Use of Pumped Hydro Energy Storage to Compliment

Renewable Energy: A case study for Cumra, Turkey

MEHMET NUMAN KAYA1, FARUK KÖSE2

1Karamanoğlu Mehmetbey University, Mechanical Engineering Department, Yunus Emre Campus, Karaman, Turkey 2Selcuk University, Mechanical Engineering Department, Aladdin Keykubat Campus, Konya, Turkey

mnumankaya@kmu.edu.tr1, fkose@selcuk.edu.tr2

Abstract: Energy has become one of the main requirements of human beings today.

Different energy supply methods have been developed until today but the limitation of fossil fuels pointed researches to work on renewable energy systems since renewable energy sources are unlimited, clean and sustainable. The dependency of renewable energy sources on the weather and climate was another problem for researchers because of the requirement of firm power. Energy storage systems have been seen as a solution to prevent power fluctuations and supply firm power from energy production systems. The situation is same for Turkey, investments on renewable energy sources increases day by day and this causes Turkey to require energy storage systems to balance the energy in the network. In this paper, bulk energy storage methods, especially pumped hydro energy storage, are examined. A case study is performed to meet the electrical energy demand of irrigation pumps which have huge electrical energy consumption in total and used for irrigation in Alibeyhuyugu, Cumra, Turkey. Simulation and also economic analysis results have been presented.

Keywords: energy, storage, pumped, hydro, plants, renewable 1. INTRODUCTION

Energy dependency is an important issue because of the significance of energy security especially for the developing countries such as Turkey. Today, Turkey imports more than half of its energy requirement from neighbouring countries. Thus, Turkish country has developed a plan to support energy production from renewable energy sources (RES) and increase the amount of generated energy from alternative energy types as much as possible until 2023. Recently, solar, wind and hydro power usage have increased and still increasing, however, it seems that energy storage will be necessary in the future. There are generally three commercial bulk energy storage methods – pumped hydro energy storage (PHES), compressed air energy storage and energy storage through batteries – applied around the world today. Pumped hydro energy storage have more advantageous compared to others since it is more efficient and have higher storage capacity. Because of these reasons, more researches have been conducted about combining renewable energy generation with pumped hydro energy storage. Dursun B. and Alboyacı B. worked on the contribution of wind-hydro pumped storage systems in meeting Turkey’s electric energy demand and specified that

Wind/hydro solutions not only guarantee the continuous capability to cover the electricity demand of local grid, but minimizes the dependency on imported fuel and also reduces the negative resulting from the usage of fossil fuels [1]. Vieira and Ramos conducted a study on optimization of operational planning for wind/hydro hybrid water supply systems and found out that with the optimization mode it is possible to save up to 47% of the energy costs when compared to the normal operation mode [2]. Castronuovo and Lopes studied about Optimal operation and hydro storage sizing of a wind–hydro power plant and found out that yearly 11.91% profit can be obtained by purchasing energy in low demand periods and selling in high demand periods in Portugal [3]. Jaramillo and his colleagues defined in their study that it is possible to guarantee continuous availability feature of firm power by means of the hydropower used to compensate for wind fluctuations [4]. Denault and his colleagues specified that any proportion of wind up to 30% improves the production deficit risk profile of an all-hydro system [5]. Dursun and his colleagues studied on finding an optimal wind-hydro solution for the Marmara region of Turkey to meet electricity demand and specified that energy demand fulfilment of the Marmara region can be efficiently realized by a wind-hydro power system at a very low and reasonable energy cost [6].

In this study, a wind – pumped hydro hybrid power system is designed to meet the electrical energy demand of irrigation pumps in Alibeyhuyugu, Cumra, Konya. Energy share of each component is simulated and economic analysis was performed in order to investigate the feasibility of the system.

2. PHES AND OTHER BULK ENERGY STORAGE METHODS

There are some significantly important advantages of energy storage and these are listed in Table 1 [7,8].

Table 1 Advantages of Energy Storage

Advantage Explanation

Efficiency All power plants have an optimum operation in which they run at specific outputs. These can be operated optimally by using energy storage plants Intermittent power source

balancing

Energy storage methods can be used to cope with the unreliability of intermittent power sources.

Peak shaving Fast-responding energy storage plants can be used to match relatively small increases in demand more flexibility when managing their power grid Faster lead-in times Some energy storage methods allow for much faster lead-in times that are

useful to match the rapid changes in demand.

