1st INTERNATIONAL BLACK SEA CONGRESS ON ENVIRONMENTAL SCIENCES (IBCESS) Giresun, Turkey • August 31 - September 03, 2016

IBCESS

FP103

NEGATIVE EFFECT OF E-WASTE ON ENVIRONMENTAL HEALTH AND

RECYCLING

Dogru S.

1, Argun Y.A.

1, Bingul Z.

2and

Altikat A.

31 Environmental Health Programme, Vocational School of Health Services, Igdir University, Igdir, Turkey

sevtap.dogru@igdir.edu.tr

2 Department of Environmental Engineering, Engineering Faculty, Igdir University, Igdir, Turkey

3 Department of Civil Engineering, Engineering Faculty, Igdir University, Igdir, Turkey

ABSTRACT

Today, the production of electrical and electronic equipment is one of the industries which have growth power giddily. The electronic waste has become the fastest growing waste in the world due to constant improving electronic industry and increasing consumption trend. Electronic waste (e-waste) can pollute the environment and threaten human health because of their toxic substances content. Electronic waste contain environmentally harmful organic (Polybrominated diphenyl ethers, polychlorinated biphenyls, etc.) and inorganic (Pb, Sb, Hg, Cd, Ni, etc.)

substance. Because of these substances they have adverse effects on human and

environmental health. On the other hand e-waste have greatly precious metal (Cu,

Ag, Au, Pd, etc.) content. If recycling processes applied to them, both adverse effects on the environment and human health will be reduced and it will be contributed to the national economy by protection of precious metal resources. In this study, it has been demonstrated Turkey’s e-waste potential, contents and effects of environmental health, providing benefits by recycling contained precious metals and economic impacts.

FP103

845

INTRODUCTION

The brand new developments that took place in scientific fields as well as information and communication technologies during the last quarter of 20th century has created and raised such a consciousness that the use of computers should take place in all areas of the community, in every phase of the daily life and brought electronic trade into a strategical prominence in ensuring economical development and social welfare. Producing and managing the information and then applying it to industry thus turning it into social utility has become one of the most important indicators of competitive power (Canpolat, 2001). The extension of markets and the technological development in this sense continuously accelerated the substitution of new equipment and caused the increase of electrical and electronical equipment waste at a tremendous rate (Ciggin, 2006). There exists a dark side in the depth of the scintillating and glamorous rise of information technologies (Puckett et al., 2002). Electronical wastes include a great number of (>1000) different organic (flame retardants containing chlorine/bromine, various plastics etc.) and inorganic (Hg, Pb, Cd, Cu, Fe, Al vb.) matters. Due to such matters in their contents, the storage, incineration or elimination of e-wastes in dump sites along with domestic wastes causes significant environment problems (Widmer et al., 2005).

Electrical and electronical equipment wastes are the types of solid wastes that gather the fastest among other urban wastes and the increase rates of electrical and electronical wastes are three times bigger than those of urban wastes (Ciggin, 2006). In this sense, the fact that e-wastes release harmful impacts on the environment in case dismantling or incineration, the issue like the re-collection, incineration, and elimination of such wastes because of the fact that they are made up of valuable materials that bring economical benefits have become prominent (Ergulen & Buyukkeklik, 2008).

In this study, the types, contents and components of ever increasing e-wastes that have been on the rise not only in Turkey but also in the whole world, waste market potential, their harmful impacts on environment and human health and the economical effects as a result of the recycle and regaining of valuable materials have been presented.

The Definition and Types of E-Waste

In relation to the control of waste electrical and electronic equipment, the regulations defined the electrical and electronic equipment as equipment that are designed in a way to not exceed 1000 volt alternative or 1500 volt direct current, that need electrical current and electromagnetic field and that are used for the production, transfer and measurement of these currents and fields (MoEU, 2012).

FP103

T.C Ministry of Environment and Urban Planning categorized the electrical and electronic appliances under ten categories. These main categorizes are like the following (MoEU, 2012).

