THE INVESTIGATION OF THE TEMPERATURE EFFECT ON THE SCREW CONNECTION ON STEEL STRUCTURES

Akbar Sheidaei HABASHI

Faculty of Engineering, Department of Civil Islamic Azad University, Tabriz Branch, IRAN civilakbar@yahoo.com

(Geliş/Received: 23.10.2012; Kabul/Accepted in Revised Form: 20.01.2013)

ABSTRACT: Recent international regulations have special terms for considering high temperature effects on steel and steel made product. Steel structures junctions are most important factor that determines these structures behavior firing and its effect on screw connection of steel structures behavior is studied by using finite difference method and ANSYS software. Results are compared with valid experimental results which finally led to appropriate responses to numerical modeling for such issues.

Key words: temperature, screw connections, steel structures, finite elements method

Çelik Yapılar Üzerindeki Vida Bağlantılarına Sıcaklığın Etkisinin İncelenmesi

ÖZET: Günümüz uluslararası yönetmelikler çelik ve çelikten mamul üzerine yüksek sıcaklığın etkilerini dikkate alan özel terimler ihtiva etmektedir. Çelik yapıların birleşimleri en önemli faktörlerdir. Bunlar yapıların yangına karşı davranışını belirlemektedir. Çelik yapı üzerindeki vida bağlantılarının davranışı sonlu farklarlar yöntemi ve ANSYS yazılımı kullanılarak incelenmiştir. Analiz sonuçları geçerli deney sonuçları ile karşılaştırılmış ve bu tür sorunlar için sayısal modellemeye uygun cevaplara ulaşılmıştır. Anahtar kelimeler: sıcaklık, vida bağlantıları, çelik yapılar, sonlu elemanlar yöntemi

1. INTRODUCTION

One of the most important parts of steel structures which transfer force to other parts and staddles is connection between different segments. Noticing the way most of the steel structures fail under different loading we find that weak connection may be one of the important factors in destruction of steel structures. After that world trade towers ruin by airplane collision and burned we found that even if a structure could resist a collision of a giant airplane it is so frail about firing and low strength of steel in high temperature cause the structures demolish.in recent decades researchers studied steel behavior, steel member and steel structures in hot temperatures. These studies often needs laboratory tests and

considering high expenses and number of repeats for getting acceptable results we found difficulties of such studies in IRAN.

Screw connections because of high performance speed and their reliability consider one of the best connections for steel member. One connection for joist and steel column is using corner screw connection. In this connection corners are mounted on joist wings and sometimes on joist which by joining them in to wings connection provided. Simplicity of this method increase the structures speed and make it popular in steel structures industries.

Beas on previous section studying these connections at high temperature which indicating a fire in building numerical studies may be ended

in good approximated results cause laboratory expenses drift. here we used ANSYS modeling. We are going to find relation between forces effect connection and its behavior using rotation-moment or rotation-moment-rotation-temperature curves so using this curves we will be able to understand behavior of these connections in different conditions.

2. EXPERIMENTS

Based on introduction for studying steel structures behavior during fire we need experiments simulate similar condition so it’s possible to make structure in real or smaller size and then burned or just simply build part of structure as a model, in this case we need to apply a force similar to real condition by using structural analyses.

Here we use Aziznamini’s

(Azizinamini,1982) results for corner connections in standard temperature which is known for numerical studies of corner connection and uses as a primitive reference in standard temperature.

For models going to be used in high temperature we use Saedi et al. (Saedi et al.,2006). Experiment results for comparing model accuracy which examined this connection in different temperature.

Modeling and numerical discussion: ANSYS software used for parametric modeling of samples. Samples parametric Finite element models made by APDL according to parametric geometrical and mechanical features of materials period of time is needed for different modeling considerably decreased.

3. CONNECTION NUMERICAL MODELING USES THESE ASSUMPTIONS

-All segments like joists, columns, corners and sockets and spanners model by one order eight nodes SOLID65 element. Such elements consider thermal differences so we can apply the effect of fire in high temperature experiment.