Reduction in energy import Efficient operation of power plants by using energy storage power plants can help to reduce energy import

Generally, there are three main bulk energy storage methods – pumped hydro energy storage, compressed air energy storage and battery storage. All these have some advantageous and disadvantageous compared to each other.

PHES systems consist of four main components which are upper reservoir, lower reservoir, hydro turbine(s) and hydro pump(s). When there are low energy demand and excess electrical energy, water is pumped from the lower reservoir to upper reservoir and when there is high energy demand, water is driven from the upper reservoir to lower reservoir to generate electricity. In these systems, reversible turbine/generator units can be used which can work as a pump and turbine. PHESs are very efficient options with an efficiency ranging from 70 to 85%. The biggest disadvantage of pumped-storage plants is their dependency on suitable topological sites which are limited and concentrated in specific areas. Also, these areas which can provide the needed altitude difference for the reservoirs are mainly located far away from those areas where power is necessary [7,9].

Fig. 1 Schematics of a PHES plant (left) and a compressed air storage plant (right) [10,11]

Compressed air energy storage (CAES) is following the well known principles of mechanical energy storage solutions like compressed air energy storage . In these systems, compressors are used to press air into an underground cavern where it is stored at 50 to 70 bars and when the power is necessary, the pressurized air is then used to run a gas-fired turbine. Making use of the stored air reduces the necessary gas input to less than 40

per cent compared to a conventional gas-fired power plant with equal output. The biggest limitation of CAES systems is the difficulty to find appropriate geological conditions [10]. Another generally used energy storage method is storage through batteries where the electricity is stored through a chemical process. They are mostly successfully used in smaller installations for the maintenance of steady electricity flow, however, batteries are also used in large-scale applications recently with the development of technology. They consist of galvanic elements – a combination of two different electrodes and one electrolyte. Most widespread battery technologies are Lead acid batteries, Nickel cadmium (NiCd) batteries, Sodium sulphur batteries (NAS batteries), Lithium ion (Li-ion) batteries, Sodium nickel chloride batteries. The most important advantages of batteries are their flexibility and universal capability - which make them very useful for mobile applications -, high efficiency and the capability of batteries to provide electricity immediately [10].

3. COMBINING WIND POWER WITH STORAGE SYSTEMS

Wind energy is one of the renewable energy sources that rely on the weather conditions. When there is electricity demand on a system covering the electricity needs from the wind turbines while there is no wind blowing, there will be an energy deficit. Furthermore, when the energy production from the wind is higher than the instantaneous energy need of a system, not used energy will be wasted. Therefore, it is necessary to combine wind power plants with a storage system. As an example, wind pumped hydro power plants can be used for reliable energy production. Combining wind power plants with PHES plants gives the flexibility to user when to store or use the wind power. In these systems, surplus energy is stored as potential energy in the hydro-pump storage system by pumping the water from a lower reservoir to a higher reservoir. If there is higher demand, the stored energy is used to cover the need. Briefly, combined wind and energy storage systems can be regarded as a reasonable way of both storing the energy and keeping the energy continuity of the system. Wind energy can be used efficiently in this way [6].

4. CASE STUDY FOR ALIBEYHUYUGU, CUMRA, KONYA

Alibeyhuyugu is a small town located in Cumra, Konya that is 9 km distant from Cumra district and 41 km distant from Konya. The population is nearly 6000 and the main source of live hood is the agriculture of the small town. The region's economy relies mostly on agriculture and stockbreeding. Mostly corn crops and different types of vegetables are planted in the region. The location of the Alibeyhuyugu on the map is shown in Fig. 2 [12].

Fig. 2 Alibeyhuyugu, Cumra, Konya [12]

Alibeyhuyugu (ABH) Irrigation Corporation is a co-op that is established to supply water demand for rural irrigation. Today, the corporation has 118 irrigation wells with submerged pumps and the corporation sells irrigation water to the farmers for a reasonable price. Irrigation is supplied through submerged irrigation pumps that have input powers changing

between 45 and 110 kW. Annual mean energy consumption of irrigation pumps is about 6000 MWh. Pumps are in operation only in seven months of the year. This period is called the irrigation period that begins in April and ends in October. Monthly mean energy consumption of irrigation pumps is shown in Fig. 3.