1. Large household appliances (Refrigerator, washing machine, electrical heatings, etc.)

2. Small household appliances (Electrical vacuum cleaner, toaster, iron and such) 3. Information and telecommunication appliances (Computers, printers, mobile

phones, etc.)

4. Consumer equipment (Radio and television receivers, video cameras, musical instruments, etc.)

5. Lightning equipment (Direct and compact fluorescent bulbs etc.)

6. Electrical and electronic instruments (apart from large and fixed industrial instruments (Drills, saws, sewing machines, welding machines, soldering machines, etc.)

7. Toys, entertainment and sports equipment (Video games, machines operating with tokens)

8. Medical devices (Radiotherapy, cardiology, dialysis equipment, etc.)

9. Monitor and control devices (Smoke detector, thermostat, heat regulators, etc.) 10. Automats (Money, beverage automats, etc.)

Today, the expected life of electrical and electronical appliances and products is only a few years. The technological development expectations of the consumers are the primary reasons having a tremendous impact on this situation. Within this concept, apart from the function life cycle concept for the product, the concept of technological, economic life confronts us indicating the technological innovation or development level for the product to keep up with the times. Although many EEE maintain their function lives, they are classified as e-wastes as they have complete their expected technological life (Ciggin, 2006).

Electronic Waste Market in The World and in Turkey

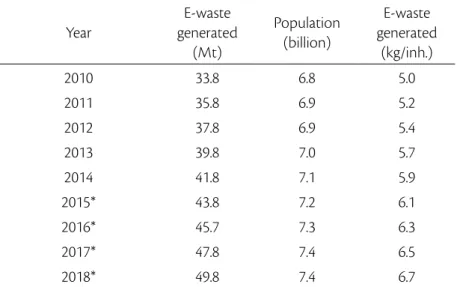

The amount of e-wastes is rapidly increasing in both developed and underdeveloped countries. The information given in Table 1 was all retrieved from The global e-waste monitor report published United Nations University in 2014. According to the Report, there is now 41.8 millions of tons of electrical and electronic waste in the world, corresponding to 5.9 kg of e-waste per capita. And it is estimated that, with an annual growth rate of 4-5 per cent, the amount of e-waste will increase by 49.8 million ton by 2018. Besides, the total amount of e-waste per capita is estimated to rise to 6.7 kg/annual per capita. (Baldé et al., 2015).

FP103

847

Table 1. Global quantity of e-waste generated (Baldé et al., 2015)

Year E-waste generated (Mt) Population (billion) E-waste generated (kg/inh.) 2010 33.8 6.8 5.0 2011 35.8 6.9 5.2 2012 37.8 6.9 5.4 2013 39.8 7.0 5.7 2014 41.8 7.1 5.9 2015* 43.8 7.2 6.1 2016* 45.7 7.3 6.3 2017* 47.8 7.4 6.5 2018* 49.8 7.4 6.7

*Data 2015 onwards are forecasts

The following Table 2 presents the 20 countries that produce the highest amount of e-waste in the world in 2014. The first three countries that produce the highest amount of e-waste rank as USA (7.1 Mt), China (6 Mt) and Japan (2.2 Mt) and Turkey takes its place in the 17th rank with 0.5 Mt of e-waste production. Due to the fact that the amount of e-waste production is in direct proportion with the welfare and prosperity of the country, it is seen that e-waste production increases in the countries where the per capita income is high. The country that produces the highest amount of electrical e-waste per capita income in the world has been determined as Norway (23,8 kg), Switzerland (26,3 kg) and Iceland (26 kg). It is seen that Turkey, whose e-waste production amount per capita is 6.5 kg annually takes its place in 82nd seat in the world rank (Baldé et al., 2015).