-For screw pre-stress we use pre-stress element.

-Screw holes diameter 1.6mm bigger than modeled screw diameter.

-Using sample symmetry and for reducing amount of calculation just half of sample is modeled around the main sheet.

-Because of column rigidity arise from stiffeners just column wings and stiffeners are modeled.

In modeling we can use CONTA174&TARGE170 elements for contact related issues these elements paired to each other so they do not infiltrate during loading process. So connection segments adjacent sheets interaction like corner, joist wing, socket, screw hole and screw modeled using this elements. Figure (1) shows models different segments and their different meshing.

Die and sockets modeled hexagonal like real form. For friction force Coulomb friction coefficient considered 0.25. In references (Ahmed

et al.,2001) and (Kishi N et al.,2001) this coefficient

considered 0.1 which class A sheets is approximately proposed amount one third (0.33) (American Institute of Steel Construction, 1995).

Since connection geometry is symmetric just quarter of connection is modeled and it needs all the symmetric points relocation closed perpendicularly. For samples in standard temperature considering compact profile of joist, so its local curvature occurs in higher stresses while finite element model von-Mises stress distribution shows that joist remain elastic so finite element local curvature canceled. For applying bending moment on connection 50 mm, normal relocation applied monotonically on joist end. This relocation at joist end causes rotation approximately 0.03 radian. Bending moment and connection relative rotation are calculated by using Equations 1 and 2.

L

P

M

=

.

(1)h

R

=

ε −

1ε

2 (2)Where M moment applied on all P connection, L end nods joist relocation, R joist length, h relative rotation of joist depth

connection, ε1 and ε2 relative horizontal relocation of upper and lower wings of joist respectively.

Figure1. Model different segments For samples in high temperature first

focused forced applied at 200 cm from column wing to put on required moment on connection and then temperature uniformly increase around connection adjacent and provided studying of temperature effect on joist-column construction configuration. Column is independent from wings so indicating that experimental tools are the same shown. Joist just can arise down lateral relocation constrained the way to prevent premature rupture cause by joist lateral torsional buckling. Also joist can expand along its axis to confirm no thermal tension arises. Complete thermal regime only felt around connection while farther areas feel standard temperature so empirical experiment can

simulate. Heating regime developed

corresponding with temperature-time diagram which arise from heating furnace according to ISO 834 (Fire resistance tests–elements of building construction, 2002) and ASTM-E119 diagrams (ASTM- E 119 – 05, 2003).

4. NUMERICAL RESULT AGAINST

EXPERIMENT

First here using connection behavior in standard temperature compare Aziznamini experimental results model validity confirmed at

standard temperatures and then at next step model loaded according to Saedi’s experiments and its validity studied.

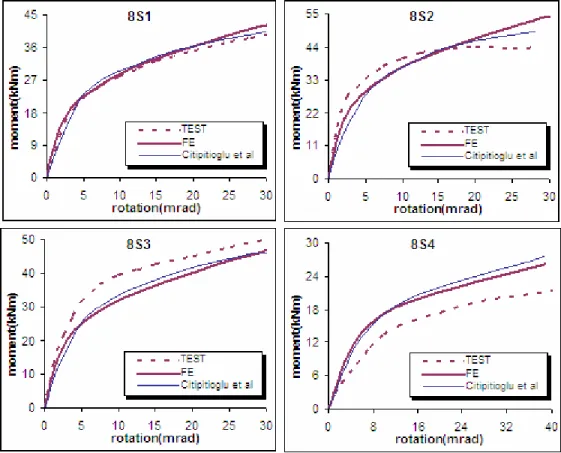

For studying modeling accuracy, finite elements of 4 experimental samples modeled according to Aziznamini’s experiments and results compared with experiments. Figure (2) shows numerical models of moment-rotation diagram compared with empirical experiments of Aziznamini and Citipitioglu numerical diagram (Haj-Ali RM et al., 2002). According to this figures finite elements model have grate correspondence with empirical result.

