are popular areas in which improved production stage has impacted daily work routine and strategic level decision making. In addition to computers and mobile devices, some cattle farmers utilize tracing technologies for more accurate data recording. Software developers are even creating online systems in which farmers can trace cattle from birth to eventual death along with other details such as diet, grazing schedules, location transfer, breeding history and keeper profiles. Collecting as many details during the life of the cattle not only helps with disease control and traceability, but also provides source verification, which is important to beef consumers as well as cattle breeders.

Conclusion

Latest technologies allow farmers to use site-specific information to improve the efficiency of fattening opretraions. As available agricultural technologies change, the success of farms depends on correctly identifying which technologies increase profit.The managers of the fattening company decide to rely on their personal experience and knowledge in their fattening decisions.This situation adversely affects the profitability of fattening enterprises and their status in the world market. For this purpose, using science and technology to produce more profitable beef production and meet the demands of the country in the globalized world continues production.

Literature

Anonim-a, 2011. Ab Uyum Sürecinde Türkiye Hayvancılık Kongresi 2011, Kırmızı Et Sektörü Komisyonu Çalışma Sonuç Raporu.

Anonim-b, 2011. Gıda Tarım ve Hayvancılık Bakanlığı Verileri

Anonymus, 2015. Hayvancılık Genel Müdürlüğü, Kırmızı Et Stratejisi, Ankara

Archer JA, Barwick SA, Graser H-U 2004. Economic evaluation of beef cattle breeding schemes incorporating performance testing of young bulls for feed intake. Australian Journal of Experimental Agriculture 44: 393-404

Ayyar, B.V., Arora S. , 2013. Antibody-based biosensors for detection of veterinary viral pathogens. Adv. Anim. Vet. Sci., 1 (2013), pp. 37-44

Berckmans, D., M. Hemeryck, D. Berckmans, E. Vranken, T. van Waterschoot 2015. Animal sound… talks! Real-time sound analysis for health monitoring in livestock Proc. Animal Environment and Welfare (2015), pp. 215-222

Beyene TJ, Eshetu A, Abdu A, et al. Assisting differential clinical diagnosis of cattle diseases using smartphone-based technology in low resource settings: a pilot study. BMC Vet Res. 2017;13(1):323. Published 2017 Nov 9. doi:10.1186/s12917-017-1249-3

Demirbaş, N., Talim, M., 1999. Türkiye’de Et ve Et Ürünleri Sanayinde Gelişmeler, Demirbaş, N., Tosun, D., 2005. Türkiye’de Tarımın Sanayi ile Entegrasyonu, Ortaya Çıkan

Sorunlar Ve Çözüm Önerileri. ADÜ Ziraat Fakültesi Dergisi 2(2):27–34.

Exadaktylos, V. M. Silva, D. Berckmans 2014. H. Glotin (Ed.), Automatic identification and interpretation of animal sounds, applications to livestock production optimization. In

soundscape semiotics - localization and categorization, InTech, Rijeka, Croatia (2014), pp. 65-83

Ferrari, S. , M. Silva, M. Guarino, J.M. Aerts, D. Berckmans, 2008. Cough sound analysis to identify respiratory infection in pigs. Comput. Electron. Agric., 64 (2) (2008), pp. 318- 325

Fontana, I., E. Tullo, A. Scrase, A. Butterworth2015. Vocalisation sound pattern identification in young broiler chickens. Animal, 1-8 (2015)

Glennon, T., C. O'Quigley, M. McCaul, G. Matzeu, S. Beirne, G.G. Wallace, N. Stroiescu, N. O'Mahoney, P. White, D. Diamond‘SWEATCH’: a wearable platform for harvesting and analysing sweat sodium content. Electroanalysis, 28 (2016), pp. 1283-1289

Göncü Karakök, S., Darcan,N., Görgülü, M., Özgürsoy,S., 2008. The Necessities of New Technologies Usage at Turkish dairy Farms to Increase Competitive Skills at Global Market. 4th International Conference on Information and Communication Technologies in Bio and Earth Sciences (HAICTA 2008), September 18-20, 2008, Athens, Greece Göncü, S., Koluman, N., Görgülü, M., 2016. The New Technology Usage at Turkish Dairy

Farms to Better Milk Quality. 9th International Scientific Conference on Applied Sciences and Engineering. : 6-6- 2016. Nippon Hotel, İstanbul-Turkey.

Göncü,S., Koluman,N., Mevliyaoğulları,E., 2015. Entansif Süt Sığırcılığında İşletmelerinde Kullanılan Sürü Yönetim Yazılımları Karşılaştırması. 9. Ulusal Zootekni Bilim Kongresi, 3-5 Eylül 2015, Konya.

