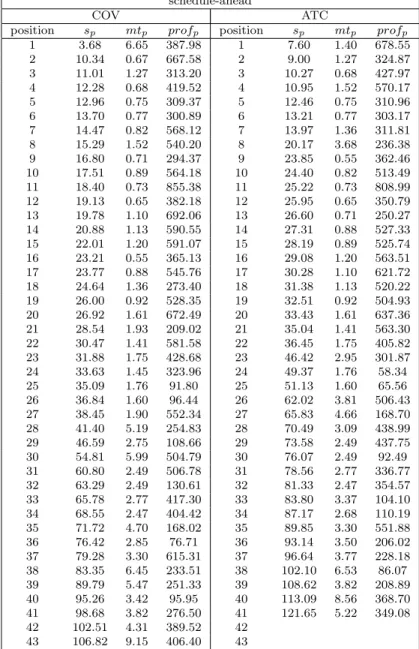

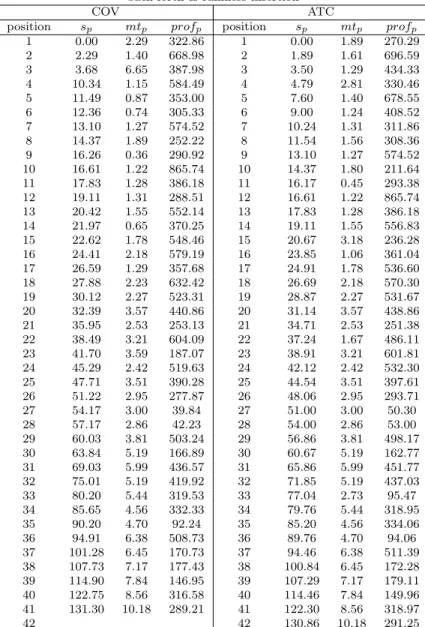

Single CNC machine scheduling with controllable processing times and multiple due dates

Tam metin

Şekil

Benzer Belgeler

The user has requested enhancement of the downloaded file... 1) Medicinal and Aromatic Plant and Drug Research Centre (TBAM), Anadolu University, 26470, Eskisehir, Turkey; 2) Faculty

Impacts of battery characteristics, driver preferences and road network features on travel costs of a plug-in hybrid electric vehicle (phev) for long-distance trips.. The shortest

Keywords: weakly-supervised learning, concept learning, rectifying self-organizing map, association with model evolution, clustering and outlier detection, conceptmap,

Hence the respect for minority rights of Turkey ’s Greeks was deemed conditional upon the full protection of the rights of Greece ’s Turkish Muslim minority in western Thrace..

Third, the intensity and the brutality of the Armenian-Turkish nationalist confrontation in the last years of the Ottoman Empire was also due to the fact that they were the last

“the essential point is that any such group [Turkish citizens of Kurdish origin] should have the opportunity and material resource to use and sustain its natural languages

Data analysis confirmed our expectations regarding a diversified framing of issues concerning ethnic and religious minorities in the parliamentary work of ‘minority

the issue of educational rights content with providing the whole of the national citizens with equal educational opportunities without addressing the