Table 2. The distribution of annual e-waste per capita in the world in 2014 (Baldé et al., 2015)

FP103

Environmental Impacts of E-Wastes

The majority of the matters of e-wastes today is comprised of metals (iron, copper, and aluminum). However, this situation will change within time with the producer designs and consumer attitudes (UNEP, 2013). Figure 1 indicates the amounts of metal and plastic included in e-wastes.

Figure 1.WEEE material composition (Taberman et al., 2013; Wilkinson et al., 2001) Copenhagen”, “title” : “Environmental consequences of incineration and landfilling

of waste from electr(on

Electrical and electronic devices contain a lot of hazardous elements and components. When these appliances and devices complete their economic life, they can have negative impacts on the environment and human health as long as they are not regained by accurate recycling or eliminated permanently (Akin & Kuru, 2011). The harms of the materials/elements contained in e-wastes are the following:

Heavy Metals and Other Metals

Lead (Pb): Lead is found especially in CRT tubes, old solders, integrated circuits, batteries and many electronic devices and appliances such as batteries (Manesh, 2007). Accumulated in nature and has a highly toxic effect on plants, animals, and microorganisms. It has been proven that lead which can cause immense damages on nervous and endocrine systems, blood circulation, kidney and reproduction systems have negative impacts on brain development. 40 percent of the lead in dump sites and 70 per cent of the heavy metals stem from e-wastes. 20 per cent of TV and computer screens contain Pb. Each computer contains 2-4 kg of Pb. The Pb in dump sites can be mixed in underground and surface waters as leach (MoEU, 2016). 10 gr of lead pollutes 25.000 tons of earth and makes 200.000 liters of water unusable (Rei, 2015).

FP103

849

Mercury (Hg): 22 per cent of worldwide Hg consumption comes from electrical and electronic devices. It is used in thermostat, level sensors, relays, buttons, discharge/ fluorescence bulbs, medical devices, data transmission, telecommunication, mobile phones, batteries, printed circuits, keys, etc. (MoEU, 2016). Harmful for kidneys and brain. Toxic even in low quantities. Can accumulate in the body and be transmitted with breast milk. When it mixes with water, it can easily have access to all organisms especially the fish and cause accumulation. Harmful to health if it is exposed to in the long term (Manesh, 2007).

Barium (Ba): A soft white metal, barium is used in the front panel of cathode ray (CRT) to protect the users from the radiation. A short period of exposure to barium may cause muscle weakness, brain, heart, liver and splenic diseases (Manesh, 2007; MoEU, 2016).

Chromium VI (Cr+6): Causes allergic reaction when it gets into contact with the skin. Easily absorbed into the cell and has a toxic impact. It may cause DNA damage, asthma, and bronchitis. Used in disk drivers and various coatings to protect corrosion. Besides, it is used for galvanized steel plate and hardened steel (Manesh, 2007; MoEU, 2016).

Beryllium (Be): Used in power sources, connectors, main card and connection components. Harmful when inhaled. Classified as carcinogenic (Manesh, 2007; MoEU, 2016).

Cadmium (Cd): Being a toxic substance, cadmium is very harmful especially for the kidneys. It can cause fragile bones and toxication by being accumulated in the kidneys. Cadmium is used in printer ink, fluorescence layer (CRT screens), Ni-Cd batteries, photocopy machines (Manesh, 2007; MoEU, 2016).

Nickel (Ni): Has a negative impact on endocrine, immune system, skin and eyes. It also causes allergy reactions. Found also in Nickel, Ni-Cd, Ni-MH and electron guns ((Manesh, 2007; MoEU, 2016).

Arsenic (As): Found in diodes spreading light as gallium arsenides (GaAs) (in low quantities). Extremely toxic and have harmful effects on the health when exposed to excessive amounts (Manesh, 2007).

Zinc sulfide (ZnS): Contained in CRT screens along with rare earth elements. Holds toxic impact when inhaled.(Manesh, 2007).

Gallium arsenide (Ga):. Contained in diodes (LED) as gallium arsenides (GaAs). Harmful to health (Manesh, 2007).