Differences between numerical modeling and experimental results depends on different factors like modeling simplification, experimental defects, waist stresses, connection surface interactions, friction and screw pre-stress forces. Screw pre-stress forces and friction coefficient are two important factors for connection behavior especially at nonlinear part of connection while it is difficult to approximate their exact values. Another important factor of difference is nonlinear constructive law for materials, especially when the only diagram is stress-strain so difference between diagrams increase in nonlinear region.

Figure2.Aziznamini and Citipitiglu moment-rotation diagrams

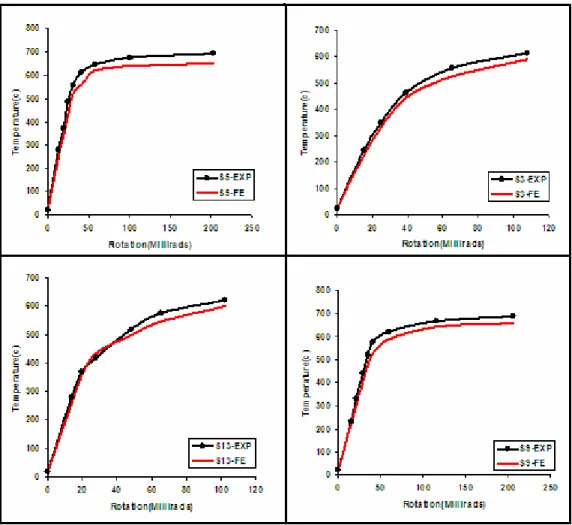

Figure (3) shows correlated numerical model compered with correlated form of Saedi, 2006 research.

Figure (4) shows numerical models temperature-rotation compered Saedi et al., researches these diagrams for all connections corresponds properly with experimental result corresponds properly while in plastic region there is a small difference explained before.

Figure 4. Temperature-rotation diagram Figure (5) shows moment-rotation

diagrams in different temperature resulted by numerical modeling which we can obviously observe connection flexural capacity by increase temperature.

5. CONCLUSIONS

Finite element segments analysis done for studying up and down corner screw connections behavior with main corner and, up and down corner connection without main corner at standard and high temperatures using finite element ANSYS software. Connection segments modeled using solid elements and segment contacts with

contact elements explained using coulomb friction law. Steel members and connection segments considered nonlinear. In high temperature model stress-strain diagrams we considered total temperature degree to simulate connection features decries at high temperatures and finally compare this simulation result compared with experimental data. Results shows acceptable accordance between predicted and measured data both inelastic and plastic region. So it proves finite element technic capable to predict connection response acceptably both in standard and high temperatures.

Figure 5. Moment-rotation in different temperatures REFERENCES

Ahmed, Kishi N, Matsuoka K, Komuro M. “Nonlinear analysis on prying of top- and seat-angle connections”, Journal of Applied Mechanics 2001; 227-36.

AISC, Manual of steel construction-Load and resistance factor design. Chicago (IL): American Institute of Steel Construction, 1995.

ASTM- E 119 - 05a, Standard Test Methods for Fire Tests of Building Construction and Materials, 2003.

Azizinamini, Monotonic response of semi-rigid steel beam to column connections, MS thesis, University of South Carolina, Columbia, 1982.

Citipitioglu AM, Haj-Ali RM, Withe DW, “Refined 3D finite element modeling of partially restrained connections including slip”, Journal of Constructional Steel Research, 2002, 8:995-1013.

ISO 834, Fire resistance tests - elements of building construction, 2002.

Kishi N, Ahmed A, Yabuki N., “Nonlinear finite element analyses of top 50 and seat-angle with double web-angle connections”, Journal of Structural Engineering and Mechanics 2001;12:201-14.

Saedi Daeryan A., A Study on Behavior of Connections in Fire. MS thesis. Tehran (Iran): K.N. Toosi University; 2006.