Fig. 3 Monthly mean energy consumption of irrigation pumps

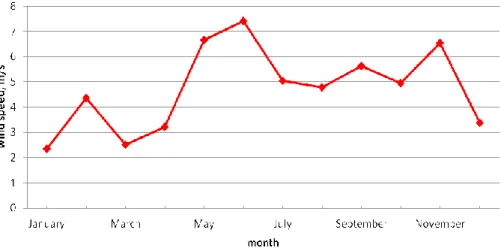

Wind climate data have been measured since 2006 with the help of a wind pole in the region and measured monthly mean wind speed values are shown in Fig. 4. The mean wind speed is measured to be 5.12 m/s at 35 m height.

Fig. 4 Monthly mean wind speeds in the region

4.1. Proposed System Model

Schematic presentation of the proposed system is given in Fig. 5. Hybrid system includes a wind park, pumped hydro power plant, irrigation pumps and all these are connected to the grid. The energy generated by the wind turbines will be used to meet the energy demand of

irrigation pumps and the hydro pump used for storage and it will be sold to grid if both do not require energy.

Fig. 5 Schematic presentation of the proposed system 4.2. Selected locations and system components

The dependency of PHES plants on suitable topological sites which are limited and concentrated in specific areas makes it difficult to find a proper place near the energy demanding system.

Fig. 6 Locations of PHES plant and wind turbines [12]

Luckily, there is a proper location found near irrigation pumps and wind turbines. The dam called May is thought to be lower reservoir and the top of the hill is planned to be used as

upper reservoir of PHES plant. For the wind power plant, another hill near PHES and irrigation pumps is selected where wind speed measurements have been performed for several years. Selected locations of PHES plant and wind turbines are shown in Fig. 6 [12].

As previously mentioned, energy consumption of the irrigation pumps is nearly 6000 MWh/year. By considering this value, two of a commercial wind turbine (WT) which has 1500 kW of capacity – 3000 kW in total – is selected. The power curve of the selected wind turbine is given in Fig. 7.

Fig. 7. Power curve of the selected WT

In addition to wind turbines, selected hydro pump and hydro turbine and their specifications are given in Table 2. Finally, upper reservoir is planned to be 62,500 m3 which is equal to

nearly 8800 kWh storage capacity.

Table 2 Characteristics of selected hydro turbine and pump

Number Power

(kW) Flowrate (m³/s) Height (m) Efficiency

* (%) Price ** ($) Hydro turbine 1 1250 3 52.5 82 500,000 Hydro pump 3 1890 (630 x 3) 2.75 (0.917 * 3) 57.5 (max - 65m) 74 300,000

*Includes electrical generator efficiency **Estimated prices including other costs

5. OPERATION STRATEGY OF THE SYSTEM

Operation strategy is evolved to make the user obtain the maximum of sum of both daily income and cost savings. Unit prices of electricity taken from Turkish Energy Market Regulatory Authority (EMRA) in the beginning of 2013 are considered by developing the algorithm and these are given in Table 2 [13].

Table 2. Unit prices of electricity

Selling Purchasing

Time Period 24 hours 6:00-17:00 17:00-22:00 22:00-06:00 Unit price (US Dollars/MWh) 73 98 153.5 58

The principles of operation strategy are summarized in the Table 3 where Pg(t) and Pd(t) are

power generation and power demand at a specific hour t, respectively. Hourly maximum storage filling rate, which depends on the storage pump power, and maximum electricity supply rate from the PHES, which depends on the hydraulic turbine power are also considered. It is assumed that the PHES system operates only in the irrigation period.

Table 3 Simplified decision rules of the system

Time period Task

06:00 – 17:00

Pg > Pd Electricity demand will be covered from production, the rest will be

used to fill the upper reservoir, and if it is full, it will be sold to the grid. Pg < Pd Determination of the electricity amount that will be used in the next

period when the electricity price is at its highest rate, this amount will be kept in the PHES, the rest will be used from the storage. If it is not enoug, the missing amount will be provided from the grid.

17:00 - 22:00

Pg > Pd Electricity demand will be covered from the production, the rest will

be stored, if the storage is full, it will be sold to the grid.

Pg < Pd All of production will be used to cover demand and the deficit will be

covered from the storage and if the storage is also not enough, deficit will be purchased from the grid.