FP103

850

Lithium (Li): Contained in lithium batteries. Explosive gasses (hydrogen) may be released if heated (Manesh, 2007).

Selenium (Se): Can be used in old-generation photocopy machines. High levels may cause adverse health effects (Manesh, 2007).

Rare earth elements: Contained in fluorescence layer (CRT screen). Irritates the eyes and skin (Manesh, 2007).

Plastics: A computer contains approximately 7 kg of plastic containing PVC. When it is burned under a certain temperature, dioxin forms. Plastic components are used in printed circuits. PVC is the most hazardous plastic (MoEU, 2016). And plastics contain organic matters that increase the risk of getting cancer (Babu, Parande, & Basha, 2007).

The metals contained in e-wastes function as catalysator in the formation of dioxins and furans and accelerate the reactions (Olie et al., 1998).

Halogenated Compounds (Organic Materials)

They are halogenated chlorides and bromides released as a result of the burning of wastes containing hazardous components. These components are preferred thanks to their flame retardant characteristics in PVC coatings of the cables and plastic components of electronic wastes. In case they are burned, they are released as dioxins and spread into the atmosphere (Akin & Kuru, 2011).

Polychlorinated biphenyls (PCB): They are found in condensers and transformers. They have a carcinogenic impact. They have a negative impact on reproduction, nervous system and endocrine systems. They cause permanent and biological accumulation.

Brominated Flame Retardants (BFR): They are neurotoxic and carcinogenic to human health and have a negative impact on reproduction. They also have important effects on hormonal functions for normal development. They leak out of the mounted areas by dissolving and spread into a certain distance by evaporating. They accumulate and are transmitted biologically. They release dioxin and furan in the case that they are burned. In low temperatures, they create wastes that are too dangerous to burn. They are used as flame retardants in plastics. They are contained in computer connection components, plastics, printed circuits, cables, sponges. Besides, they can also be found in the dust particles in work places or offices. It was determined in USA and Switzerland that it is found in vast quantities in breast milk ( MoEU, 2016).

Chlorofluorocarbon (CFC): Contained in cooling unit and insulation foam. May cause the release of toxic emissions as a result of the burning of organic materials (Manesh, 2007).

FP103

851

Polyvinyl chloride (PVC): They exist in insulating cables. High-temperature processing of cables. May release chlorine, which is converted to dioxins and furans (Manesh, 2007).

Most of the electronic wastes contain more than 1000 toxic matters. And this causes a serious environmental pollution for elimination and storage areas. The cathode ray tubes on the screens of computers, TV sets and video display devices contain high amounts of lead and heavy metals. The elimination processes of such dangerous wastes to be carried out in the waste storage areas of the cities were forbidden. With the aim of protecting the users from the X-rays, computer and TV screens contain 2 to 4 kg of lead. The commercial electronic devices already constitute the 40 per cent of the lead element in storage areas and 70 per cent of the heavy metals such as mercury and cadmium (Kaya & Sozeri, 2009). These heavy metals can be resolved with the effects of rain water and cause the surface water to get polluted (Widmer et al., 2005). The fly ashes that emerge as a result of the burning of e-wastes also include a high amount of hazardous materials (Li, Richardson, Walker, & Yuan, 2006). The Importance of The Recycling of E-Wastes

Recovery which also covers reuse and recycling can be defined as turning the com-ponents contained in the wastes into some other products or energies using phys-ical, chemical or bio-chemical methods (Aydin, 2011). In the case that e-wastes are processes appropriately, all of the precious metals that they contain can be recov-ered. This way, the protection of natural resources, reducing the amount of waste and need for primary raw materials and energy saving. Otherwise, these wastes can turn into significantly hazardous piles of toxic material resources and cause immense problems (Celik, 2007).