Göncü,S., Yeşil, M.İ., 2017. The New Technology Usage at Turkish Dairy Farms to Better Reproductive Perfomances. International Conference on Agriculture, Forest, Food Sciences and Technologies (ICAFOF 2017). Cappadocia, Nevsehir, Turkey, May 15 - 17, 2017

Göncü,S.,Gökçe, G., 2017.Türkiye’de Sığır Besiciliği İşletmelerinde Karlı ve Sürdürülebilir Üretim için Teknolojik Uygulamalar.Çukurova Tarım Gıda Bil. Der. 32: 29-34, 2017 Johnston DJ, Tier B, Graser H-U, Girard C 1999. Presenting BREEDPLAN Version 4.1.

Proceedings of the Association for the Advancement of Animal Breeding and Genetics 13: 193-196.

Kayhan, M. 2012. Hayvansal Üretimdeki Gelişmeler. Son 10 yılda Türkiye Tarımı Sempozyumu, Ege Üniversitesi- İzmir, 10.01.2012

Kim, H., J. Sab, B. Nohc, J. Leed, Y. Chung, D. Park, 2015. Automatic identification of a coughing animal using audio and video Data, Proceedings of The fourth International Conference on Information Science and Cloud Computing (ISCC2015). 18–19 December 2015. Guangzhou, China (2015)

Kim, J., T.N. Cho, G. Valdés-ramírez, J. Wang 2016. A wearable fingernail chemical sensing platform: pH sensing at your fingertips. Talanta (2016), pp. 622-628

Kizil, Ü., Genç, L., Rahman, S., Khaitsa, M.L., Genç T.T.,2015. Design and test of a low- cost electronic nose system for identification of Salmonella enterica in poultry manure. T. ASABE, 58 (3) (2015), pp. 819-826

Lee, J., B. Noh, S. Jang, D. Park, Y. Chung, H.H. ChangStress detection and classification of laying hens by sound analysis. Asian. Australas. J. Anim. Sci., 28 (4) (2015), p. 592 Levy, and K. Orsel 2015a. Feeding behavior as an early predictor of bovine respiratory

Morris C. A. and Archer J. A. (2007) Application of new technologies in New Zealand for beef cattle and deer improvement, New Zealand Journal of Agricultural Research, 50:2, 163-179, DOI: 10.1080/00288230709510289

Mungroo N.A. , G. Oliveira, S. NeethirajanSERS based point-of-care detection of food-borne pathogens. Microchim. Acta, 183 (2) (2016), pp. 697-707

Mungroo, N.A., Neethirajan S.2014 . Biosensors for the detection of antibiotics in poultry industry—a review. Biosensors, 4 (4) (2014), pp. 472-493

Posthuma-Trumpie, G.A., J. Korf, A. van AmerongenLateral flow (immuno) assay: its strengths, weaknesses, opportunities and threats. A literature survey. Anal. Bioanal. Chem., 393 (2) (2009), pp. 569-582

Rutten C.J. , A.G.J. Velthuis, W. Steeneveld, H. Hogeveen 2013. Can sensor technology benefit mastitis control, 2013, Proceedings of the British Mastitis Conference (2013) Sixways, Worcester (2013, November), pp. 23-34

Sellier, N., E. Guettier, C. StaubA review of methods to measure animal body temperature in precision farming. Am. J. Agric. Sci. Technol., 2 (2) (2014), pp. 74-99

Spahr, S.L. 1989. New Techniques in the mechanization and automation of cattle production systems.Chapter 3 in New Techniques in Cattle Production. C.J.C. Phillips, ed. Butterworths, England.

TURKSTAT, 2019.

VanNuffel, A. ,I. Zwertvaegher, S. VanWeyenberg, M. Pastell, V.M. Thorup, C. Bahr, B. Sonck, W. Saeys 2015. Lameness detection in dairy cows: part 2. Use of sensors to automatically register changes in locomotion or behaviorAnimals, 5 (3) (2015), pp. 861- 885

Wileman B. W., Thomson D. U. Reinhardt C. D. Renter, D. G. 2009. Analysis of modern technologies commonly used in beef cattle production: Conventional beef production versus nonconventional production using meta-analysis. Journal of Animal Science, Volume 87, Issue 10, 1 October 2009, Pages 3418–3426,

Wolfger, B., K. S.Schwartzkopf-Genswein, H. W.Barkema, E. A. Pajor, M.Yücel, S., 2007. Ankara İli Tarım İşletmelerinde Sığır Besiciliği Üretim Faaliyetinin Teknik Ve Mali Analizi. Ankara Üniversitesi Fen Bilimleri Enstitüsü Zootekni Anabilim Dalı. http://acikarsiv.ankara.edu.tr/browse/2500/