22:00 – 06:00

Pg Electricity production will be sold to the grid. (0,065 dollar cents/kWh)

Pd Electricity demand will be bought from the grid. (0,058 dollar cents

/kWh)

If the storage is not full, it will be filled. *Pg = Electricity generation from wind energy, Pd= electricity demand

6. RESULTS

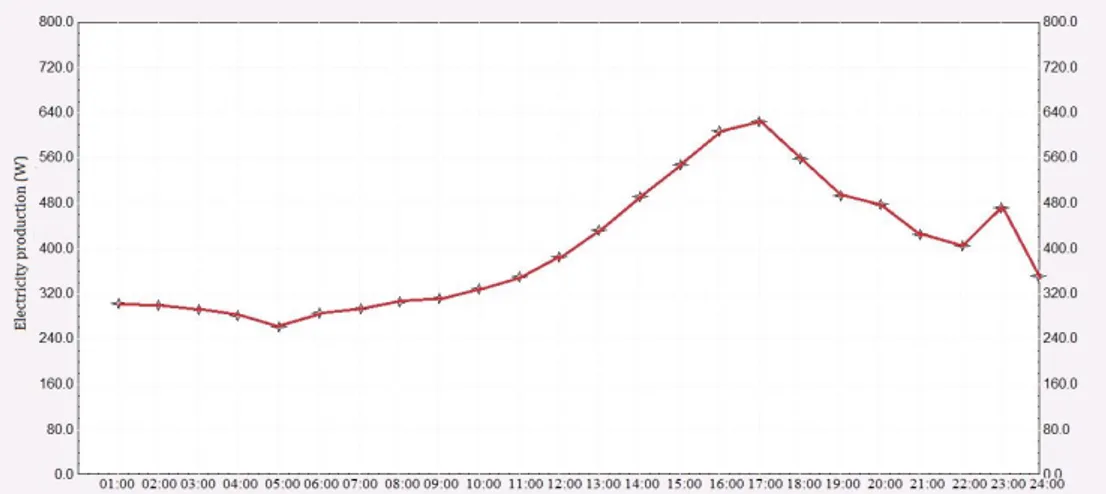

Monthly and hourly mean electricity production results are presented in Fig. 7 and Fig. 8, respectively. The annual electricity production and capacity factor of the selected wind turbine in the region is calculated to be 3461 MWh – 6922 MWh with two WTs – and 26% respectively.

Fig. 7 Monthly mean electricity production with the selected wind turbine

Fig. 8 Hourly mean electricity production with the selected wind turbine 6.1. Simulation results of the hybrid system

Simulation results are presented graphically for two months – June and September – to be also an example for other months. Share of energy suppliers to meet the energy demand and stroge variation in June are presented in Fig. 9 and Fig. 10, respectively. In Fig. 6, Pwg

represents the total generated electricity from the WPS, Pdemand represents the total energy

demand, Pph, Pwt and Pgrid represent share of PHES, WPS and grid, resptectively to cover the

energy demand. Total energy demand is determined as 1,168,181 kWh in June and 33.8% (395,208 kWh), 14.2% (165,316 kWh) and 52% (607,657 kWh) of it is covered from the WPS, PHES and grid, respectively.

Fig. 9 Share of energy suppliers to meet the energy demand in June

Fig. 10 Storage level variation in June

Share of energy suppliers to meet the energy demand and stroge variation in September are presented in Fig. 11 and Fig. 12, respectively. Total energy demand is determined as 412,432 kWh in September and 40.1% (165,554 kWh), 31.9% (131,400 kWh) and 28% (115,477 kWh) of it is covered from the WPS, PHES and grid, respectively.

Fig. 11 Share of energy suppliers to meet the energy demand in September

Fig. 12 Storage level variation in September

Summary of simulation results are presented in Table 4. It can be seen that the share of WPS and PHES system varies between 24.9 – 61.4% and 9.6 – 31.9%, respectively.

Table 4 Summary of simulation results

April May June July August September October Average

Pdemand (MWH) 70.64 916.28 1168.18 1853.85 1523.89 412.43 54.73 6000

Share of Pwt (%) 49.9 35.9 33.8 24.9 26.5 40.1 61.4 30.4

Share of Pph (%) 24.6 19.7 14.2 9.6 11.8 31.9 14.8 14.3

6.2. Economic Analysis Results

Financial parameters and summary of economic analysis results are presented in Table 5.