Physical separation method, Hydrometallurgical method, Bio metallurgical Method and Pyrometallurgical methods are used in the recycling of e-wastes. Mechanical and physical separation methods depend on the different physical characteristics of the wastes (specific gravity, magnetic sensitivity, electrical conductivity, etc.). These characteristic differences cause metal and plastics to be separated (Cui & Forssberg, 2003). The pyrometallurgical method is used for the recycling of metals that do not contain iron included in e-wastes. Using burning, melting, rigidification and fusion in plasma arc furnaces or blast furnaces, the recycling of metals that do not contain iron is ensured as a result of high-temperature reactions. The pyrometallurgical pro-cess is a mechanism that ensures the concentration of metals such as platinum and platin (Hoffmann, 1992). Even though the pyrometallurgical process is used widely, it has several disadvantages. For example, during the melting procedure, the flame retardant and polyvinyl chloride (PVC) included in the content of e-waste cause the emergence of dioxins that require special emission controls. Besides, not all metals are completely separated during the pyrometallurgical process. For this reason, in some cases, it can be necessary to apply hydrometallurgical process following the pyrome-tallurgical one (Ikinci, 2014). The hydromepyrome-tallurgical method is the procedure of the

FP103

processing of solid materials acidic series or corrosive leach (the transition of metals to liquid form using corrosion with acid and base chemicals). The solutions are sub-jected to processes such as solvent extraction, adsorption and ion change. Electrolyte purification, chemical reduction or crystallization processes are applied to solutions (Sadegh et al., 2007). Biometallurgy is a new, cleaner and environment-friendly tech-nology. Biosorption is a process that uses a suitable biomass for the sorption of heavy metals from aqueous solutions. This is a physicochemical mechanism and based on ionic change and adsorbed with metal ion surface complexes (Željko et. al., 2009). Under the provision that natural resources are not limitless and used attentively, it is beyond any doubt that, one day, these resources will come to an end. The developed countries who are not conscious of this fact with the emerging energy crisis and efforts to increase the life standards in addition to the prevention of the wastage of natural resources have been seeking out new ways and strive to improve their cur-rent methods to recycle these wastes and reuse them (Celik, 2007).

Economical Impacts of E-Wastes

The recycling of e-wastes is in important factor not only on the human health and environmental problems but also in the prevention of the wastage of sources regard-ing the precious metals that they include, thus additionally pavregard-ing the way for the efficient use of the resources of the country. Because these e-wastes contain pre-cious metals such as aluminum (Al), copper (Cu), palladium (Pd) and gold (Au), the equipment and appliances that have completed their life cycle turn out to be good candidates of recycling process (UNEP, 2009). The secondary raw materials acquire using recycling will decrease the need for primary raw materials. The small amount of need for primary raw materials will decrease the mining prospecting and hoisting activities of raw materials as well as the harms to be given to the environment during these activities.

The purity of the metals contained in waste PCBs is ten times higher than that of contained in minerals (Bleiwas & Kelly, 1994). A ton of printed circuit boards contains approximately 80–1500 gr of gold, 160–210 kg of copper. This rate reveals 40-800 times higher proportion than the gold concentration existing in regions conducting gold production activities in the USA and similarly 30-40 times higher content of ore than the copper concentration in the regions where copper production is carried out (Bleiwas & Kelly, 1994). The amount of gold extracted from 47000 tons of per-sonal computer wastes is higher than the amount of 17 tons of gold ore; the amount of precious metals acquired by means of the recycling of the circuits of a thousand mobile phones is equal to precious metal content that respectively 250 tons of silver, 24 tons of gold, 9 tons of platinum and 9000 tons copper ore contains (EPA, 2011). Approximately 30 tons of lead ore is necessary to process to derive 1 ton of pure lead extract, 330000 tons of gold or platinum ore is necessary to process to derive 1 ton of pure gold and platinum extract. 1 ton of pure metal to be extracted with the help of

FP103

853

recycling will both decrease the cost that is necessary to process such an amount of ore and decrease the harm given to the environment (Kaya & Sozeri, 2009).

CONCLUSION

The fast-growing technology causes an increase in the demand for electronic prod-ucts to which a brand new one is added every single day. This fast increase in the demand for electronic devices causes immediate destruction and consumption of natural resources that are already limited. In the event that currently used electrical and electronic products and appliances complete their economic life, or the users change them with the brand new ones in the market cause these products to turn into e-wastes. Because of the fact that e-wastes contain hazardous and toxic mat-ters in them, they pollute the parent elements of the environment and nature (air, water and soil) and pose a significant threat to human health. On the other hand, because of the precious metals and reusable materials that these wastes contain, their usage as a secondary raw material has turned into a agenda topic recently. Giv-en the economic potGiv-ential and harms that e-wastes cause in the Giv-environmGiv-ent, the accurate conduct of the recycling procedures of e-wastes by the conscious people is becoming mandatory. Both natural source consumption is reduced on a great lev-el, and environmental pollution is prevented utilizing recycling. The decrease in the consumption of natural resources brings along with it the economical prosperity. The parent elements of the environment should be considered as a whole. Any pos-sible pollution of any of the elements causes the other elements to distort or get polluted. Besides, human beings are directly effected from these because they are in contact with the environment all the time. It is the humans that pollute and cleans the environment they live in. With an attempt to decrease the amount of e-wastes; the recycling procedures should be applied appropriately. For these procedures to continue without coming across any problem, the tracking and implementation of waste management procedures must be conducted by professional staff. While re-cycling, the best waste management is decomposition in the source. For this reason, the society, the community should be made aware of collecting the e-wastes in the source. The number of recycling facilities should be increased and the institution should conduct the immediate collection of e-wastes. The key rule for living in a clean and healthy society is that everyone should be aware of their responsibilities and act in line with these responsibilities.

REFERENCES

1. Akin, B., & Kuru, A. (2011). Damages, Management And Evaluation of Applications in Turkey Of Electrıcal And Electronıc Waste (E-Waste). Istanbul Aydin University Journal,

3(12), 1–12.

2. Aydin, B. (2011). Recovery Of Waste Electrical And Electronic Equipments. Unpublished Master’S Thesis, Suleyman Demirel University, Institute of Science, Isparta.

FP103

3. Babu, B. R., Parande, A. K., & Basha, C. A. (2007). Electrical and electronic waste: a global environmental problem. Waste Management & Research, 25(4), 307–318.

4. Baldé, C.P., Wang, F., Kuehr, R., Huisman, J. (2015). The global e-waste monitor – 2014. United Nations University, IAS – SCYCLE, Bonn, Germany. Retrieved from https://goo. gl/wbmu3P

5. Bleiwas, D., & Kelly, T. (1994). Obsolete Computers, “ Gold Mine,” or High-Tech Trash? Resource Recovery from Recycling. United States Geological Survey, (july).

6. Canpolat, O. (2001). E-Commerce and Developments in Turkey. Ankara: Ministry of Industry and Trade.

7. Celik, C. (2007). Recycling Of Waste Electrical And Electronic Equipments. Unpublished Master’S Thesis, Istanbul Technical University, Institute of Science, Istanbul.

8. Ciggin, C. T. (2006). Plant Design For Recovery Of The Waste Electrical And Electronic

Equipments And Research Of The System Parameters. Unpublished Master’S Thesis,

Istanbul Technical University, Institute of Science, Istanbul.

9. Cui, J., & Forssberg, E. (2003). Mechanical recycling of waste electric and electronic equipment: a review. Journal of Hazardous Materials, 99(3), 243–263.

10. EPA. (2011). Electronics Waste Management in the United States Through 2009.

Prepared by ICF International For U . S . Environmental Protection Agency Office of Resource Conservation and Recovery, (May), 49.

11. Ergulen, A., & Buyukkeklik, A. (2008). Waste Management And E-Waste In Context Of Economic And Environmental Dimensions Of Sustainable Development. Nigde

University Economics And Administrative Sciences Journal, 1(2), 19–30.