Table 5 Financial parameters and economic analysis results

The total investment cost and basic payback period are calculated to be nearly 6.4 million dollars and the about 10 years, respectively. However, it is considered that the PHES plants is operated only in 7 months – in the irrigation period – and that it will not operate for 5 months.

7. CONCLUSION

In this study, bulk energy storage systems are generally examined and the use of these combined with wind power plants is investigated. A case study is performed for Cumra, Turkey to meet the electricity need of irrigation pumps. Results show that wind and pumped hydro storage plant complement each other well and these combination helps to user to increase the reliability of power supply. Wind turbine costs, hydro turbine and pump costs of PHES plant directly influence the investment cost and economic analysis results. The basic payback period is found to be about 10 years, however, this value is calculated by considering that the PHES plants operates annually only in 7 months. Operating PHES plant in the remaining months will increase the profits and thus the basic payback period will drop. This will help the combined system to be more feasible. In addition, a great amount of CO2

emission will be prevented and this shows that the hybrid system will be an environmentally friendly solution both locally and nationally.

8. ACKNOWLEDGEMENTS

The wind speed measurements in the region is funded and supported by the Alibeyhuyugu Irrigation Corporation.

9. REFERENCES

[1] Dursun B., Alboyacı B., The contribution of wind-hydro pumped storage systems in meeting Turkey’s electric energy demand, Renewable and Sustainable Energy Reviews, 14, 2010, pp. 1979-1988

[2] Vieira F., Ramos H. M., Optimization of operational planning for wind/hydro hybrid water supply systems, Renewable Energy, 34, 2009, pp. 928–936

Total investment cost ($) 6,430,901 Sum of annual cost savings and income ($) 644,284 Operation and maintenance cost($) 33,427 Net Present Value – NPV($) 687,971 Internal Rate of Return – IRR (%) 8.16 Basic Payback Period – BPP (year) 10.53

[3] Castronuovo D.E., Lopes J.o, Optimal operation and hydro storage sizing of a wind– hydro power plant, Electrical Power and Energy Systems, 26, 2004, pp. 771–778. [4] Jaramillo O.A, Borja M.A, Huacuz J.M, Using hydro power to complement wind energy: a

hybrid system to provide firm power, Renewable Energy, 29, 2004, pp. 1887-1909. [5] Denault M., Debbie D., Couture S., Complementarity of hydro and wind power:

Improving the risk profile of energy inflows, Energy Policy, 37, 2009, pp. 5376–5384. [6] Dursun B., Alboyaci B., Gokcol C., Optimal wind-hydro solution for the Marmara region

of Turkey to meet electricity demand, Energy, 36, 2011, pp. 864-872

[7] Kaya, M., N., “Design and Optimization of a Wind-Pumped hydro hybrid Power system”, MS Thesis (in Turkish), Selcuk University, Konya, Turkey

[8] Harrack, B., 2010, Vision of Earth, Why energy storage is usefull [online],

http://www.visionofearth.org/industry/renewable-energy/renewable-energy-review/why-electrical-energy-storage-is-useful/, [ziyaret tarihi: 19 Ekim 2011].

[9] Kenny, Y. C. Cheung, Simon T. H., Cheung, R. G., De Silva, N., Matti, P. T., Singh, J. R., Woo, J. J., 2003, Large-Scale Energy Storage Systems, , Imperial College London, England. [10]Hessami, M. A., & Bowly, D. R. (2011). Economic feasibility and optimisation of an

energy storage system for Portland Wind Farm (Victoria, Australia).Applied Energy, 88(8), 2755-2763.

[11] Ridge energy storage. The economic impact of CAES on wind in TX, OK, and NM: final report; June 27, 2005

[12] Google maps, maps.google.com.

![Fig. 1 Schematics of a PHES plant (left) and a compressed air storage plant (right) [10,11]](https://thumb-eu.123doks.com/thumbv2/9libnet/4563880.83446/3.892.98.810.425.662/fig-schematics-phes-plant-compressed-storage-plant-right.webp)

![Fig. 2 Alibeyhuyugu, Cumra, Konya [12]](https://thumb-eu.123doks.com/thumbv2/9libnet/4563880.83446/4.892.193.722.727.1028/fig-alibeyhuyugu-cumra-konya.webp)