12. Hoffmann, J. E. (1992). Recovering precious metals from electronic scrap. JOM, 44(7), 43–48.

13. Ikinci, O. A. (2014). E-Waste: Both Treasury and Hazards. Science and Technology, TUBITAK, (June), 36–39.

14. Kaya, M., & Sozeri, A. (2009). A Review of Electronic Waste (E-Waste) Recycling Technologies:“Is E-waste an Opportunity or Threat?” In Proceedings. 138th Annual

Meeting, San Francisco,TMS, Warrendale, PA, 1055–1060.

15. Li, Y., Richardson, J. B., Walker, A. K., & Yuan, P.-C. (2006). TCLP Heavy Metal Leaching of Personal Computer Components. Journal of Environmental Engineering, 132(4), 497–504. 16. Manesh, P. (2007). E-Waste: WEEE Other Side of the Digital Revolution. Toxics Link

Factsheet, November(31), 1–6. Retrieved from http://toxicslink.org/docs/06184_ewaste.

17. Ministry of Environment and Urbanism (MoEU). (2012). Directive For The Control Of Waste Electrical And Electronic Equipment. Official Journal No:28300, Turkey. Retrieved from http://goo.gl/A5ZrAc

18. Ministry of Environment and Urbanism (MoEU). (2016). Waste Electrical And Electronic Materials. Retrieved from may 10, 2016: http://www.csb.gov.tr/dosyalar/images/file/ elektronikatiklar.pdf

19. Olie, K., Addink, R., & Schoonenboom, M. (1998). Metals as Catalysts during the Formation and Decomposition of Chlorinated Dioxins and Furans in Incineration Processes. Journal of the Air & Waste Management Association, 48(2), 101–105.

FP103

855

Exporting Harm: The High-Tech Trashing of Asia. The Basel Action Network, Seattle. Silicon

Valley Toxics Coalition.

21. Rei. (2015). Electronic Waste. Rei Recycling Industry, (January), 62–76. Retrieved from may 10, 2016: http://goo.gl/nVzr9q

22. Sadegh Safarzadeh, M., Bafghi, M. S., Moradkhani, D., & Ojaghi Ilkhchi, M. (2007). A review on hydrometallurgical extraction and recovery of cadmium from various resources.

Minerals Engineering, 20(3), 211–220. http://doi.org/10.1016/j.mineng.2006.07.001

23. Taberman, S-O; Carlsson, B; Erichson, H; Brobech, J.; and Gregersen, J. (1995). Environmental consequences of incineration and landfilling of waste from electr(on)ic equipment. TemaNord report to the Nordic Council of Ministers, Copenhagen.

24. UNEP. (2009). Recycling – from e-waste to resources. Sustainable Innovation and

Technology Transfer Industrial Sector Studies. Retrieved from may 10, 2016: http://goo.

gl/dRFbd1

25. UNEP. (2013). Metal Recycling: Opportunities, Limits, Infrastructure, A Report of the

Working Group on the Global Metal Flows to the International Resource Panel. Reuter, M. A.; Hudson, C.; van Schaik, A.; Heiskanen, K.; Meskers, C.; Hagelüken, C.

26. Widmer, R., Oswald-Krapf, H., Sinha-Khetriwal, D., Schnellmann, M., & Böni, H. (2005). Global perspectives on e-waste. Environmental Impact Assessment Review, 25(5), 436– 458.

27. Wilkinson, S., Duffy, N., & Crowe, M. (2001). Waste From Electrical and Electronic Equipment in Ireland : a Status Report-Epa Topic Report, (May), 35, 68–75.

.

28 Željko, K., Marija, K., Dragana, I., Vesna, N., & Milisav, R. (2009). Hydrometallurgical process for extraction of metals from electronic waste, Part I: Material characterization and process option selection. Metalurgija, 243–231 ,(4)15.